Anti-blocking device for KR process stirring desulfurization lifting trolley

A stirring desulfurization and anti-jamming technology, which is applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problems affecting the production and operation costs of steel mills and the overall cycle of production and operation, and achieve simple and reasonable structure, stable lifting, Guarantee the effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

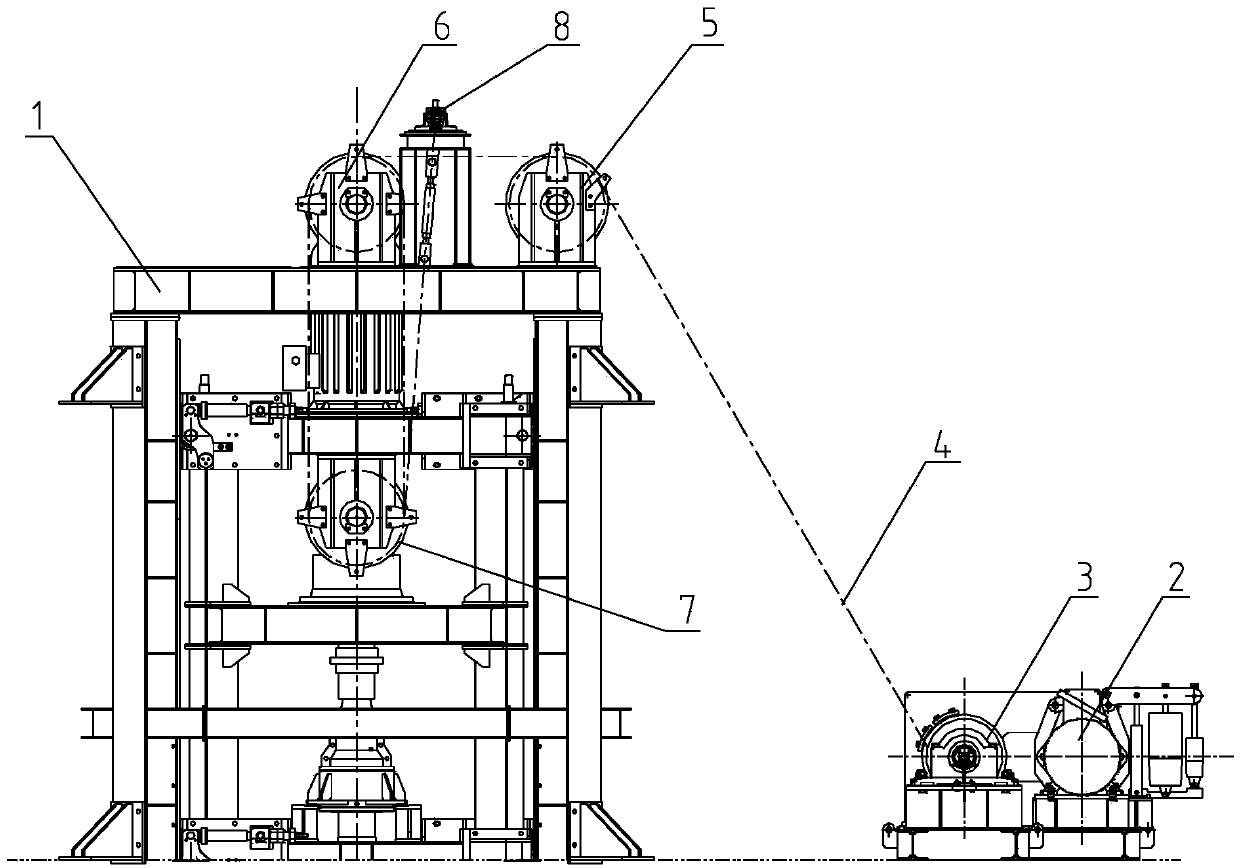

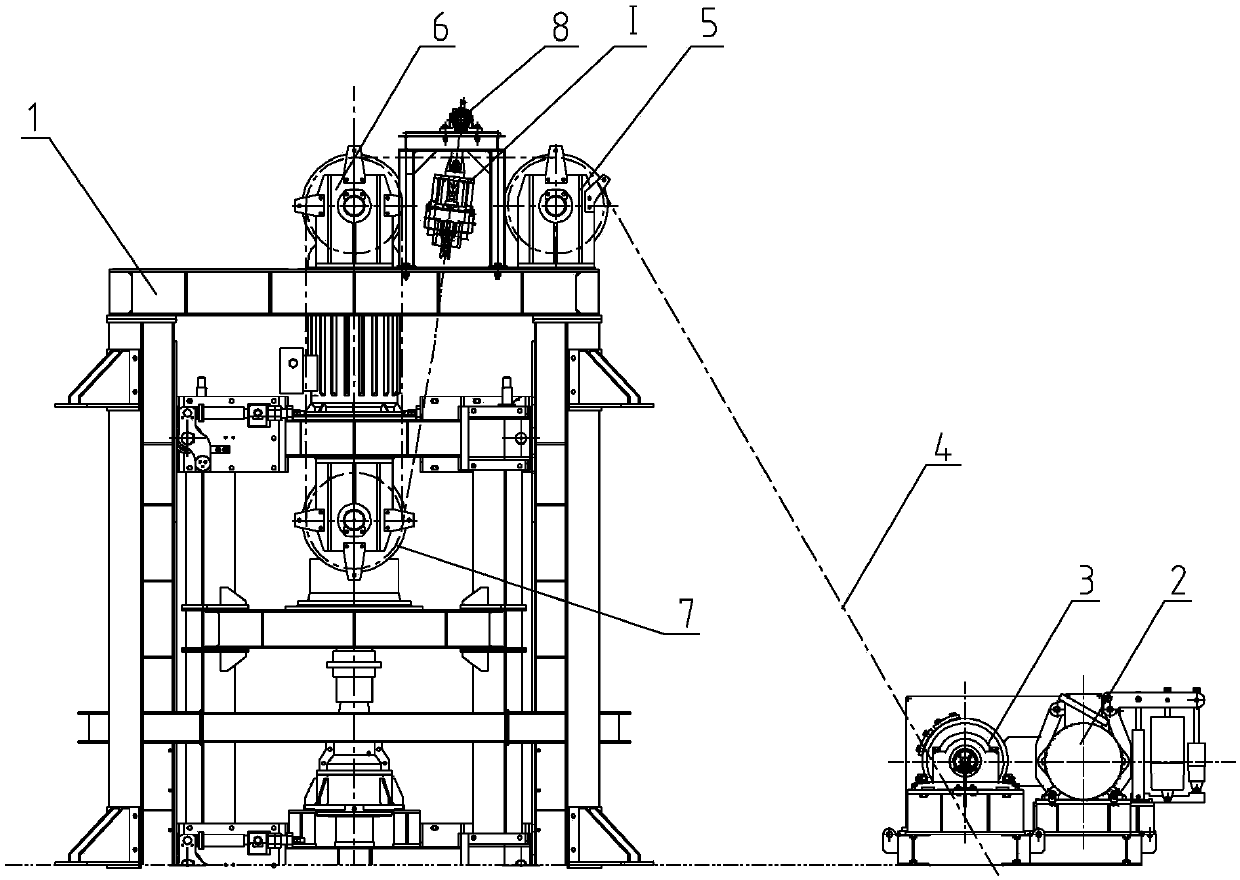

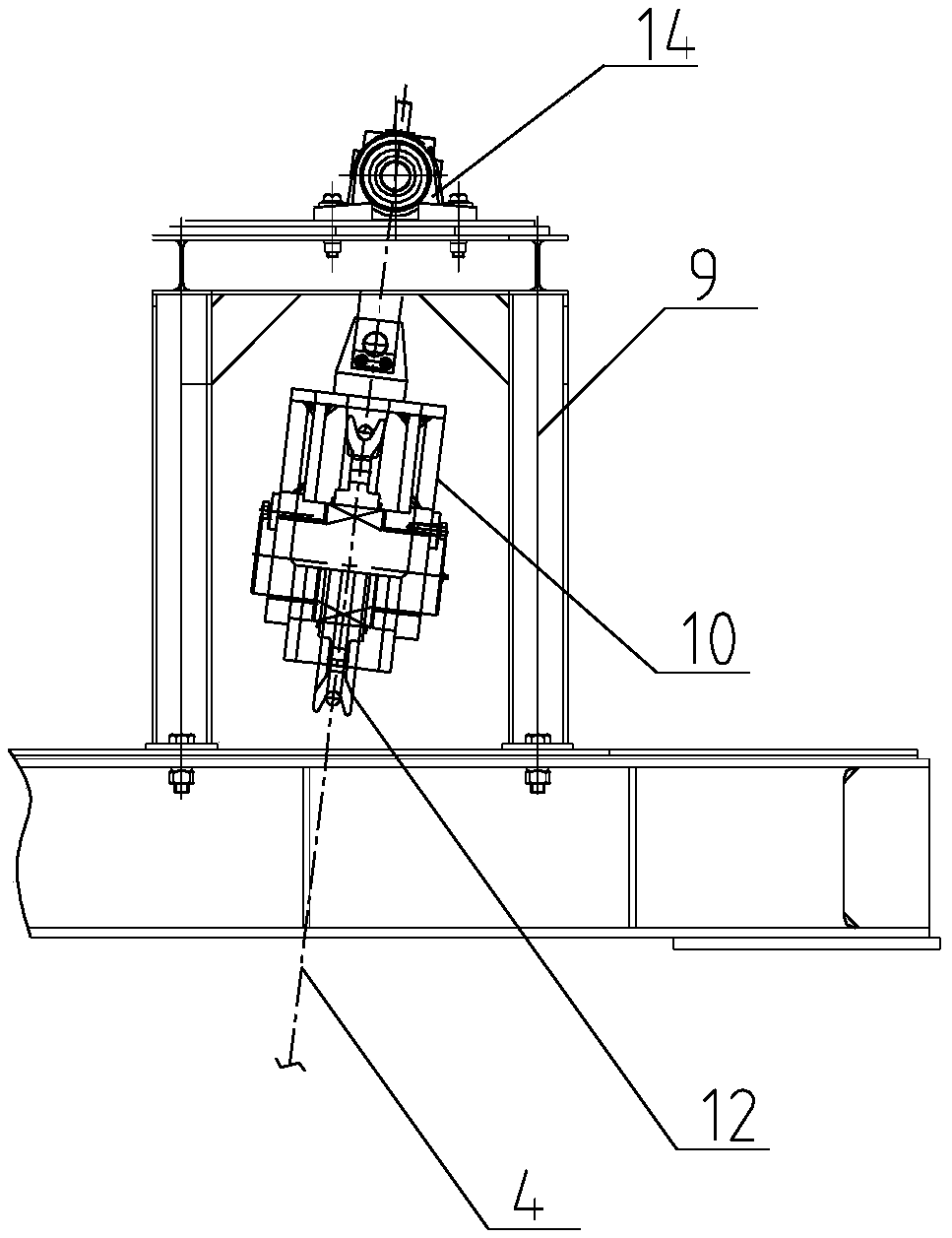

[0031] Such as Figure 2-Figure 4 As shown, an anti-jamming device for a stirring and desulfurizing lifting trolley in the KR process of the present invention, the lifting trolley is arranged in the stirring frame 1, and a group of lifting trolley transmission mechanisms are respectively provided on both sides of the stirring frame 1, and the lifting trolley The transmission mechanism is composed of a fixed pulley 5, a fixed pulley 2 6, a movable pulley 7 and a wire rope 4; the driving mechanism of the lifting trolley includes a lifting motor 2 and a wire rope reel 3; the anti-jamming device I includes a fixed bracket 9, a movable bracket 10, Transmission wheel 12, vertical seat bearing 14, support seat 13 and adjusting bolt 15; the fixed bracket 9 is fixed on the top of the stirring frame 1, and is located between two groups of lifting trolley tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com