A kind of frp stirrup forming device and reinforcement cage manufacturing method

A forming device and stirrup technology, applied to nets, household appliances, and other household appliances, to achieve the effects of convenient and quick use, small space, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

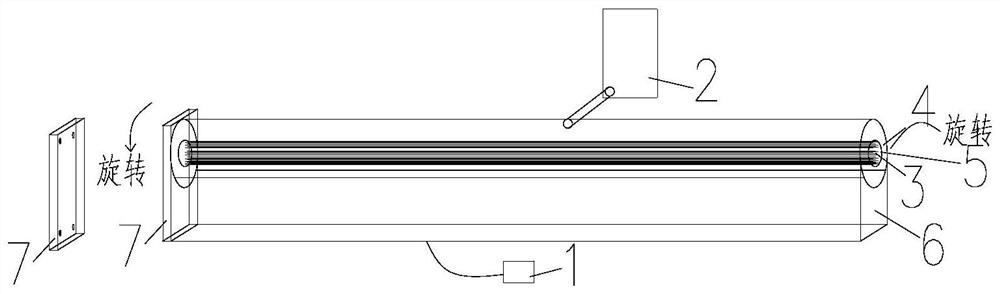

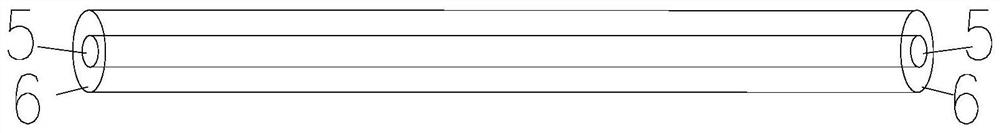

[0026] see figure 1 , figure 2 and image 3 , a FRP stirrup forming device, comprising a mandrel 4, a through hole for placing a fiber bundle 3 is provided in the middle of the mandrel 4, a gear box 6 is provided below the mandrel 4, and a glue injection is provided on the axial surface of the mandrel 4 hole, the glue outlet of the glue injection machine 2 is connected to the glue injection hole, and the two ends of the mandrel 4 are respectively set with a forward-rotating jig and an overturning jig. The gear box 6 is used to drive the forward-rotating jig and the overturning jig to drive the mandrel 4 to rotate forward. and reverse rotation, one end of the mandrel 4 is open, and the other end is sealed by a sealing cover 7, both the forward-rotating fixture and the flipping fixture are gears, and the gear box 6 is provided with several driving gears meshing with the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com