Single type universal hinge type expanding joint with thickness and crack detecting device

A crack detection and detection device technology, applied in the field of pipeline expansion joints, can solve the problems of heavy maintenance and replacement, short service life of expansion joints, economical personal injury, etc., achieve low manufacturing costs, enhance overall performance, and improve safety Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

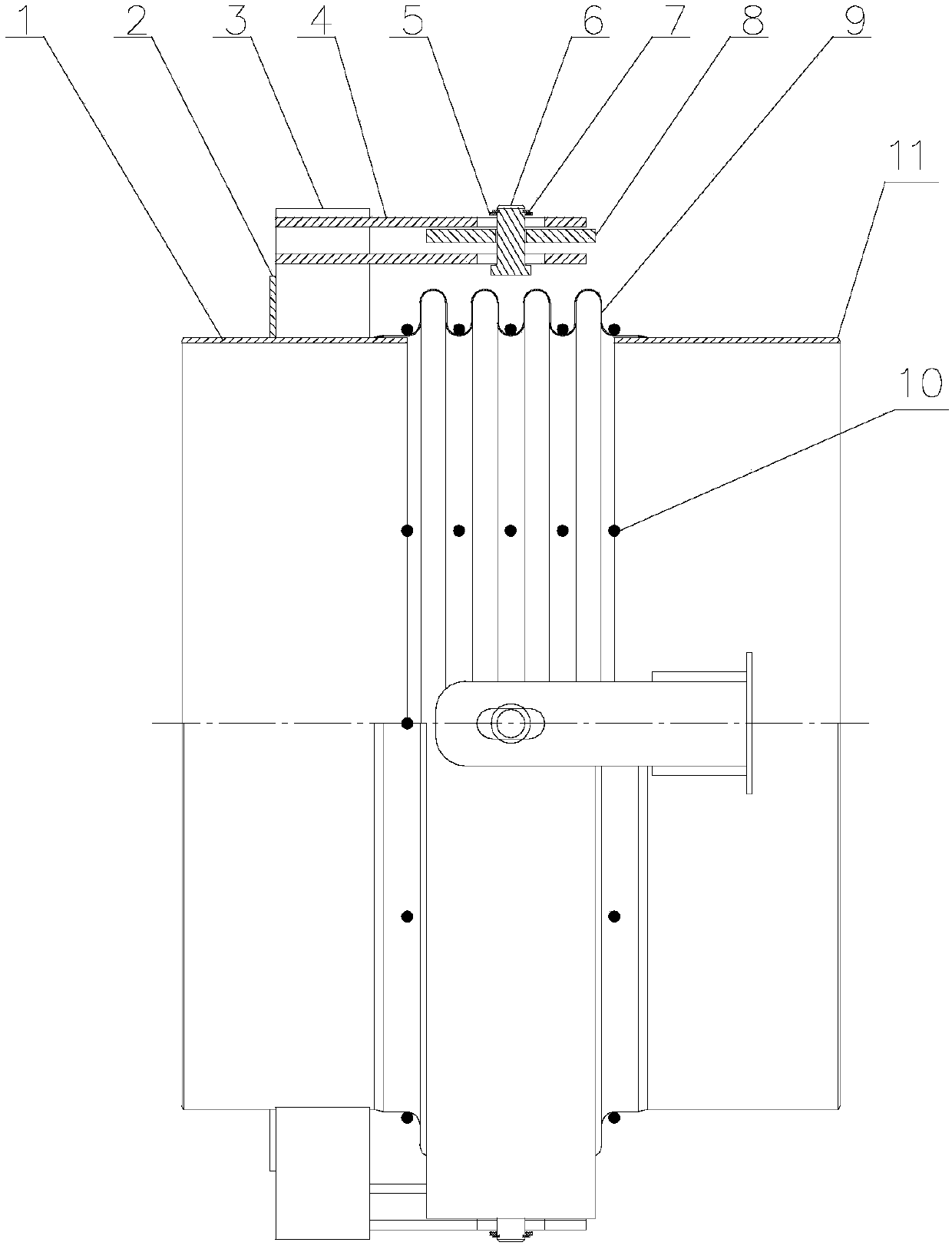

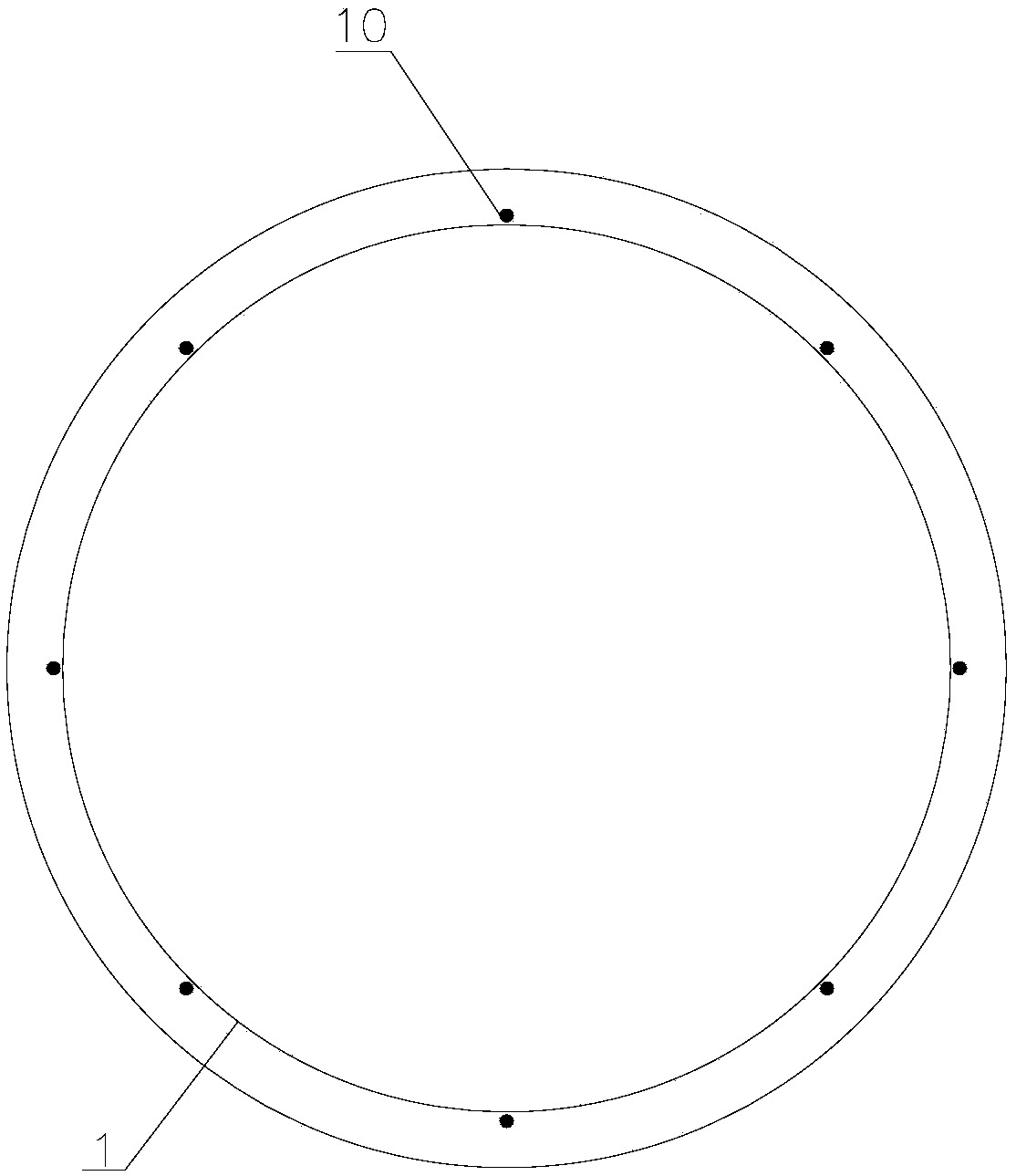

[0017] Such as figure 1 and figure 2 As shown, the single-type universal hinge expansion joint equipped with thickness and crack detection devices includes an expansion joint body, a detection device and a control device. 11. A detection device is provided on the bellows 9; the detection device includes a thickness and crack detection device 10, and the control device includes a signal transmission device, a data processing device and a data terminal; the detection device is electrically connected to the power supply and the signal transmission device respectively, and the signal The transmission device is electrically connected to the data processing device by wire or wirelessly, and the data processing device is electrically connected to the data terminal.

[0018] In this embodiment, the outer surface of the left connecting pipe 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com