Pad damping and vibration reduction mute floor

A damping and padding technology, which is applied in the field of vibration-absorbing floors and subway car vibration-damping floors, can solve the problems of low padding, achieve the effects of improving the strength too low, improving the damping effect, and improving the damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

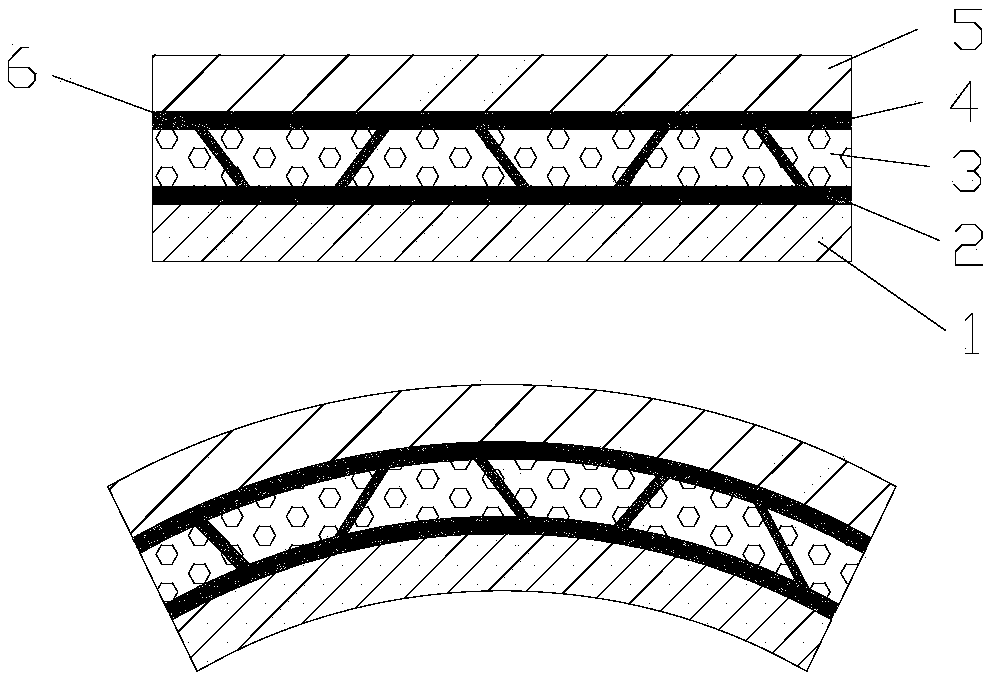

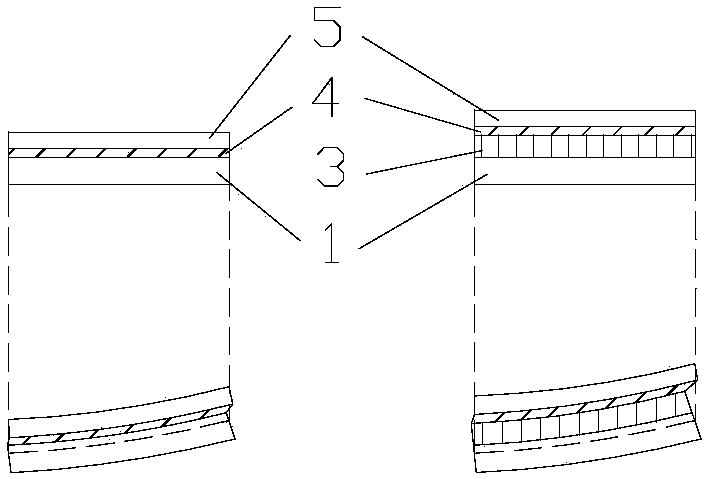

[0034] The raised damping, vibration-reducing and silent floor includes the compartment substrate, the viscoelastic damping layer I, the padding layer, the viscoelastic damping layer II, and the constraining layer arranged in sequence. The compartment substrate, the viscoelastic damping layer I and the cushion layer form the constrained damping structure I; the cushion layer, the viscoelastic damping layer II and the constrained layer constitute the constrained damping structure II. The thickness of the viscoelastic damping layer I, the viscoelastic damping layer II and the viscoelastic damping layer III are all 1 mm, the thickness of the cushion layer is 24 mm, and the thickness of the constraining layer is 2 mm. The cushioning layer is composed of a plurality of closely arranged trapezoidal blocks, and the adjacent trapezoidal blocks are bonded with a viscoelastic damping layer III. The trapezoidal block is an isosceles trapezoidal block, the height of the isosceles trapezoi...

Embodiment 2

[0043] The difference from Example 1 is that the height of the damping and vibration reduction mute floor, the thickness of the viscoelastic damping layer I, the viscoelastic damping layer II and the viscoelastic damping layer III are all 1.5mm, and the thickness of the cushioning layer is 12mm , the thickness of the constrained layer is 3mm. The trapezoidal block is an isosceles trapezoidal block, the height of the isosceles trapezoidal block is the thickness of the cushion layer, the length of the upper side is 140mm, and the length of the lower side is 170mm. The constrained layer 4 is a light aluminum alloy material with a density of 2.70-2.85g / cm 3 .

[0044] The preparation of the carbon nanotube modified polyurethane foam, in the step (3), react the B component mixed with the hydroxylated carbon nanotube and the A component isocyanate at a temperature of 80°C and a pressure of 15MPa , the carbon nanotube modified polyurethane foam can be obtained. The interval betwee...

Embodiment 3

[0046] The difference from Example 1 is that the damping and noise-absorbing floor is raised, the thickness of the viscoelastic damping layer I, the viscoelastic damping layer II and the viscoelastic damping layer III are all 0.5mm, and the thickness of the cushioning layer is 18mm , the thickness of the constrained layer is 4mm. The trapezoidal block is an isosceles trapezoidal block, the height of the isosceles trapezoidal block is the thickness of the cushion layer, the length of the upper side is 70mm, and the length of the lower side is 100mm. The constrained layer 4 is a light aluminum alloy material with a density of 2.70-2.85g / cm 3 .

[0047] In the preparation of the carbon nanotube-modified polyurethane foam, step (3) reacts the B component mixed with the hydroxylated carbon nanotubes and the A component isocyanate at a temperature of 60°C and a pressure of 16MPa to obtain Carbon nanotube modified polyurethane foam. The interval between the adjacent hollow grooves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com