Anaerobic tank for sewage treatment

A sewage treatment and anaerobic pool technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc., can solve the problems of incomplete purification and poor sealing, and achieve the solution of incomplete purification , Improve the sealing performance and improve the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

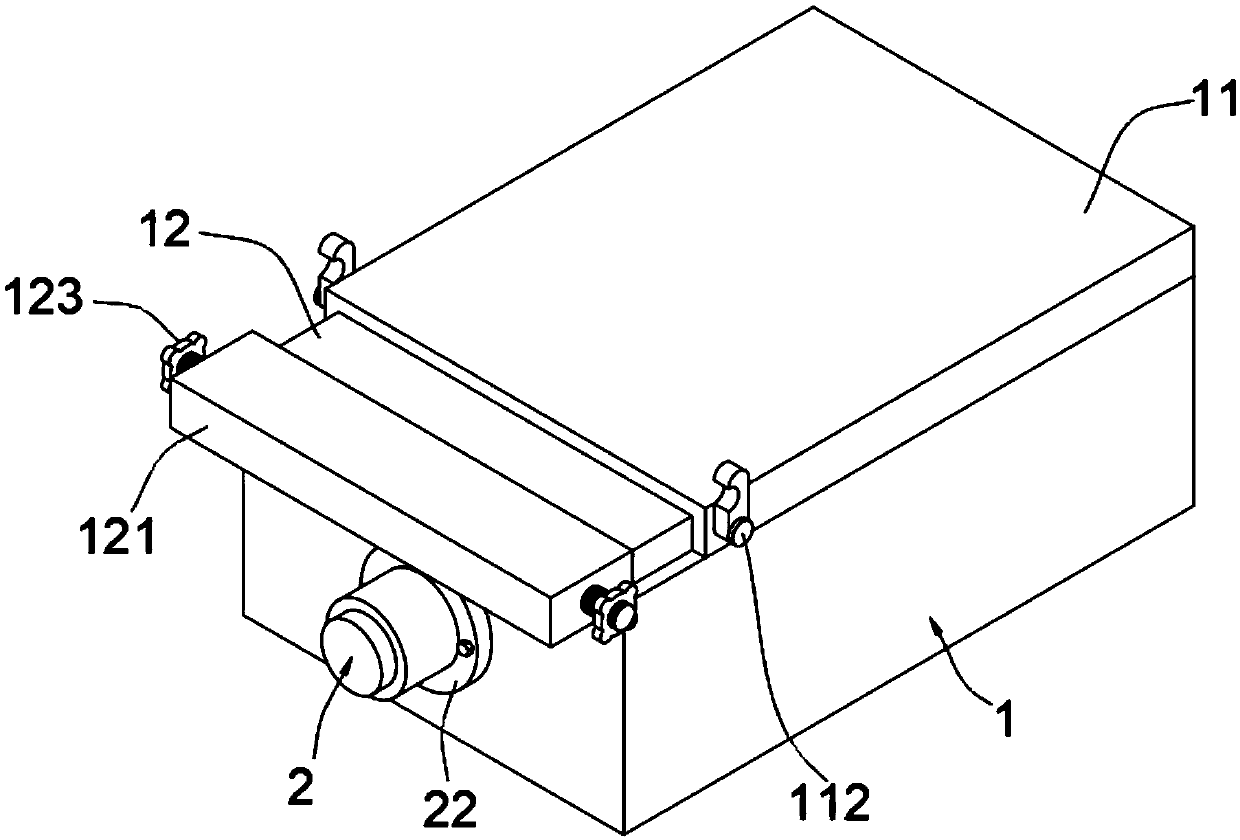

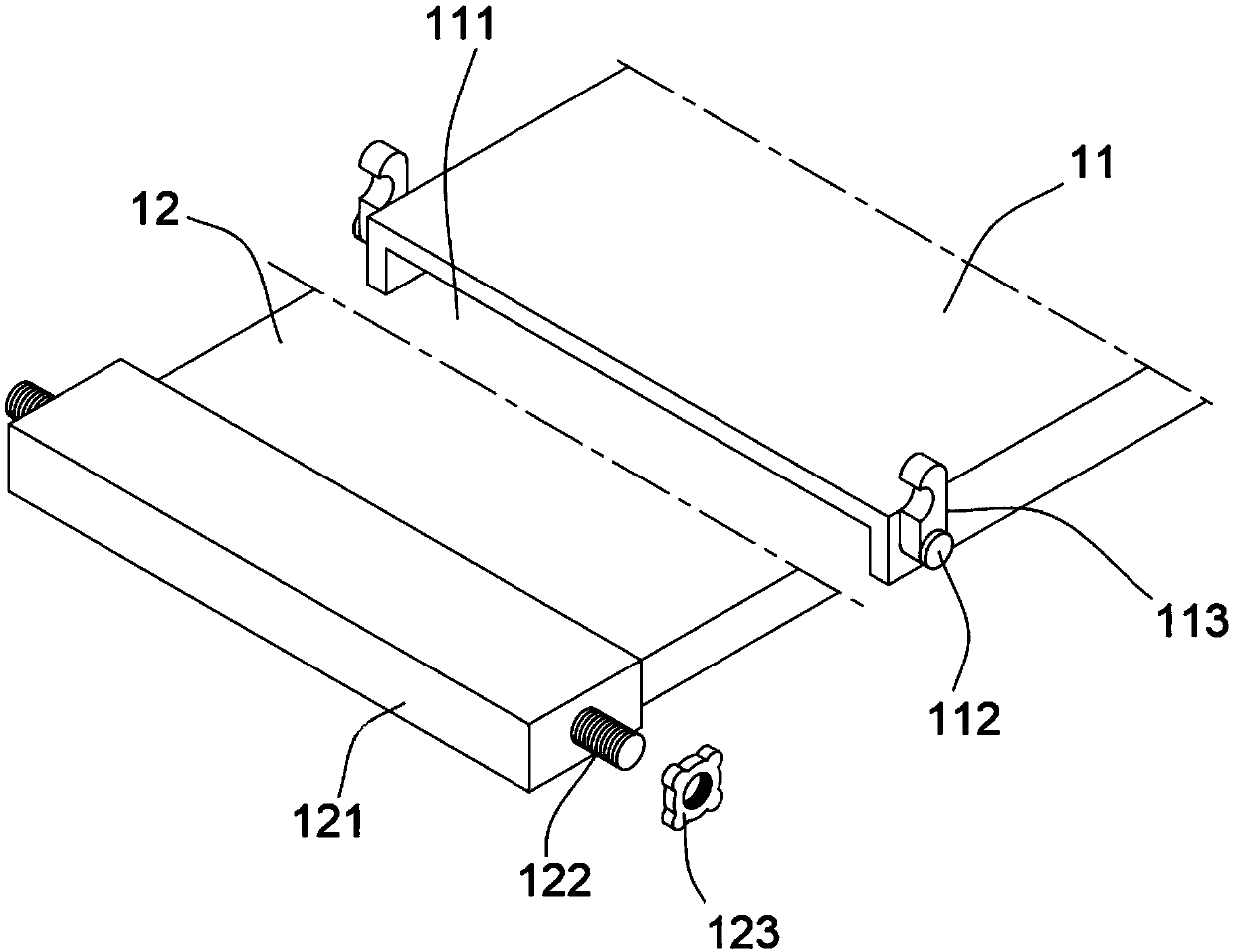

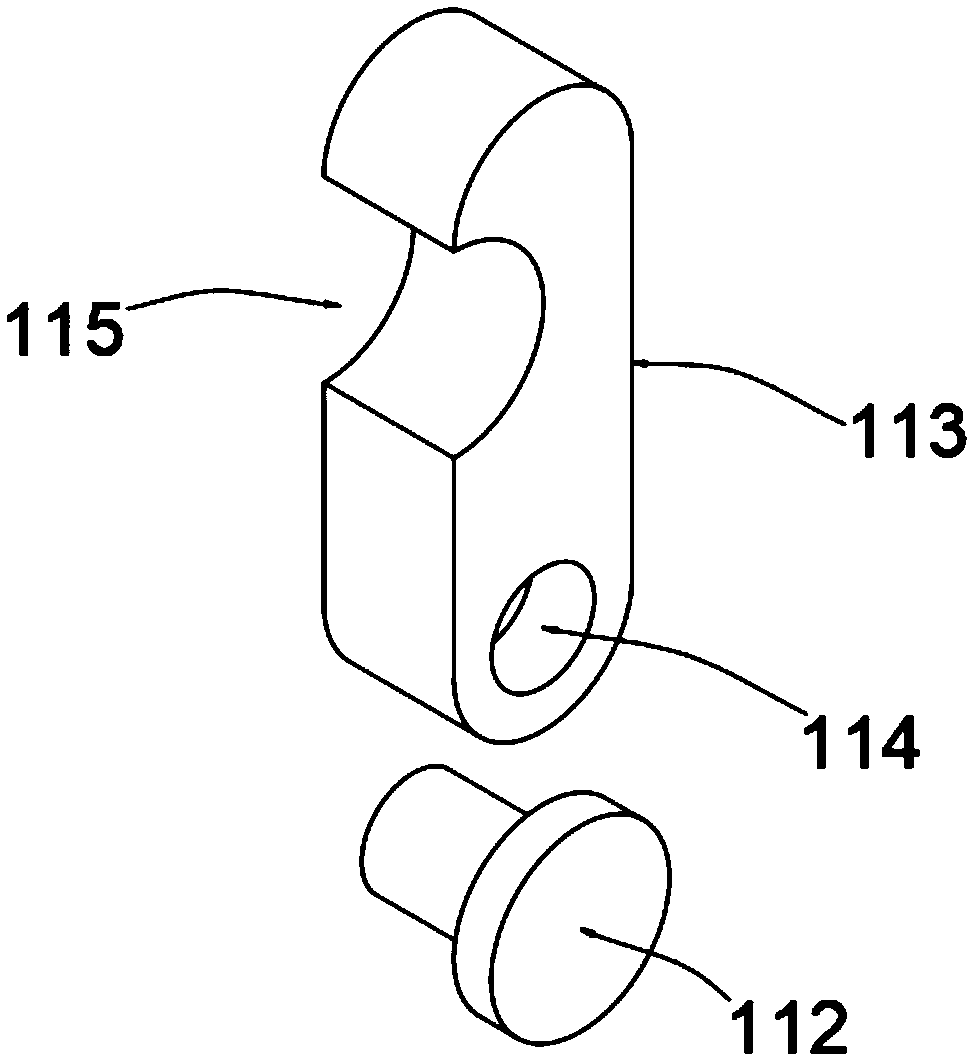

[0031] An anaerobic pond for sewage treatment, such as figure 1 , figure 2 and image 3 As shown, including the anaerobic pool 1, the upper surface of the anaerobic pool 1 is tightly welded with a loam cake 11, the lower surface of the loam cake 11 is provided with a slideway 111, and the slideway 111 is provided with a slide plate 12, and the slide plate 12 passes through the slideway 111 is slidingly connected with the upper cover 11, one end of the slide plate 12 is tightly welded with a stopper 121, both sides of the upper cover 11 are tightly welded with a rotating shaft 112, the rotating shaft 112 is provided with a fixed block 113, and the bottom end of the fixed block 113 is provided with a through The hole 114 and the top of the fixing block 113 are provided with a notch 115 , both sides of the block 121 are tightly welded with a screw 122 , the screw 122 is provided with a nut 123 , and the nut 123 is threadedly connected with the screw 122 .

[0032] In this embo...

Embodiment 2

[0039] As the second embodiment of the present invention, in order to make the purification of the anaerobic pool more thorough, the inventors make improvements to the structure of the anaerobic pool 1, as a preferred embodiment, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the front end face of the anaerobic pool 1 is provided with a perforation 13, and the perforation 13 runs through the front end face of the anaerobic pool 1, a first bearing 131 is installed in the perforation 13, and a second bearing 131 is installed on the rear end inner surface of the anaerobic pool 1. Bearing 132, the front end of anaerobic tank 1 is provided with motor 2, is provided with stirring shaft 21 on the output end of motor 2, and one end of stirring shaft 21 is provided with screw hole 211, and stirring shaft 21 is connected with motor 2 through screw hole 211 The output end is screwed, and several collars 212 are tightly welded on the stirring shaft 21 , and several pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com