Segment hoisting structure and method in ship construction

A hoisting method and ship technology, applied in ship construction, ship parts, ship design, etc., can solve problems such as equipment collisions in sections, and achieve the effects of improving construction efficiency, reducing labor costs, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

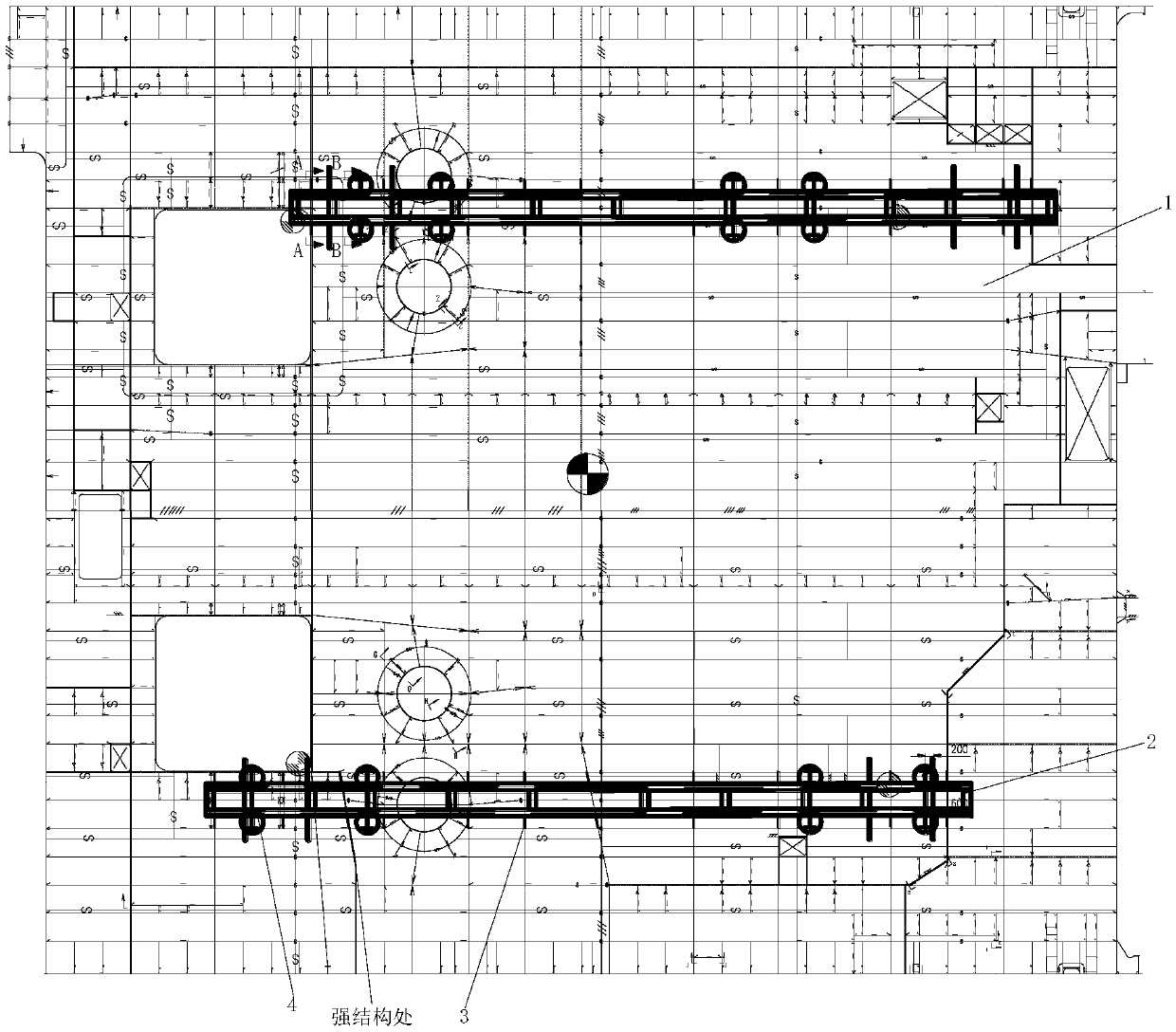

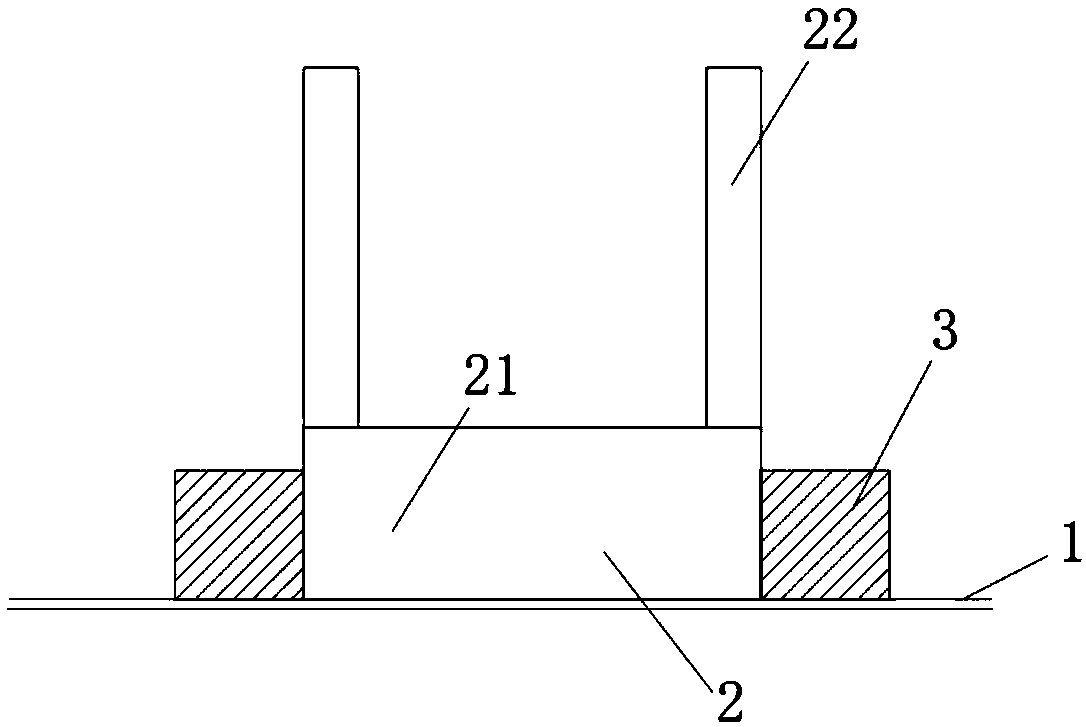

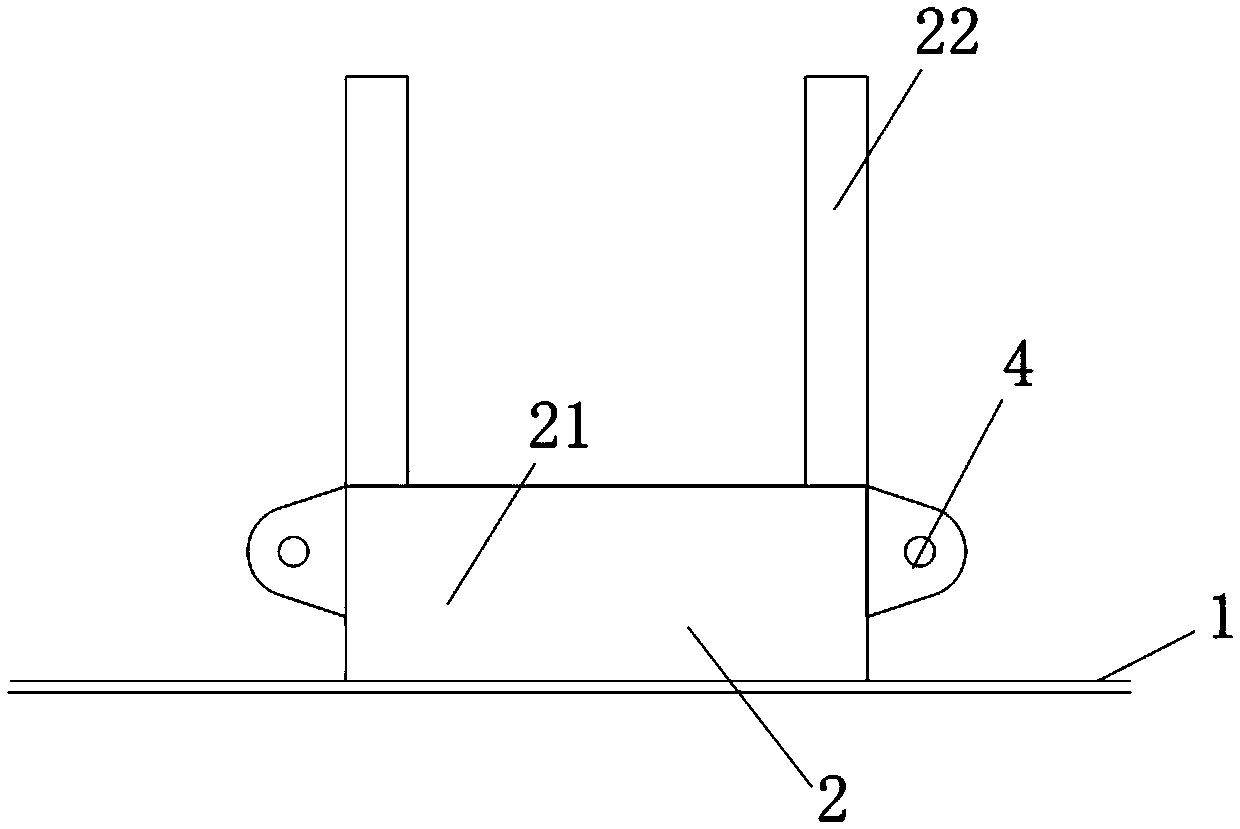

[0020] The segmented hoisting structure in the ship building of this embodiment is as follows: Figure 1-3 As shown, it includes two distance-keeping beams 2, several code plates 3 and lifting lugs 4. The distance-keeping beams 2 are arranged at intervals on the deck 1 on the weak and thin sections of the ship, and the code plates 3 It is a square structure, one side of the code plate 3 is welded to the lower end of each distance-keeping beam 2 sides, the bottom edge of the code plate 3 is welded to the deck 1, and the code plate 3 is connected to the distance-keeping beam 2 and the deck 1, and is located at the The code plates 3 on the same side of the distance beam 2 are arranged at intervals, and the positions of the code plates 3 on the opposite side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com