Condenser, and centrifugal chiller equipped with the same

a centrifugal chiller and condenser technology, which is applied in the direction of refrigeration components, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of deterioration in condensation efficiency and impair performance as a cold instrument, and achieve the effect of suppressing deterioration in condensation efficiency and effective air bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, embodiments of the present invention will be described with reference to the drawings.

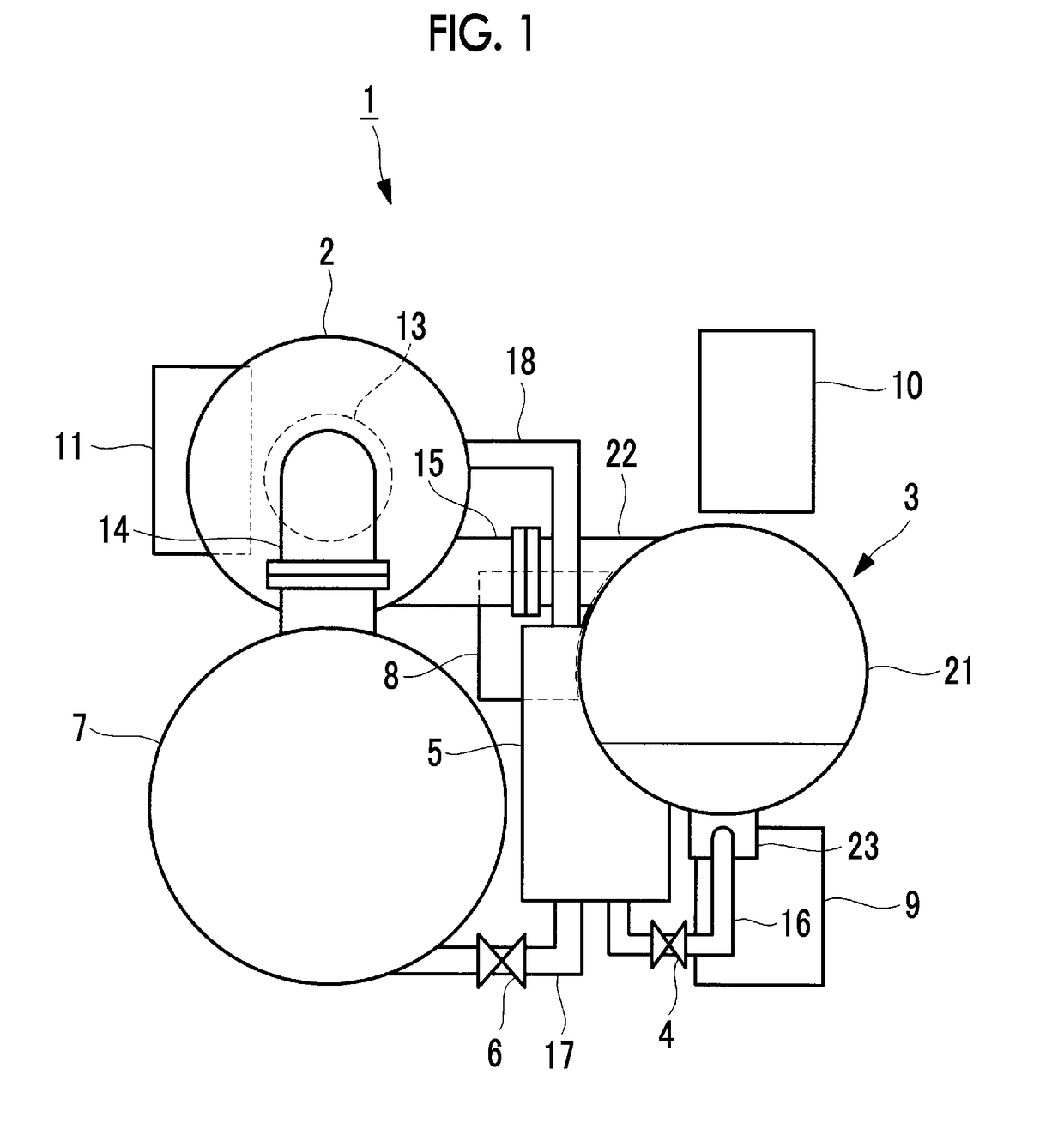

[0026]FIG. 1 is a general view of a centrifugal chiller according to an embodiment of the present invention. A centrifugal chiller 1 is configured in a unit state including a turbo compressor 2 that compresses a refrigerant, a condenser 3, a high-pressure expansion valve 4, an economizer 5, a low-pressure expansion valve 6, an evaporator 7, a lubricant tank 8, a circuit box 9, an inverter unit 10, an operation panel 11, and the like. The lubricant tank 8 is a tank storing lubricant supplied to bearings, a speed increaser, and the like of the turbo compressor 2.

[0027]The condenser 3 and the evaporator 7 are formed in cylindrical shell shapes having high pressure resistance and are disposed so as to be parallel and adjacent to each other in a state where their axis lines extend in a substantially horizontal direction. The condenser 3 is disposed at a position relatively higher than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com