A shaft end self-sealing structure with high speed and high pressure difference

A technology with self-sealing structure and high pressure difference, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pump components, etc., to enhance throttling effect, prevent shaft end leakage, and improve technology maturity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a shaft end self-sealing structure with high rotating speed and high pressure difference, which significantly reduces the pressure difference inside and outside the rotating machine and effectively prevents the shaft end leakage of the supercritical rotating machine. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

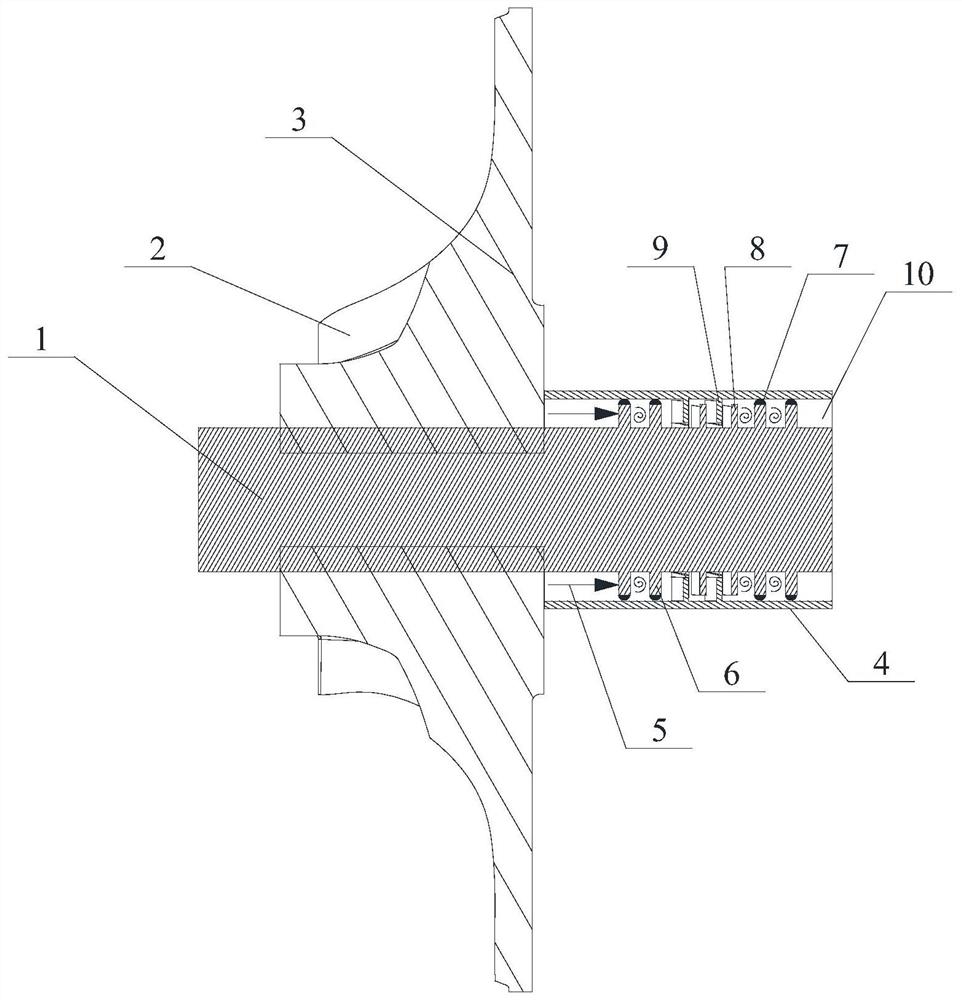

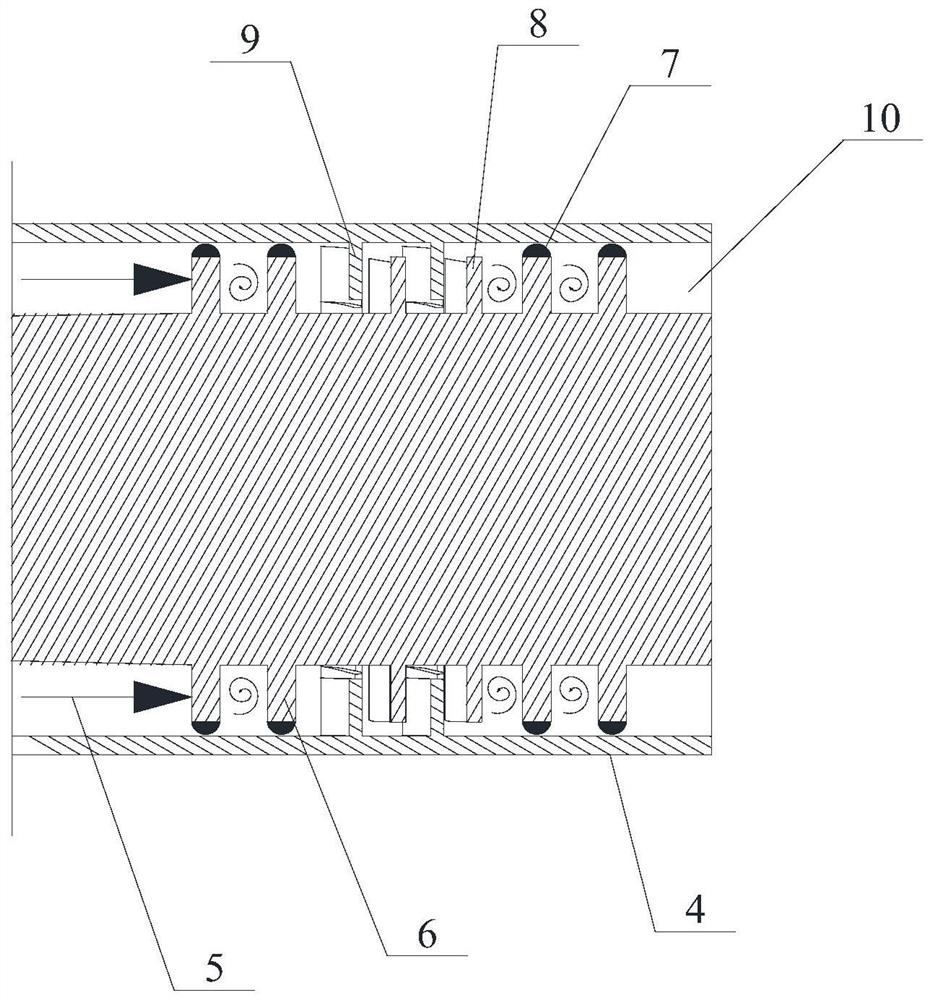

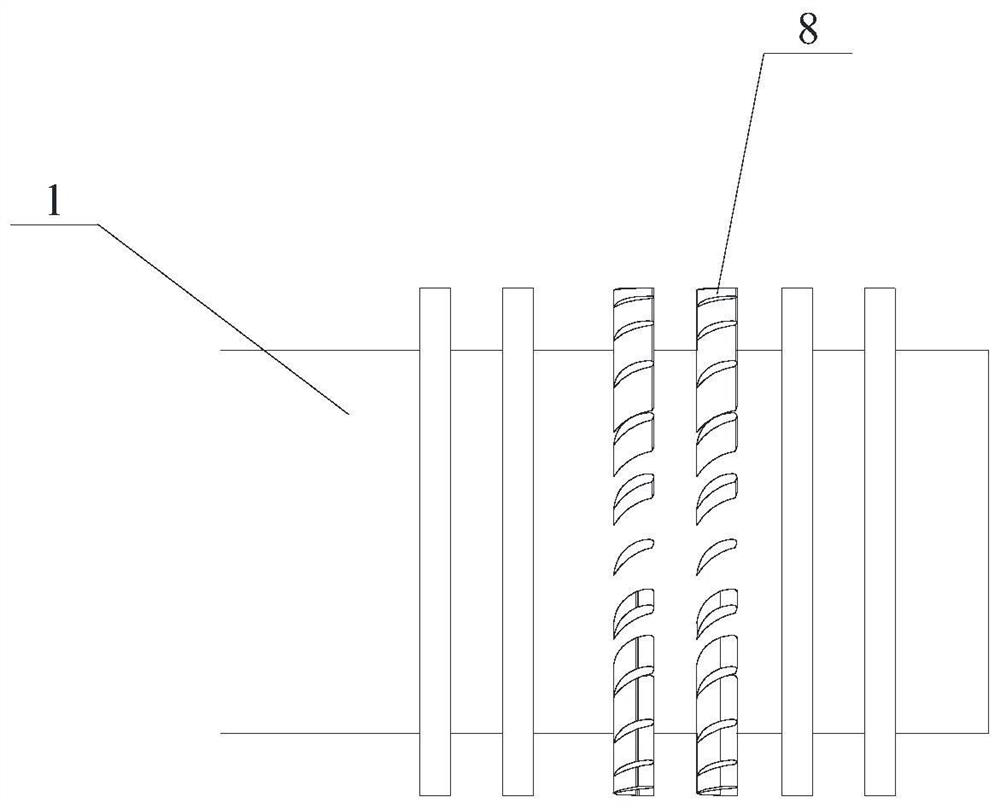

[0021] Such as figure 1 As shown, the present invention provides a high speed and high pressure difference shaft end self-sealing structure, which is placed on the rear side of the main impeller blade 3 of the rotating machine, and is arranged on the rotating shaft 1 of the rotating machine and the casing 4 on the outer periphery of the rotating shaft 1 , including combined labyrinth seal group and axial flow compression self-sealing group.

[0022] The combined labyrinth seal set includes a plurality of side-by-side circumferential metal hard seal teeth 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com