Fault diagnosis method for chiller

A chiller and fault diagnosis technology, which is applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve problems such as imbalance, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

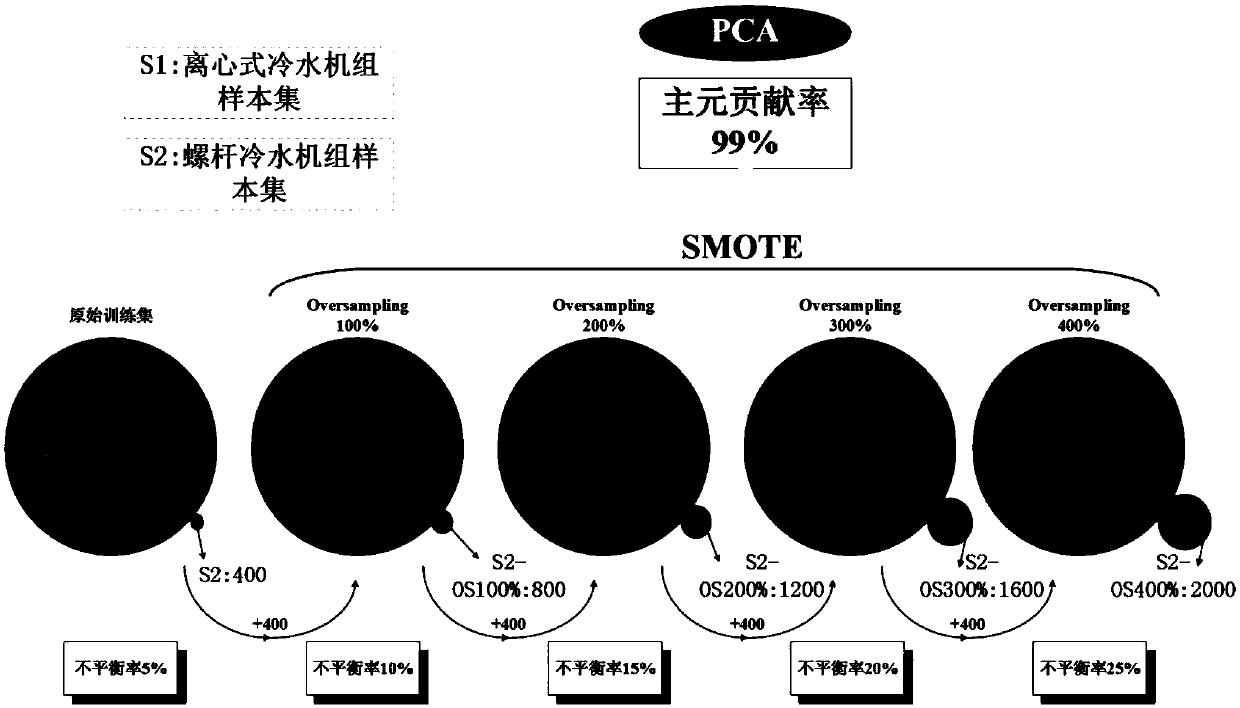

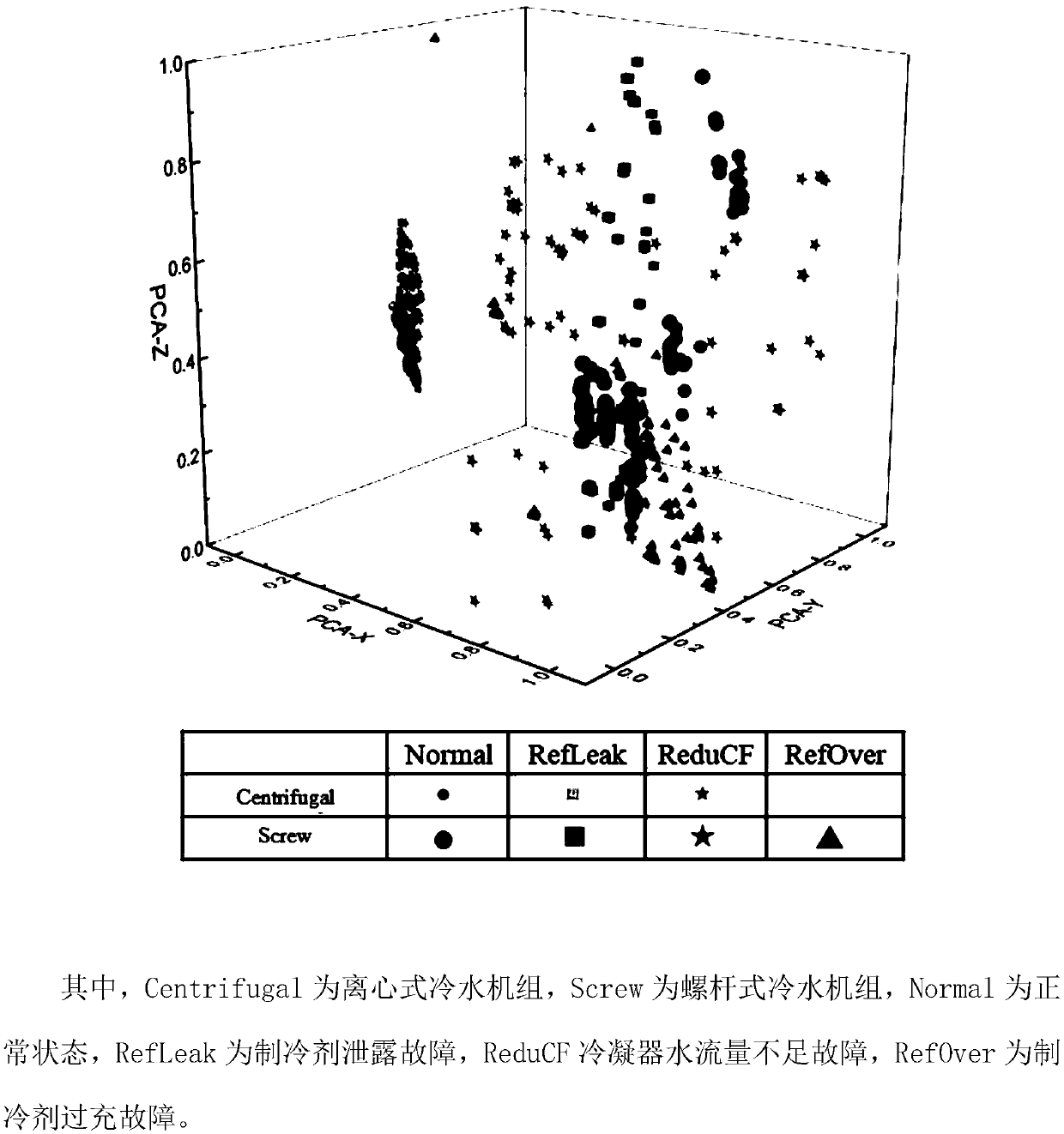

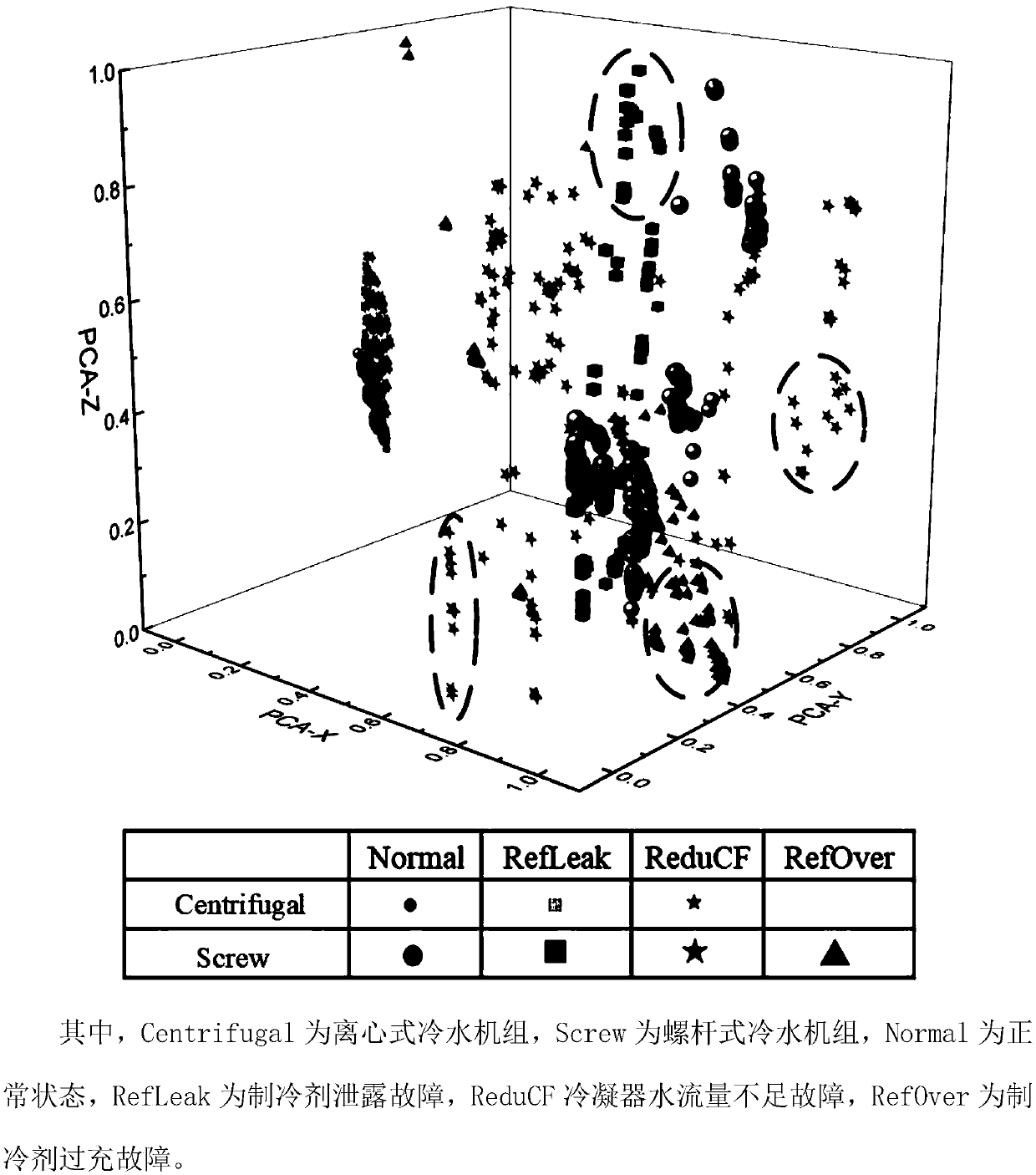

[0032] The invention adopts the synthetic minority class over-sampling technology, and provides a PCA-SMOTE-SVM algorithm-based chiller fault diagnosis method for fault diagnosis of different types of chiller sets.

[0033] Carry out the fault simulation experiment on the screw chiller and collect the fault simulation experiment data of the screw chiller. The fault simulation experiment data of the screw chiller includes normal data and fault simulation data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com