Dedusting composite security door

An anti-theft door and door body technology, which is applied in the manufacturing field of anti-theft doors and indoor doors, can solve the problems of insufficient pressing of steel plates, insufficient connection strength of fixed steel plates, and stress concentration in the door body, so as to improve the distribution of internal stress and increase the Life practicability, the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

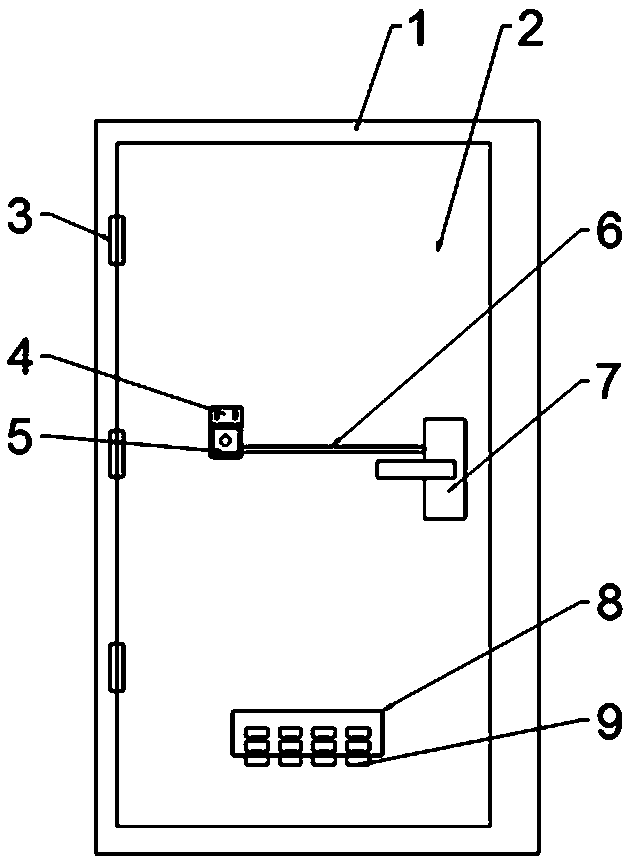

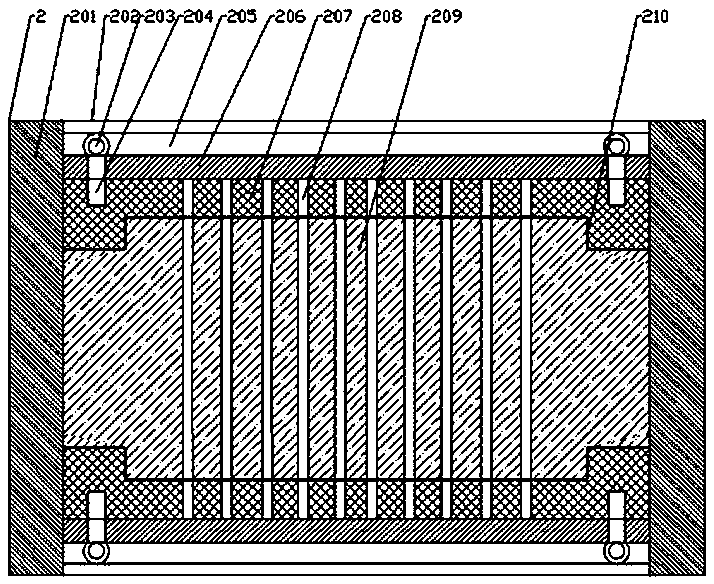

[0013] see Figure 1~2 , a dust-removing composite anti-theft door, comprising a door body 2, a doorway 1, a hinge 3 and a door lock 7; the outside of the door body 2 is provided with a doorway 1, and one side of the door body 2 is provided with a hinge 3; Door body 2 is provided with door lock 7 on the corresponding side of hinge 3; The bottom of described door body 2 is provided with blowing device 8, and blowing device 8 is fixed in the door body 2, and blowing device 8 connects power supply, and blowing device 8 The door body 2 at the position of the air outlet is provided with an air outlet on the side facing the outside, and the air outlet is provided with a deflector 9, and the deflector 9 is arranged obliquely downward, and the deflector makes the wind force concentrate on the shoe upper; The door body 2 is provided with a switch 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com