Tundish funnel

A funnel and slot cover technology used in the manufacture of tools, casting melt containers, and controlling the pouring of molten metal from a ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description and examples of the present invention should not be used to limit the scope of the present invention. Other examples, features, aspects, embodiments and advantages of the invention will be apparent to those skilled in the art from the following description. As will be appreciated, the invention contemplates alternative embodiments other than those exemplary embodiments specifically discussed herein without departing from the scope of the invention. Accordingly, the drawings and descriptions should be regarded as illustrative and not restrictive in nature.

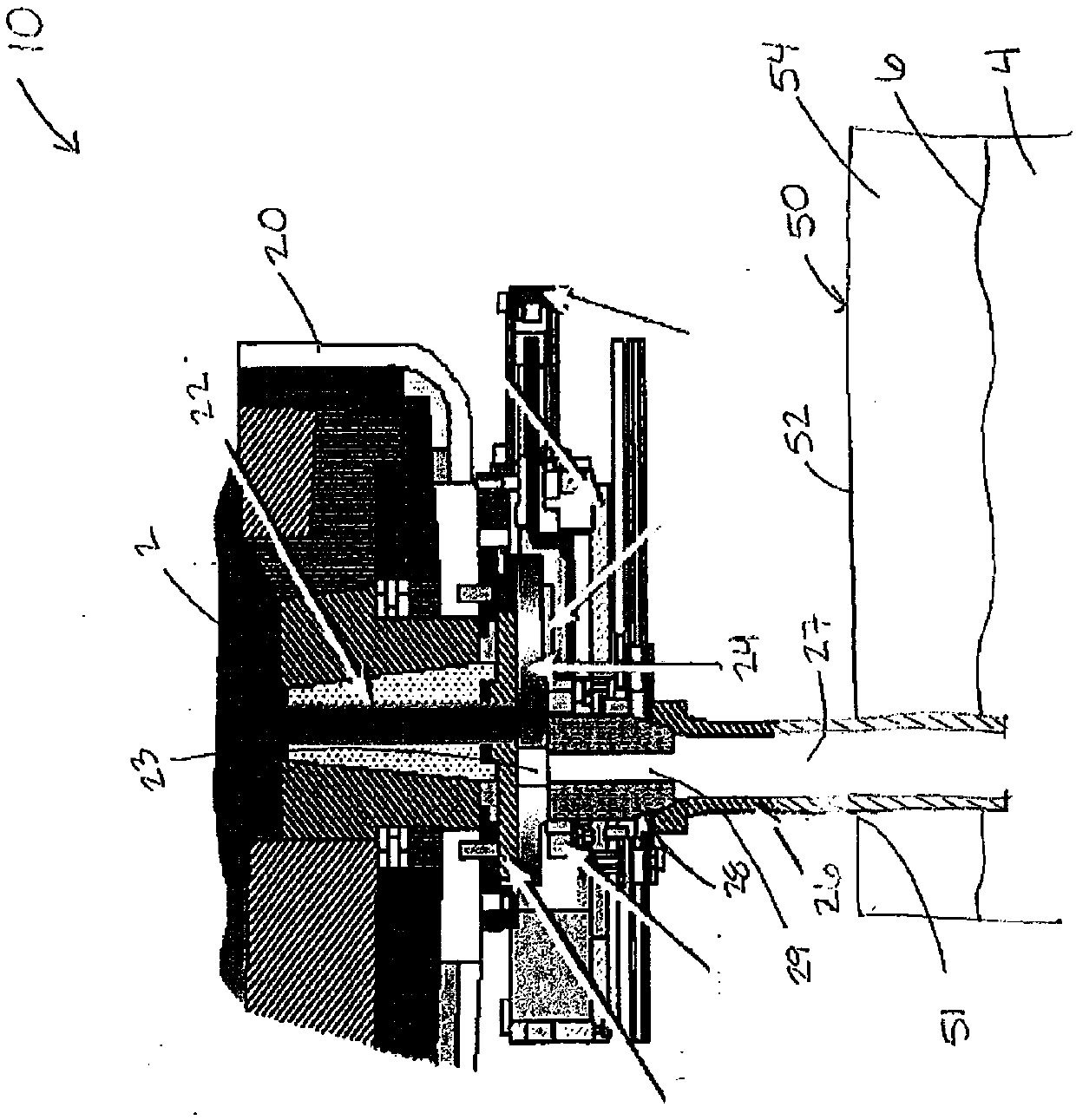

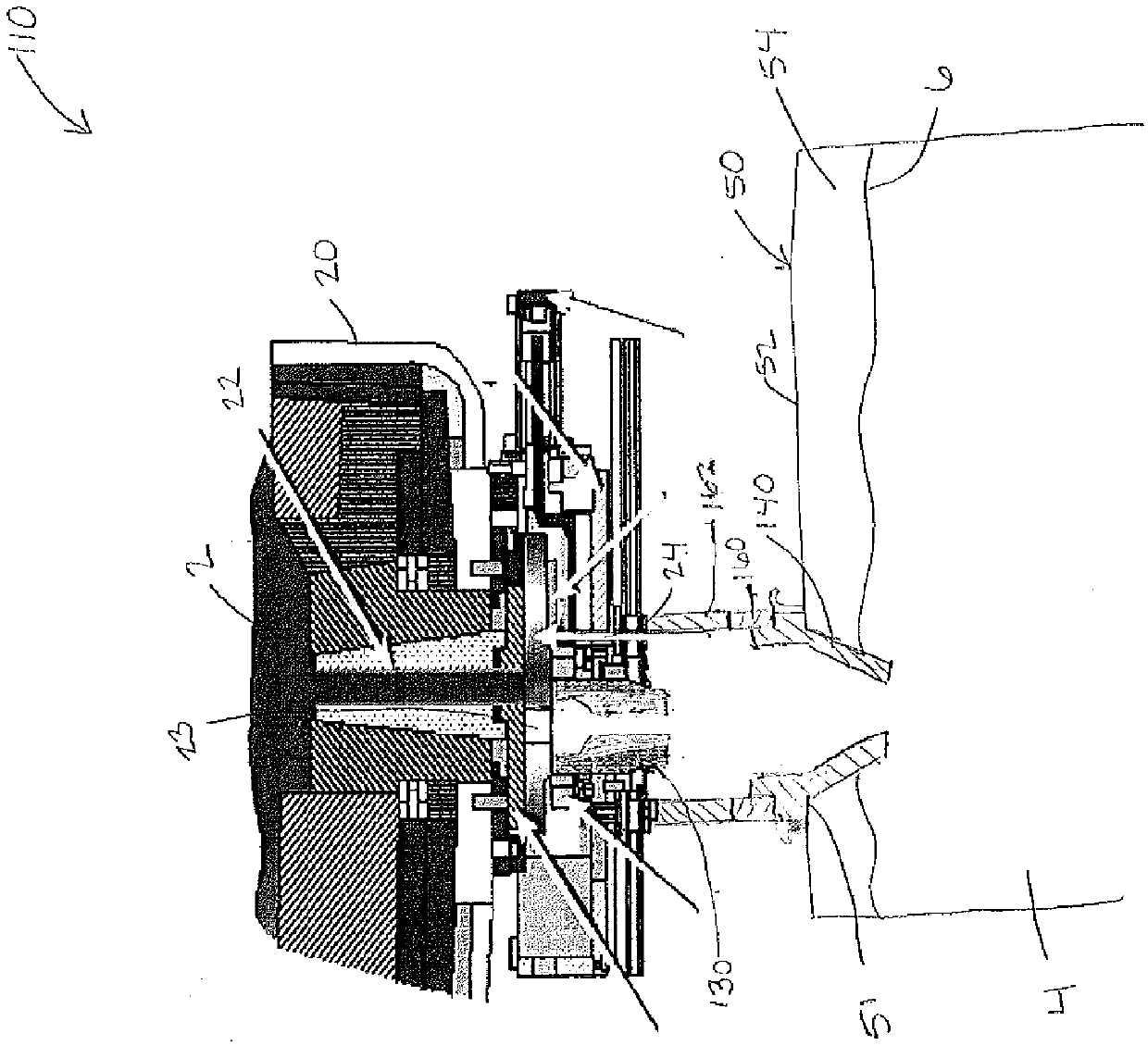

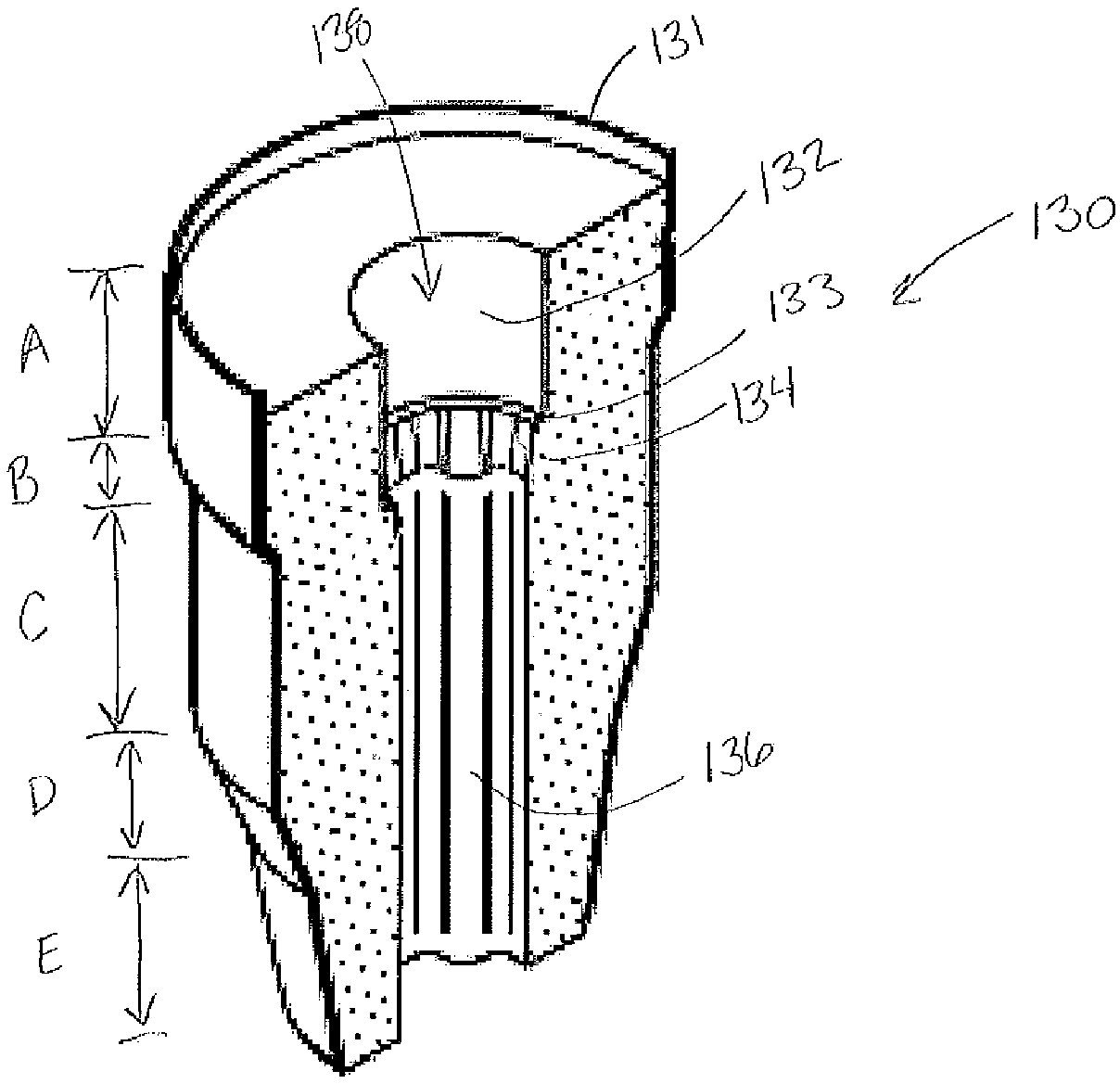

[0024] figure 1 A typical continuous casting machine (10) is shown having a ladle (20) coupled to a feeder trough (50) through a ladle shroud (26). As shown, the liquid steel (2) stored in the ladle (2) flows through the ladle nozzle (22) to the sliding gate (24). The sliding gate (24) can be opened and closed by selectively aligning the opening (23) of the sliding gate (24) with the lad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com