Intelligent anchor bolt and steel plate support structure having same

An intelligent anchor bolt and anchor bolt technology, which is applied to connecting components, measuring devices, instruments, etc., can solve the problems of large amount of anchor bolts, limited monitoring window time, and labor consumption for a long time, so as to save maintenance costs and improve safety. The effect of performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

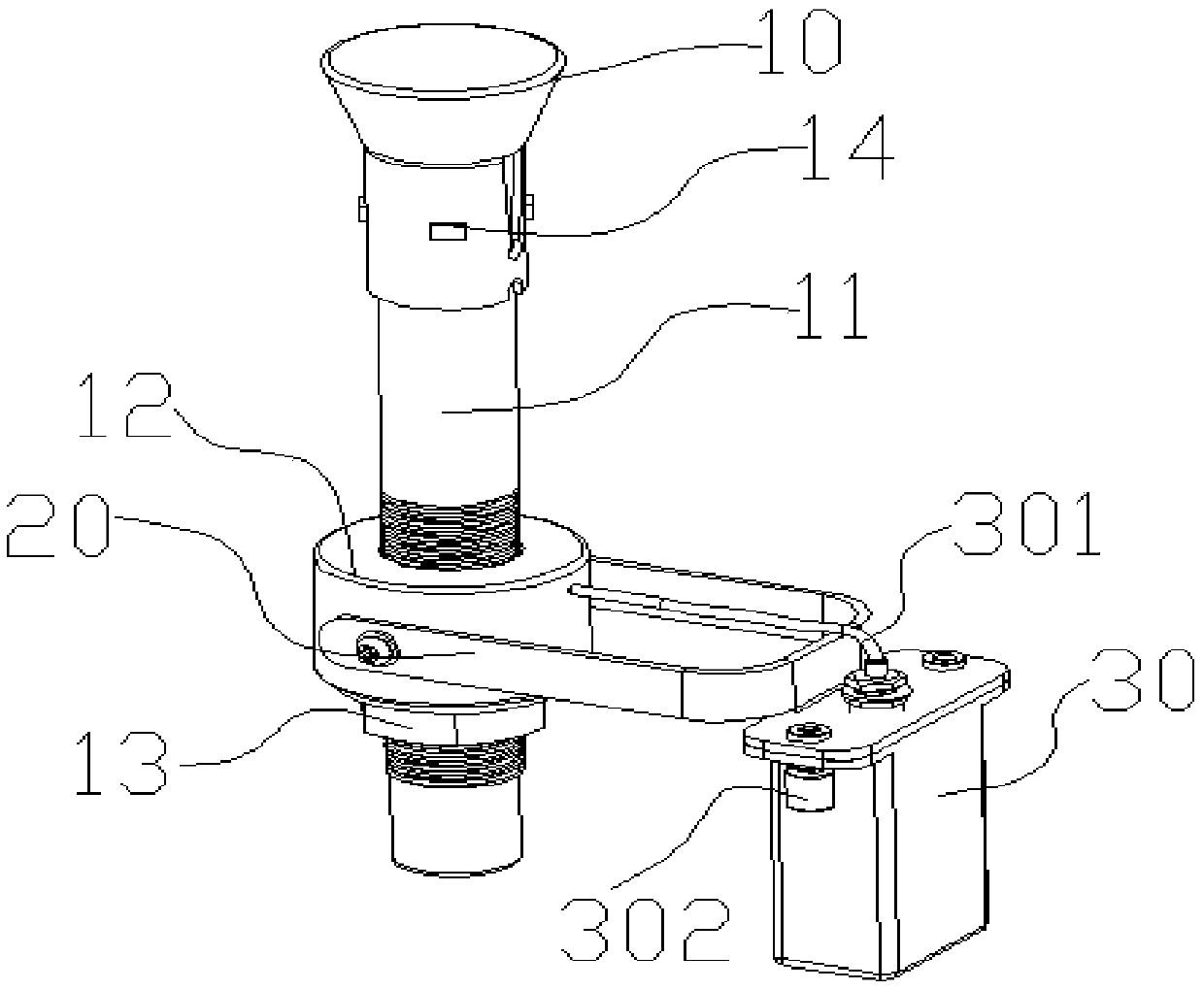

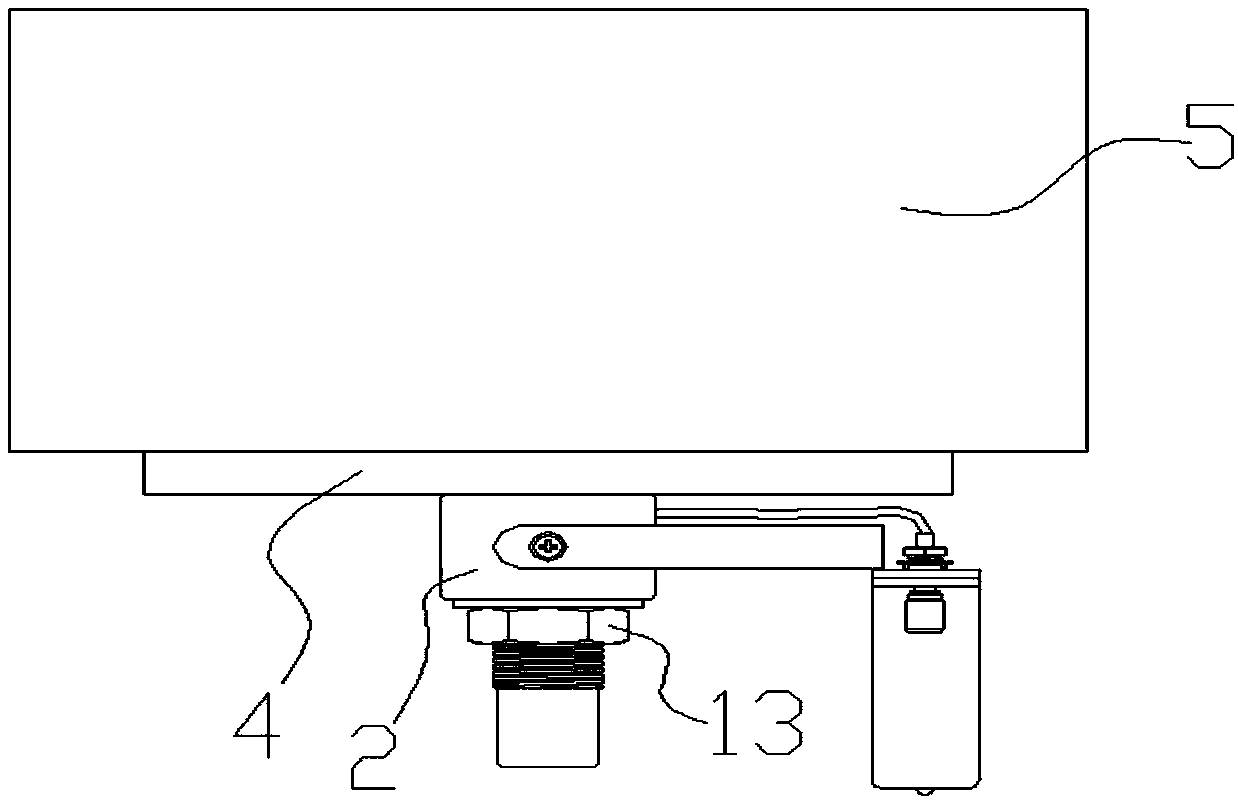

[0028] with the help of figure 1 and figure 2 The technical solution of the present invention is schematically described. The anchor bolt includes an anchor bolt seat 10, a screw rod 11 and a nut 13, and also includes a washer 12, which is sleeved on the screw rod and located on the anchor bolt seat. 10 and nut 13 between. The anchor bolt seat 10 of the anchor bolt in this embodiment can be set in different shapes according to engineering needs, according to factors such as the hardness of the anchored base, as in this embodiment figure 1 The shown anchor seat 11 is conical, and can also be set in other shapes. Preferably, the outer diameter of the anchor seat 11 is larger than the outer diameter of the screw rod 11, so as to better play an anchoring role.

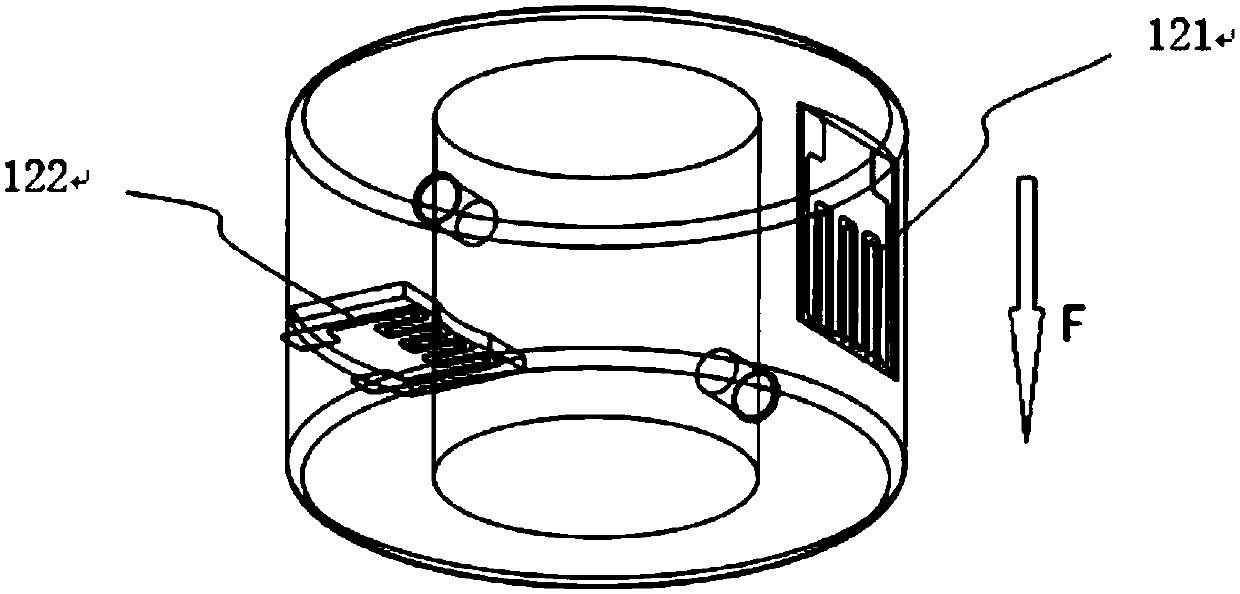

[0029] In order to realize the intelligent monitoring of intelligent anchors, such as Figure 4-Figure 5 The smart anchor bolt shown is provided with an axial pretightening force early warning mechanism, and the pretig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap