Walking beam type oil pump additionally provided with speed increaser to adjust jig frequency

A technology of beam pumping unit and speed increaser, which is applied in the fields of exploitation fluid, wellbore/well parts, earthwork drilling and production, etc., and can solve problems such as difficult adjustment of pumping strokes, large installed power of motor, high starting current, etc. , to achieve significant energy-saving effects, increase torque, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

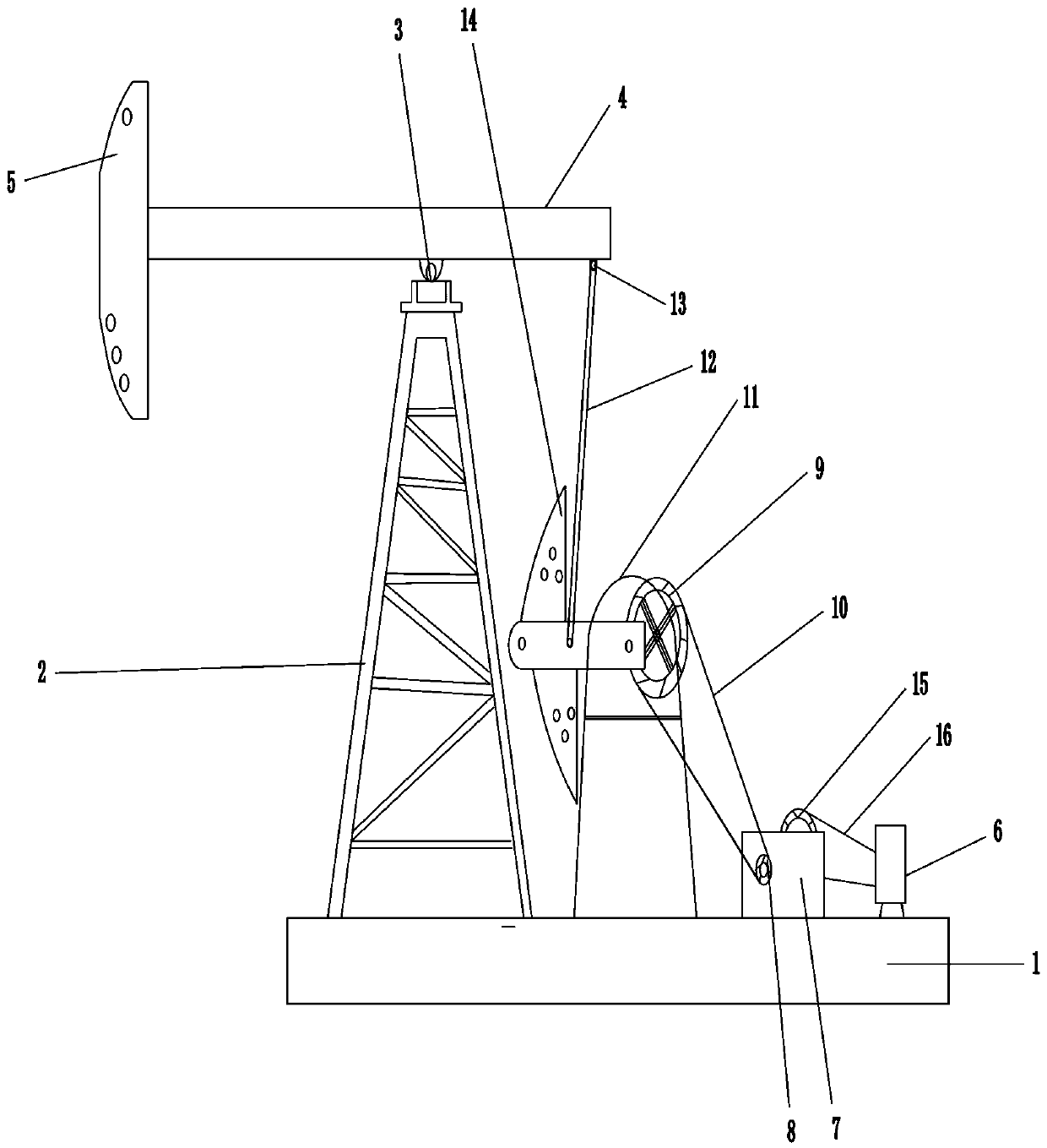

[0009] according to figure 1 As shown in the beam pumping unit of the present invention that adjusts stroke times by adding a speed increaser, a base 1 is provided, the left side of the base 1 is connected to the bracket 2, the top of the bracket 2 is connected to the central bearing assembly 3, and the central bearing assembly 3 is connected to the The beam 4, the left end of the beam 4 is connected to the donkey head 5, the right part is connected to the bearing 13, the lower end of the bearing 13 is connected to the connecting rod 12, the right part of the base 1 is connected to the reduction box 11, the speed increaser 7 and the motor 6; the motor 6 is connected to the output belt pulley Small belt 16, the other end of the small belt 16 is connected to the input pulley 15, the speed increaser 7 is connected to the output pulley 8, the output pulley 8 is connected to the large belt 10, the other end of the large belt 10 is connected to the large pulley 9, and the large pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com