High-efficiency wet type dust cleaning device for oil pressing mill

A cleaning device and high-efficiency technology, applied in cleaning equipment, cleaning machinery, applications, etc., can solve problems such as low water spray pressure, unclean spray cleaning, oil stains or sundries on the ground, to prevent damage and protect The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

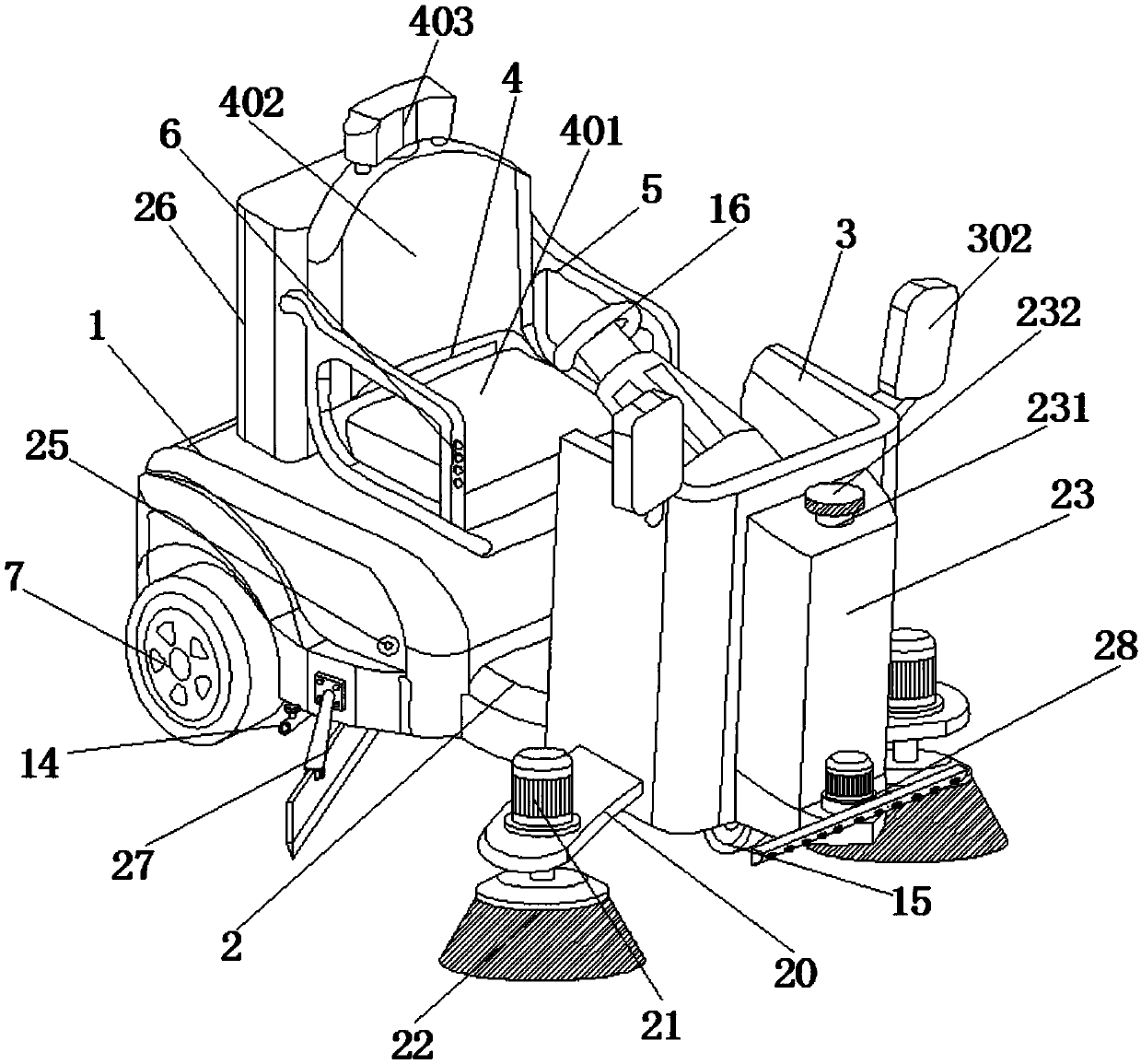

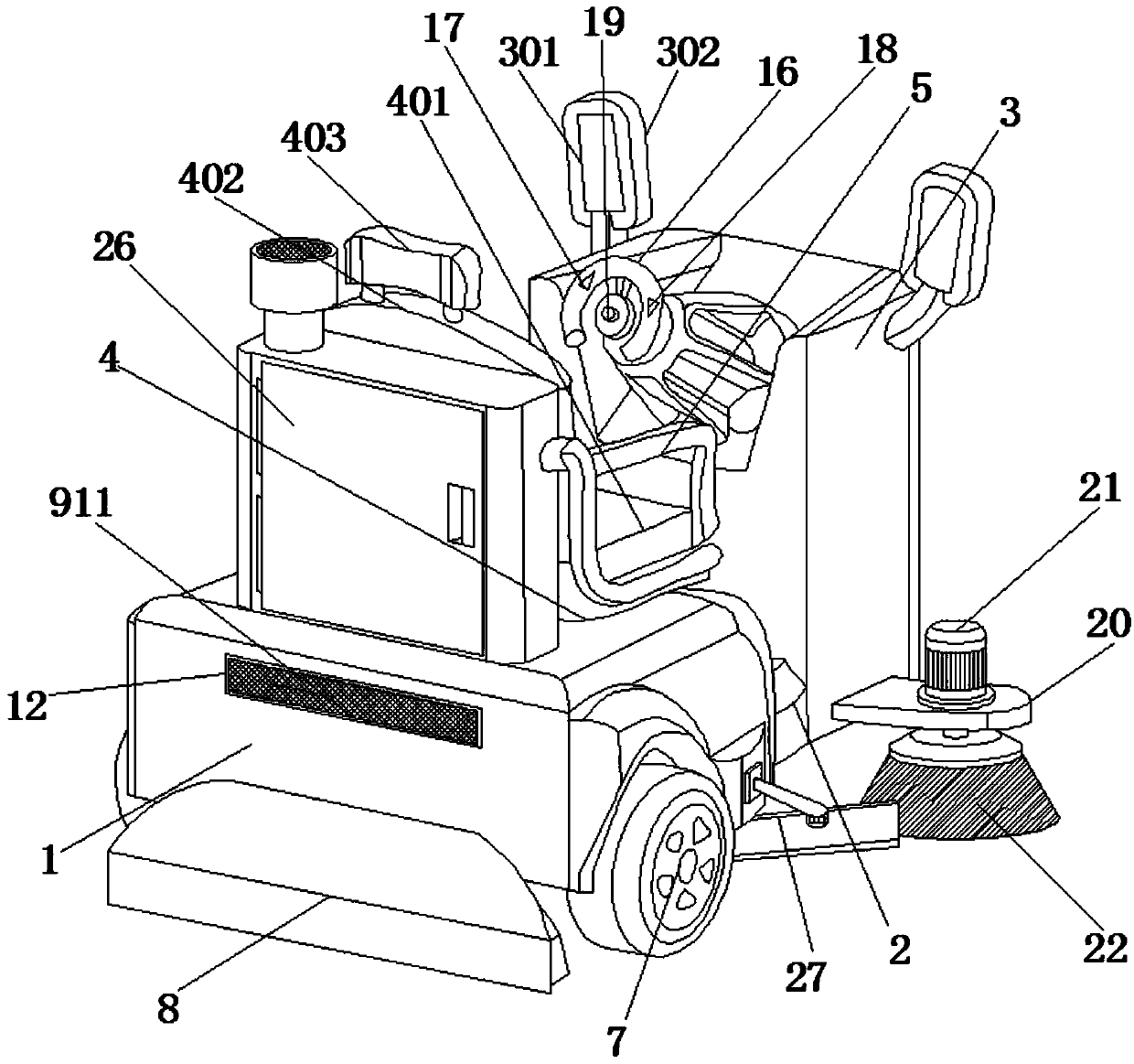

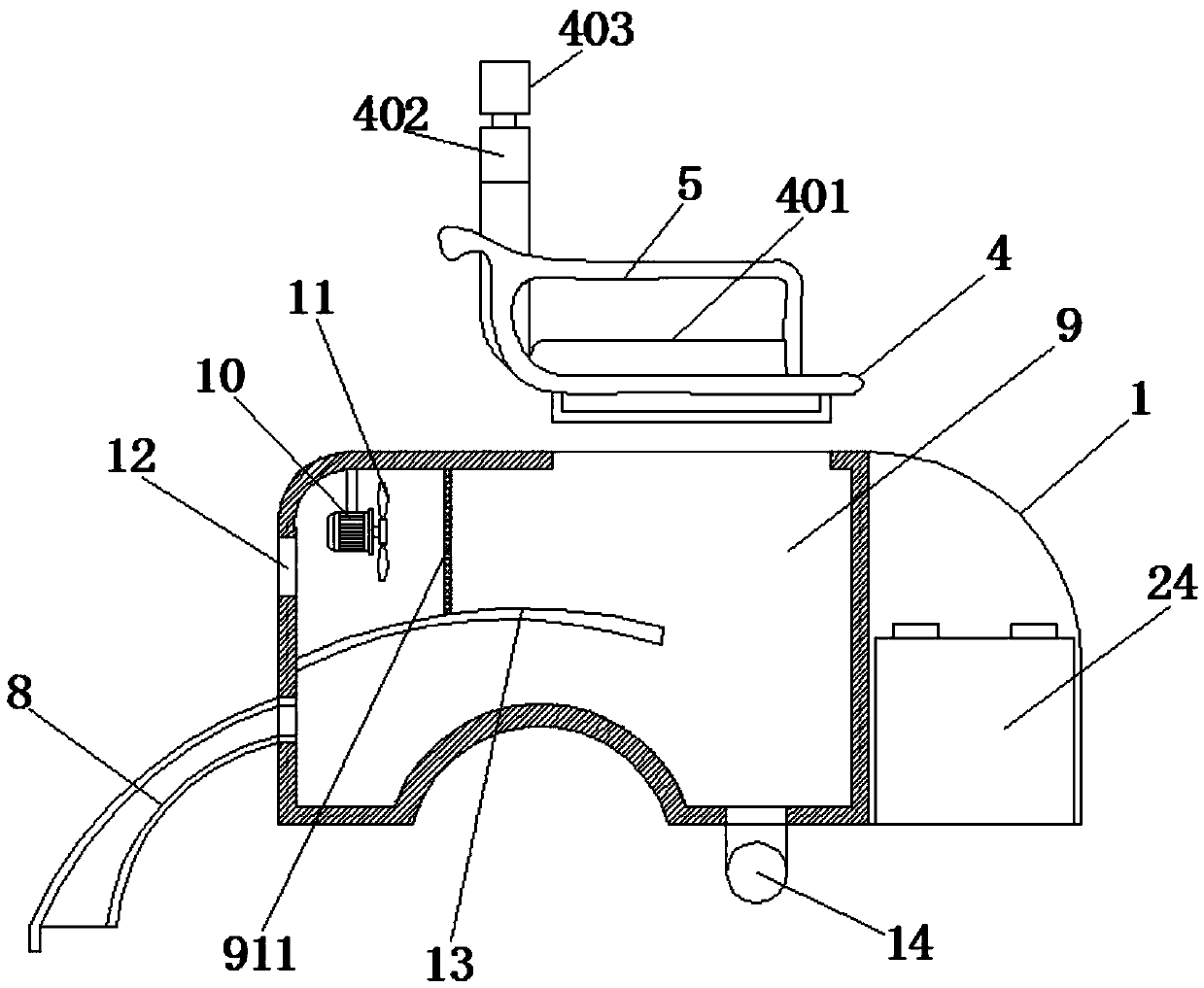

[0037] as attached figure 1 to attach Figure 9 shown

[0038] The invention provides a high-efficiency wet dust-reducing cleaning device for an oil press, including a vehicle body 1, pedals 2, headstock 3, seat 4, handrails 5, control buttons 6, driving roller device 7, water suction pipe 8, and waste water bin 9 , the first motor 10, the first fan 11, the exhaust port 12, the deflector 13, the waste water discharge valve 14, the steering wheel 15, the steering wheel 16, the forward button 17, the backward button 18, the brake button 19, the support plate 20, the first Two motors 21, cleaning brushes 22, water tanks 23, batteries 24, charging holes 25, appliance storage boxes 26, scraping devices 27 and high-pressure water spray devices 28, the bottom of the front end of the vehicle body 1 is welded to the pedal 2, and the The front end of the pedal 2 is welded with the front end 3, the front end of the top surface of the vehicle body 1 is plugged with the seat 4, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com