Automatic dismounting device for PCB

A PCB board, automatic disassembly and assembly technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of PCB board damage, restricting the efficiency of disassembly and assembly, and reducing costs, to improve disassembly and assembly. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

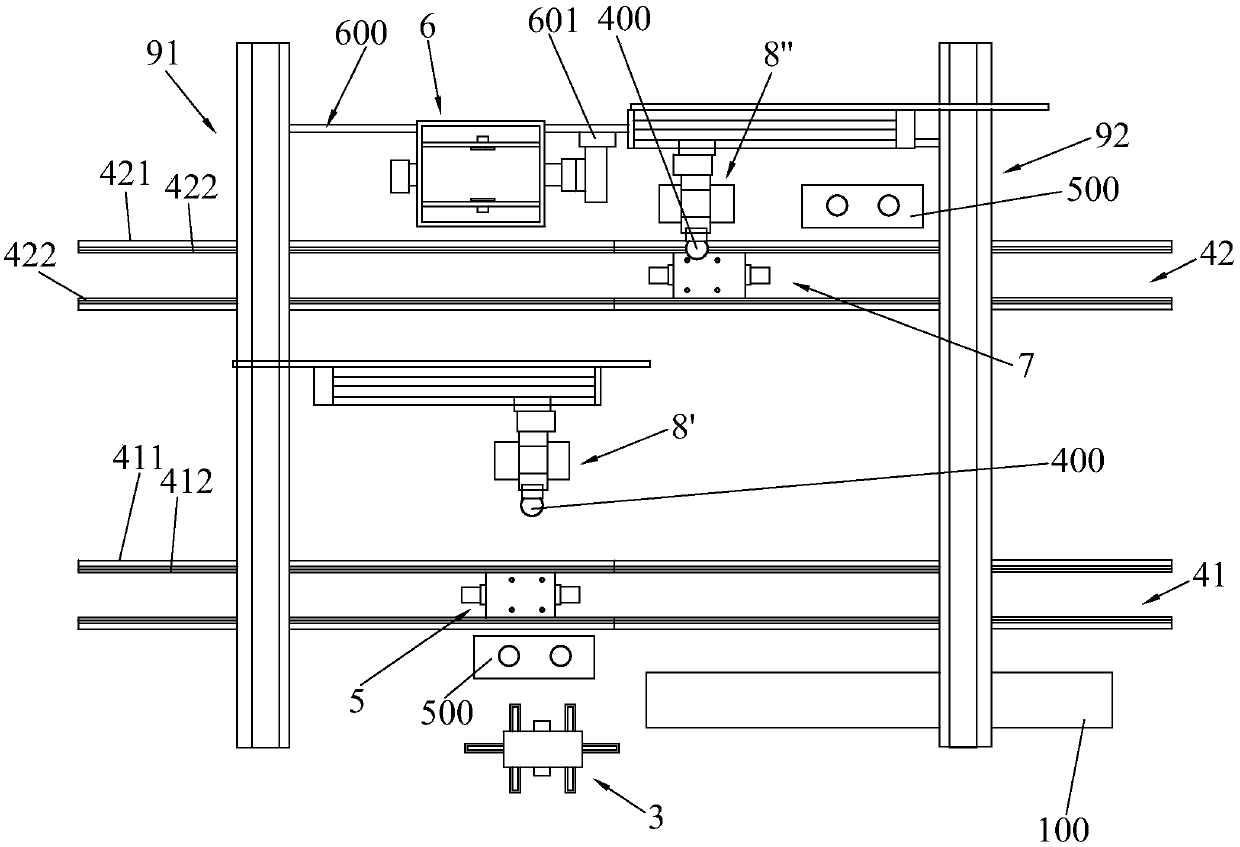

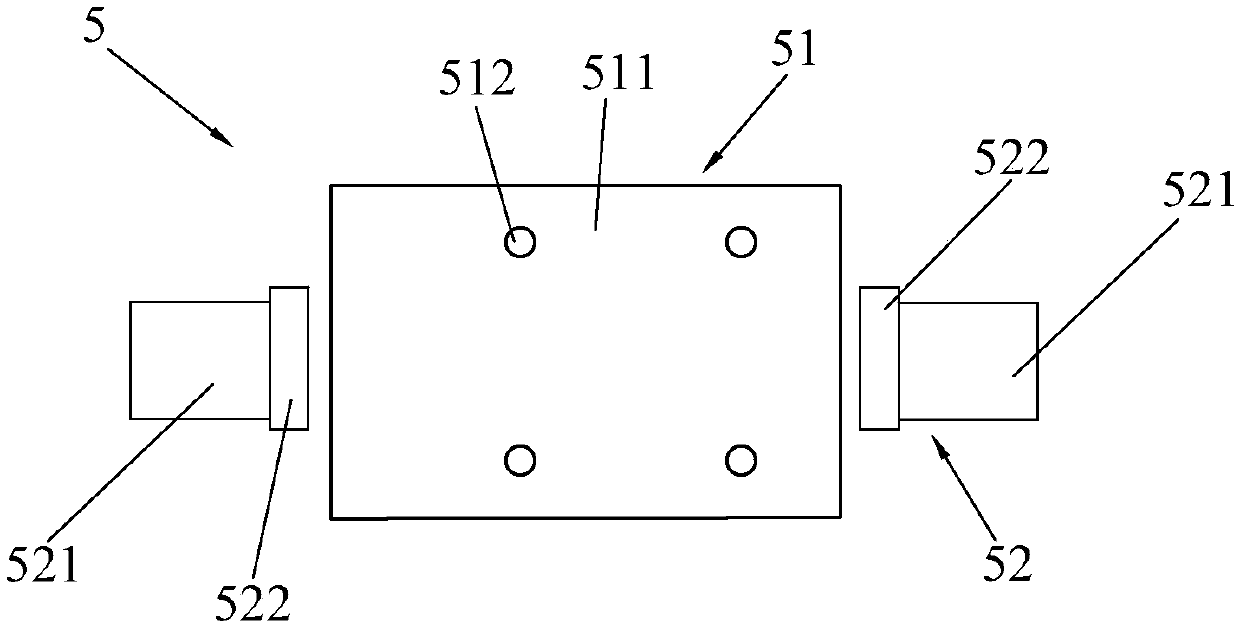

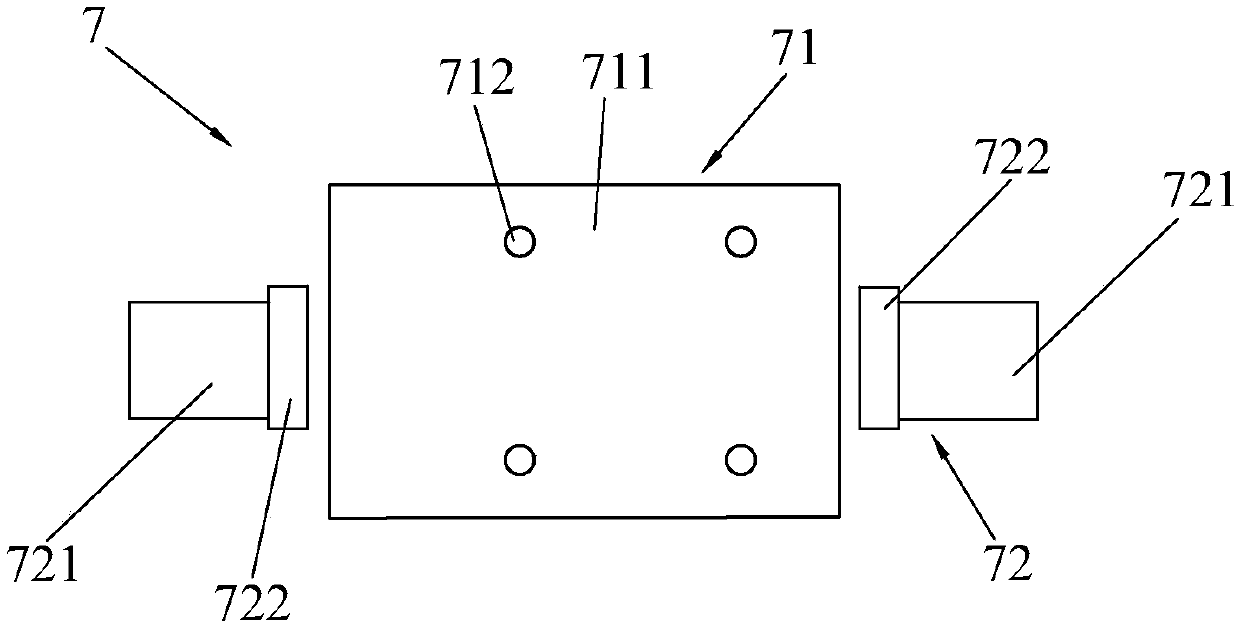

[0023] see Figure 1 to Figure 5 , the invention discloses a PCB board automatic disassembly equipment, comprising an empty board feeding device 3, a first conveying track 41, a first disassembling device 5, a flipping device 6, a second conveying track 42, a second disassembling device 7. The hand gripping device 8 and the manipulator device, the empty board feeding device 3 is used to provide an empty PCB board (not shown); the first conveying track 41 is used to transport the front clamp and can make the front clamp stop at The first disassembly position; the first disassembly device 5 is located at the first disassembly position, and is used to drive the front clamp to lock the empty PCB board transferred thereto or to drive the front clamp to unlock the semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com