Dehumidification drying device for regenerated plastic particles

A technology of recycled plastic particles and a drying device, which is applied in the field of recycled plastic processing, can solve the problems such as the difficulty of fully drying the particles with water and moisture, and achieve the effects of improving the dehumidification and drying efficiency, avoiding mutual adhesion and ensuring the quality of forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

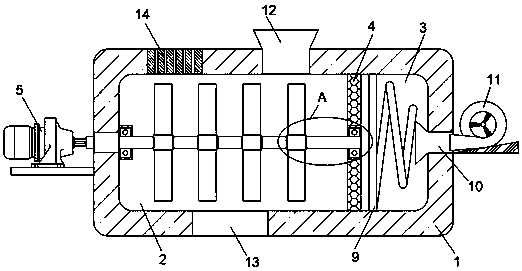

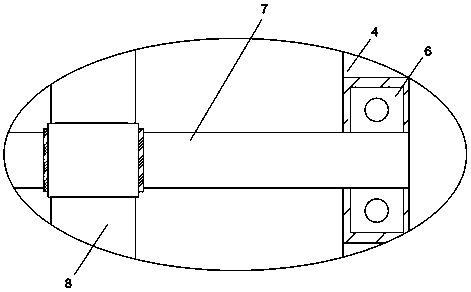

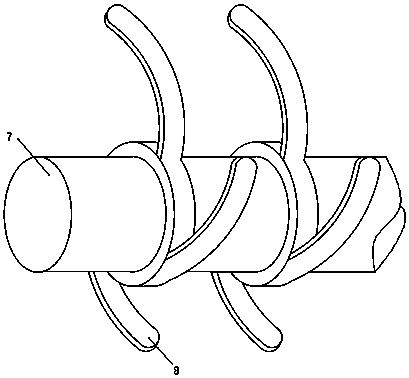

[0021] refer to Figure 1-3 , a dehumidification and drying device for recycled plastic particles, including a cylinder 1, the cylinder 1 adopts a stainless steel structure to avoid erosion caused by water, and the cylinder 1 is horizontally separated into a drying chamber 2 and a heating chamber 3 by a ventilation plate 4, and the drying The outer ends of the chamber 2 and the heating chamber 3 are respectively provided with a servo motor 5 and a blower 11. The servo motor 5 is a motor with a product model of KM10086, and the blower 11 is a small fan with a product model of W2S130-AA03-01DE. A rotating shaft 7 is horizontally arranged in the drying chamber 2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com