Disc cutter changing robot simulation test bed and application method thereof

A technology for simulating test benches and disc-shaped hobs, applied in manipulators, manufacturing tools, etc., can solve problems such as high cost, difficult tool box position changes, complex structures, etc., and achieve the effect of easy handling and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

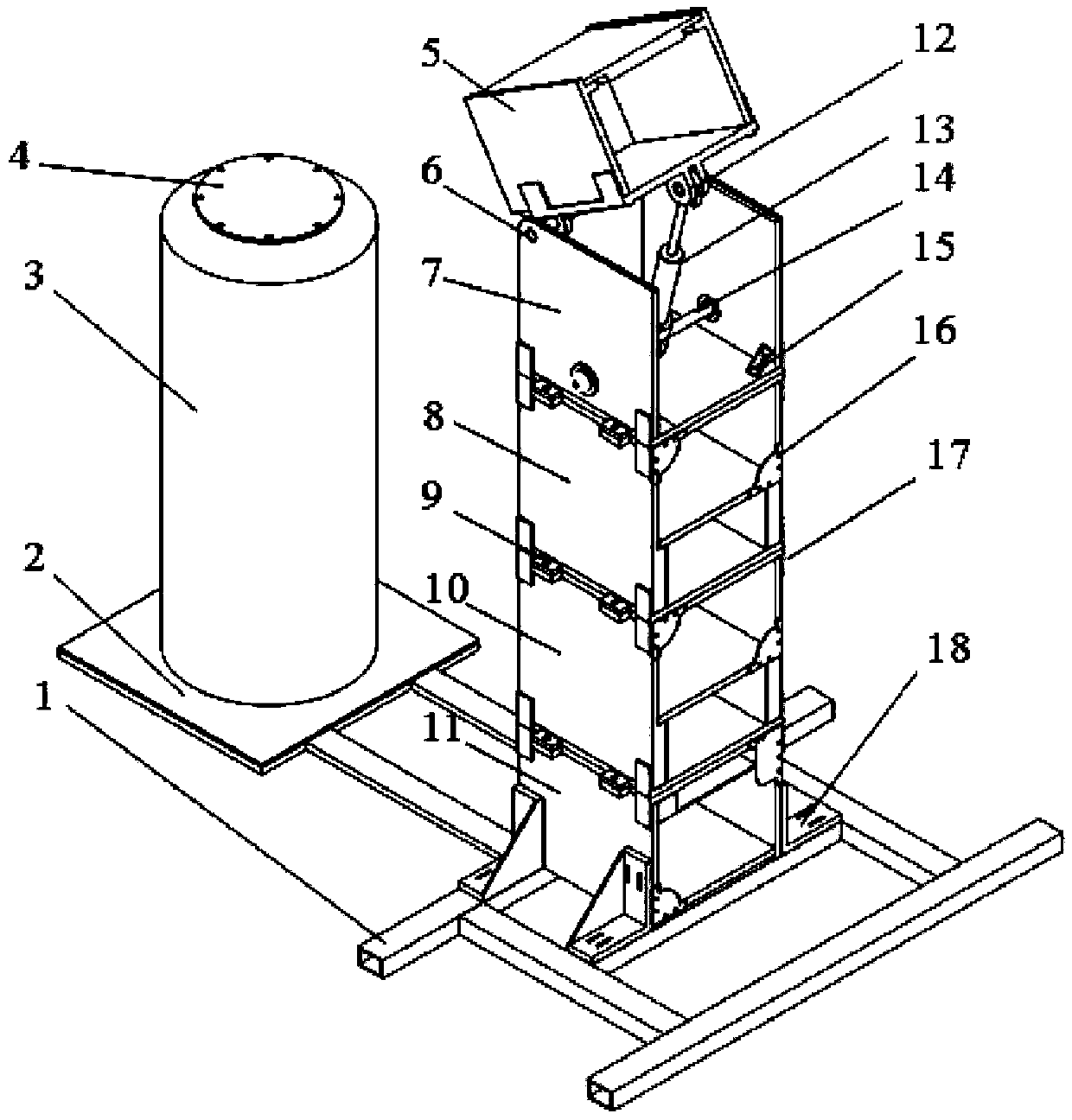

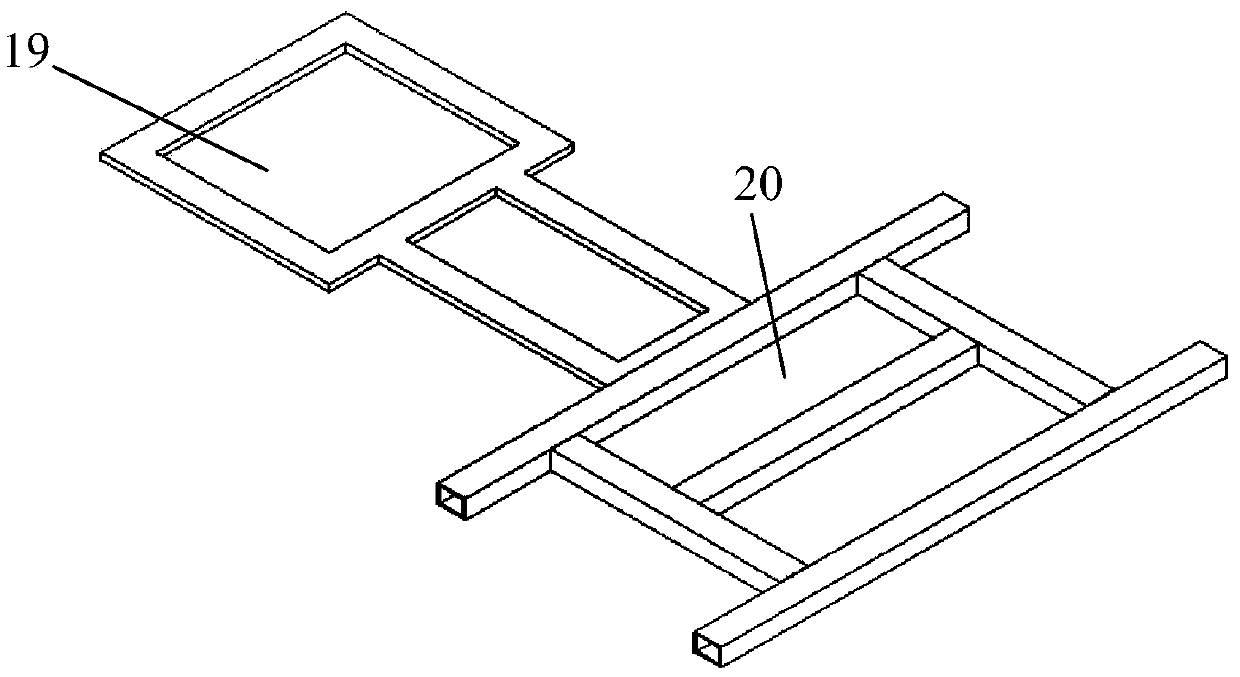

[0045] Such as figure 1 , 2 As shown, a simulation test bench for a disc-shaped hob tool changing robot of the present invention includes a test bench base 1, a tool changing robot mounting seat and a tool box module, wherein the test bench base 1 includes a tool changing robot mounting seat area 19 and The knife box module area 20 is installed, and the tool changing robot mounting seat is installed on the tool changing robot mounting seat area 19; the knife box module is installed on the knife box module area 20.

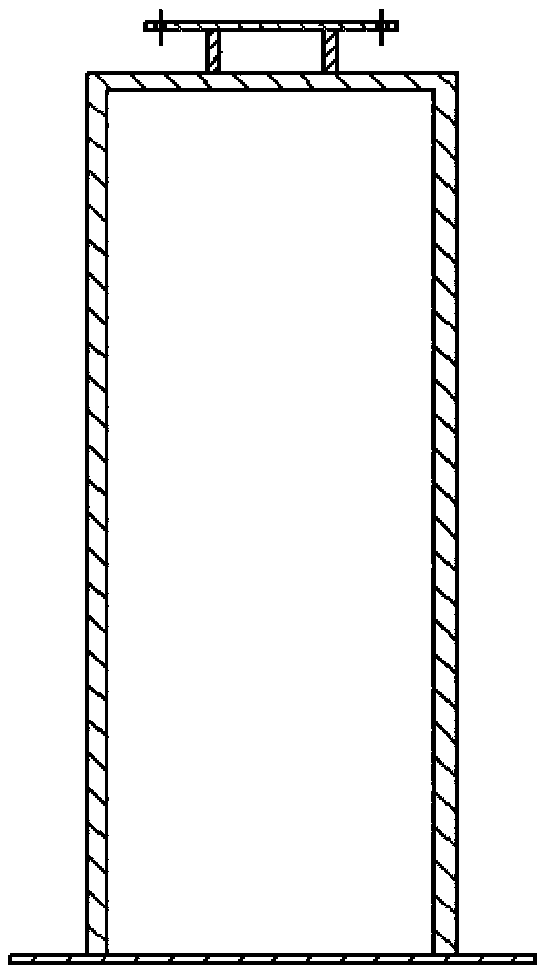

[0046] The tool changing robot mounting base comprises a tool changing robot mounting base base plate 2, a tool changing robot mounting base base 3 (such as image 3 shown) and the flange disc 4 of the tool changing robot mounting base, wherein the tool changing robot mounting base base 3 is installed on the tool changing robot mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com