Semi-ellipsoidal pot box vibration absorber filled with iron tailing sand and ceramsite mixed particles and preparation method of semi-ellipsoidal pot box vibration absorber

A technology of tailings sand and semi-ellipsoid, applied in chemical instruments and methods, friction shock absorbers, other chemical processes, etc. Vibration, disturbance and insufficient contact times, etc., to achieve the effects of excellent comprehensive performance, simple structure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

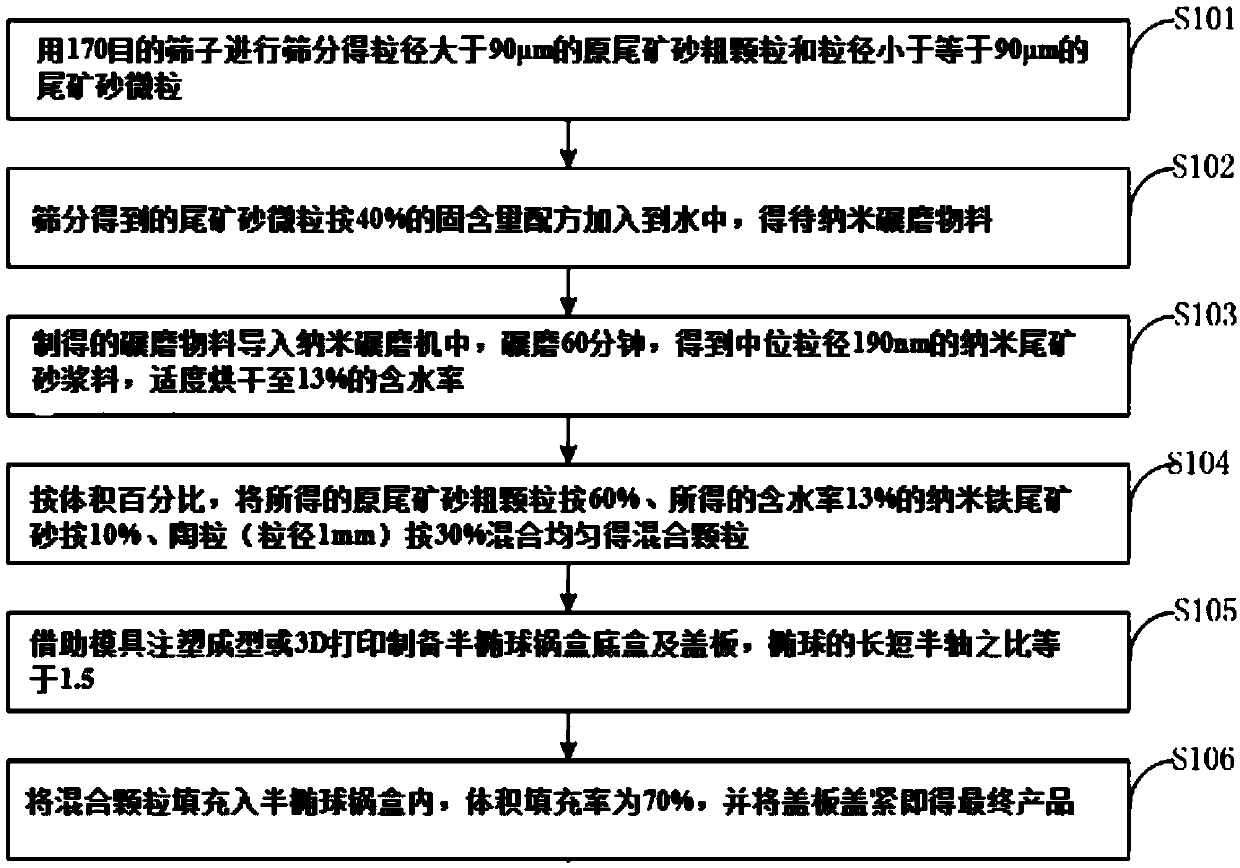

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings

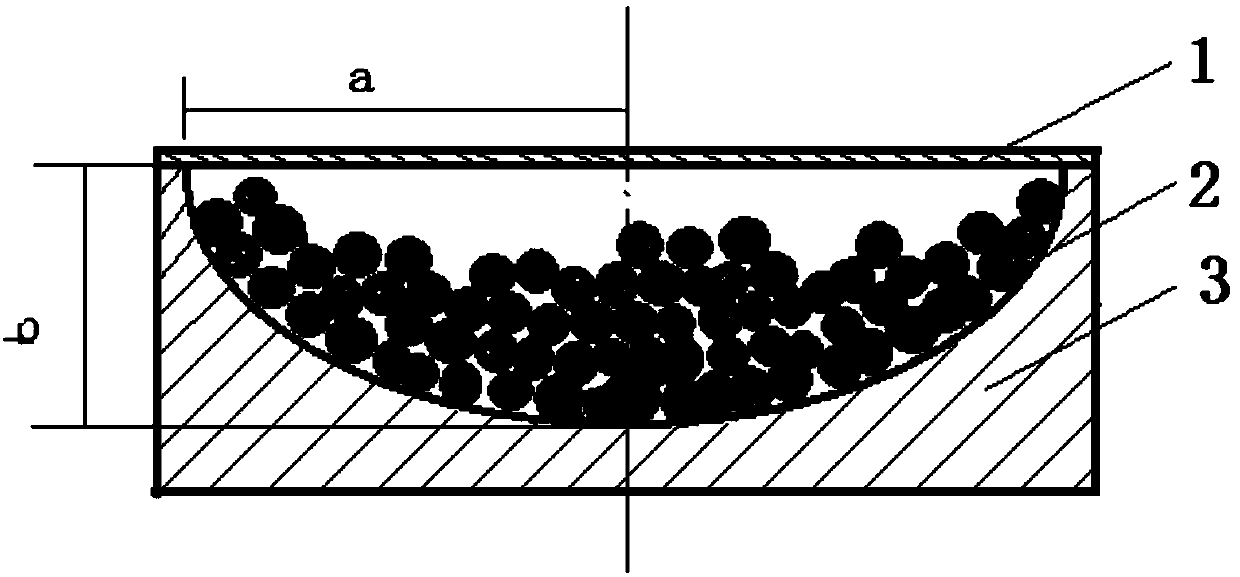

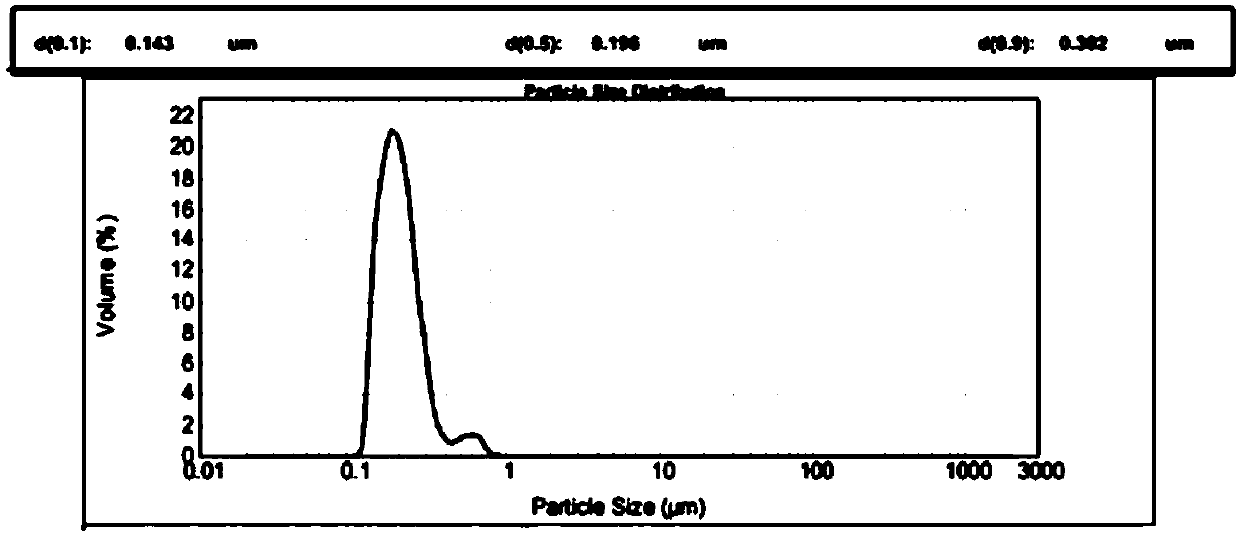

[0027] The embodiment of the present invention provides a semi-elliptical pot box shock absorber filled with mixed particles of iron tailings sand and ceramsite. Composed of loosely packed mixed granules 2 in an ellipsoidal pot box, see attached figure 2 , the mixed particle 2 accounts for 70% of the volume in the pot cavity, and the mixed particle 2 is composed of the following components by volume percentage: 60% of the original tailings sand particles, 30% of the ceramsite and 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com