SMT chip mounting method and system

A technology of placement and placement machine, which is applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of low work efficiency, error-prone, unsatisfactory work efficiency, etc., and achieves high efficiency and high placement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The following is a detailed description of the specific implementation of the present invention. It is necessary to point out that the following implementation is only used for further description of the present invention and cannot be understood as a limitation of the protection scope of the present invention. Some non-essential improvements and adjustments made still belong to the protection scope of the present invention.

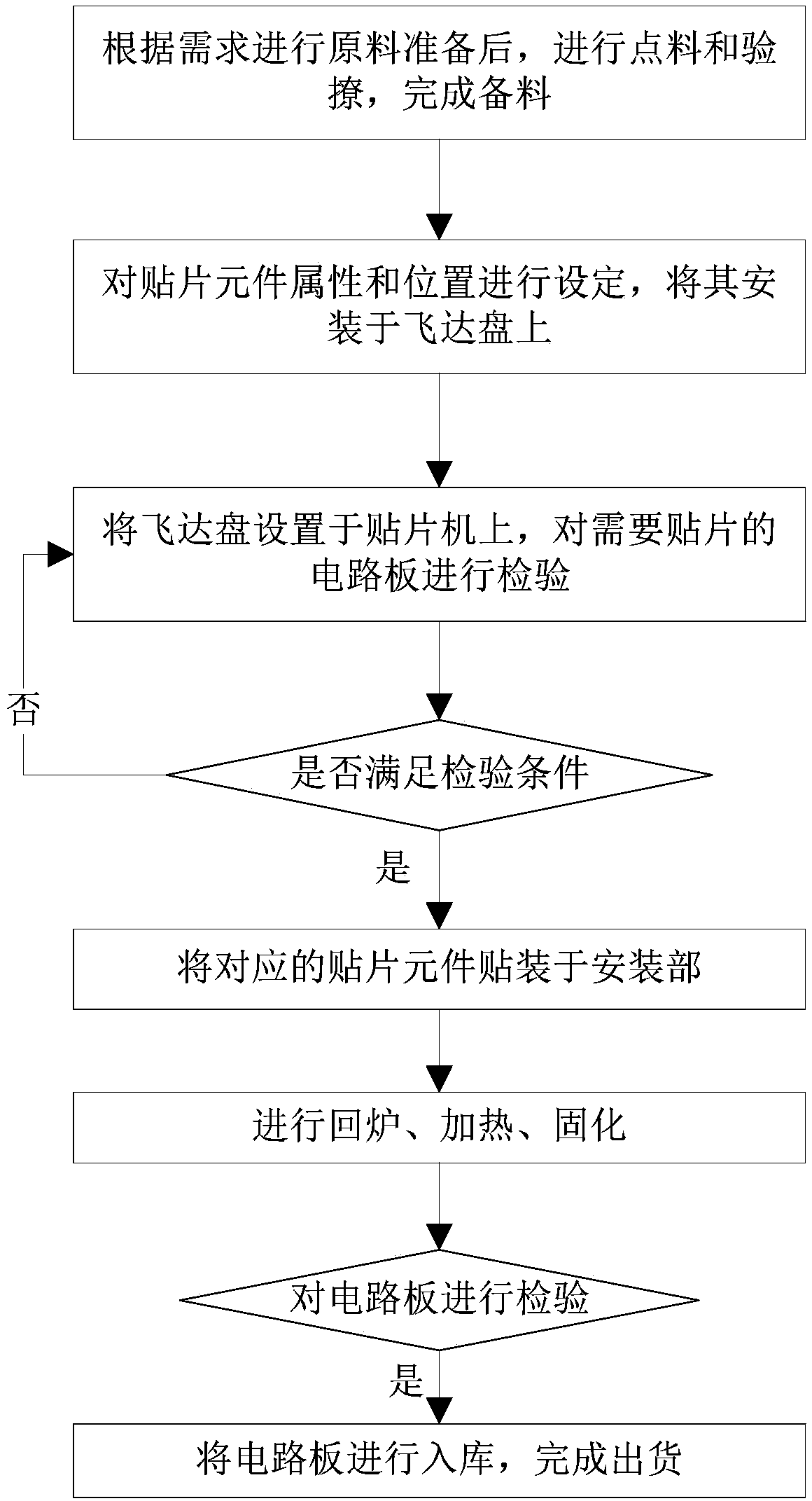

[0027] The present invention provides a SMT patch method, the specific process is as attached figure 1 Shown.

[0028] First of all, place an order according to the customer's requirements. The customer can send the raw materials or the processing plant will purchase the raw materials on their behalf. After the raw materials are purchased, they will be put into the warehouse, and then the materials will be counted and inspected according to the process requirements, and the materials will be prepared according to the actual requirements. After complet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap