Purification type melting device for metal

A melting device and purification technology, applied in chemical instruments and methods, lighting and heating equipment, furnace types, etc., can solve the problems of high energy consumption, pollution, liquid metal and flue gas without forming a shunt structure, etc., to improve environmental protection. performance, the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

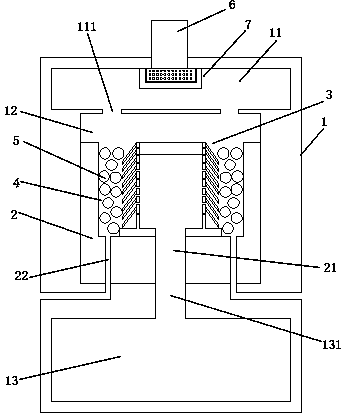

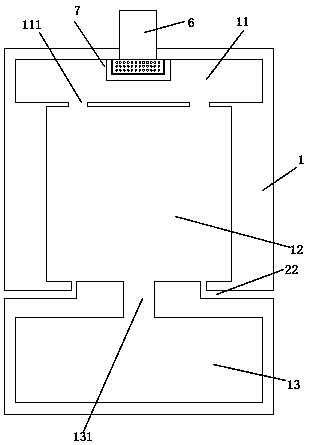

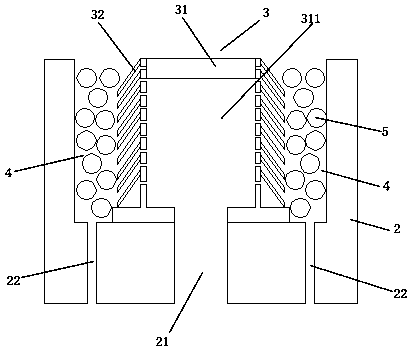

[0020] Such as Figures 1 to 5 As shown, a purification type metal melting device includes a furnace body 1, a carrier column 2, a gas guiding and flow blocking mechanism 3, an exhaust pipe 6, and an adsorption mechanism 7; the lower end of the furnace body 1 is provided with a heating ventilation chamber 13; the middle part of the furnace body 1 is provided with an installation groove 12; the upper end of the furnace body 1 is provided with an exhaust chamber 11; the heating ventilation chamber 13 can be a furnace. The upper end of the heating ventilation cavity 13 communicates with the installation groove 12 through the connecting channel 131; the upper end of the installation groove 12 communicates with the exhaust chamber 11 through the annular ventilation groove 111; Exhaust pipe 6; the cross-section of the carrier column 2 is a U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com