Fuel cell cooling fin

A technology of fuel cells and heat sinks, applied in fuel cells, circuits, electrical components, etc., can solve problems such as difficult to ensure the uniformity of flow channel thickness, poor sealing reliability of the overall board surface, uneven fastening force, etc., to achieve the problem of finding And the effects of easy replacement, low cost, and guaranteed thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

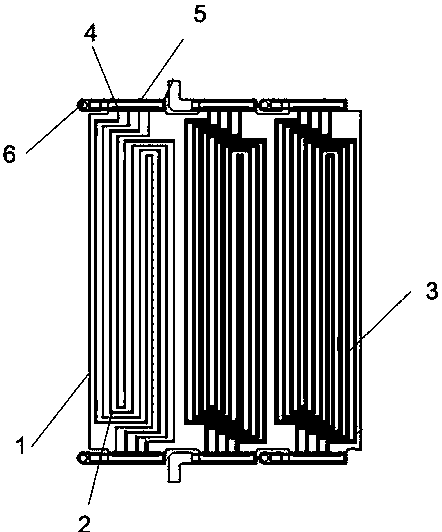

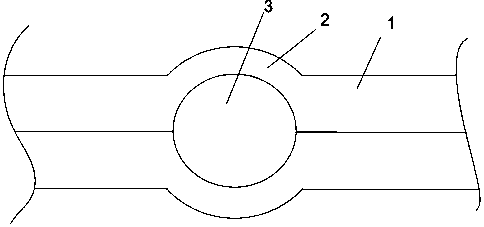

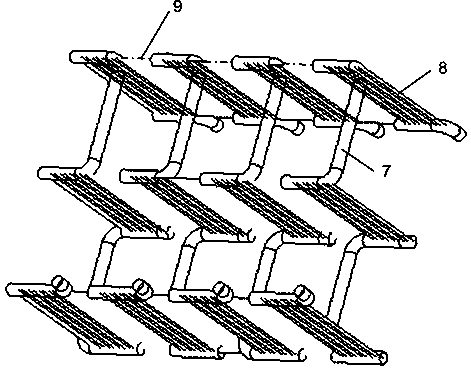

[0022] figure 1 In this embodiment, three radiators are connected in parallel to form a radiator unit. The cooling unit includes three cooling bodies. Each heat sink includes a heat sink body, and the heat sink body is composed of two aluminum sheets 1 with the same structure. Each of the pipelines 4 is fixed inside, and the pipelines 4 pass through the channels of the three radiators, and the pipelines 4 are provided with gaps 5 . The stamped and formed through grooves 2 distributed on the two aluminum sheets 1 of each radiator are relatively connected to form a cavity. The cavity is equipped with a liquid pipe 3 that constitutes a liquid circulation flow channel, and the liquid pipe 3 is sandwiched between the two aluminum sheets 1. . The liquid circulation channel is a circuitous channel. The head end / tail end of the liquid pipe 3 are respectively collected to the upper and lower end channels of the aluminum sheet, and the head end / tail end of the liquid pipe 3 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com