Natural gas pipeline capable of branching

A technology for natural gas pipelines and branches, applied in the direction of pipeline protection, heat insulation protection of pipelines, pipes, etc., can solve problems such as natural gas leakage, inconvenience of life, and influence on normal transportation of natural gas pipelines, so as to reduce economic losses and ensure normal life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

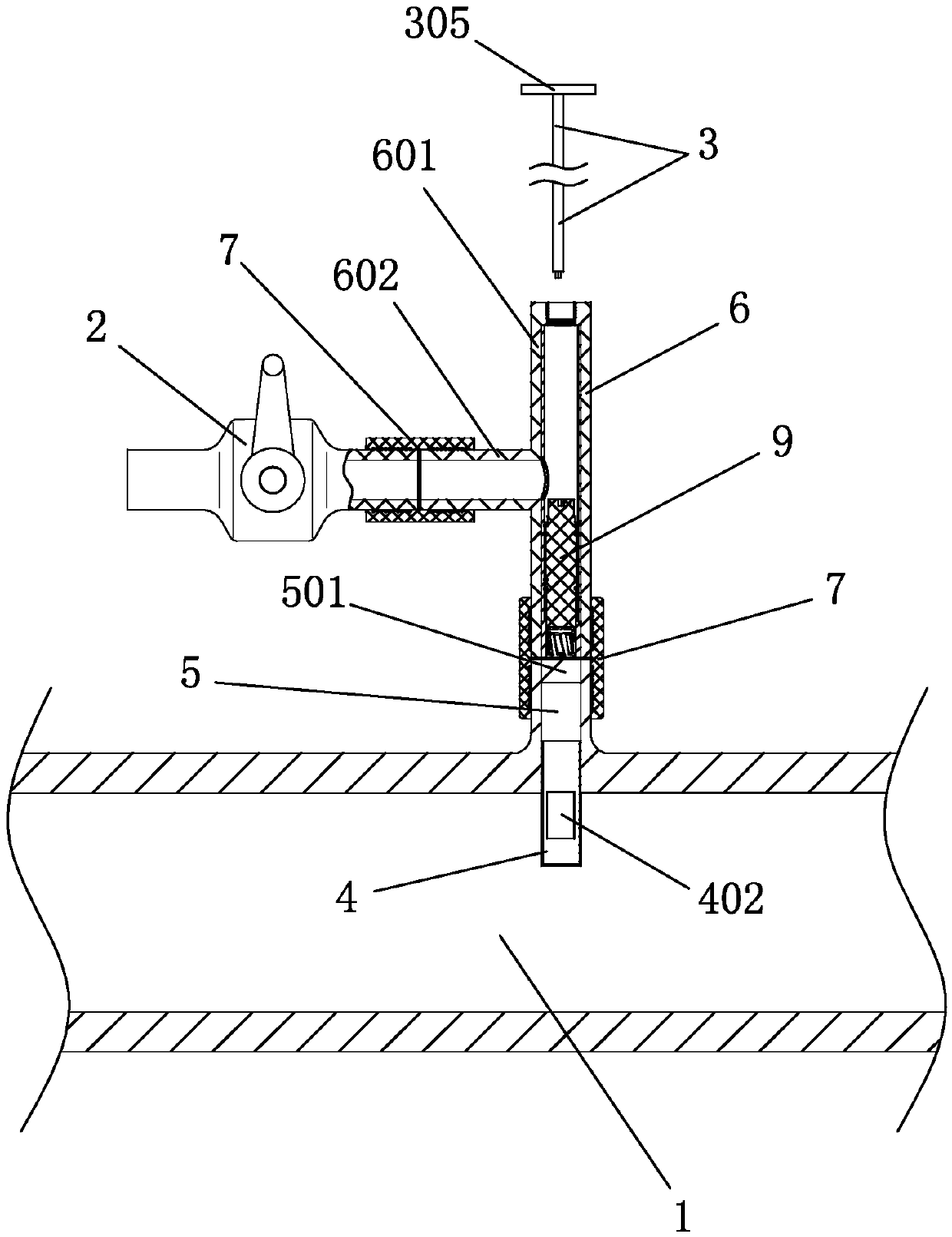

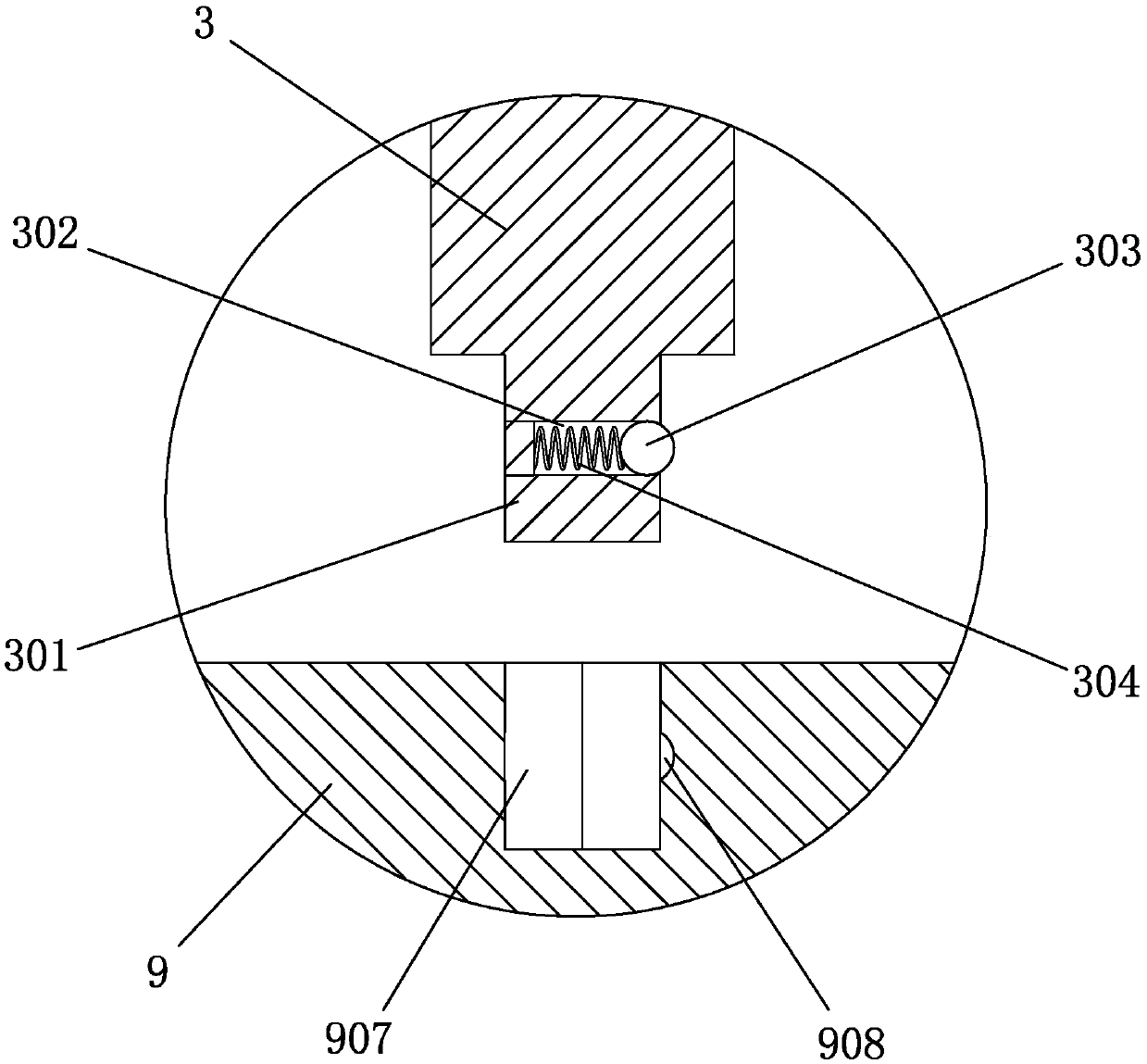

[0036] see Figure 1 to Figure 9 , a branchable natural gas pipeline, at least including a pipe body 1, a release mechanism is provided on the pipe body 1, and the release mechanism at least includes a release pipe 5, a gas outlet pipe 6, a release valve 2 and a detachable The drive rod 3.

[0037] The release pipe 5 is upright on the outer wall of the pipe body 1 and integrally formed with the pipe body 1, and the release pipe 5 communicates with the pipe hole of the pipe body 1; a sealing partition for sealing the pipe hole of the discharge pipe 5 is arranged horizontally in the release pipe 5 501, the sealing partition 501 is integrally formed with the inner wall of the release pipe 5 .

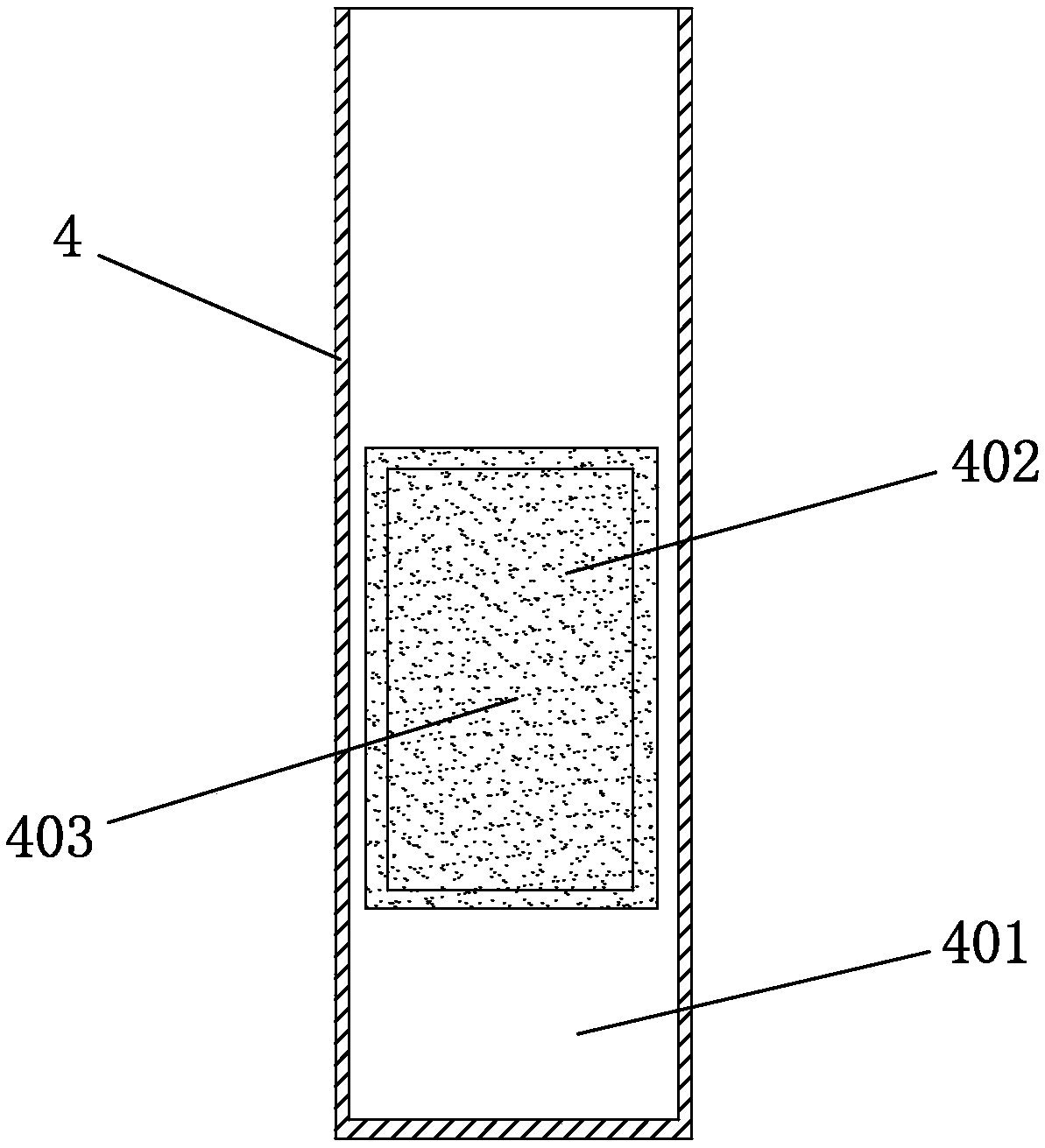

[0038] An ash collection tube 4 is located at the opening of the lower end of the release pipe 5 inside the pipe body 1. The bottom of the inner cavity o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap