A flat vulcanization production line for the production of long rubber materials

A flat-plate vulcanization, long-strip technology, applied in the field of rubber molding, can solve the problems of excessive template quality and low production efficiency, and achieve the effect of satisfying continuous processing, improving processing efficiency and facilitating filler operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

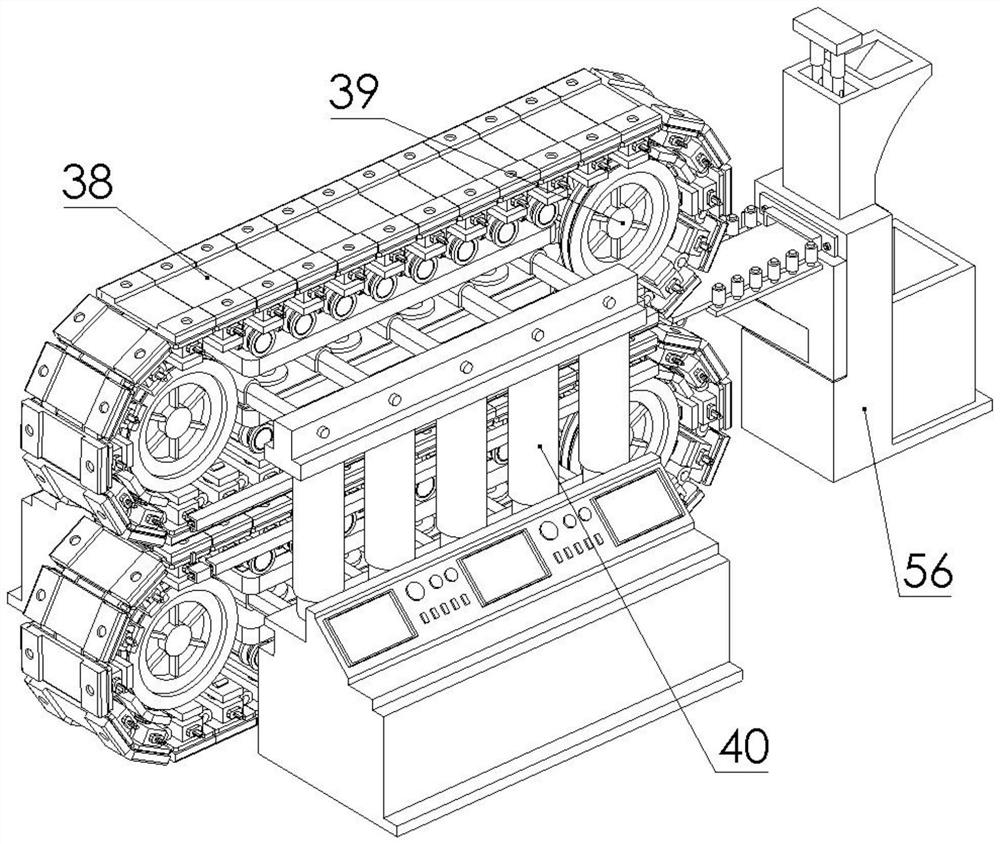

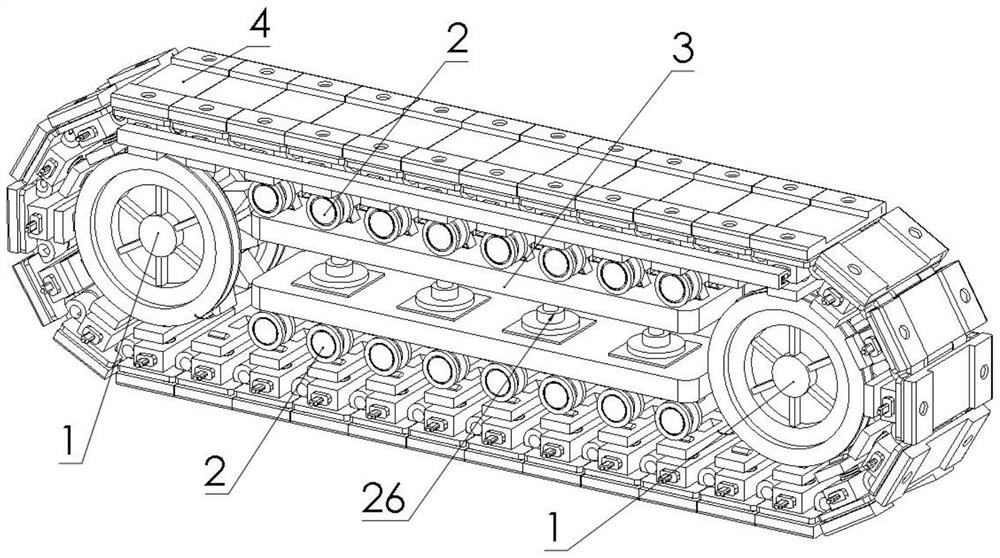

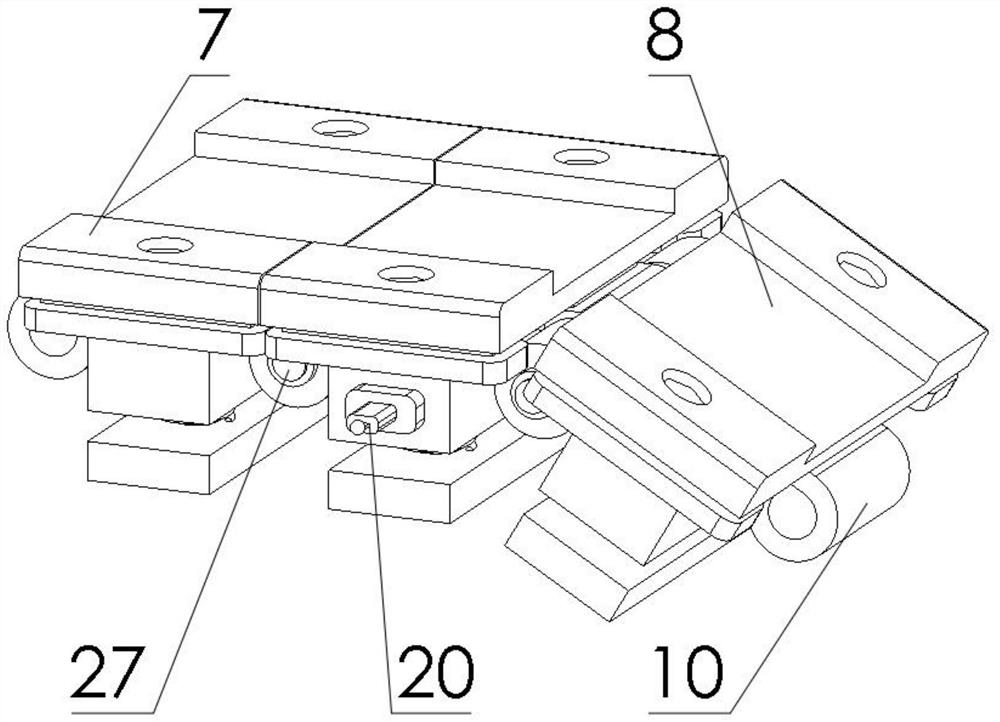

[0042] like Figure 1-Figure 19 As shown, the specific structure of the present invention is: a crawler-type flat plate vulcanizer for the production of long strip rubber, which includes a crawler-type vulcanizing plate device 38, a vulcanizing plate transmission device 39, a vulcanization pressing device 40 and a vulcanizing plate device 38. Feeding device 56; the crawler-type vulcanizing plate device 38 is formed by a plurality of electrothermal compression die chain plates 4 that are fastened to each other front and rear, and a set is provided up and down; On the inner side of 38, the vulcanization plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com