Hydroponic transplanting production line of leaf vegetable seedlings

A production line and seedling technology, which is applied in the field of leafy vegetable seedling hydroponic transplantation production line, can solve the problems of low work efficiency and increased labor cost of leafy vegetable seedling hydroponic transplantation, achieve large-scale production, and ensure continuous automatic work , Reduce the effect of seedling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

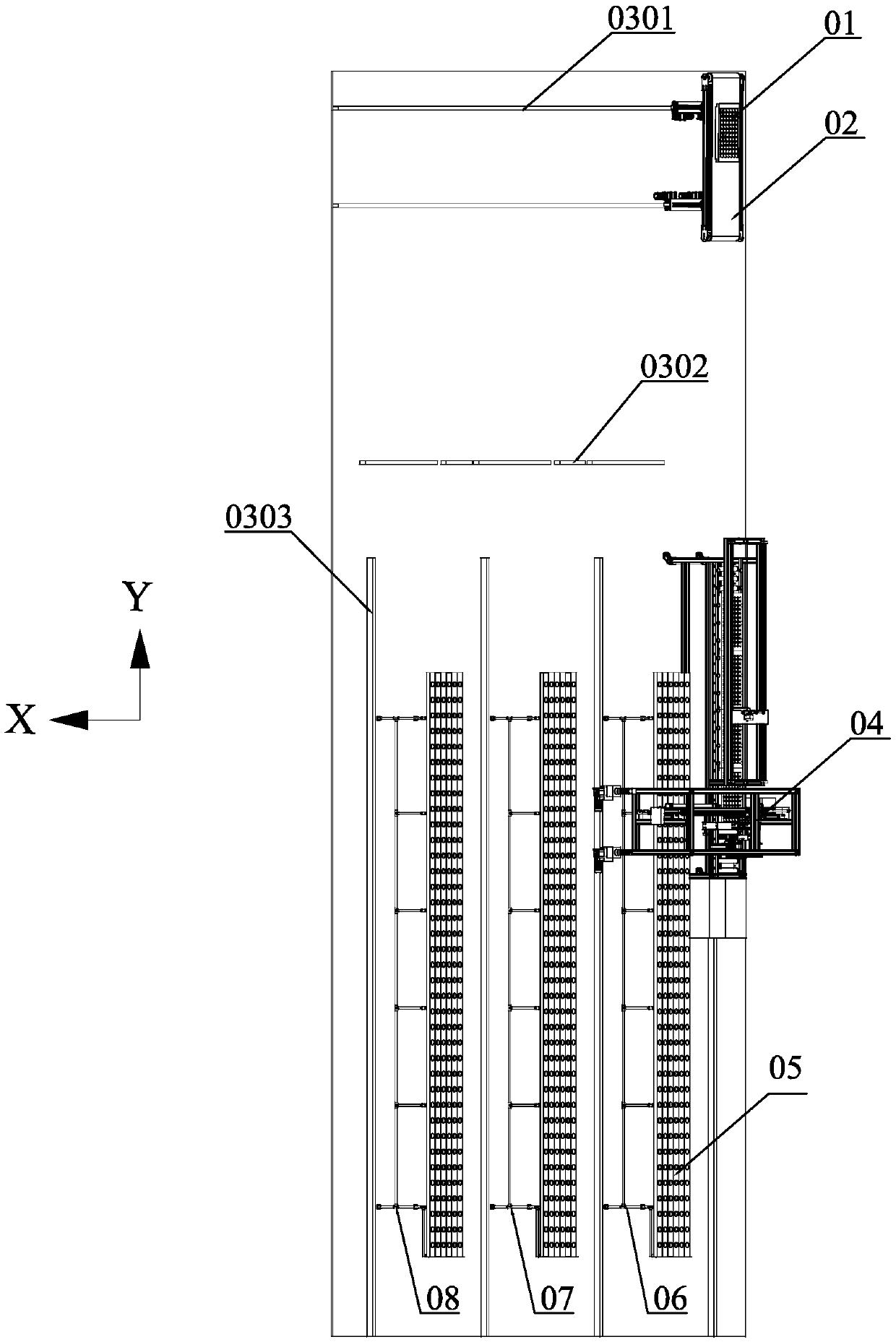

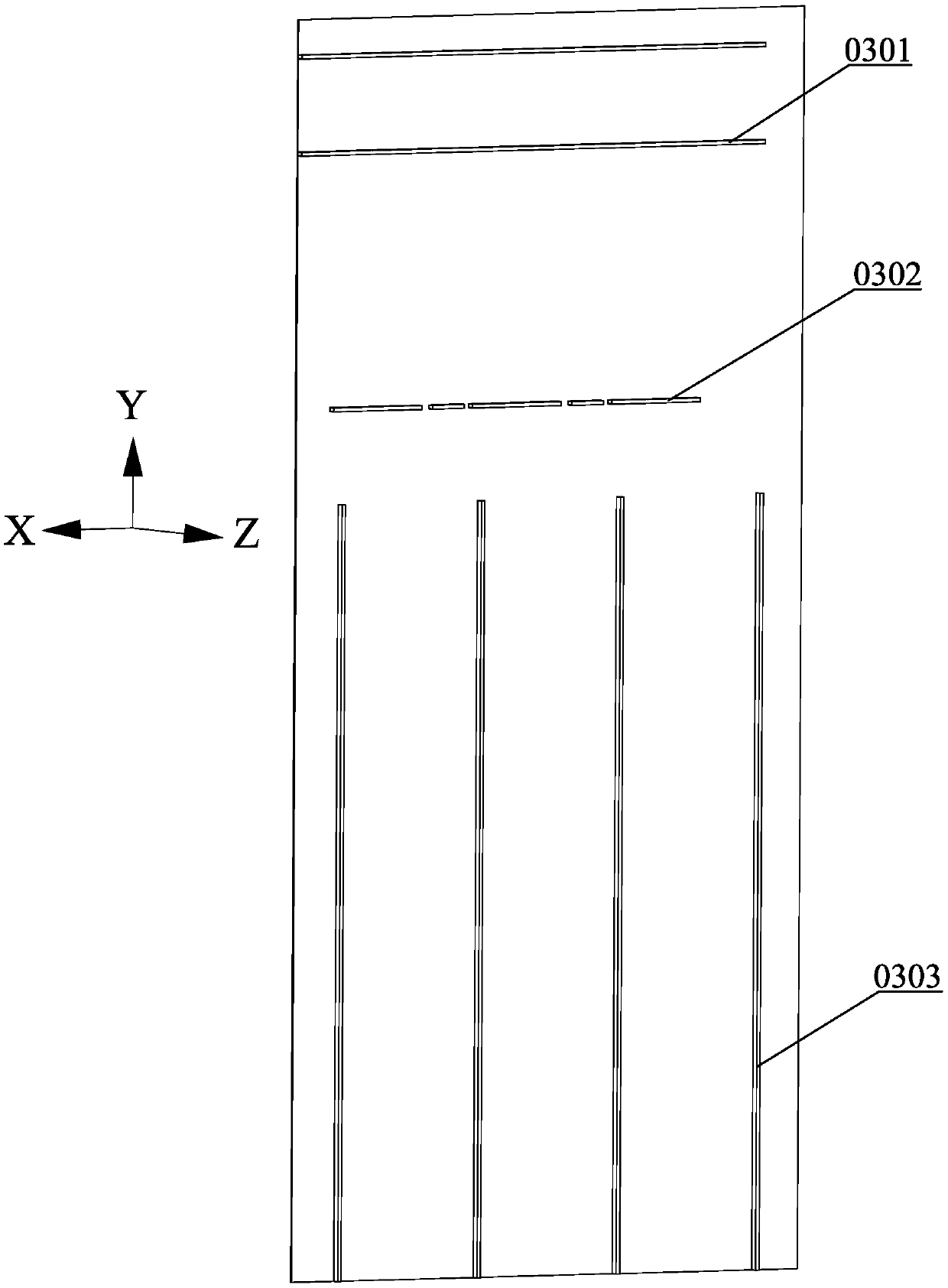

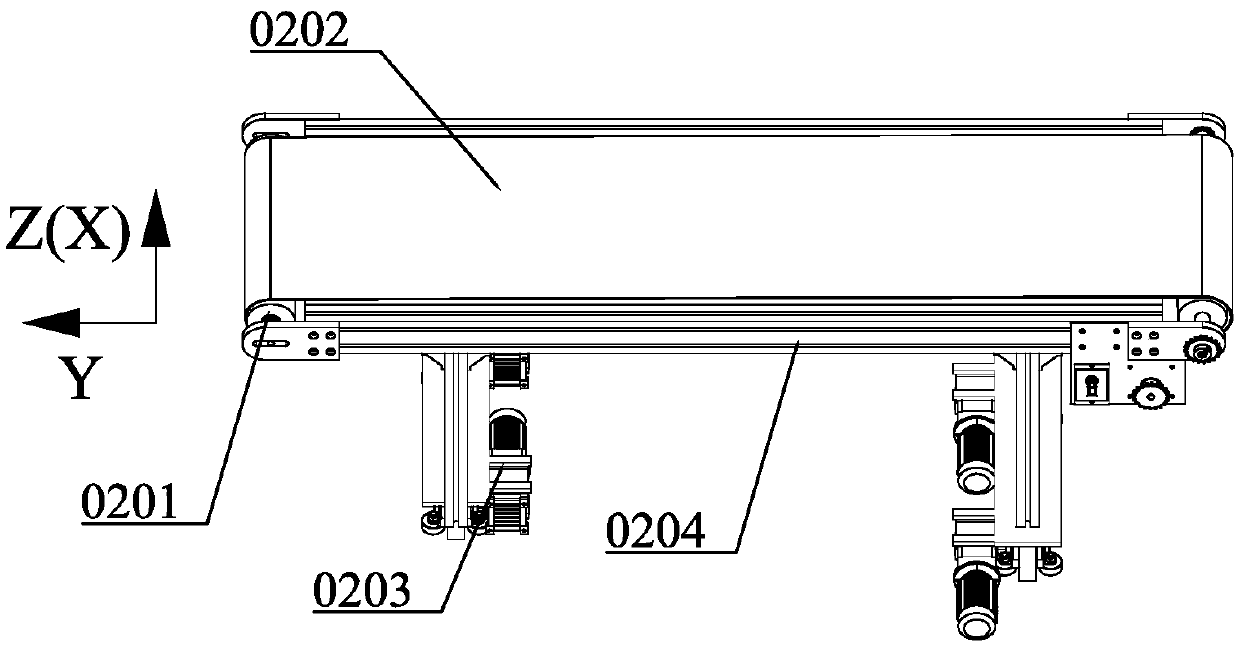

[0040] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0041] For the convenience of description, the X, Y, Z coordinate system is adopted in this paper, and the X axis and the Y axis form a horizontal plane (the direction of the X axis is figure 1 The left and right directions in the middle), the Z axis is perpendicular to the X-Y horizontal plane and upwards is the positive direction.

[0042] Conventional leafy vegetable seedling hydroponic transplantation technology is to put the hole plate 01( Figure 16 As shown) the hole seedlings were transplanted to the hydroponic tube 05 ( Figure 17 As shown, the hydroponic tube used in the present invention is an empty long strip hydroponic tube, and the tube holes on the hydroponic tube are equidistantly distributed) in the tube holes; due to the frequent manual operation, the labor intensity is high and the production efficiency is low, so the present invention A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com