Shear-resistant spherical steel bearing

A type of steel and support technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of complex production, potential safety hazards, vertical tensile stress damage of supports, etc., and achieves easy material and processing, simple structure, and reduced damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification, but the protection scope of the present invention is not limited thereby.

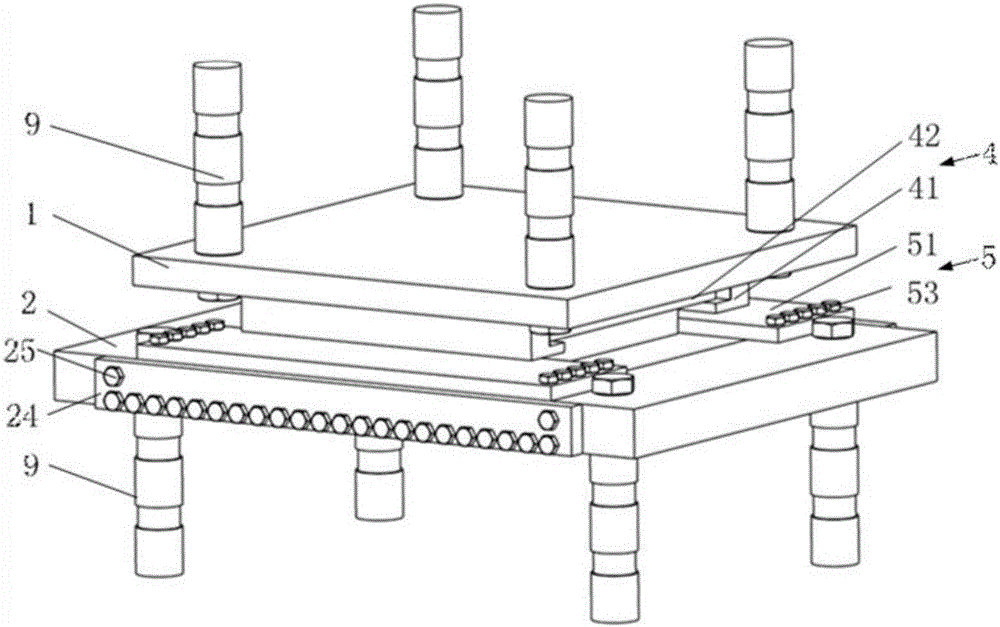

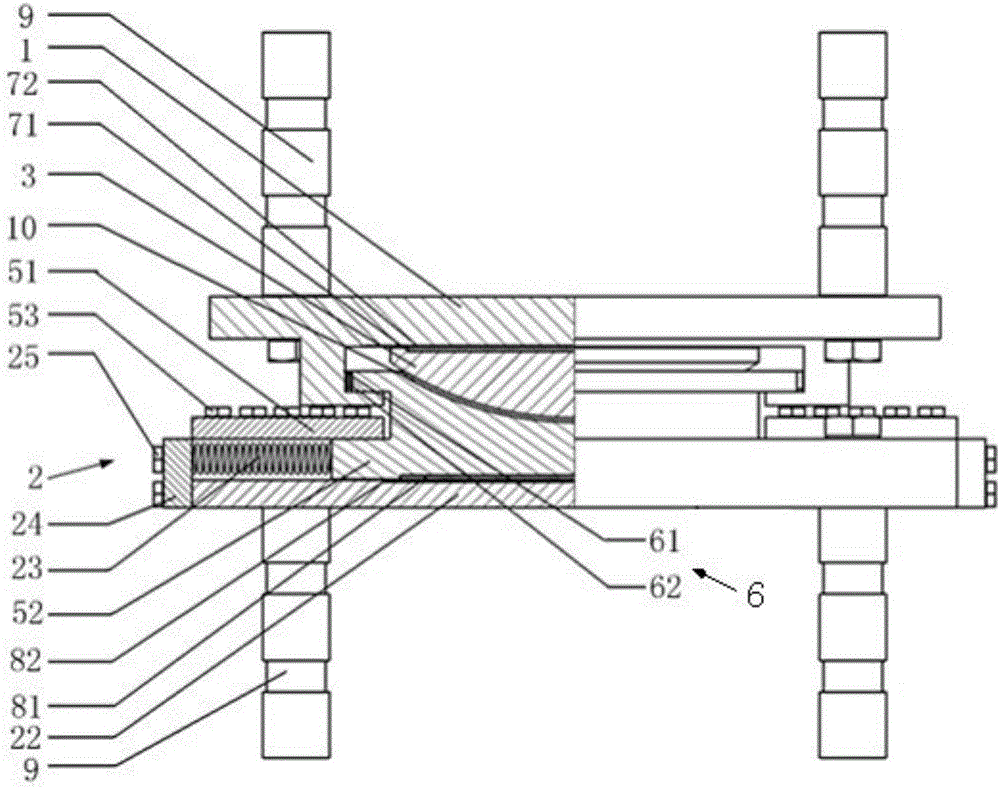

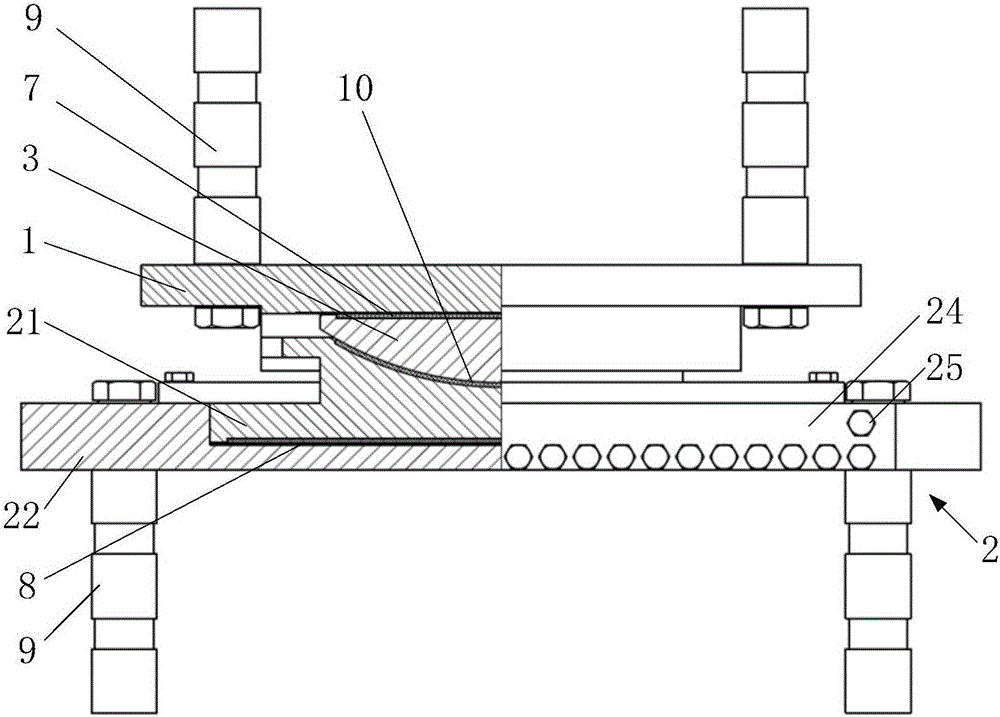

[0028] Figure 1 to Figure 4 This embodiment of the anti-shear spherical steel support is shown. The anti-shear spherical steel support of the present invention is suitable for a large-span superstructure with large horizontal shear rigidity. In this embodiment, the shear-resistant spherical steel support includes an upper seat plate assembly 1, a lower seat plate assembly 2 and a spherical crown lining plate 3. The upper seat plate assembly 1 is fixed on the bridge girder bottom plate through an anchor steel rod 9. The lower seat plate assembly 2Fixed on the pier by anchoring steel rods 9, the spherical crown lining 3 is slidably arranged between the upper seat plate assembly 1 and the lower seat plate assembly 2, and the spherical crown lining plate 3 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com