Low groove-type steel and concrete composite beam

A technology of steel-concrete composite beams and channel steel, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of prolonging the construction progress, consuming manpower and material resources, and not being able to fully utilize the characteristics of steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present disclosure will be further described in detail below in conjunction with the drawings and embodiments. It can be understood that the specific implementations described here are only used to explain related content, rather than to limit the present disclosure. In addition, it should be noted that, for ease of description, only parts related to the present disclosure are shown in the drawings.

[0046] It should be noted that the embodiments in the present disclosure and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present disclosure will be described in detail with reference to the drawings and in conjunction with the embodiments.

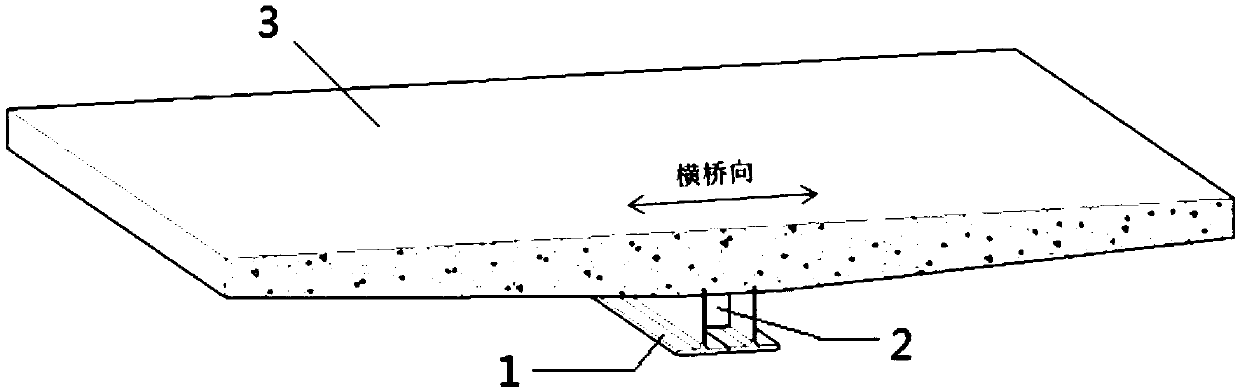

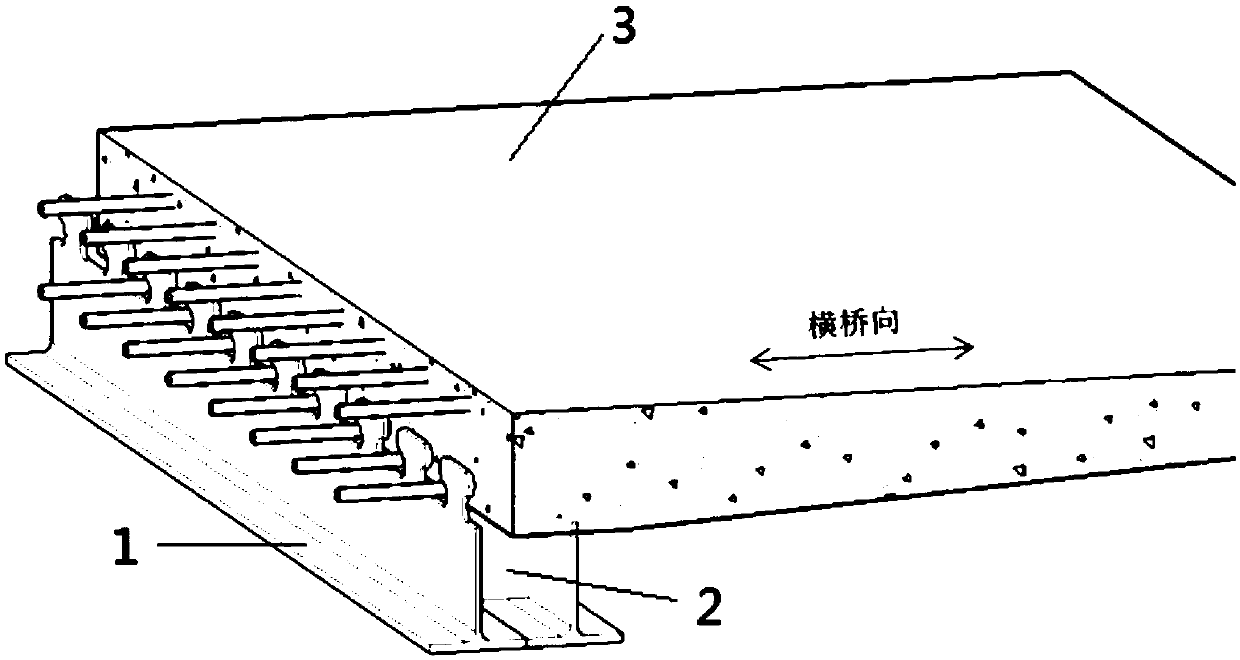

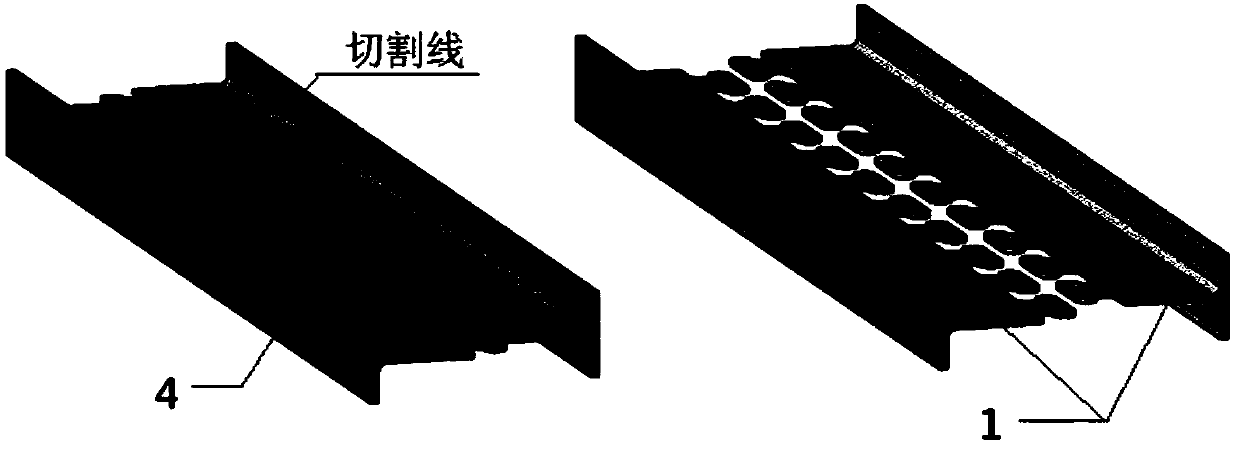

[0047] The present disclosure provides a structural form of a low-height channel steel-concrete composite beam with sufficient bearing capacity and spanning capacity, which can be conveniently and quickly prefabricated and is suitable for small-span highway bridges, pedestri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com