Core penetrating assembled foundation for power transmission line

A power transmission line and assembled technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of inability to ensure the compactness of foundation pit backfill, construction quality, unfavorable hoisting in place at the construction site, and the self-heavy weight of individual components, etc., to achieve improvement Mechanized construction efficiency, reduced difficulty of installation and positioning, and high degree of marketization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

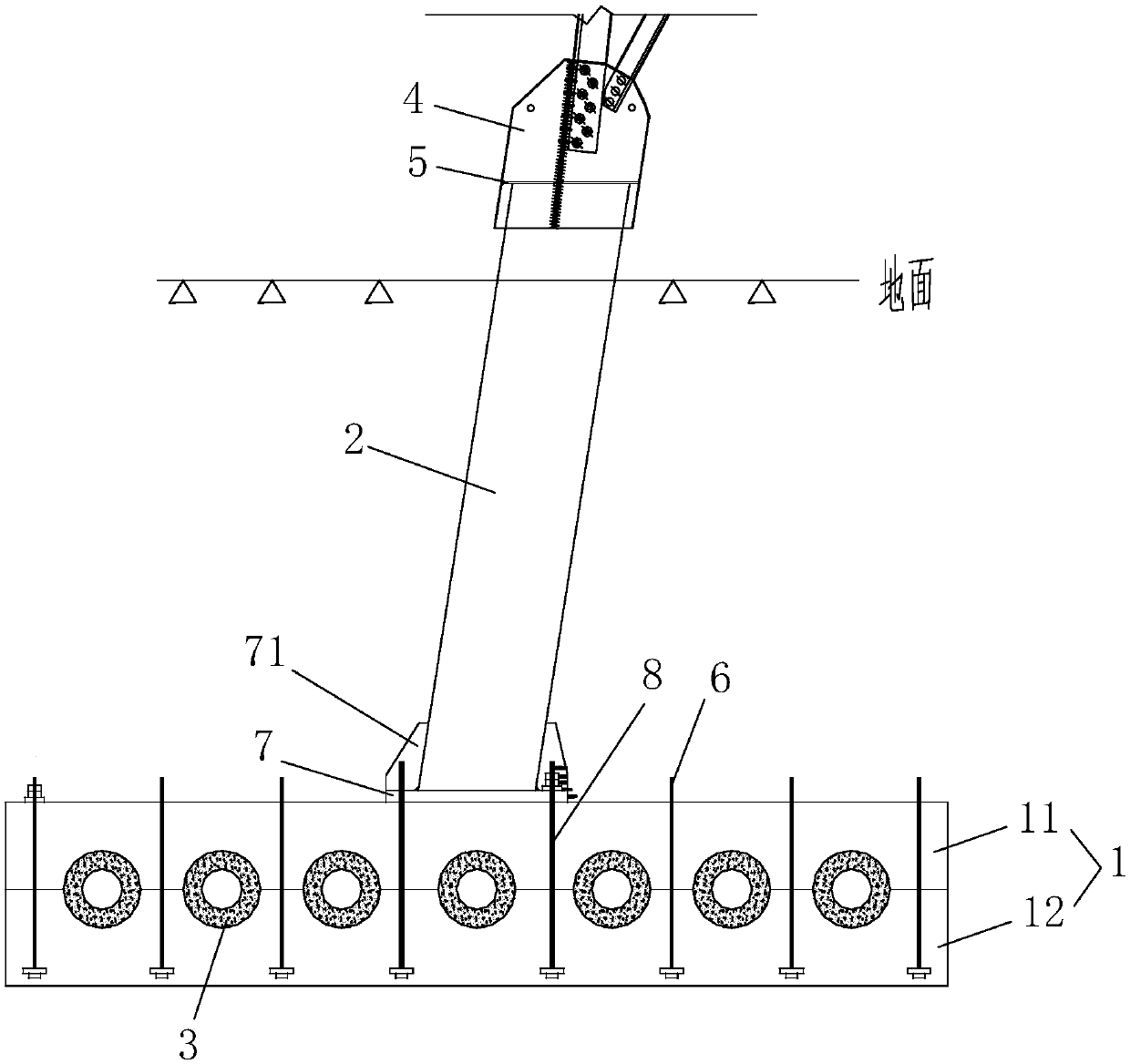

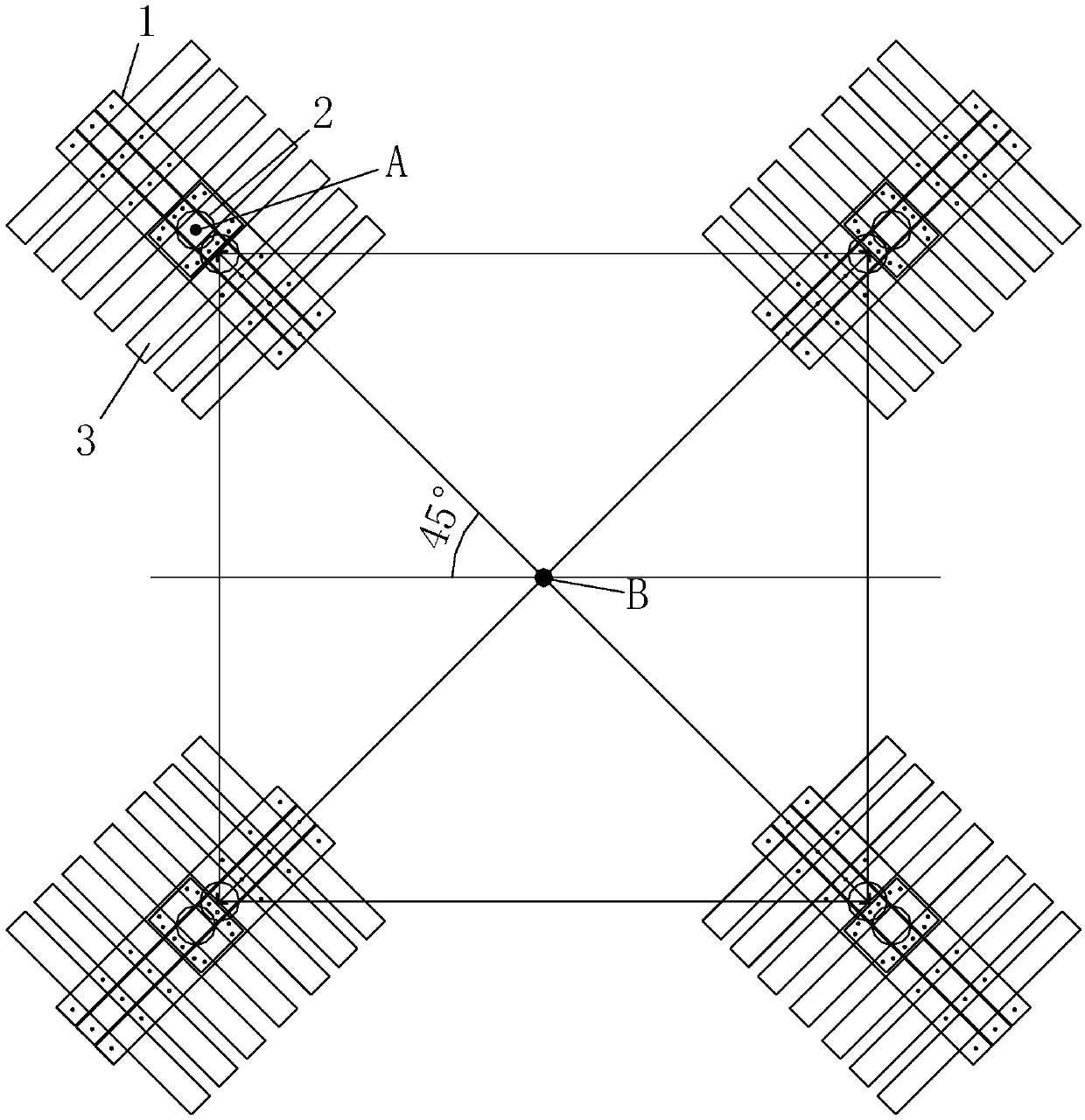

[0019] Such as figure 1 A piercing fabricated foundation for transmission lines is shown, including a beam 1, a column 2 connected to the upper surface of the beam 1, and a PHC pipe pile 3 arranged through the beam 1 along the width direction of the beam 1, and the top of the column 2 The cross beam 1 is connected with the tower leg of the iron tower through the cross leg 4, and the beam 1 is a prefabricated concrete beam PHC pipe pile 3. A plurality of PHC pipe piles 3 are evenly arranged along the length direction of the beam 1, forming the effect of "piercing through the center" of the PHC pipe pile.

[0020] Further, the upright column 2 is a steel pipe arranged obliquely, and the inclination direction and inclination angle of the upright column 2 coincide with the inclination direction and inclination angle of the tower legs of the iron tower, and the top of the uprigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com