An intermittent feeding mechanism

A feeding mechanism and intermittent technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of increasing equipment purchase and use costs, low intermittent time accuracy, and confusion in production lines. The effect of low acquisition cost, low maintenance and use cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

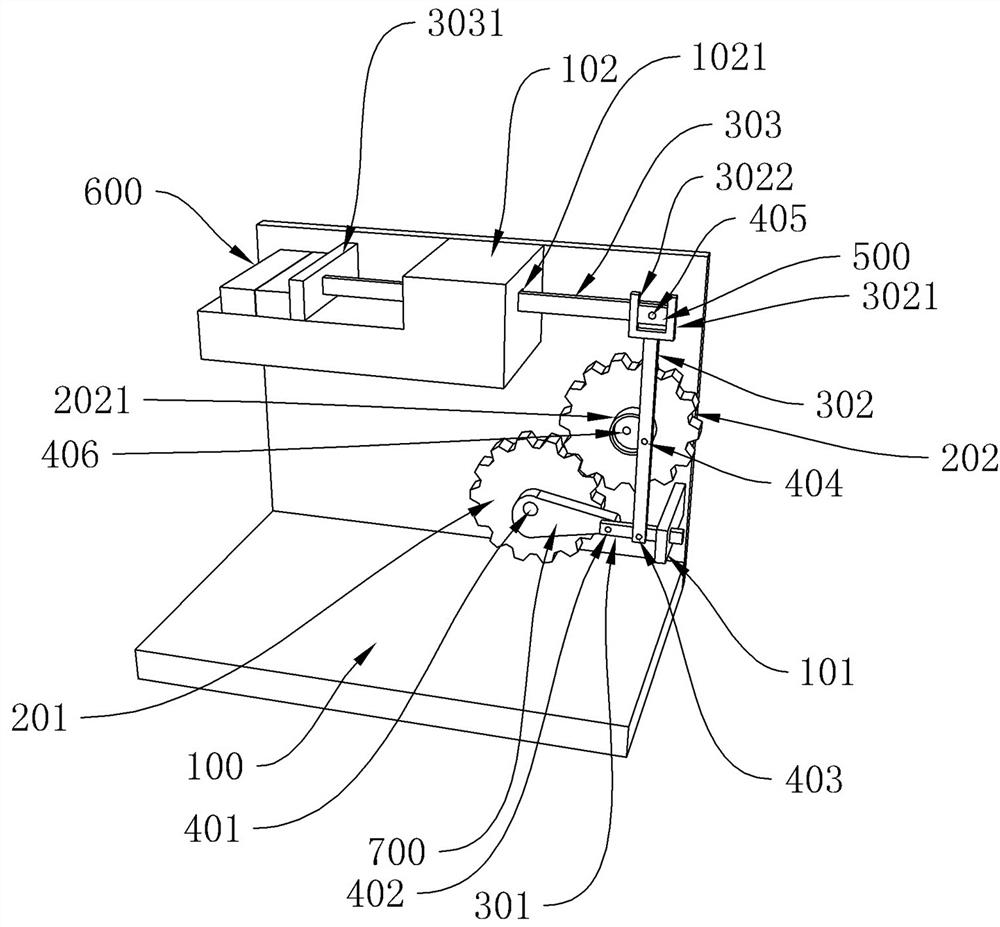

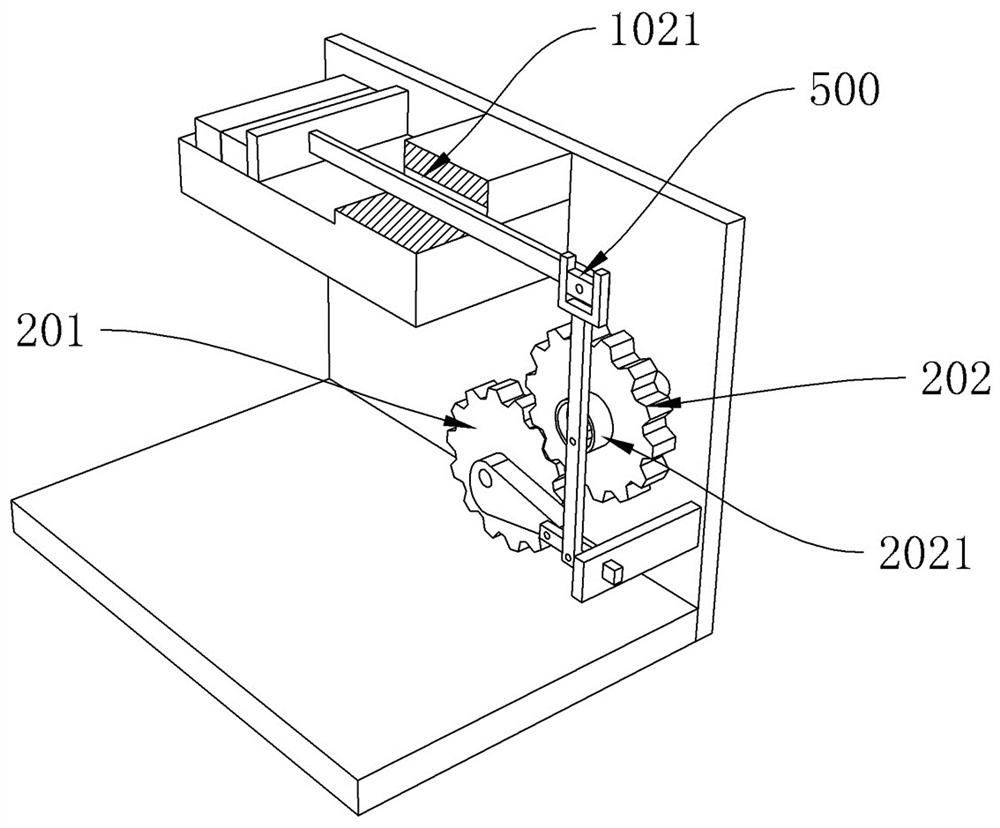

[0023] see Figure 1 to Figure 4 , an intermittent feeding mechanism, including a frame 100, the frame 100 is fixed with a guide plate 101 and a bracket 102;

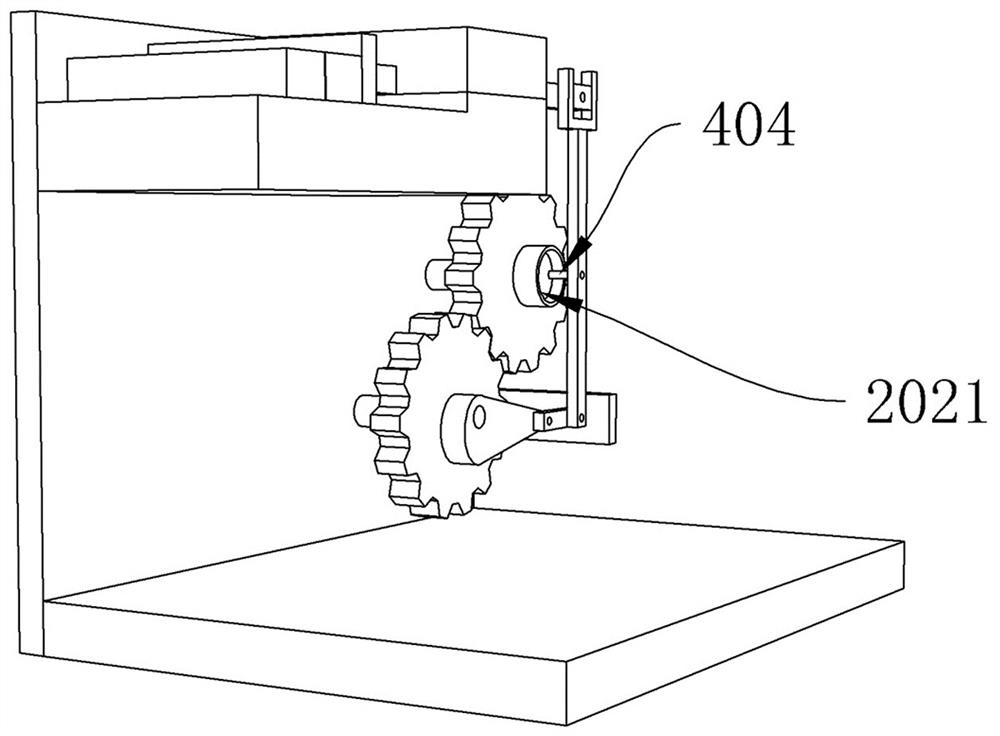

[0024] The frame 100 is also equipped with a driving gear 201 and a driven gear 202, and the driving gear 201 and the driven gear 202 mesh with each other to form a gear transmission structure;

[0025] The driving gear 201 is hingedly assembled with the arc end 701 of the connecting plate 700 through the first connecting pin 401, and the end of the connecting plate 700 away from the arc end 701 is hinged with the end of the first connecting rod 301 through the second connecting pin 402 Assembly, the other end of the first connecting rod 301 is loaded into the first guide groove 1011 of the guide plate 101;

[0026] The middle part of the first connecting rod 301 is hingedly assembled with the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com