Oxygen bomb replacement protection device

A protection device and oxygen bomb technology, applied in the installation device of container structure, gas/liquid distribution and storage, ship construction details, etc., can solve the problems of human body harm, high oxygenation pressure, safety accidents, etc., to protect the human body, Prevents spillage and improves safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

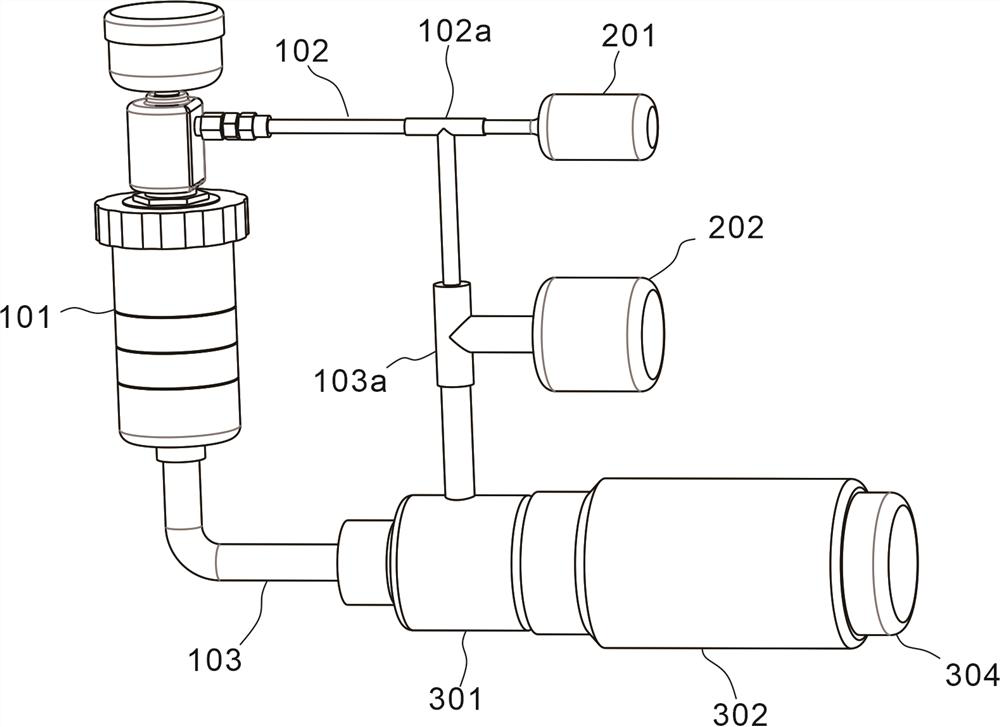

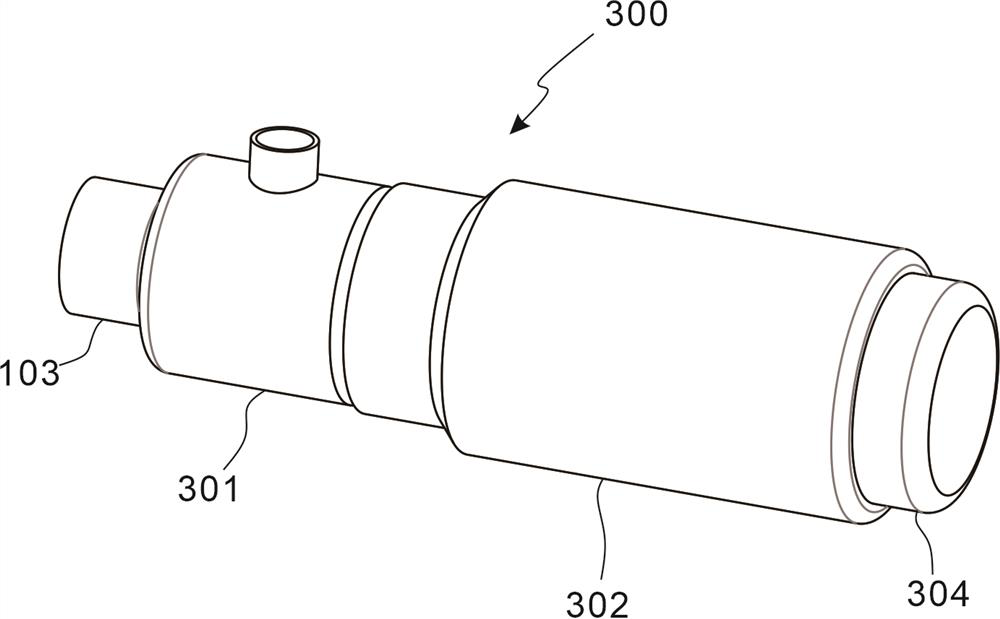

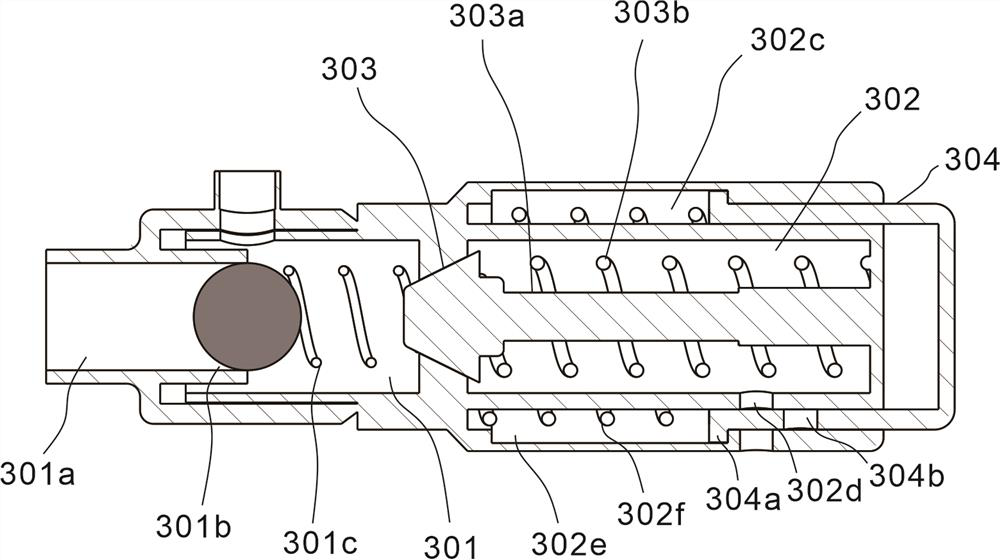

[0030] refer to Figure 1~2 For the first embodiment of the present invention, an oxygen bomb replacement protection device is provided, which includes an oxygen bomb assembly 100, including an oxygen bomb 101, an air inlet pipe 102 connected to the oxygen bomb 101, and an air outlet pipe 103; The air assembly 200 is connected with the oxygen bomb assembly 100, including the air inlet box 201 connected with the air inlet pipe 102, the liquid medium box 202 connected with the air inlet pipe 102; and the protection assembly 300, connected with the outlet pipe 102; The gas pipe 103 is connected, including a water storage area 301 , a pressure relief area 302 connected to the water storage area 301 , a valve core 303 arranged in the pressure relief area 302 , and a push rod 304 connected to the valve core 303 .

[0031] Among them, the oxygen bomb assembly 100 is an oxygen bomb experimental device, the ventilation assembly 200 inflates the inside of the oxygen bomb 101, dilutes th...

Embodiment 2

[0033] refer to Figure 2~4 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that: the air intake pipe 102 is provided with a first one-way valve 102a, and the air intake box 201 passes through the air intake pipe 102 delivers gas to the oxygen bomb 101, the liquid medium tank 202 is also connected to the protection assembly 300, and the liquid medium tank 202 delivers liquid medium to the water storage area 301; the liquid medium tank 202 is connected to the water storage area A second one-way valve 103a is provided on the connecting pipeline of the zone 301 . The liquid medium box 202 keeps the inside of the water storage area 301 full of liquid medium, and the liquid medium box 202 stores a liquid medium, and the water storage area 301 absorbs the harmful gas produced by the combustion of the oxygen bomb 101; The air inlet box 201 delivers inert gas.

[0034] The water storage area 301 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com