Method for separating and purifying amomum villosum mesophyll protoplasts

A protoplast, separation and purification technology, applied in plant cells and other directions, can solve the problem of unclear protoplast yield and vitality factors, and achieve the effects of simple operation, broad application prospects, high yield and vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 A kind of method for separation and purification of mesophyll protoplasts of S. vulgaris

[0046] The present embodiment provides a method for isolating and purifying mesophyll protoplasts of S. solani, comprising the following specific steps:

[0047] S1. Material preparation and pretreatment: The shoot tips of rhizomes of the long-fruit cultivation type were inoculated on MS solid medium to induce sterile seedlings. Robust and lush sterile seedlings, select healthy leaves with a leaf length of 30-40 mm for the preparation of protoplasts; remove the veins of the sterile seedling leaves with a sterilized blade, and cut them into about 0.5 mm in the vertical direction of the veins. The thin strips were pretreated by adding a CPW solution containing 0.5M mannitol in a mass-to-volume ratio of 1g:20mL, and suspended in the dark, 28°C, and 120r / min for 1h to complete the preplasma separation;

[0048] S2. Isolation of protoplasts: add enzymatic hydrolysis solut...

Embodiment 2

[0054] Example 2 The effect of pretreatment on protoplast isolation

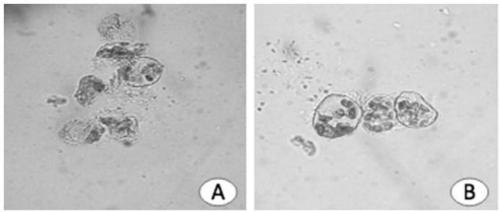

[0055] 1. Experimental group: Take the sterile leaves of S. solani, tear off the lower epidermis with tweezers or cut into 0.5mm thin slices, weigh 1 g and place it in a triangular flask containing 20 mL of CPW solution containing 13% mannitol, and place it in a dark place. , 28 ℃, 120r / min suspension culture for 1h, to complete the separation of the pre-plasma wall. Control group: no pretreatment. The mesophyll cells of P. solani before and after preplasma separation treatment were as follows: figure 1 shown.

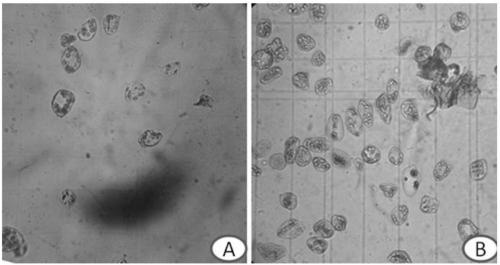

[0056] 2. Put the experimental group and the control group in step 1 into 15 mL of enzymatic hydrolysis solution respectively for enzymatic hydrolysis. After 10 hours of enzymatic hydrolysis, the yield and activity of protoplasts were observed under a microscope. The result is as figure 2 The results showed that there was no significant difference in the protoplast yield between the two groups...

Embodiment 3

[0057] Example 3 Effects of different enzymolysis solutions on the yield and activity of protoplasts

[0058] Cut the sterile leaves of Cordyceps sinensis into 0.5mm and put them into each combination of enzymolysis solution (Table 1), and shake the enzyme solution at low speed for 10h in the dark. Observe the separation of protoplasts under a microscope to determine the best combination of enzyme concentrations. . The results are shown in Table 1 and image 3 shown. The results showed that protoplasts could be obtained by the combination of different concentrations of cellulase and isolated enzymes. When the concentration of isolated enzyme is 0.5%, the yield and activity of protoplasts have concentration effects on cellulase. When the concentration of cellulase is 1.5%, the yield and activity of protoplasts are the highest at 6.12×10 6 Pieces / g·Fw and 81.21%. When the concentration of isolated enzyme was increased to 1.0%, the yield and activity of protoplasts also had t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com