Dynamic gas distribution and gas supply device

A gas supply device and dynamic gas distribution technology, which is applied in the direction of gas and gas/steam mixing, transportation and packaging, mixer accessories, etc., can solve the problems of low efficiency of gas distribution device, high production cost, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

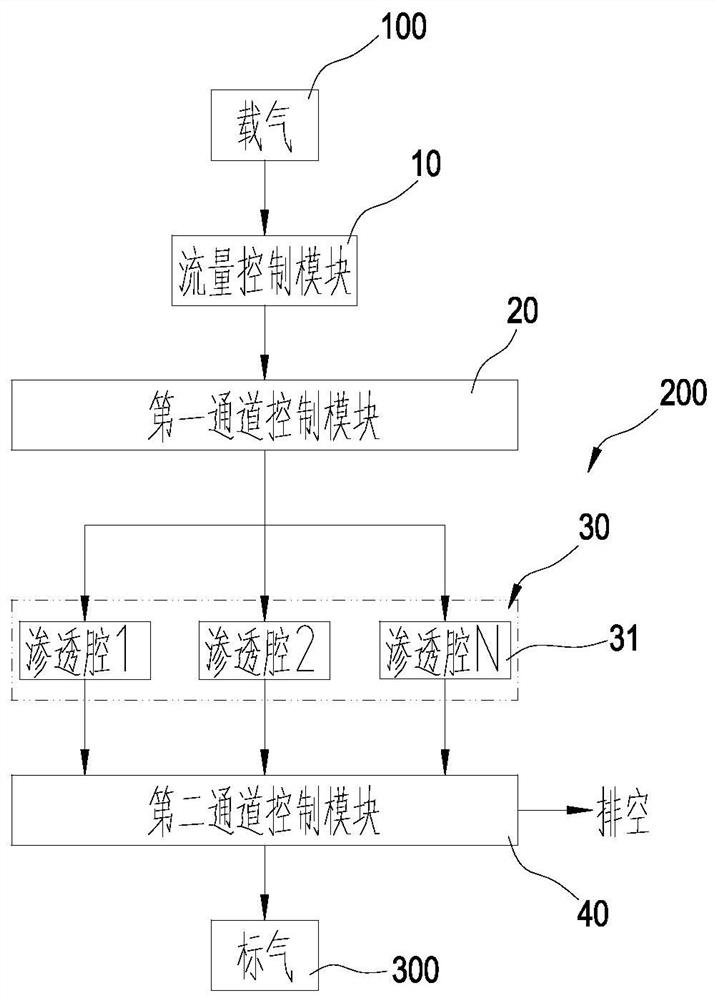

[0038] figure 1 It is a schematic diagram of the principle of a dynamic air distribution and air supply device according to an embodiment of the present invention, such as figure 1 As shown, the carrier gas 100 forms a continuous standard gas 300 under the action of the dynamic gas distribution and gas supply device 200, wherein the dynamic gas distribution and gas supply device 200 forms a parallel arrangement inside and can alternately switch the gas distribution aisle. Specifically, the gas distribution channel includes:

[0039] The flow control module 10 splits the carrier gas 100 into at least two groups of independent and parallel gas channels whose flow rates can be controlled individually;

[0040] The first channel control module 20 is used to regulate and control the connected air channels, and realize exchange-type communication control between the air channels;

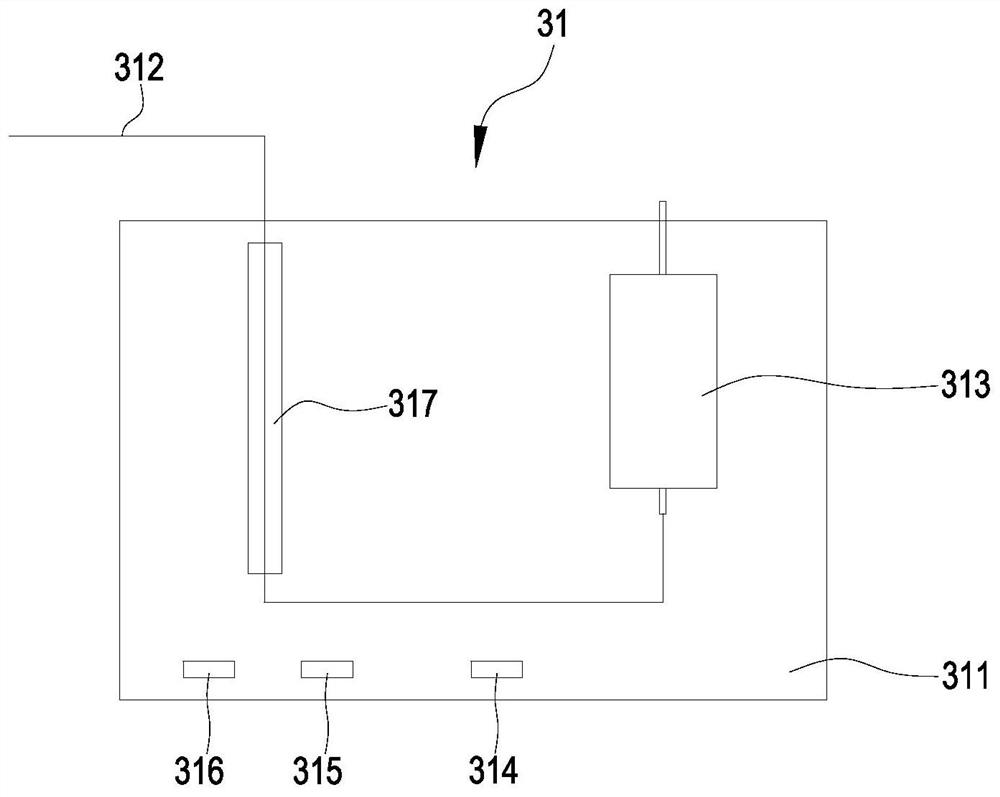

[0041] The permeation module 30 is assembled from at least two permeation chambers 31 that are inde...

Embodiment 2

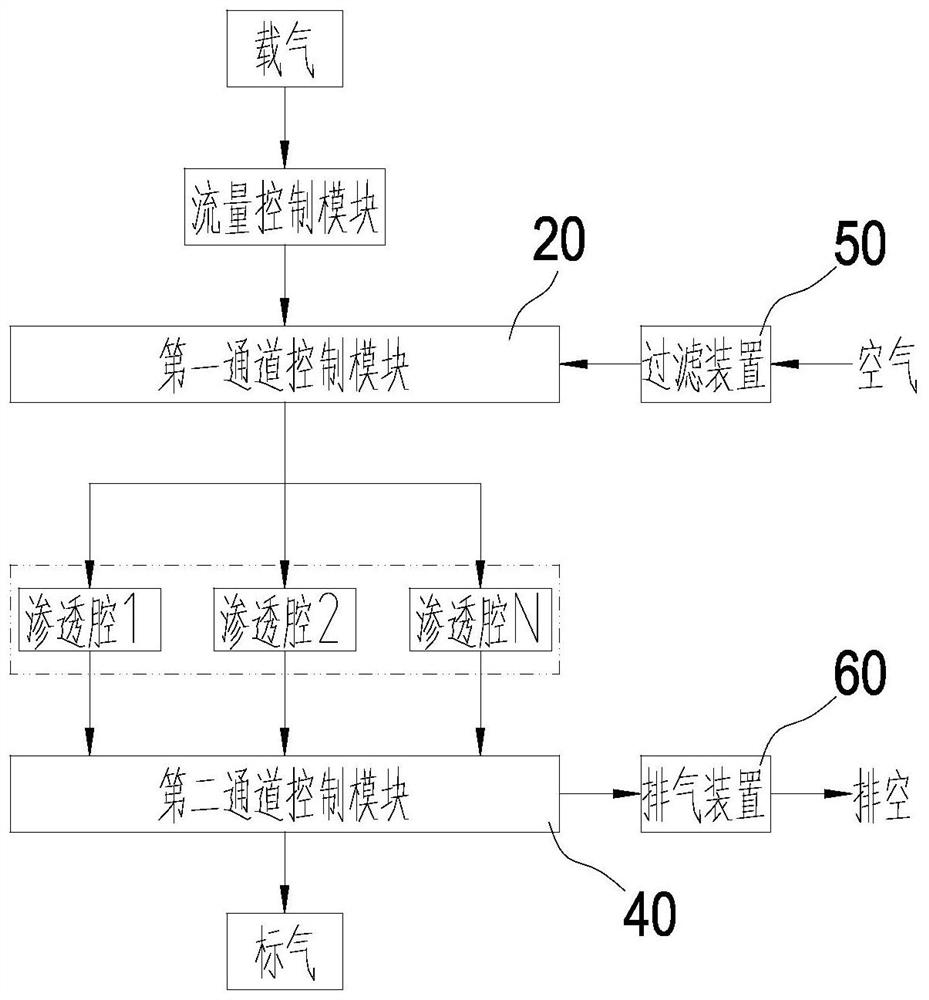

[0052] The difference between this embodiment and Embodiment 1 lies in the way and principle of entering into the osmosis module 30 to provide stable microenvironmental balance of the permeability inside the osmosis cavity. Such as image 3 As shown, in this embodiment, the dynamic gas distribution and gas supply device 200 also includes a balance unit arranged at the inlet end of the first channel control module 20 and the outlet end of the second channel control module 40 to dynamically balance the permeation cavity , the balance unit includes an exhaust device 60 switchably communicated with the second channel control module 40, and a ventilation branch arranged between the first channel control module 20 and the air communication end; wherein, the air flows through the first channel control After the module 20, under the allocation of the first channel control module 20, it enters the permeation cavity 31 of the permeation module 30 in parallel, and under the action of the...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 2 is that it can realize the gas distribution for the permeation module 30 (internal gas source), and it can also be compatible with the diluted gas distribution of the external standard gas (external gas source), and each permeation chamber can be independently The settings do not interfere with each other, the gas distribution and the balanced preheating do not conflict with each other, and the switching between multiple channels is realized without any connection; and the gas distribution of the internal source and the external source can achieve complementarity without interference. At the same time, using The external source gas distribution does not affect the balanced preheating of the internal source, and realizes free switching between internal and external sources, and zero connection between gas distribution switching; it greatly improves the adaptability, flexibility and compatibility of dynamic gas distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com