Cover type annealing furnace

A bell-type annealing furnace and inner hood technology, which is applied to furnaces, furnace types, heat treatment furnaces, etc., can solve problems such as poor contact effect and poor heat dissipation effect, and achieve simple structure, improved heat transfer process, and improved uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

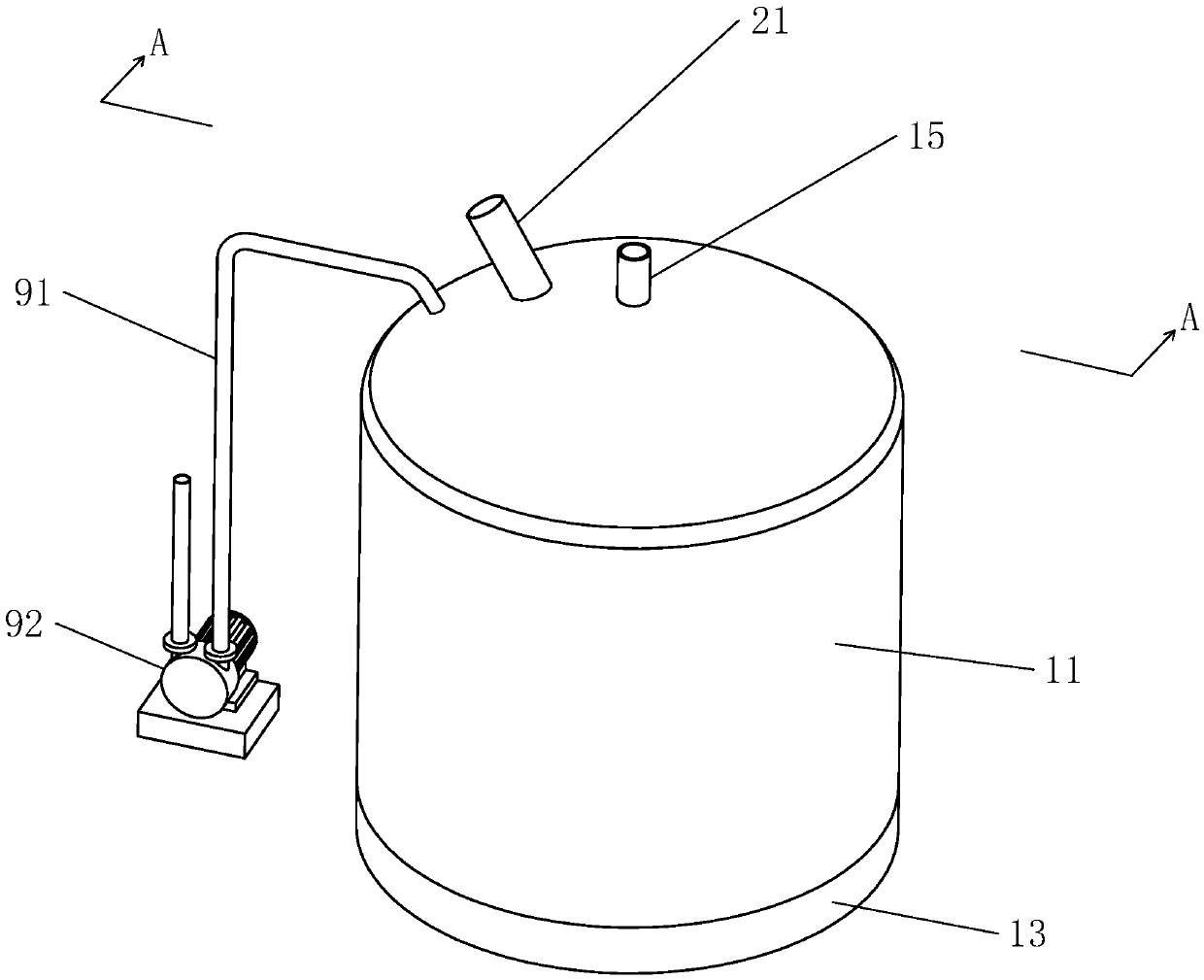

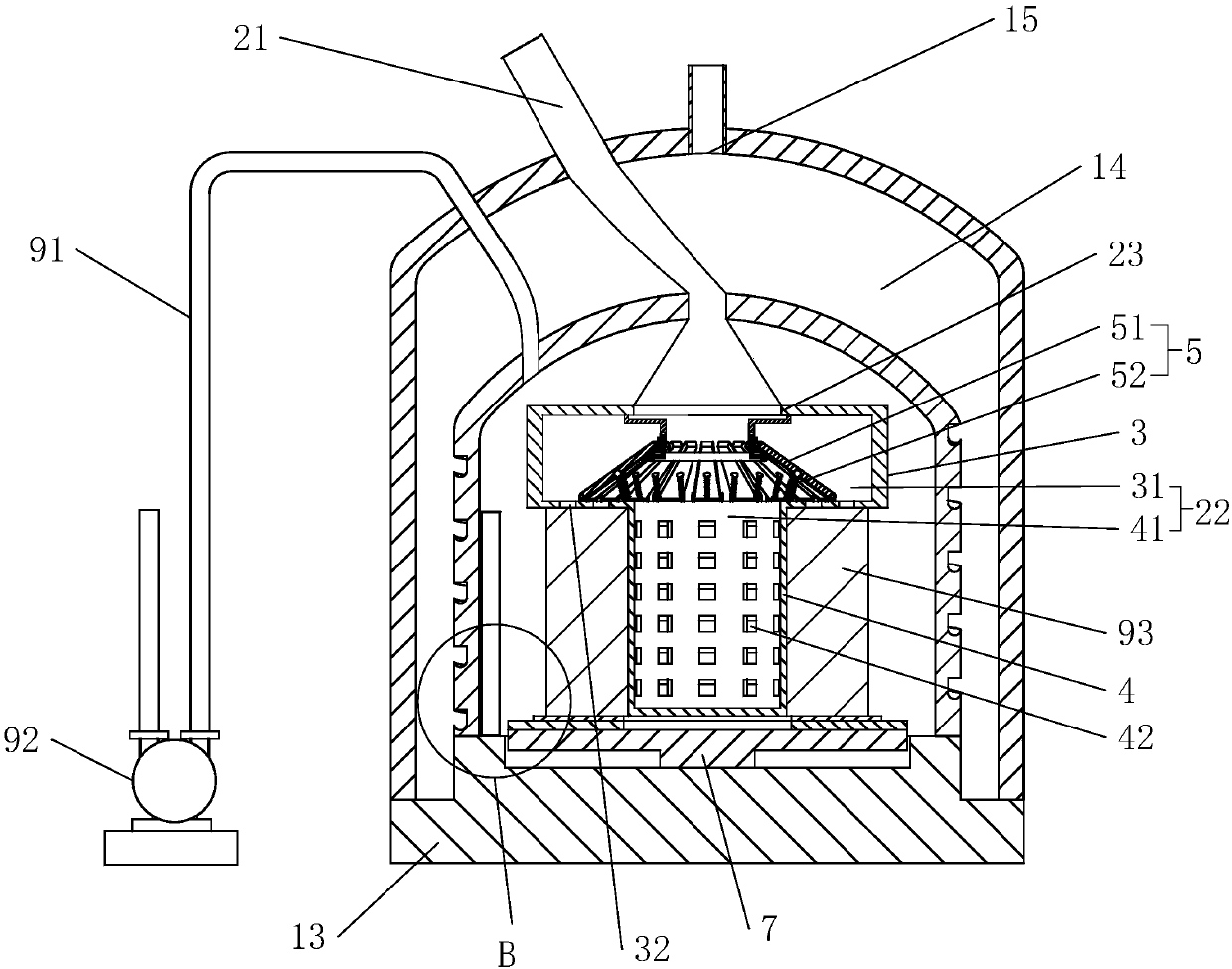

[0038] A bell annealing furnace, such as figure 1 and figure 2 As shown, it includes an outer cover 11, an inner cover 12, and a furnace bottom pedestal 13. The furnace bottom pedestal 13 is fixed on the ground, and the cross section of the furnace bottom pedestal 13 is "convex" in the vertical section of the furnace bottom pedestal 13. The outer cover 11 is installed on the edge of the furnace bottom pedestal 13, and the inner cover 12 is installed on the furnace bottom. A heat exchange cavity 14 is provided between the outer cover 11 and the inner cover 12 at the top step of the pedestal 13 .

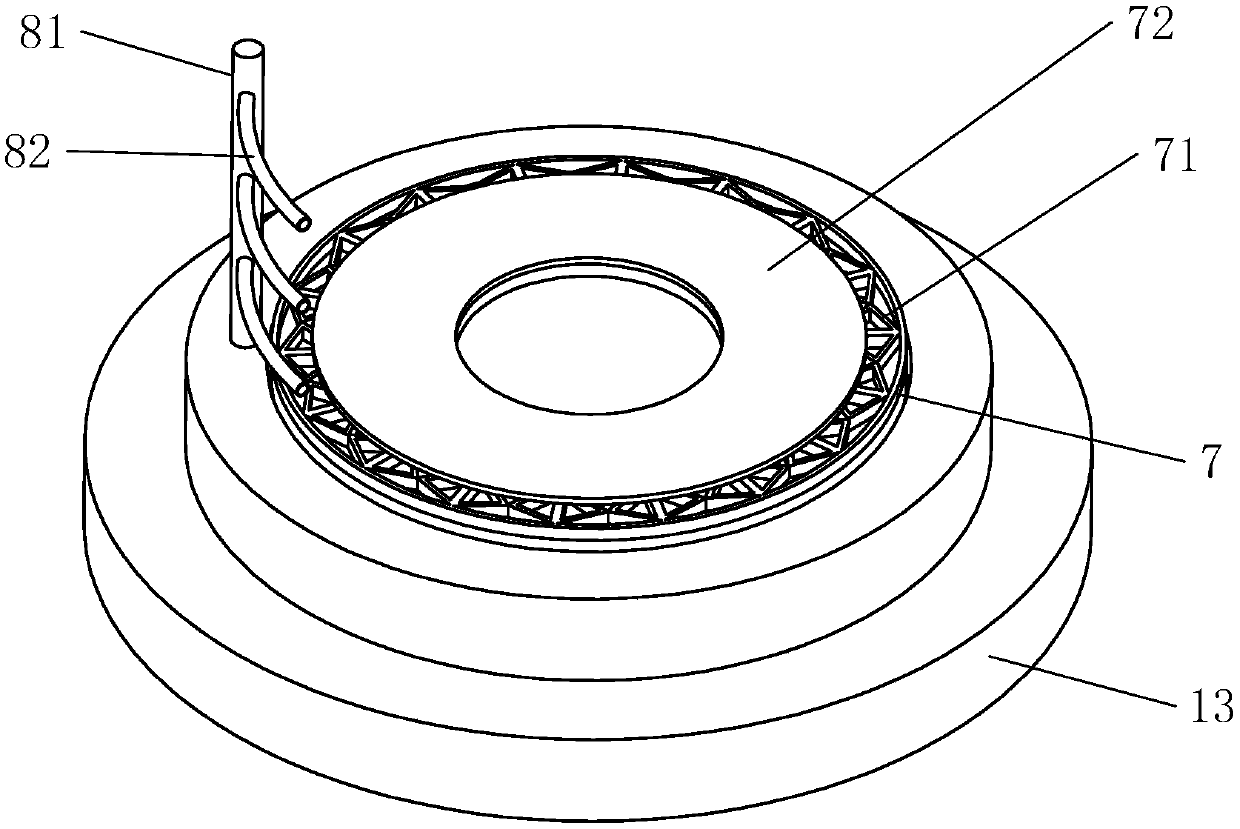

[0039] Such as image 3 and Figure 6 As shown, a circular placement frame 7 is coaxially fixed in the furnace bottom pedestal 13, and a mesh support structure 71 is arranged in the placement frame 7, and a graphite fiber gasket 72 with a circular cross section is placed on the mesh support structure 71.

[0040] Such as figure 2 and image 3 As shown, an exhaust gas pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com