Method for producing carbon nanotube fiber and carbon nanotube fiber produced thereby

一种碳纳米管纤维、碳纳米管的技术,应用在碳纳米管、定向碳纳米管、填充碳纳米管等方向,能够解决碳纳米管不易分散、不易保持分散性、难以充分表现碳纳米管优异特性等问题,达到拉伸强度增强、制备时间减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 3

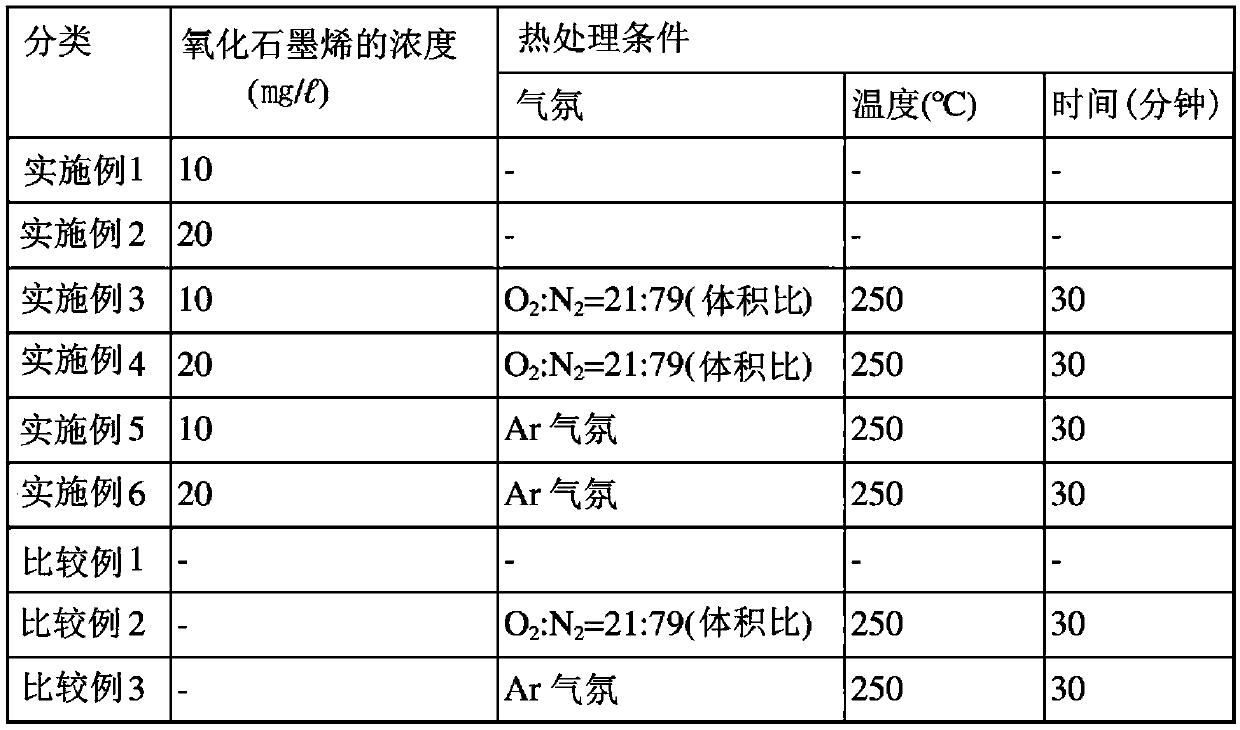

[0044] [Examples 1 to 6 and Comparative Examples 1 to 3: Preparation of carbon nanotube fibers]

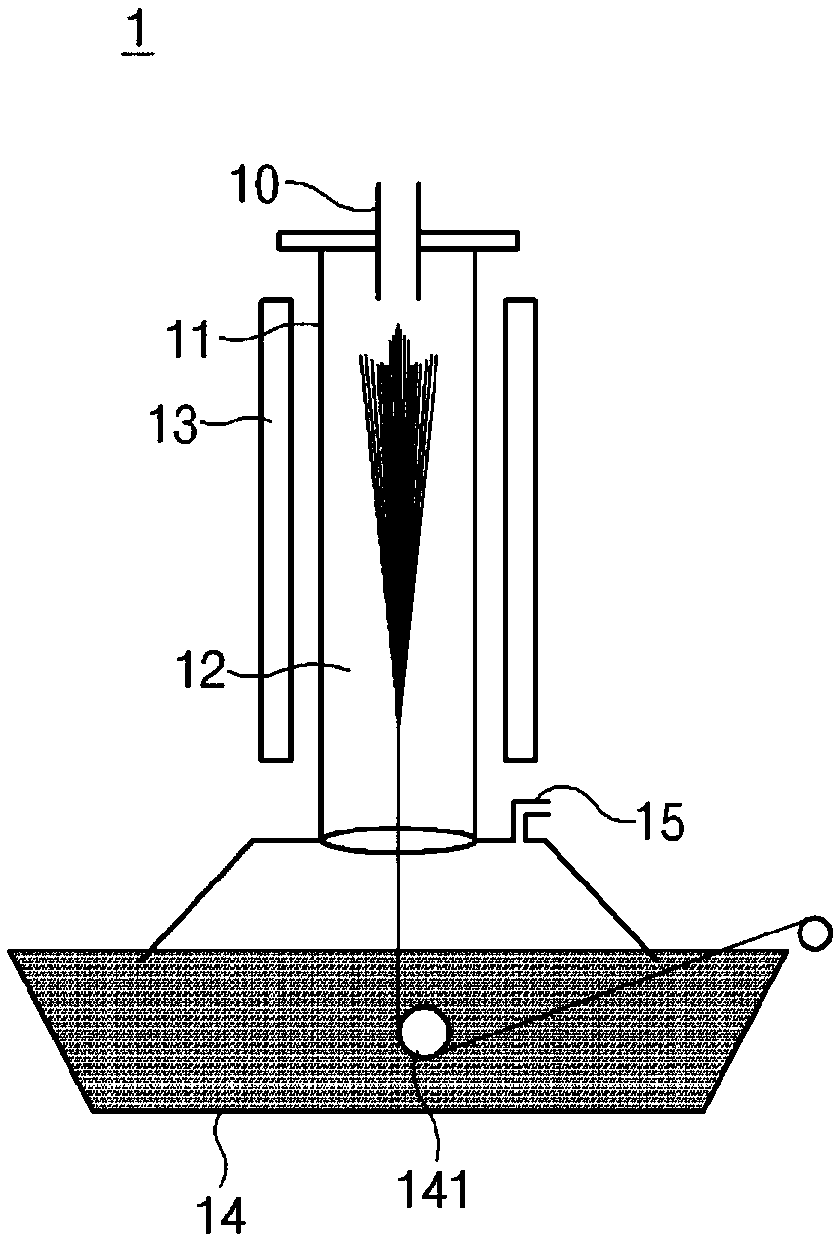

[0045] Carbon nanotube fibers are prepared by the following method using an apparatus for preparing carbon nanotube fibers, the apparatus comprising: a reactor main body including a reaction zone; an inlet located on the upper part of the main body and allowing a carbon source and a carrier gas to flow into the reaction zone; a heating device for heating the reaction zone; and a water container equipped at the lower part of the main body for discharging the carbon nanotube fibers to the outside of the device.

[0046] Under a nitrogen atmosphere, the temperature in the reaction zone was raised to 1200°C. Fe(C 5 h 5 ) 2 and sulfur (S) as a catalyst activator are placed in the reaction zone adjacent to the inlet. Fe(C 5 h 5 ) 2 and catalyst activator S, and by taking 2.0 hours -1 The gas-hour-space-velocity (GHSV) of methane was fed as the carbon source and the -1 and 13 ho...

experiment example 1

[0053] [Experimental Example 1: Characteristic Evaluation of Carbon Nanotube Fibers and Carbon Nanotube Fiber Composite Materials]

[0054] The tensile strengths of the carbon nanotube fibers of Examples 1 to 6 and Comparative Examples 1 to 3 and the carbon nanotube fiber composite material of Comparative Example 4 were measured using FAVIMAT+ (manufacturer: TEXTECHNO). The linear density of the fiber was measured according to ASTM D1577, and after the fiber tensile test, the breaking strength of the fiber was divided by the linear density to measure the tensile strength. Detailed measurement conditions are as follows. Based on Comparative Example 1, the tensile strength was evaluated as a relative value with respect to Comparative Example 1, and the values are shown in Table 2 below.

[0055] Measurement conditions: load cell is 210cN, gauge length is 2cm, and speed is 2mm / min

[0056] [Table 2]

[0057] group

Tensile Strength

Example 1

118.3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com