Concentrated acid mist purifying device

A purification device and concentrated acid technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve the problems of short time, small contact area, and low purification efficiency, so as to reduce acid gas concentration and prolong Treatment time, effect of improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

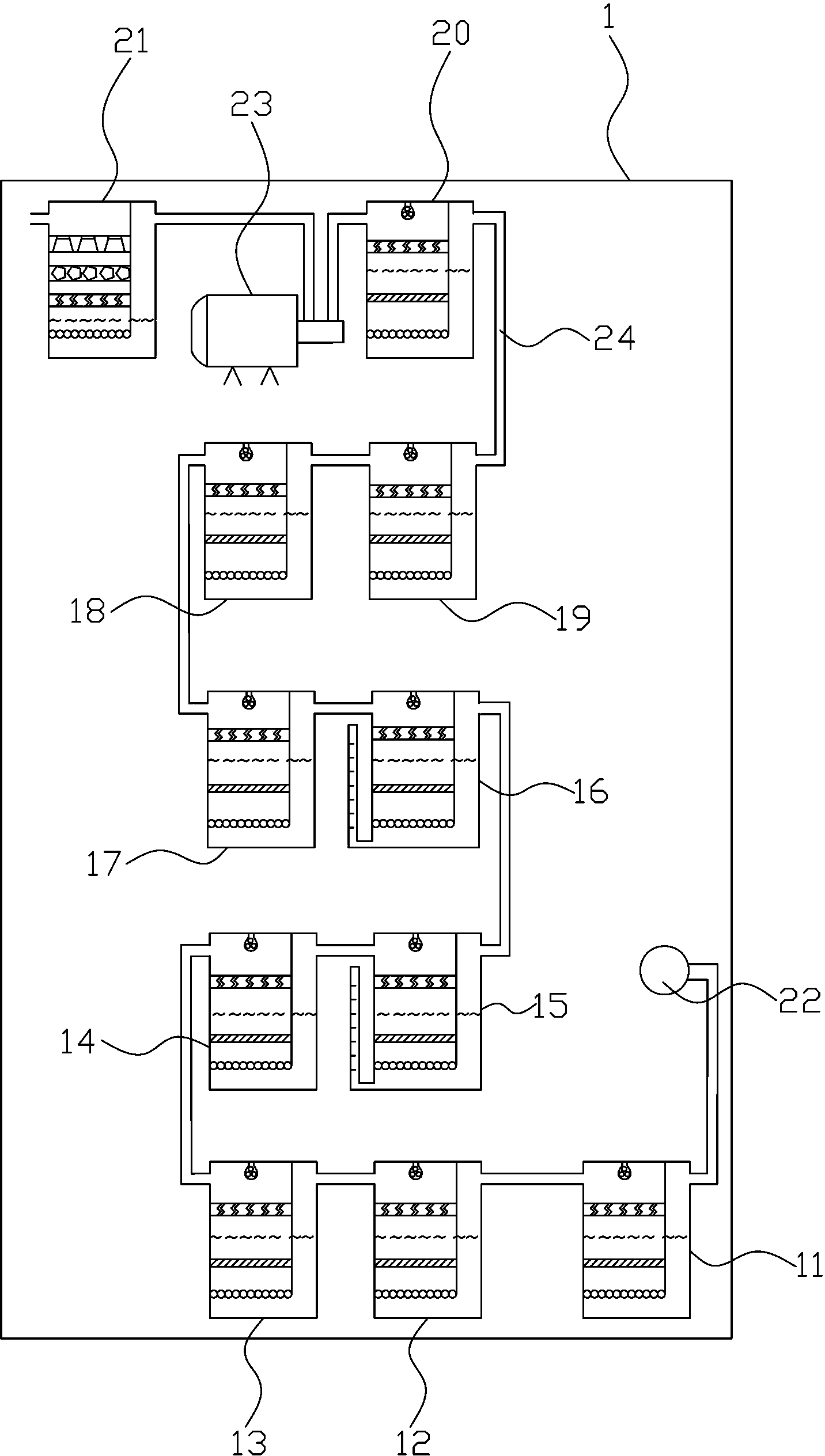

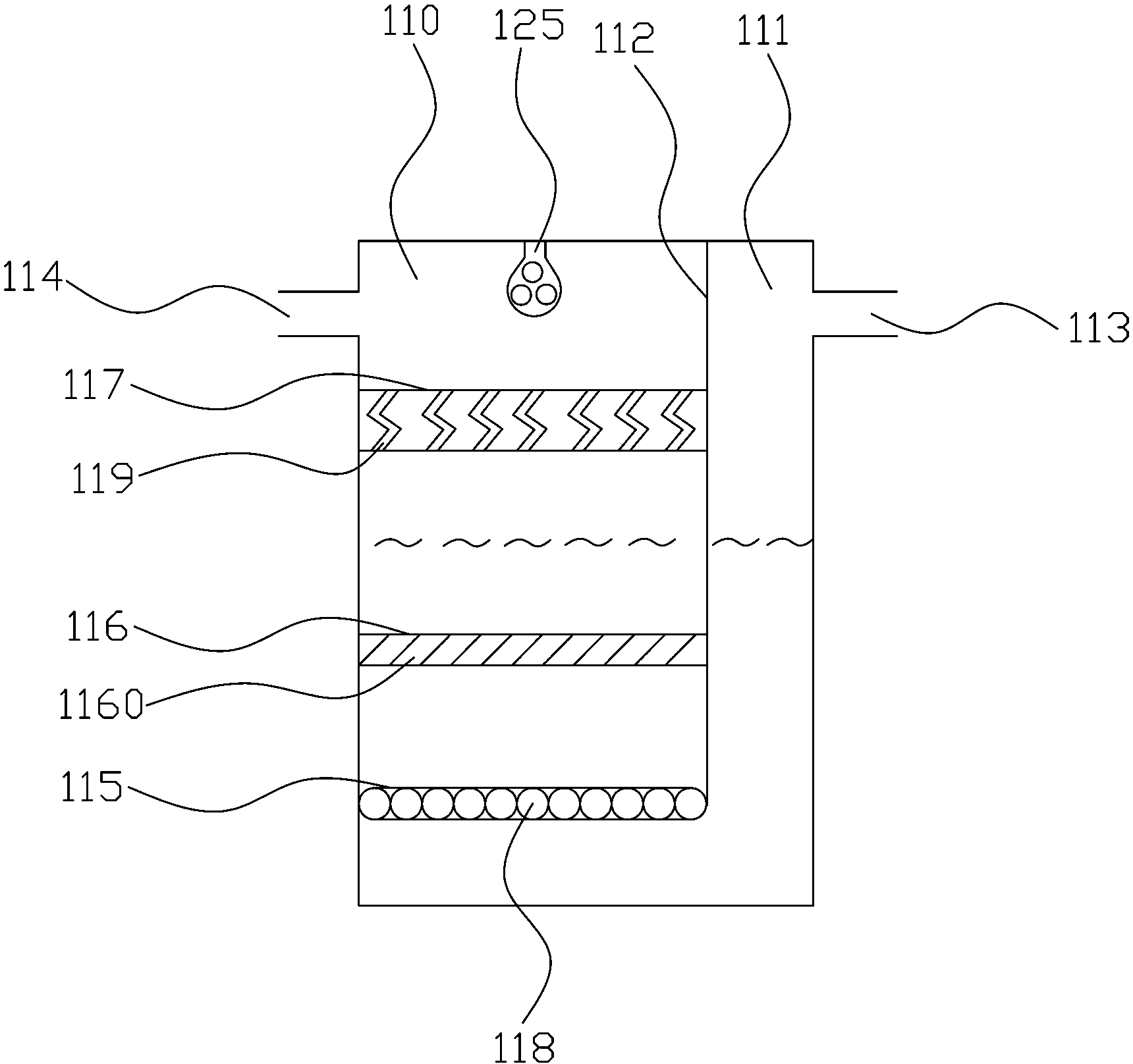

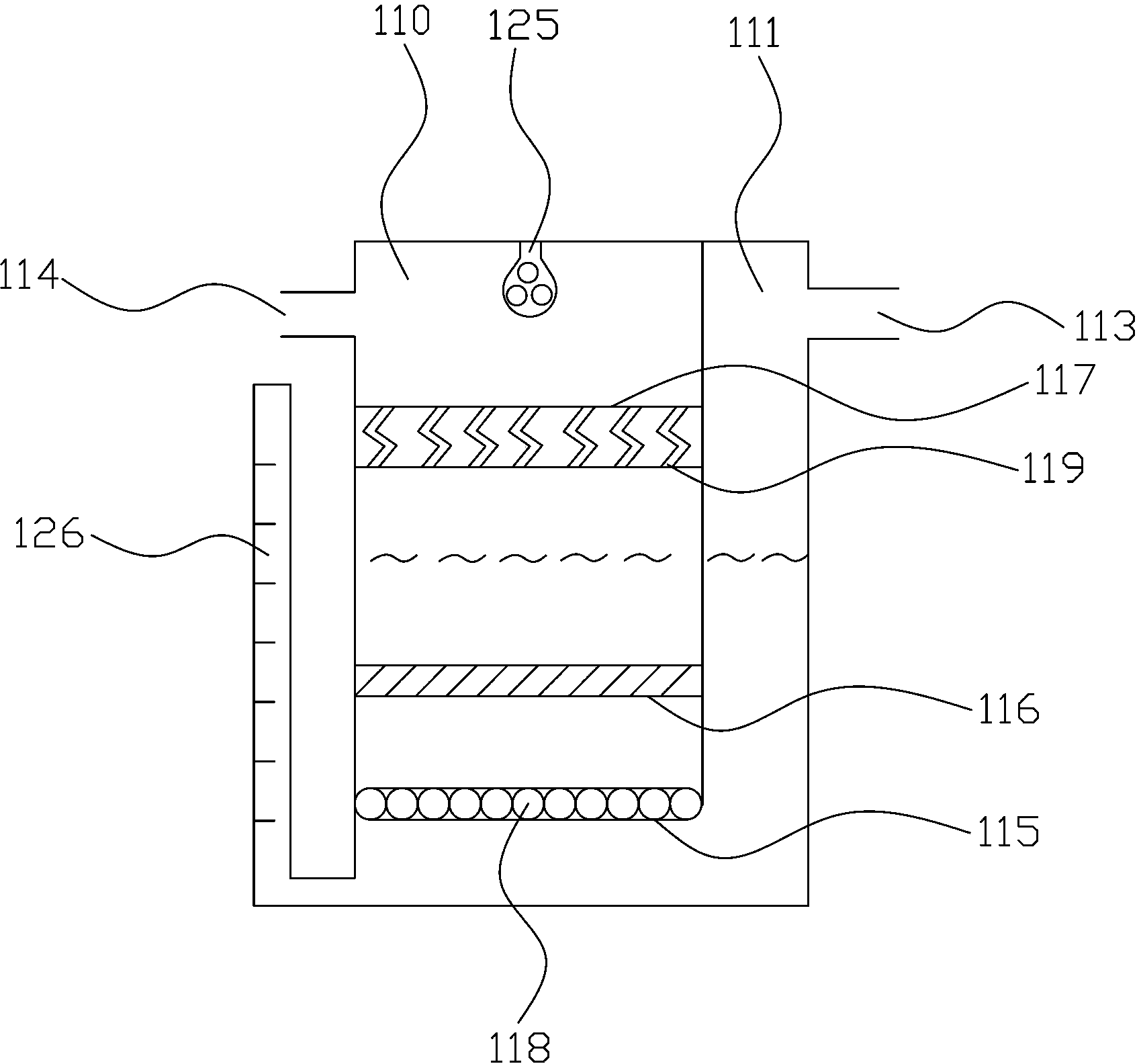

[0023] Such as Figure 1~Figure 4 As shown, a concentrated acid mist purifying device provided by the embodiment of the present invention includes a cabinet 1, and eleven airtight and liquid containers are connected in series in the cabinet 1, the first container 11, the second container 12. The liquid in the third container 13, the fourth container 14, the seventh container 17, the eighth container 18, the ninth container 19, the tenth container 20 and the eleventh container 21 is clear water, the fifth container 15 and the sixth container The liquid in the container 16 is an alkaline liquid, and the alkaline liquid is a sodium hydroxide solution with a concentration of 5% to 8%; each container is respectively fixed with a connecting plate 112 that divides the container into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com