A Frequency Response Measurement Method of Leakage Current and Touch Current

A technology of frequency response and contact current, applied in frequency measurement devices, frequency-to-amplitude conversion, measurement using digital measurement technology, etc., can solve problems such as limiting the high-frequency characteristics of operational amplifiers, and achieve enhanced capabilities, reliability, and safety Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for measuring the frequency response of leakage current and contact current, comprising the steps of:

[0027] Step 1. Perform hardware compensation for high-frequency analog signal attenuation through the frequency response measurement circuit:

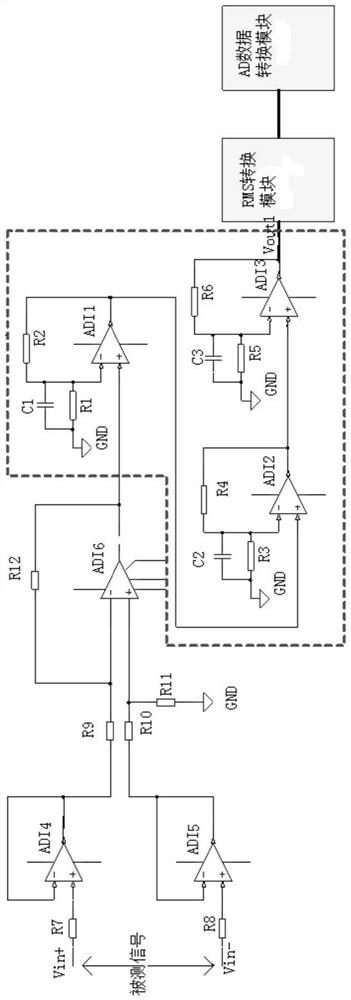

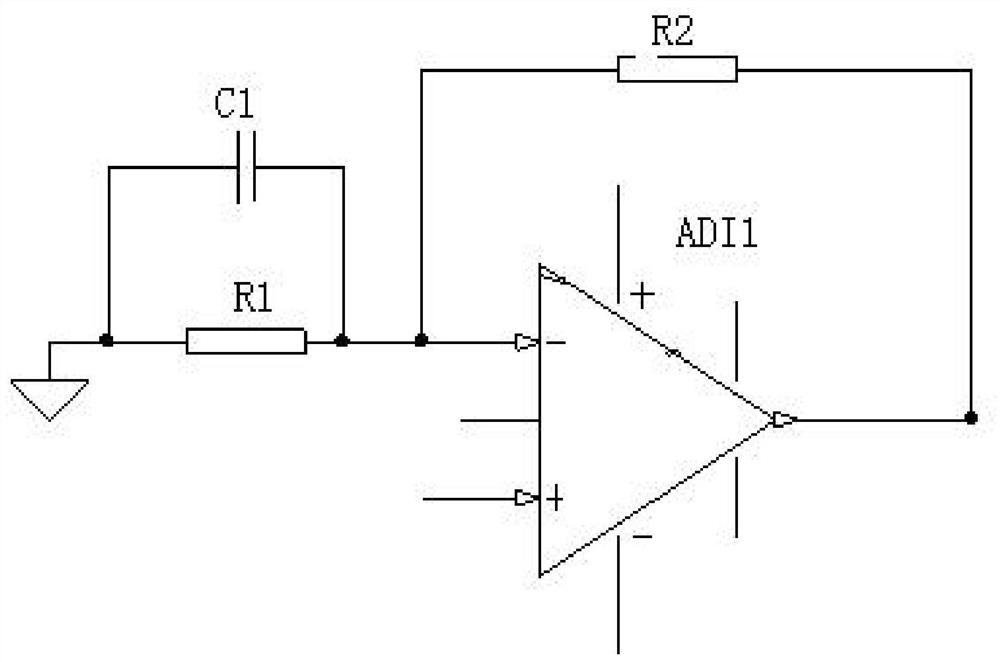

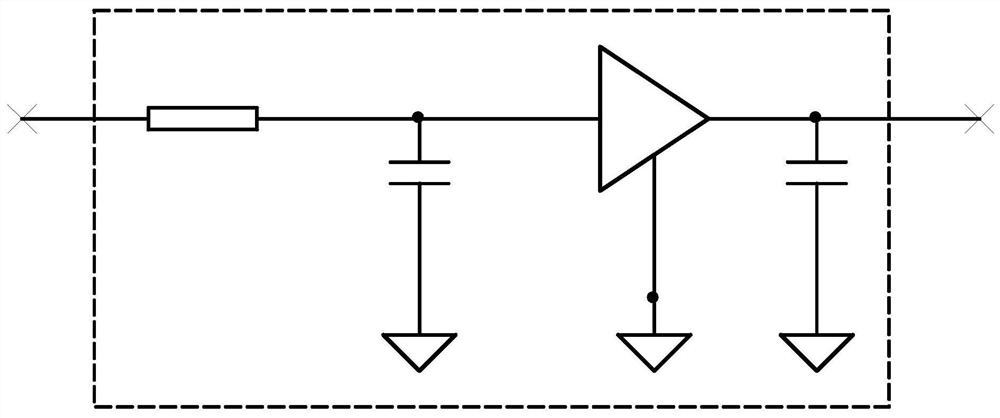

[0028] The frequency response measurement circuit is as figure 1 Shown: Vin+ of the signal under test is connected to the non-inverting input terminal of the fourth ADI operational amplifier chip (ADI4) through the seventh resistor (R7), and Vin- of the signal under test is connected to the fifth ADI op-amp chip through the eighth resistor (R8). The non-inverting input end of the put chip (ADI5), the inverting input end and the output end of the fourth ADI op-amp chip ADI4 are connected to the inverting input end of the sixth ADI op-amp chip ADI6 through the ninth resistor R9 and the sixth ADI op-amp The inverting input terminal of the chip ADI6 is connected to its output terminal through the twelfth resistor R12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com