A kind of ultra-high eigenvalue three-phase flue gas foam for oil and gas fields and its preparation method

A technology of flue gas and eigenvalues, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost of foam use and high cost of nanoparticle application, and achieve low cost, reduce industrial pollution sources, and stability enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1. Ultra-high eigenvalue three-phase flue gas foam for oil and gas fields

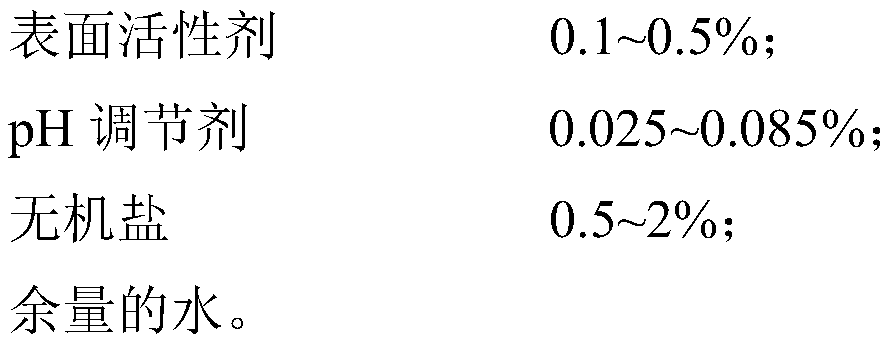

[0044] The raw materials are gas phase, liquid phase and solid phase, and the specific components are as follows:

[0045] The gas phase is the flue gas produced by the coal-fired power plant, which has undergone desulfurization, denitrification and deoxidation processes. The total fraction of nitrogen and carbon dioxide in the flue gas is ≈93%.

[0046] The maximum particle size of fly ash in the solid phase is 46 μm, the average particle size is 1.3 μm, SiO 2 Accounting for 63wt%, Al 6 Si 2 o 13 Accounting for 26wt%, Fe 2 o 3 The proportion is 6wt%, and the wetting angle of fly ash particles to distilled water is 57°; the average particle size of nano-silica in the solid phase is about 15nm, and the specific surface area is 160m 2 / g, the wetting angle of nano-silica particles to distilled water is 63°, and the mass ratio of fly ash to nano-silica particles is 8.5:1.

[0047] Th...

Embodiment 2

[0054] Example 2: Ultra-high eigenvalue three-phase flue gas foam for oil and gas fields

[0055] The raw materials are gas phase, liquid phase and solid phase, and the specific components are as follows:

[0056] The gas phase is the flue gas produced by the coal-fired power plant, which has undergone desulfurization, denitrification and deoxidation processes. The total fraction of nitrogen and carbon dioxide in the flue gas is ≈93%.

[0057] The maximum particle size of fly ash in the solid phase is 13 μm, the average particle size is 0.5 μm, SiO 2 Accounting for 71wt%, Al 6 Si 2 o 13 Accounting for 18wt%, Fe 2 o 3 The proportion is 3%, and the wetting angle of fly ash particles to distilled water is 54°; the average particle size of nano-silica in the solid phase is about 15nm, and the specific surface area is 160m 2 / g, the wetting angle of nano-silica particles to distilled water is 63°. - The mass ratio of fly ash to nano-silica particles is 8.5:1.

[0058] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com