Judgment method for regeneration time of exhaust particulate filter of diesel engine

A particle trap and determination method technology, which is applied in the direction of electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, exhaust device, etc. Issues such as risk of thermal damage to large DPFs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are used to illustrate and explain the present invention, but not to limit the present invention.

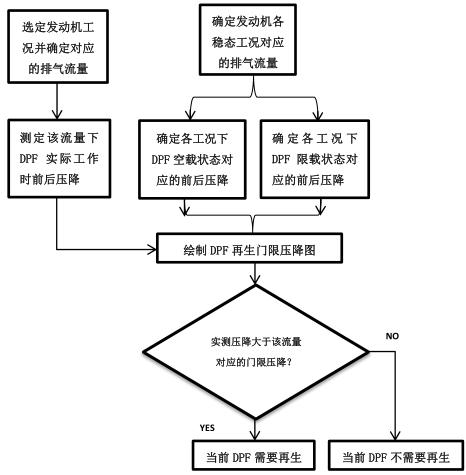

[0021] The method for judging the regeneration time of the diesel engine exhaust particulate filter of the present invention comprises the following steps:

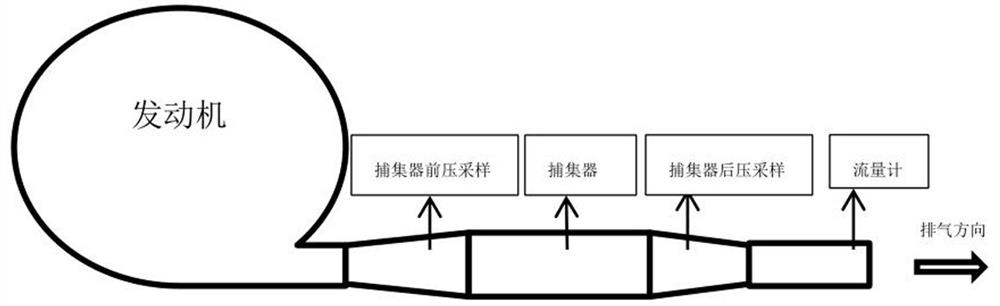

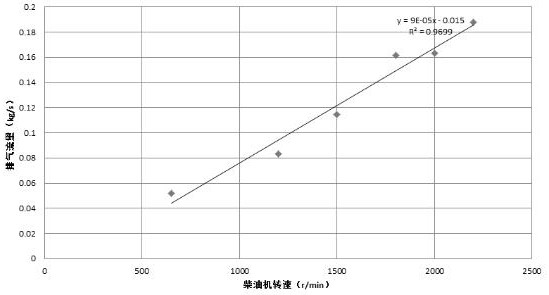

[0022] 1) Select the steady-state working conditions of the diesel engine series and measure the exhaust gas flow through the exhaust particulate filter of the diesel engine under each working condition;

[0023] 2) Determine the front-to-back pressure drop corresponding to the exhaust flow of the diesel engine exhaust particulate filter under the no-load and limited-load states under different working conditions;

[0024] 3) Draw the DPF regeneration threshold pressure drop diagram according to the obtained pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com