Rear suspension system capable of being disassembled rapidly

A rear suspension and fast technology, applied in the direction of suspension, elastic suspension, reservoir layout, etc., can solve the problems of inability to adjust the height of the vehicle, troublesome disassembly of the bearing device, unfavorable storage and other problems, to meet the needs of military transportation, Long service life, good for warehouse storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

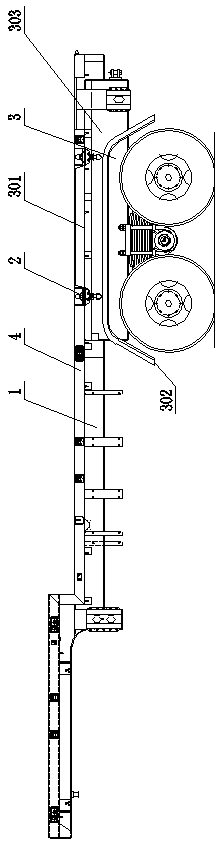

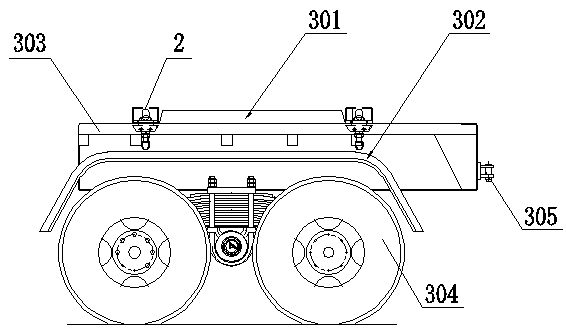

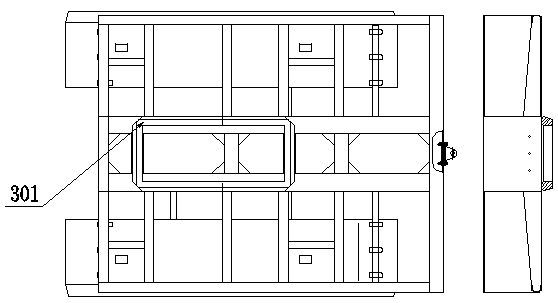

[0023] The embodiment of this quick detachable rear suspension system will be described in further detail below in conjunction with the accompanying drawings (see Figure 1~5 ):

[0024] A rear suspension system that can be quickly disassembled, which is composed of a trailer frame 1, a suspension lock device 2, a suspension travel mechanism 3, an upper loading platform 4, and an air / circuit control device 5;

[0025] The upper part of the trailer frame 1 is equipped with a top-loading platform 4, and four suspension devices 2 are symmetrically installed on the front and rear sides of the top-loading platform 4. The trailer frame 1 is connected with a suspension travel mechanism 3 through the suspension device 2. The suspension travel mechanism 3 includes wedge-shaped positioning. Boss 301, fender 302, vehicle frame 303, road wheel 304, tail hook 305; air / circuit control device 5 includes air brake mechanism, A air storage tank 501, B air storage tank 502, one-way valve 503, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com