Multifunctional fixture for clamping box-type parts

A multi-functional, component technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to meet the installation and positioning requirements of different box-type parts, low adaptability, and large structural differences, reducing Fixture cost, adjustable posture, and the effect of meeting clamping needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

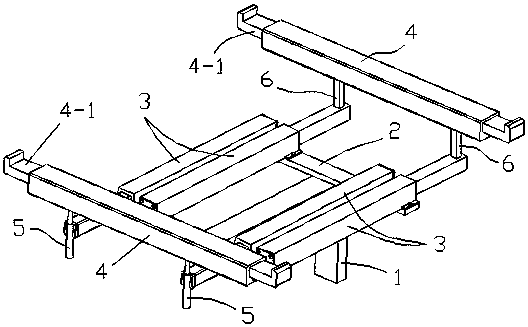

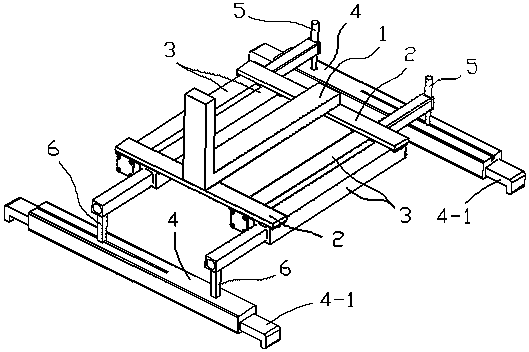

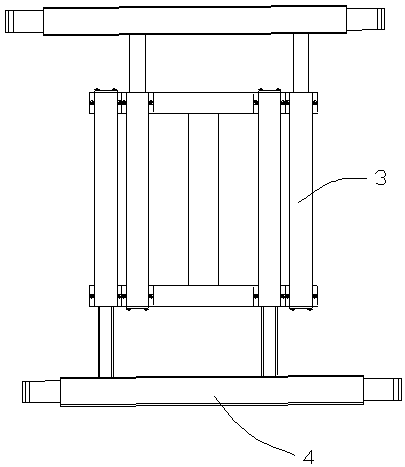

[0021] A multifunctional fixture for clamping box-type parts, the innovation of which is that the multifunctional fixture includes a load-bearing frame 1, two fixed plates 2, four telescopic arms 3, two positioning guide rails 4, and two lifting electric cylinder 5 and two support columns 6;

[0022] The load-bearing frame 1 is an inverted L-shaped structure, the lower end of the load-bearing frame 1 is connected with the transmission device, the upper end surface of the load-bearing frame 1 is parallel to the horizontal plane; the middle part of the lower end surface of the fixed plate 2 is connected with the upper end surface of the load-bearing frame 1, and The axes of the two fixed plates 2 are parallel, and there is a distance between the two fixed plates 2; the telescopic arm 3 includes a fixed section and a telescopic section; The end faces are connected, and the four telescopic arms 3 are arranged in parallel. The telescopic direction of the telescopic arms 3 is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com