Partially Filled Structural Framing Assembly Nodes with Restoration

A technology for structural frame and recovery function, which is applied in the field of partially filled structural frame assembly nodes, and can solve problems such as no longer applicable and inconvenient operation of connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

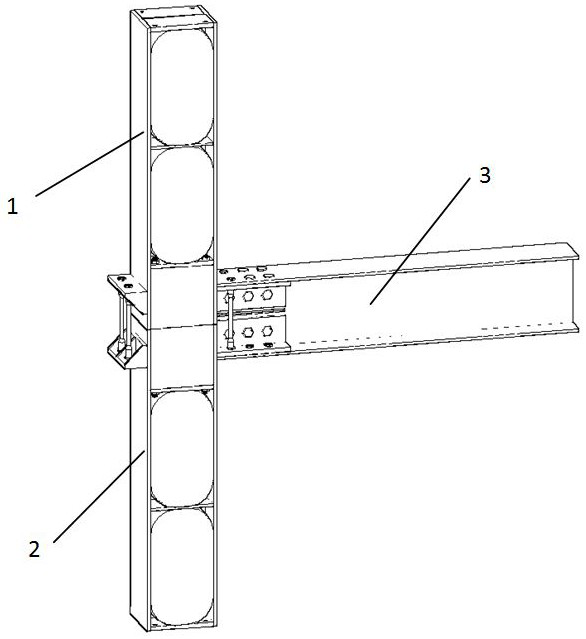

[0029] Such as figure 1 As shown, the partially-filled structural frame assembly node with recovery function of the present invention includes a partially-filled steel-concrete composite upper segment column 1, a partially-filled steel-concrete composite lower segment column 2 and an H-shaped steel beam 3.

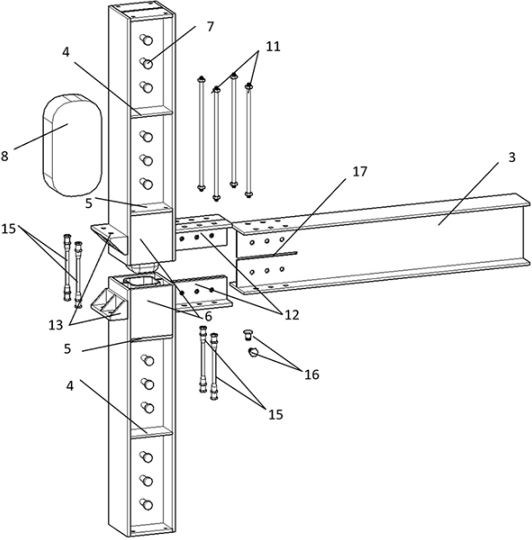

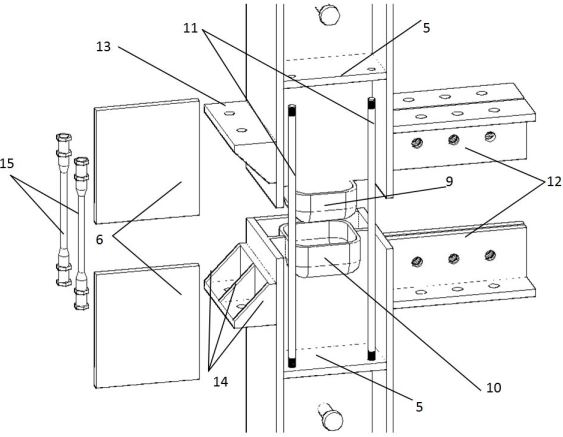

[0030] Such as figure 2 , 3 As shown, the stiffeners 4 are symmetrically arranged on both sides of the web of the segmental column H-shaped steel column, and the end stiffener 5 provided at the end of the column is provided with bolt holes at the outer corners; the upper section of the H-shaped steel web is provided with a convex box The lower section of the column H-section steel web is equipped with a concave box member 10, the combination of the two can form a shear key to effectively improve the shear resistance of the column splicing; the upper and lower section columns are both set at the ends There is a vertical end plate 6, and a semi-closed structure is formed betwee...

Embodiment 2

[0036] Such as Figure 5 As shown, in this embodiment, the H-shaped steel beam 3 is connected to both sides of the column. The flanges on both sides of the upper and lower columns are pre-welded with longitudinal angle steel connectors 12 arranged along the length of the beam. The two angle limbs of the longitudinal angle steel connectors 12 and the flanges and webs of the steel beam 3 are provided with bolt holes, and the longitudinal angle steel is connected The member 12 and the flange of the steel beam 3 are connected by shape memory alloy long bolts 15 near the first row of bolt holes on the column surface, and the remaining bolt hole positions and the longitudinal angle steel connector 12 and the steel beam web are connected by high-strength bolts 16. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com