Laser welding tooling and welding method for titanium pump core assembly

A laser welding and pump core technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult controllability of the process, poor welding strength and dimensional consistency, to ensure high efficiency and performance stability, avoid The effect of the anode is not correct and the practicability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] A laser welding method for a titanium pump core assembly, characterized in that it comprises the following steps:

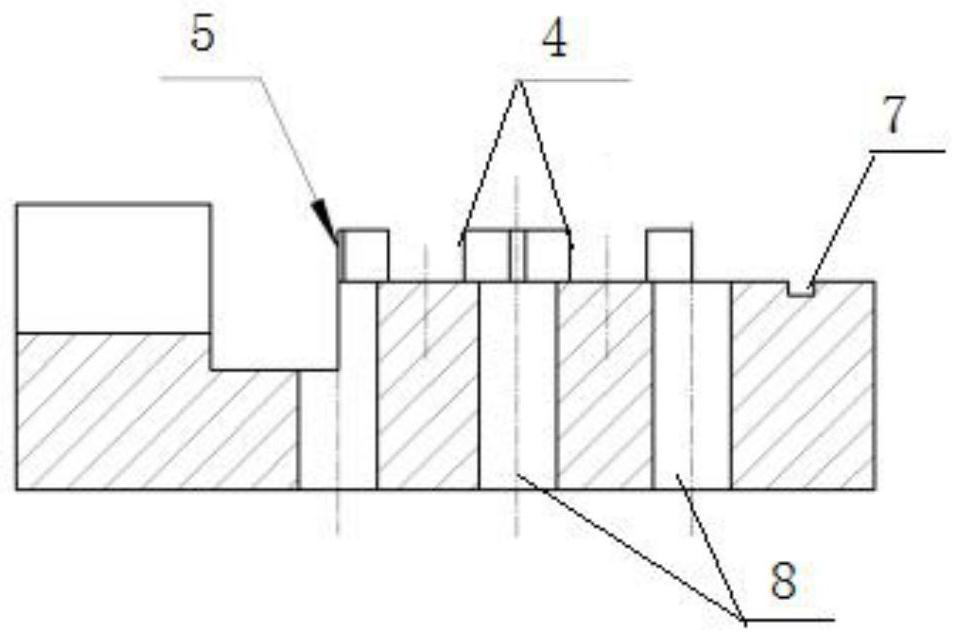

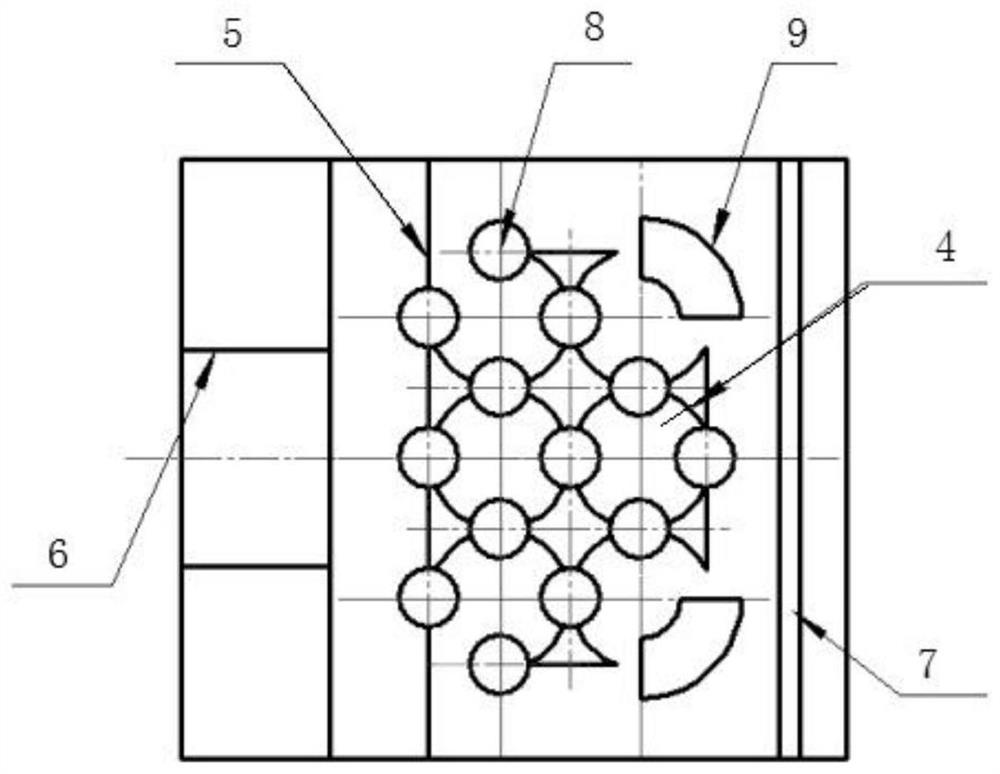

[0037] A. In the lower mold 2, sequentially install the six anodes 11 in the titanium pump core assembly 10 into the anode positioning step 4, and then install the upper cover plate assembly 12 in the titanium pump core assembly 10 into the lead wire positioning step 6, And assemble the fixed piece 13 in the titanium pump pump core assembly 10 into the fixed piece positioning step 5;

[0038] B. Assembling the fixing band 14, using the pin 3 to attach the anode 11 to the fixing piece 13 and the fixing band 14, and inserting the pin 3 into the pin positioning step 7 in the lower mold 2;

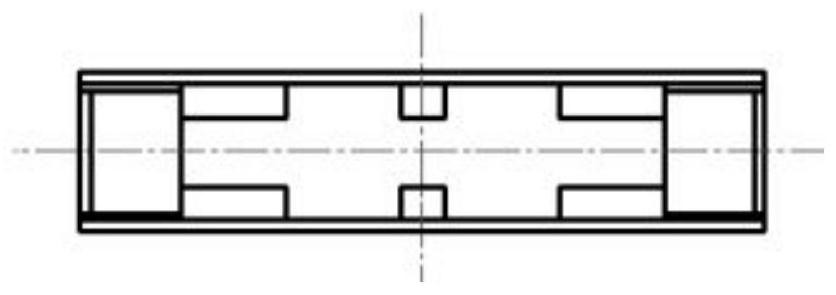

[0039] C. Then the upper mold 1 is symmetrically installed on the lower mold 2, so that the pin 3 is embedded on the pin positioning step 7 in the upper mold 1, and the anode 11, the fixed piece 13 and the upper cover plate in the titanium pump core assembly 10 are made T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com