Flaw detection device for surface of circular projectile body

A technology of flaw detection and projectile, which is applied in the field of flaw detection, can solve problems such as the threat to the inspector's life and failure of rocket inspection, and achieve the effect of reducing time and cost, reducing danger and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

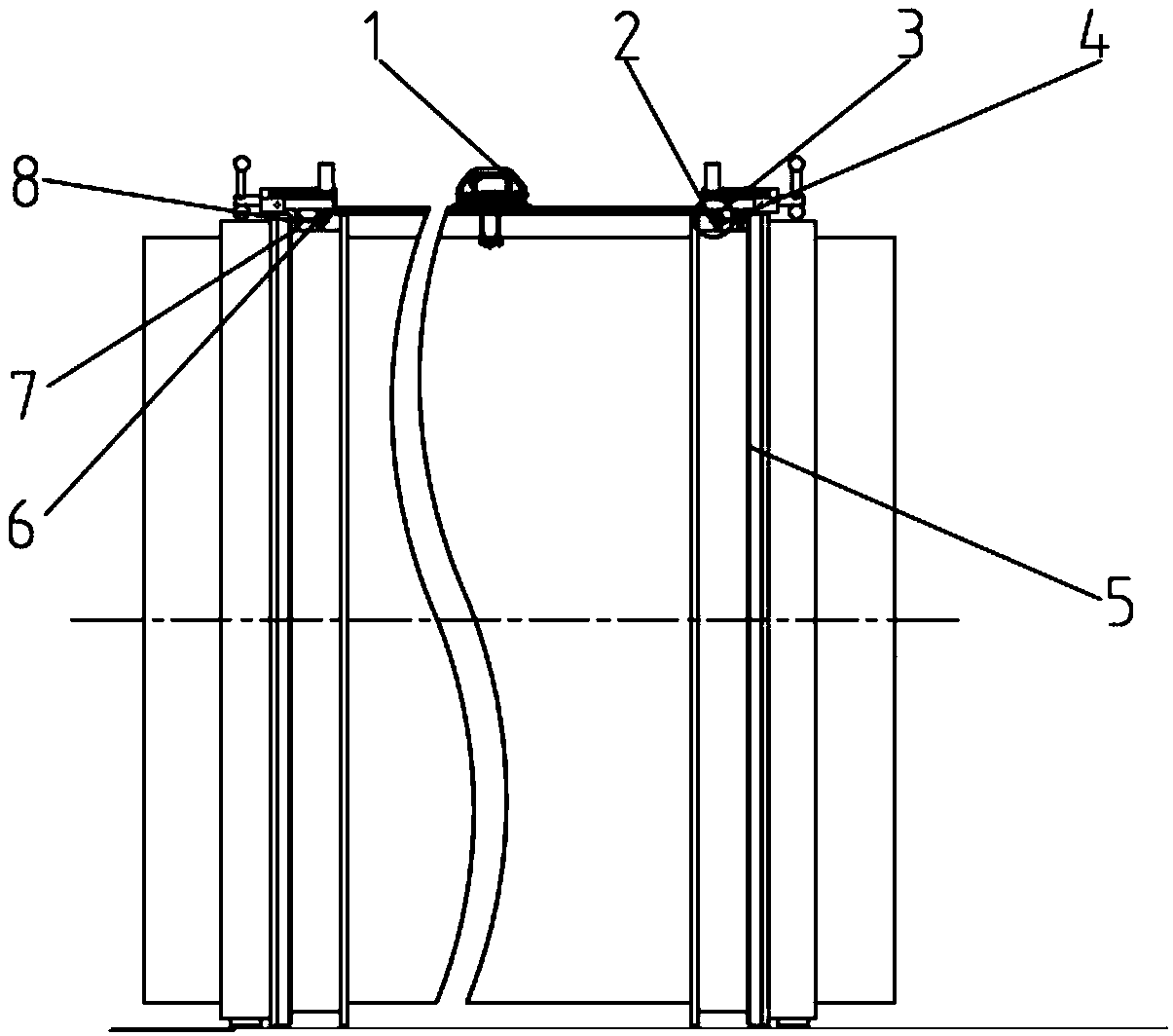

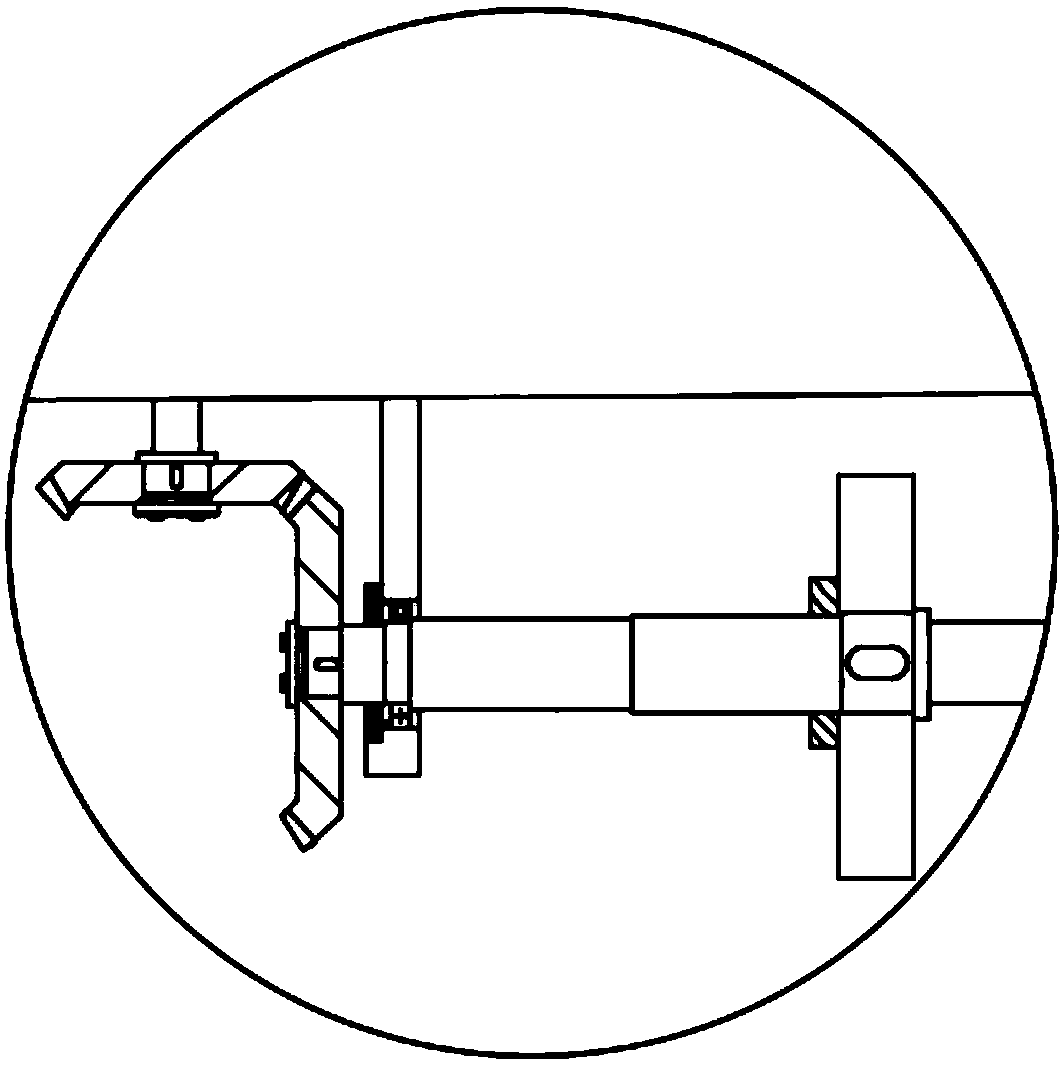

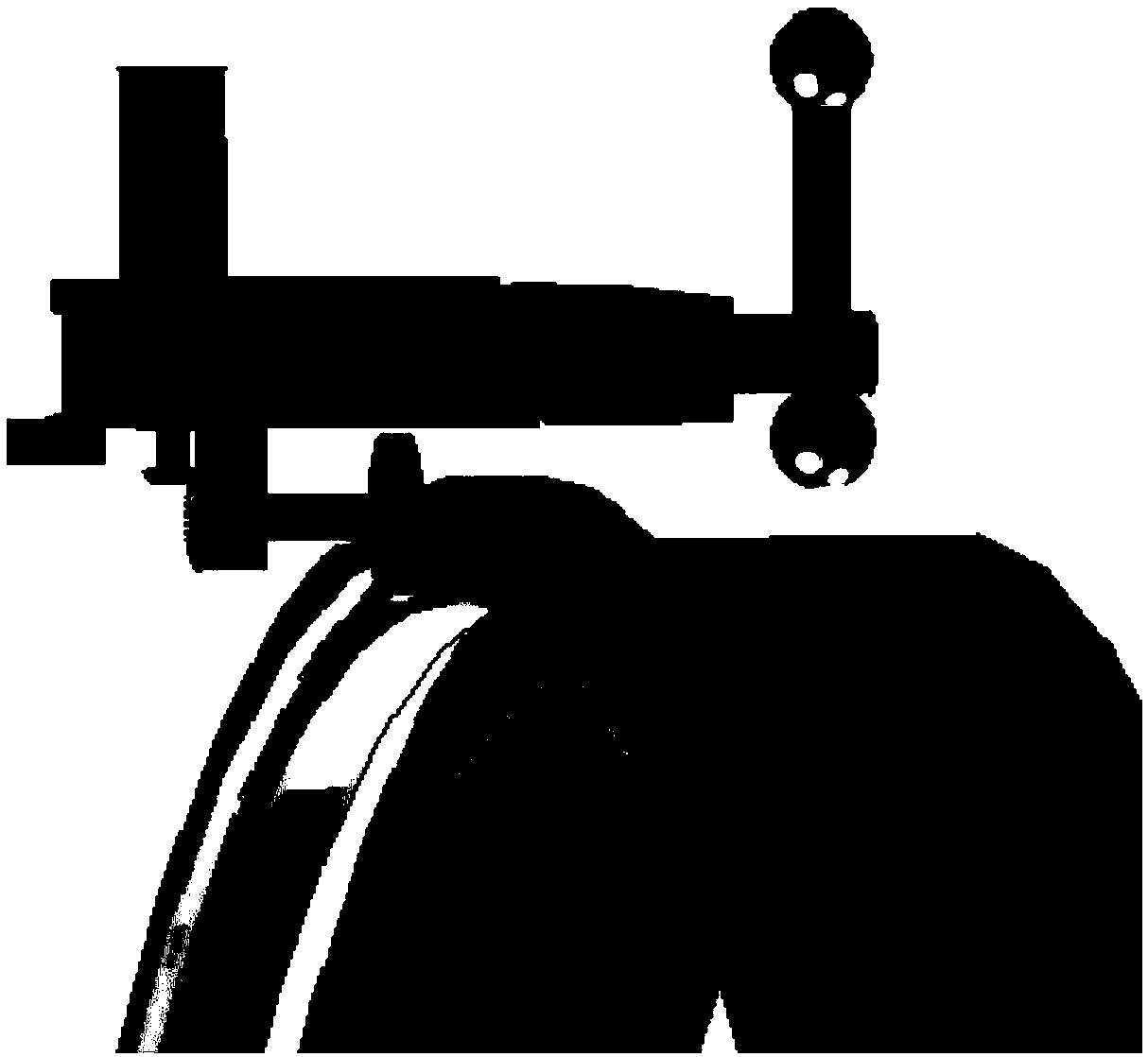

[0026] combine Figure 1 to Figure 13 , the circular projectile surface flaw detection device of the present invention comprises: 1-detection device, 2-small bevel gear, 3-bearing end cover, 4-big bevel gear, 5-inner track, 6-deep groove ball bearing, 7- -Wheel, 8-wheel shaft, 9-handle, 10-motor, 11-long track, 12-gap adjustment parts, 13-outer rail, 14-chain, 15-clip, etc.

[0027] The main function of the circular projectile surface flaw detection device is driven by a motor, and with the cooperation of various devices, it can realize multi-degree-of-freedom and all-round flaw detection on the surface of the circular projectile. The outer guide rail 13 and the inner guide rail 5 are installed and fixed on the surface of the circular projectile body through threaded connection, and the installation and disassembly of the track mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com