Pulling and milling machining method for large-diameter non-standard right-handed rotation inner thread

A technology of internal thread and large diameter, which is applied in the direction of metal processing equipment, manufacturing tools, tangent devices, etc., can solve the problems of not suitable for large diameter non-standard right-handed internal thread, so as to avoid loosening and displacement, improve service life, and The effect of improving tool durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

[0032] The present invention proposes a large-diameter non-standard right-handed internal thread drawing and milling processing method, the specific processing steps are:

[0033] Process 1: Clamping the blank.

[0034] Figure 13 The material of the blank is high-strength steel.

[0035] Process 2: Rough and fine milling the end face of the blank, the guaranteed size is 102mm.

[0036] Process 3: Rough milling the inner hole from φ220mm to φ255mm to ensure that the depth of the round hole is 102mm.

[0037] Process 4: Fine milling the inner hole from φ255mm to φ260mm to ensure that the depth of the round hole is 102mm.

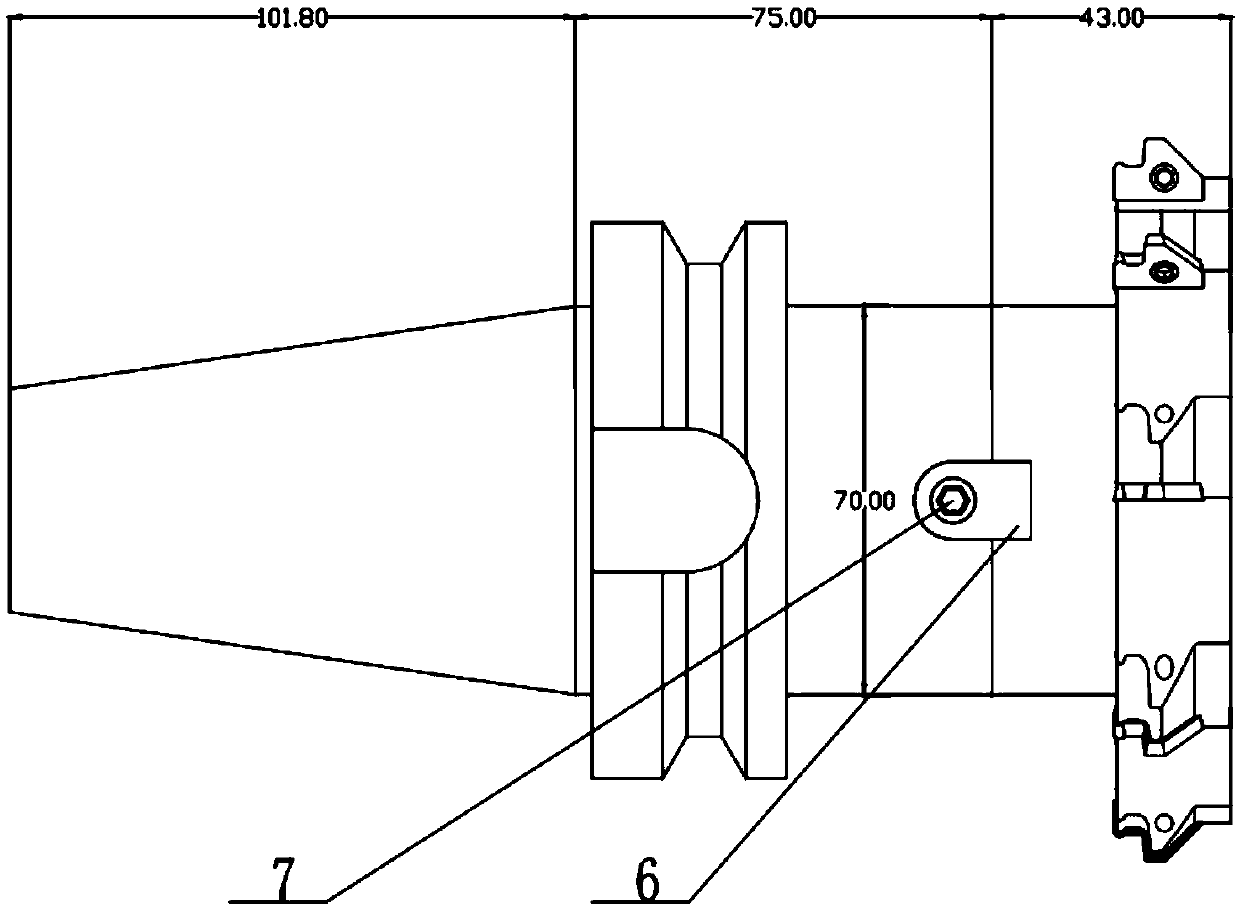

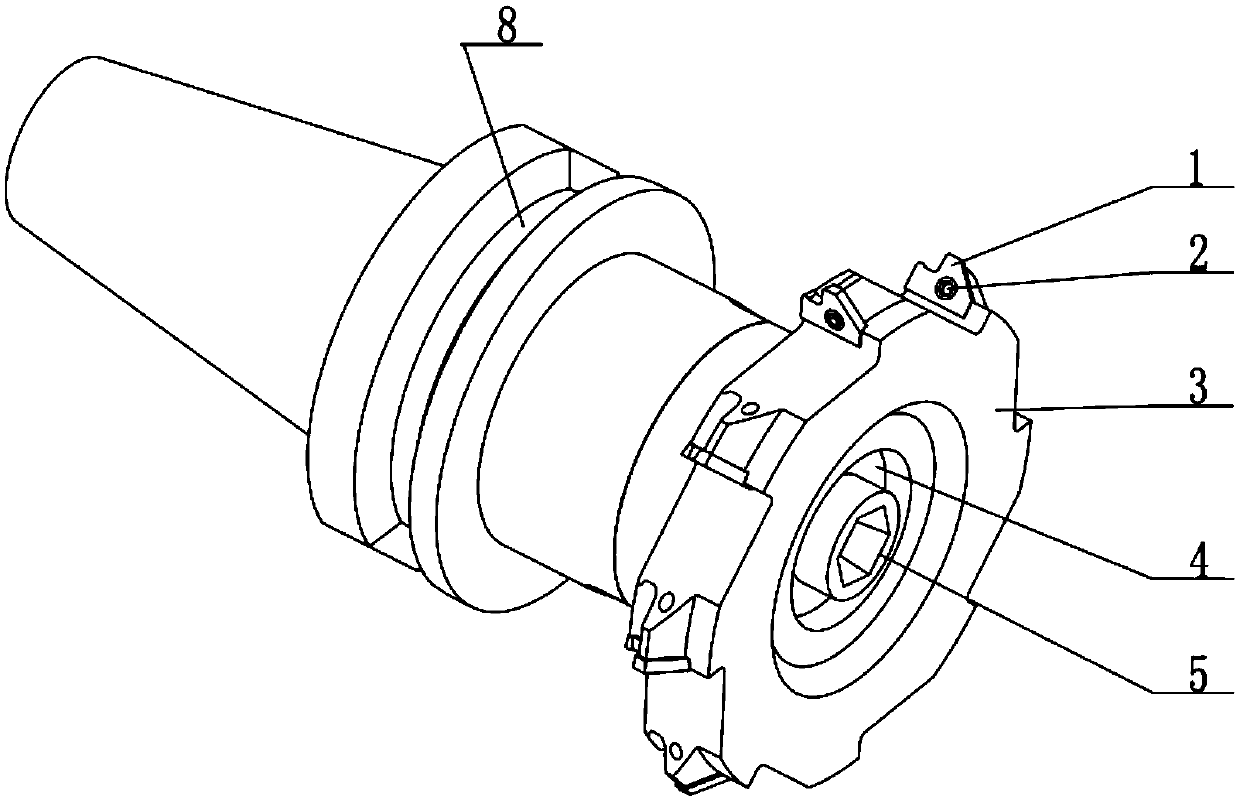

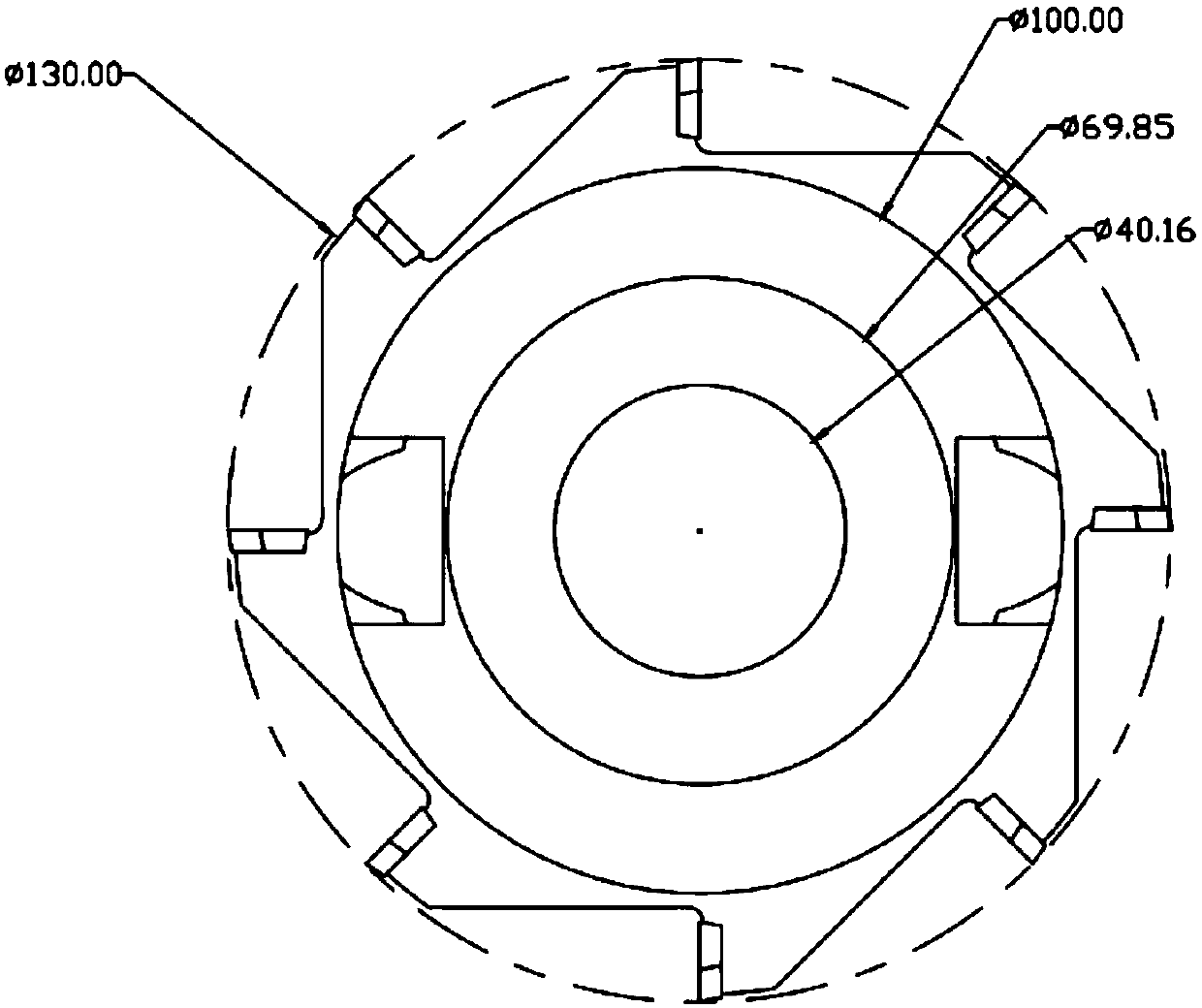

[0038] Process 5: Use a special tool system to rough mill the threaded hole of φ270 to φ265mm, and ensure the depth of the round hole to be 102mm;

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com