Patents

Literature

30results about "Filled nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20060239891A1Good electrochemical propertiesMaterial nanotechnologyHybrid capacitor electrodesMultiwalled carbonElectrochemistry

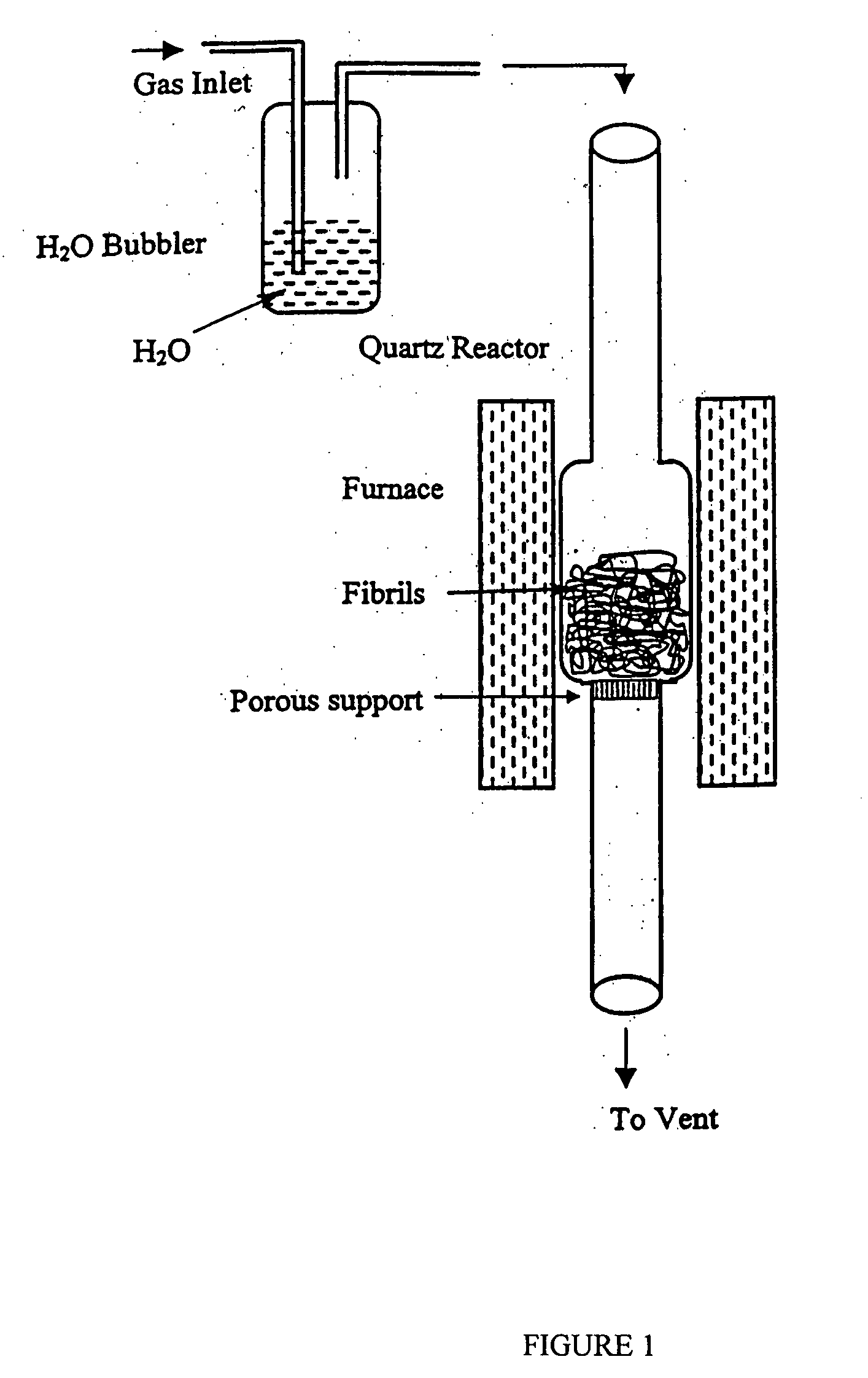

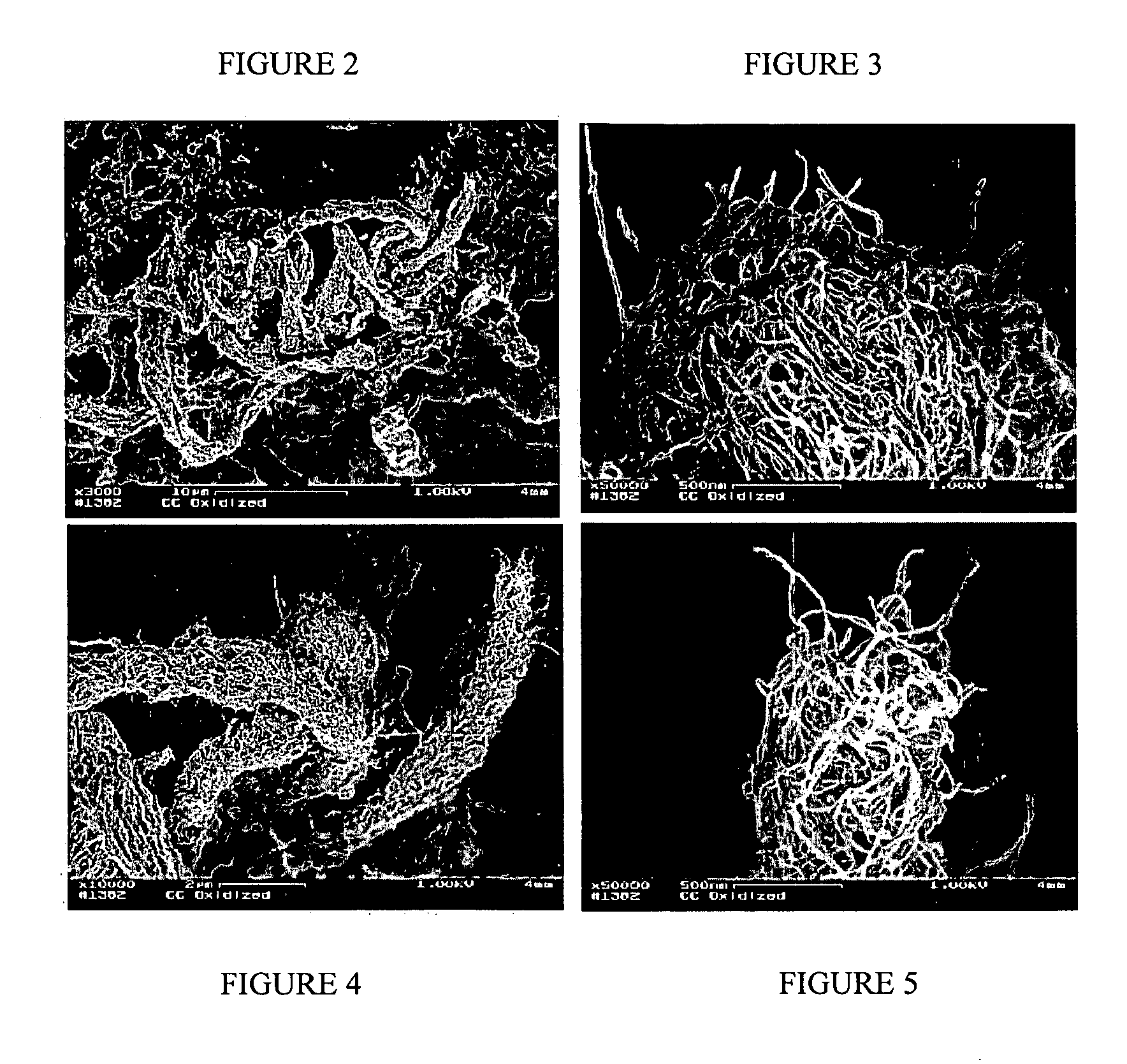

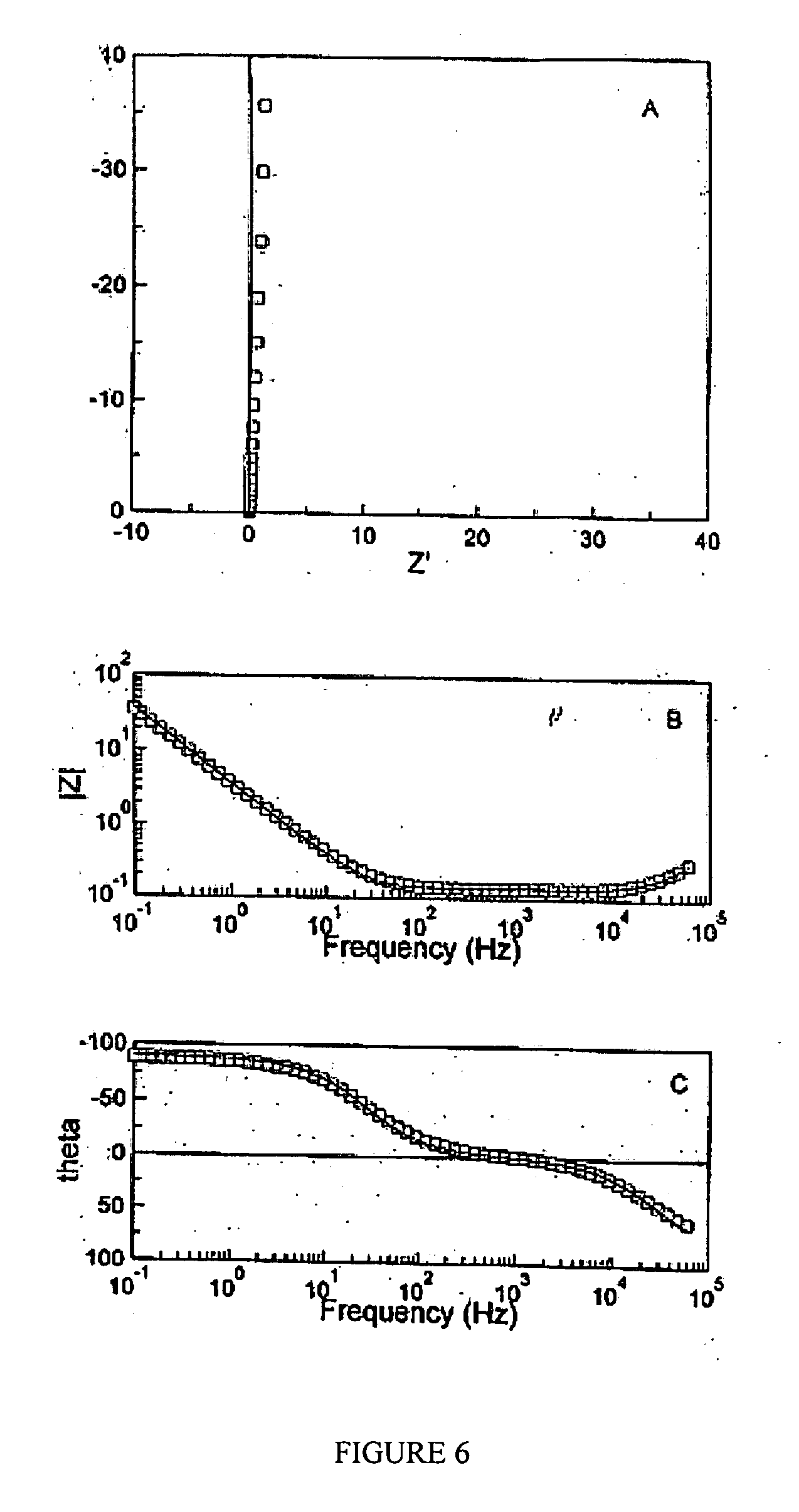

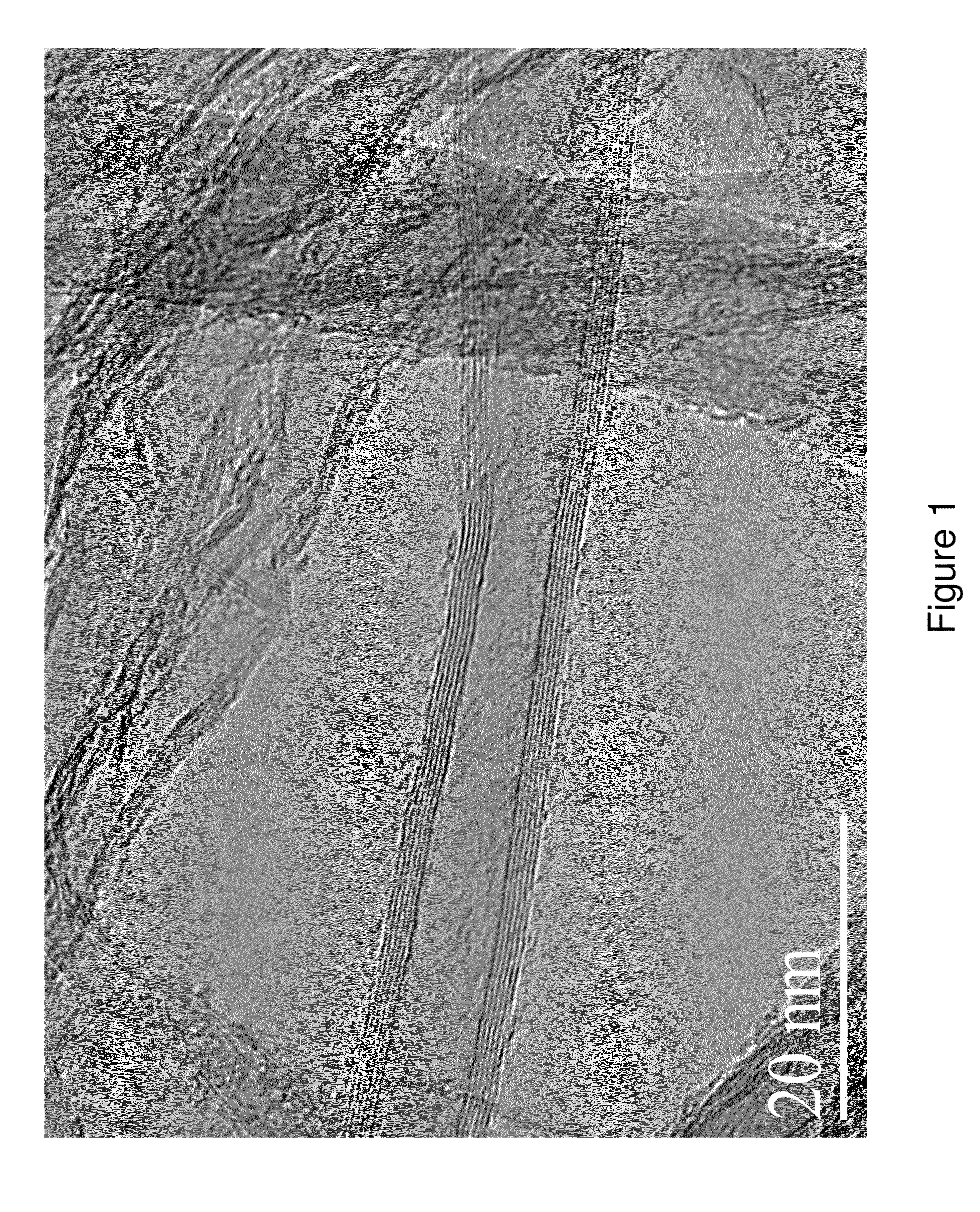

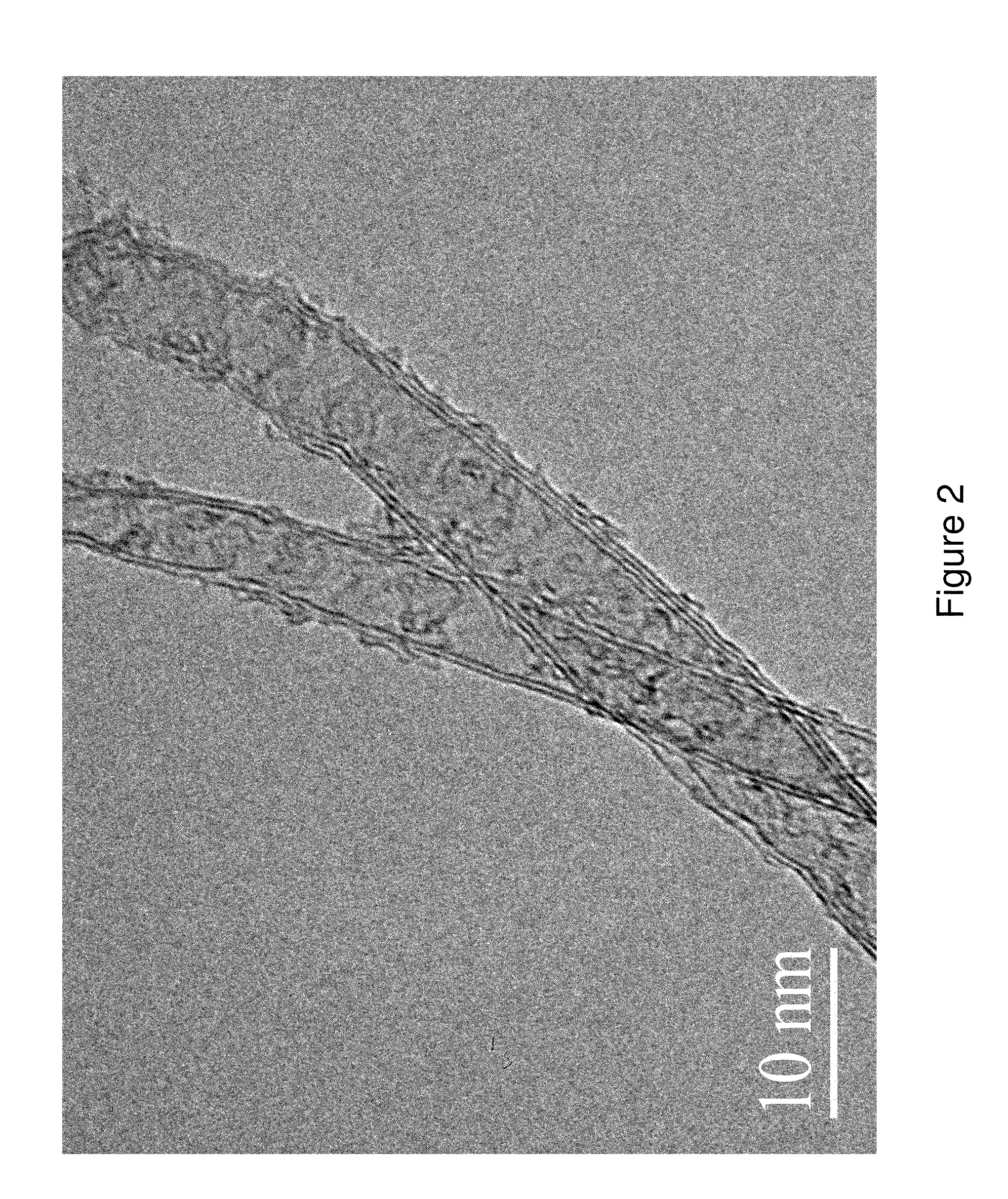

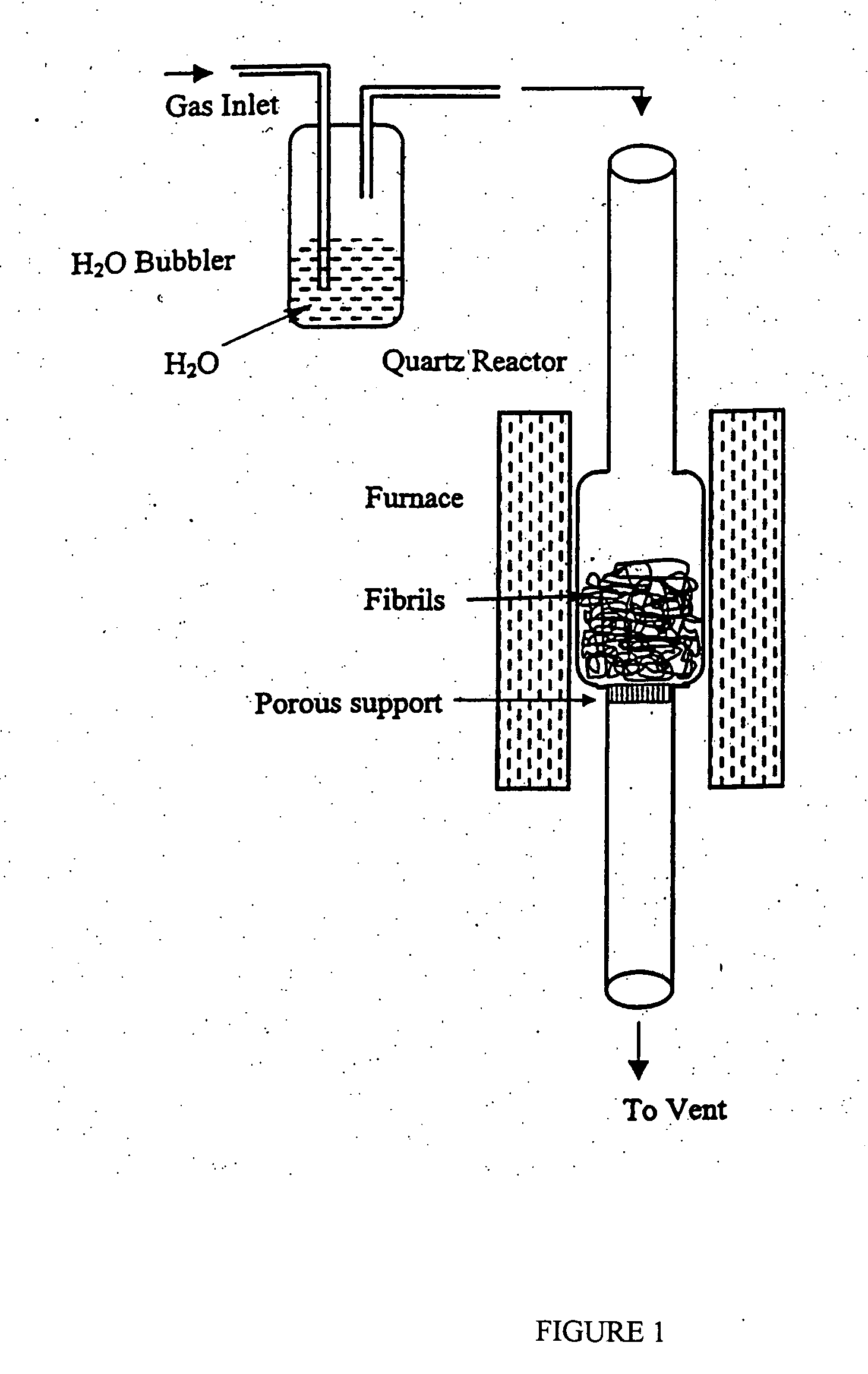

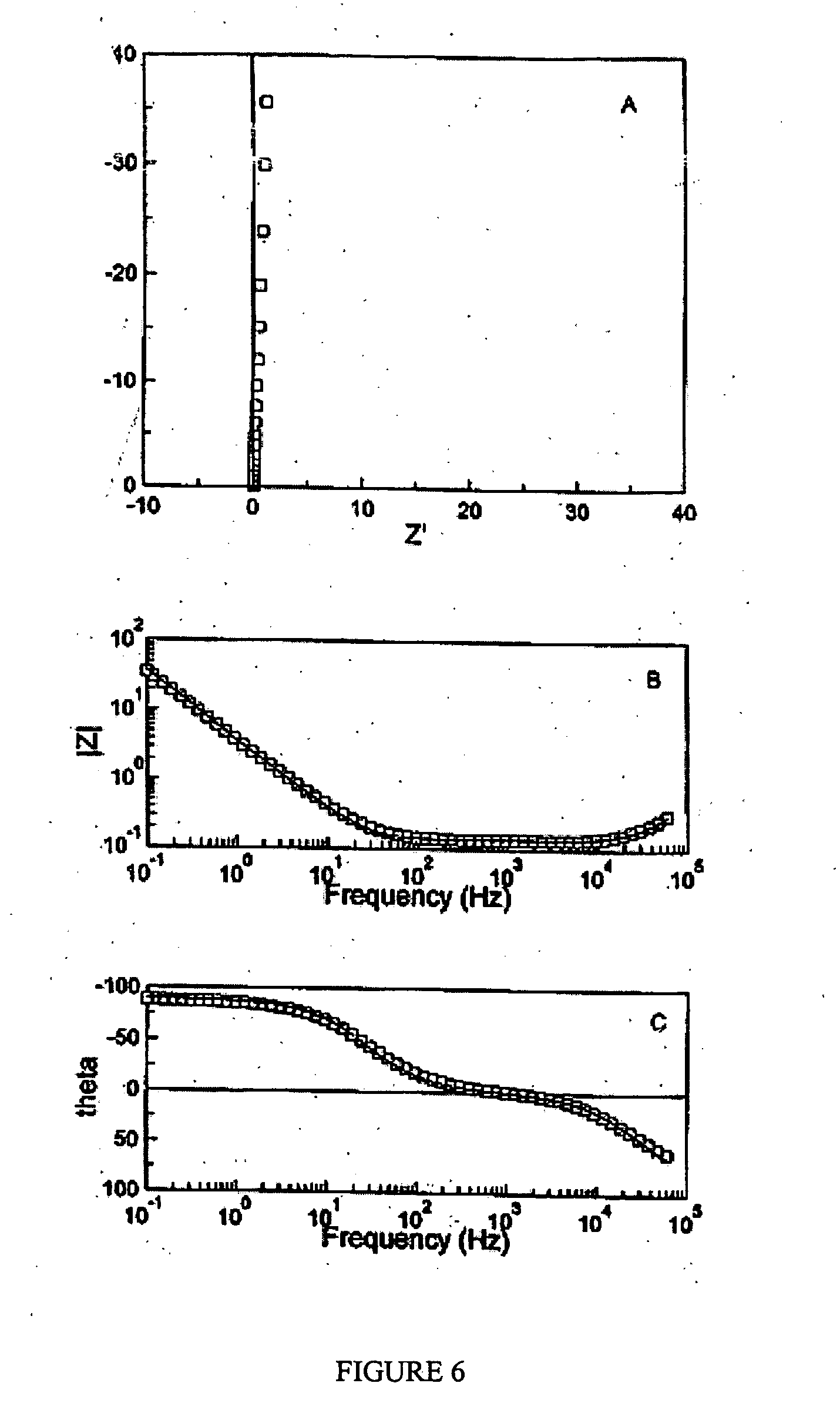

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

Cnt-infused fibers in carbon-carbon composites

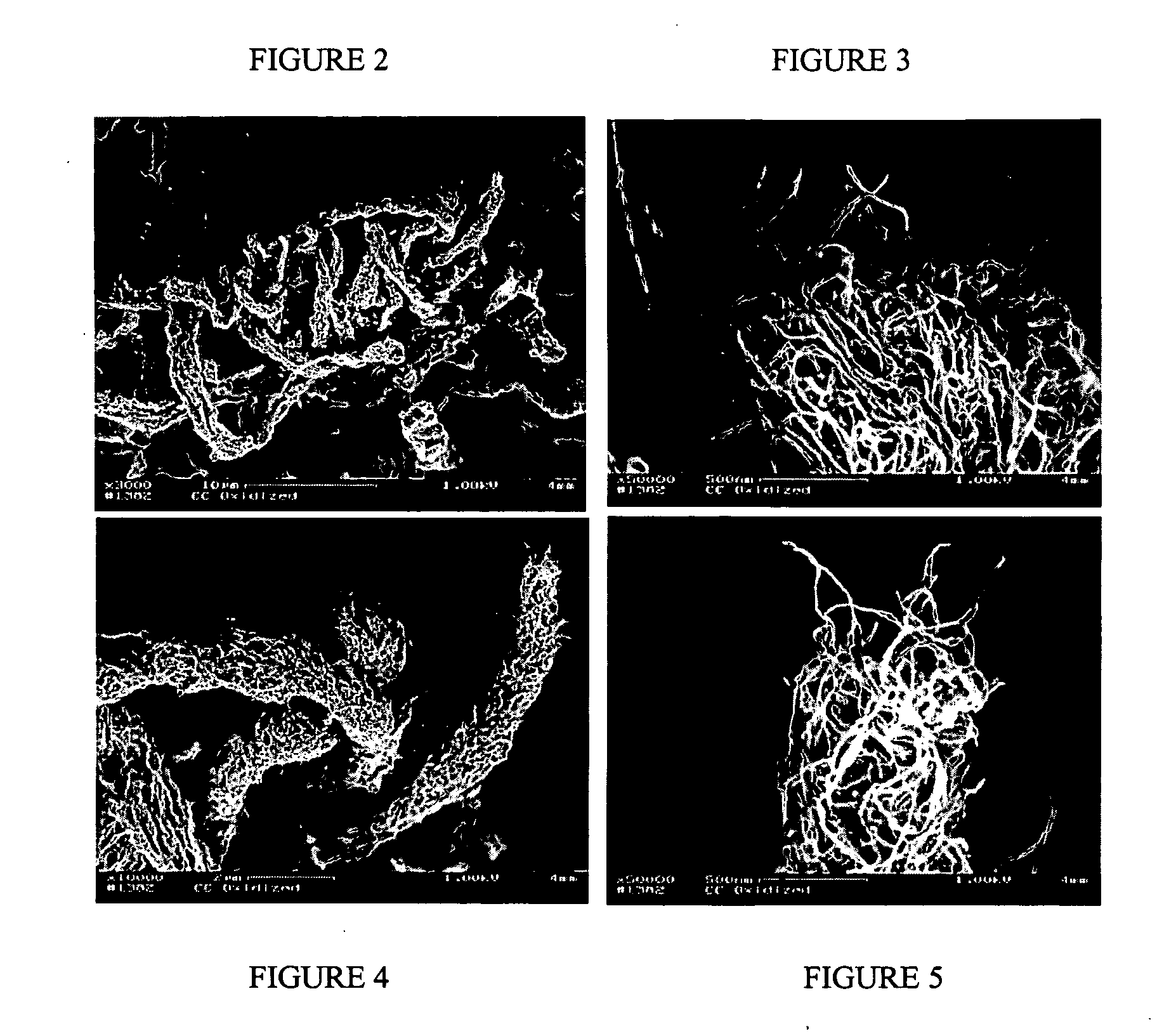

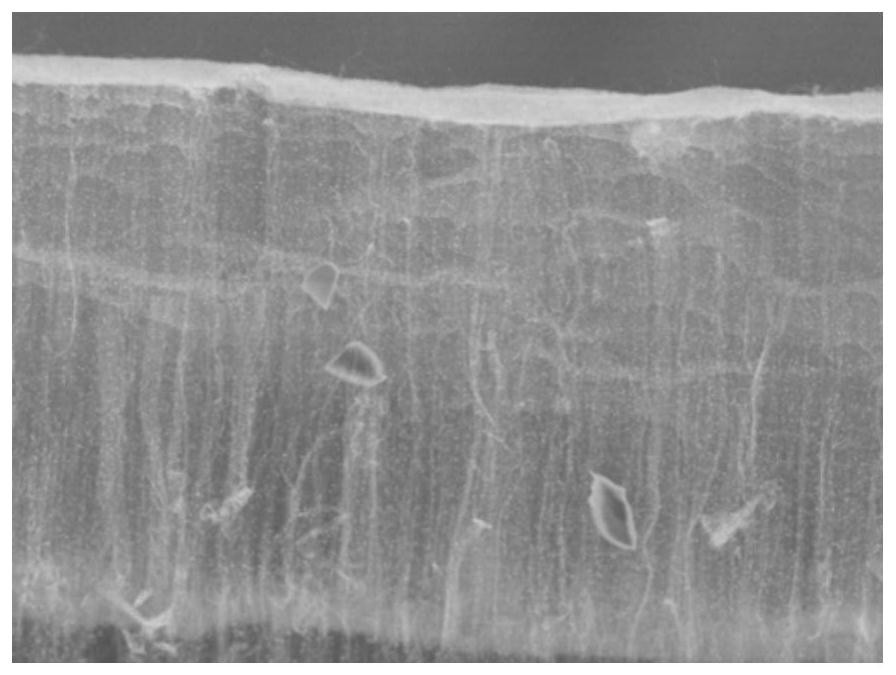

A carbon / carbon (C / C) composite includes a carbon matrix and a non-woven, carbon nanotube (CNT)-infused carbon fiber material. Where woven materials are employed, CNTs are infused on a parent carbon fiber material in a non-woven state. A C / C composite includes a barrier coating on the CNT-infused fiber material. An article is constructed from these (C / C) composites. A method of making a C / C composite includes winding a continuous CNT-infused carbon fiber about a template structure and forming a carbon matrix to provide an initial C / C composite or by dispersing chopped CNT-infused carbon fibers in a carbon matrix precursor to provide a mixture, placing the mixture in a mold, and forming a carbon matrix to provide an initial C / C composite.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20050002850A1Good electrochemical propertiesSpecificMaterial nanotechnologyElectrolytic capacitorsMultiwalled carbonChlorine dioxide

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

Interface-infused nanotube interconnect

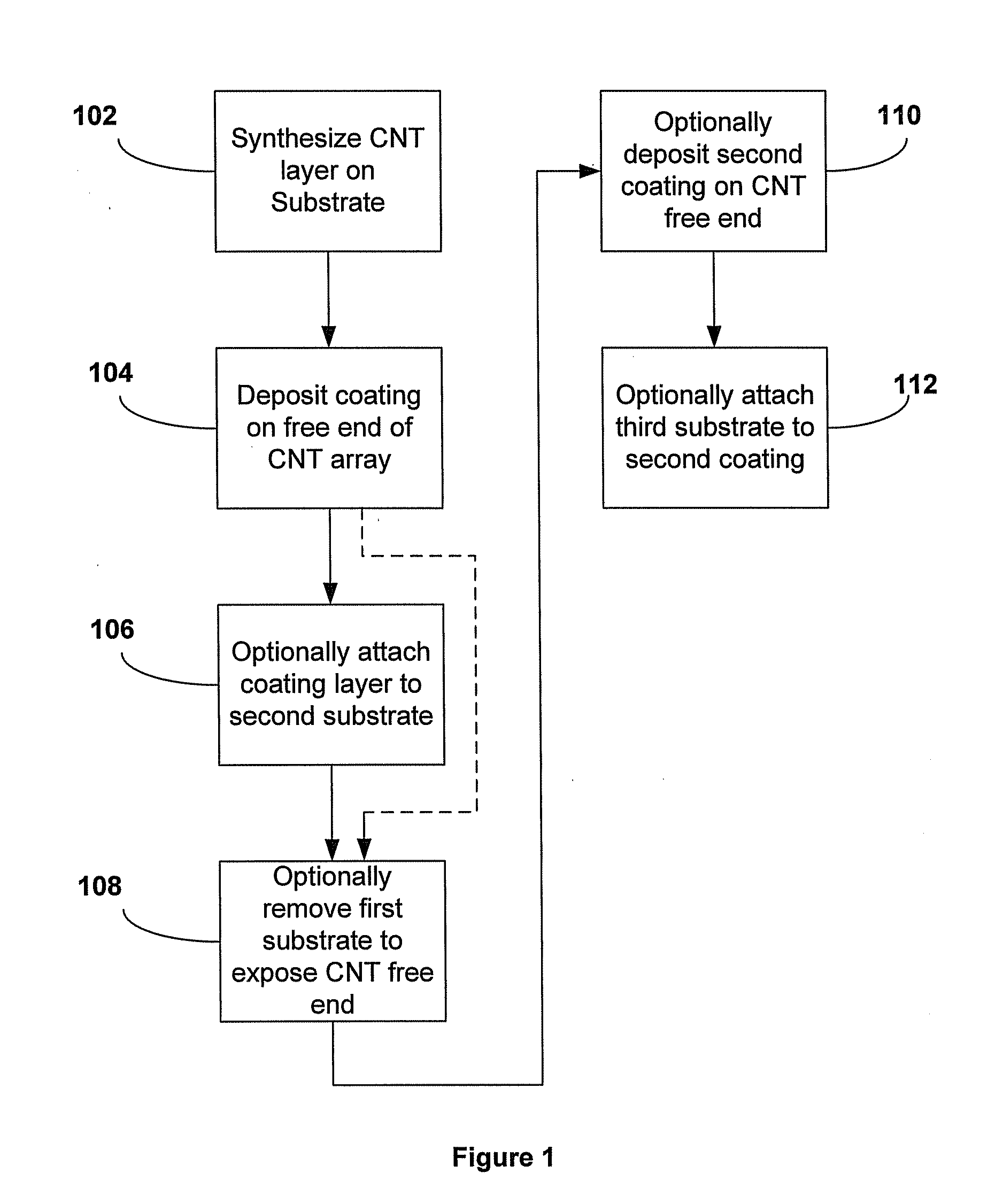

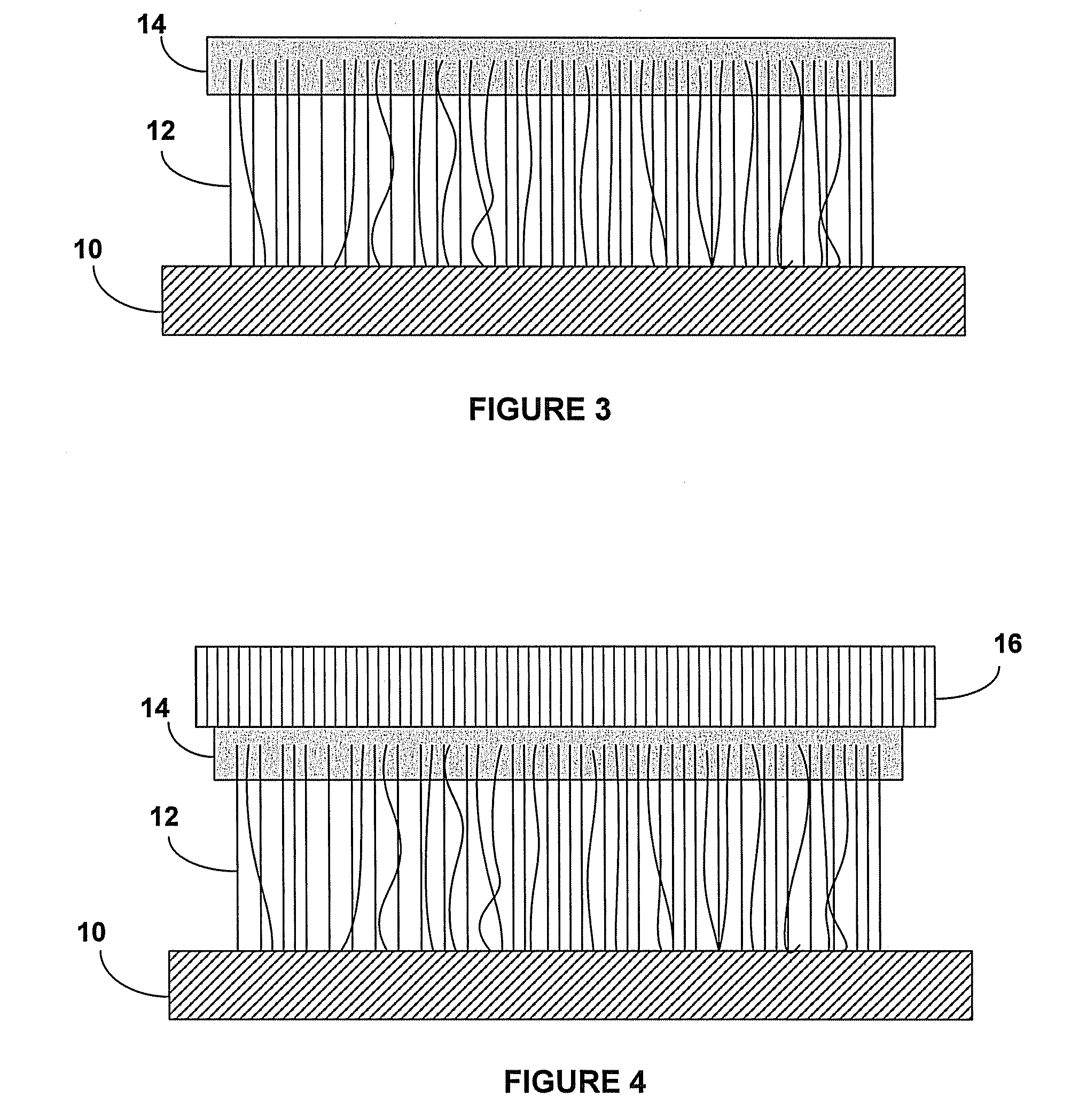

The invention relates to carbon nanotube arrays and methods for the preparation of carbon nanotube arrays. The carbon nanotube arrays include an aligned carbon nanotube array, wherein at least one of the ends of the carbon nanotube array includes a coating layer that is infused into the carbon nanotube array.

Owner:LOCKHEED MARTIN CORP

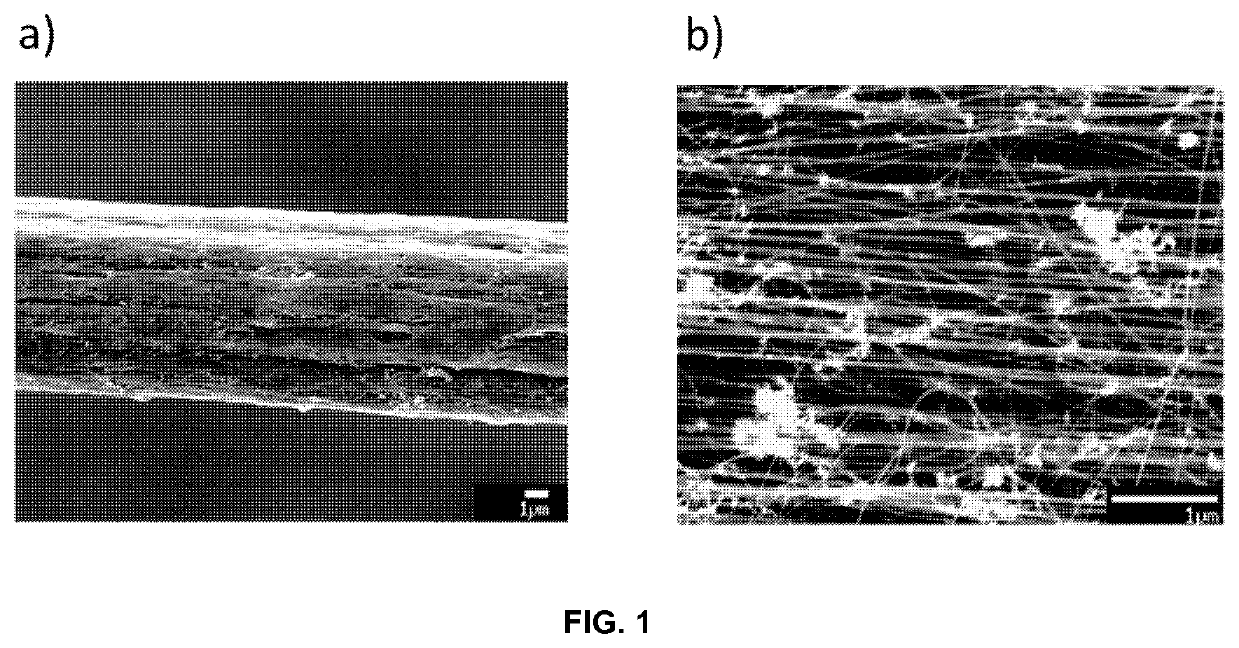

Carbon nanotube film structure and method for manufacturing the same

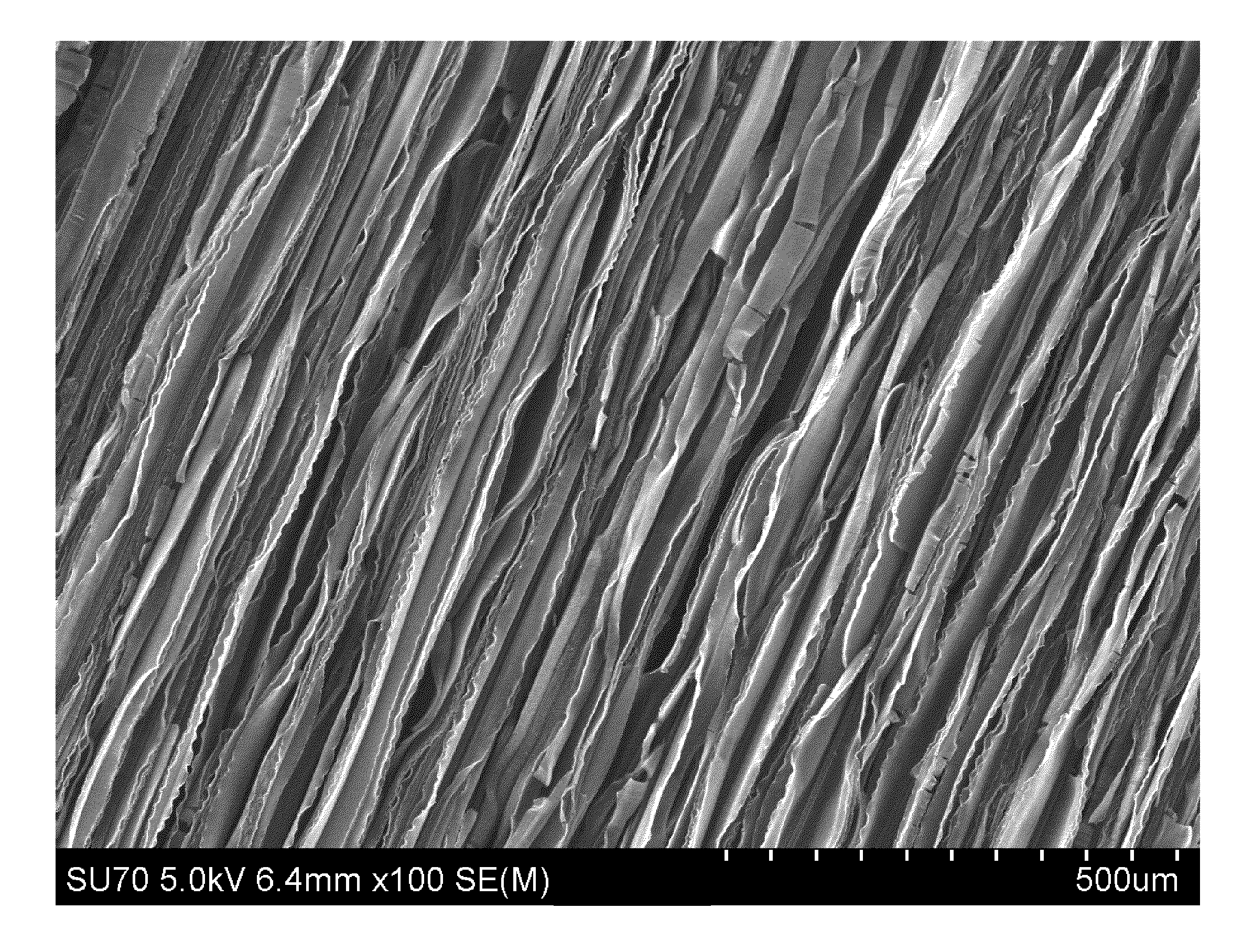

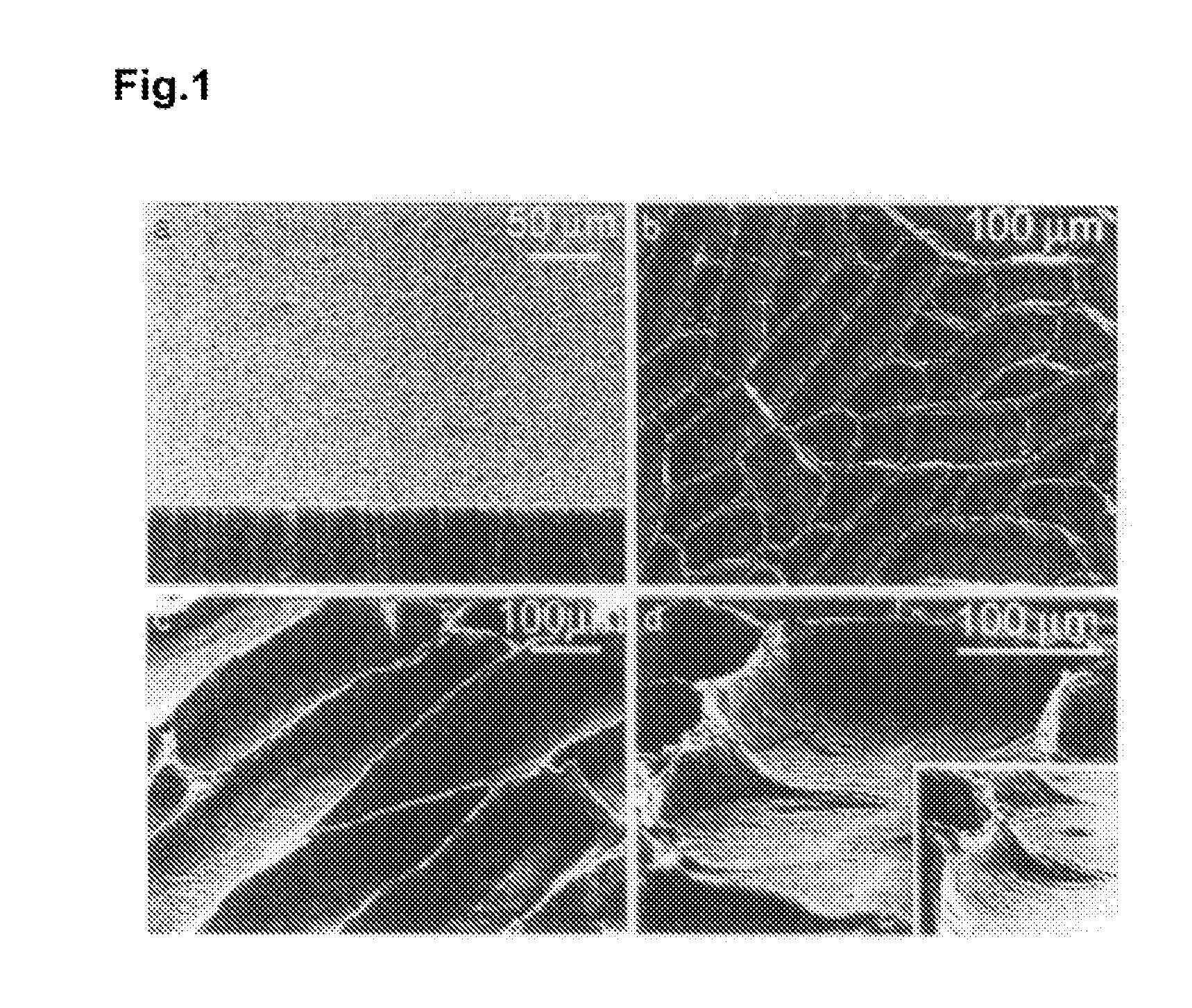

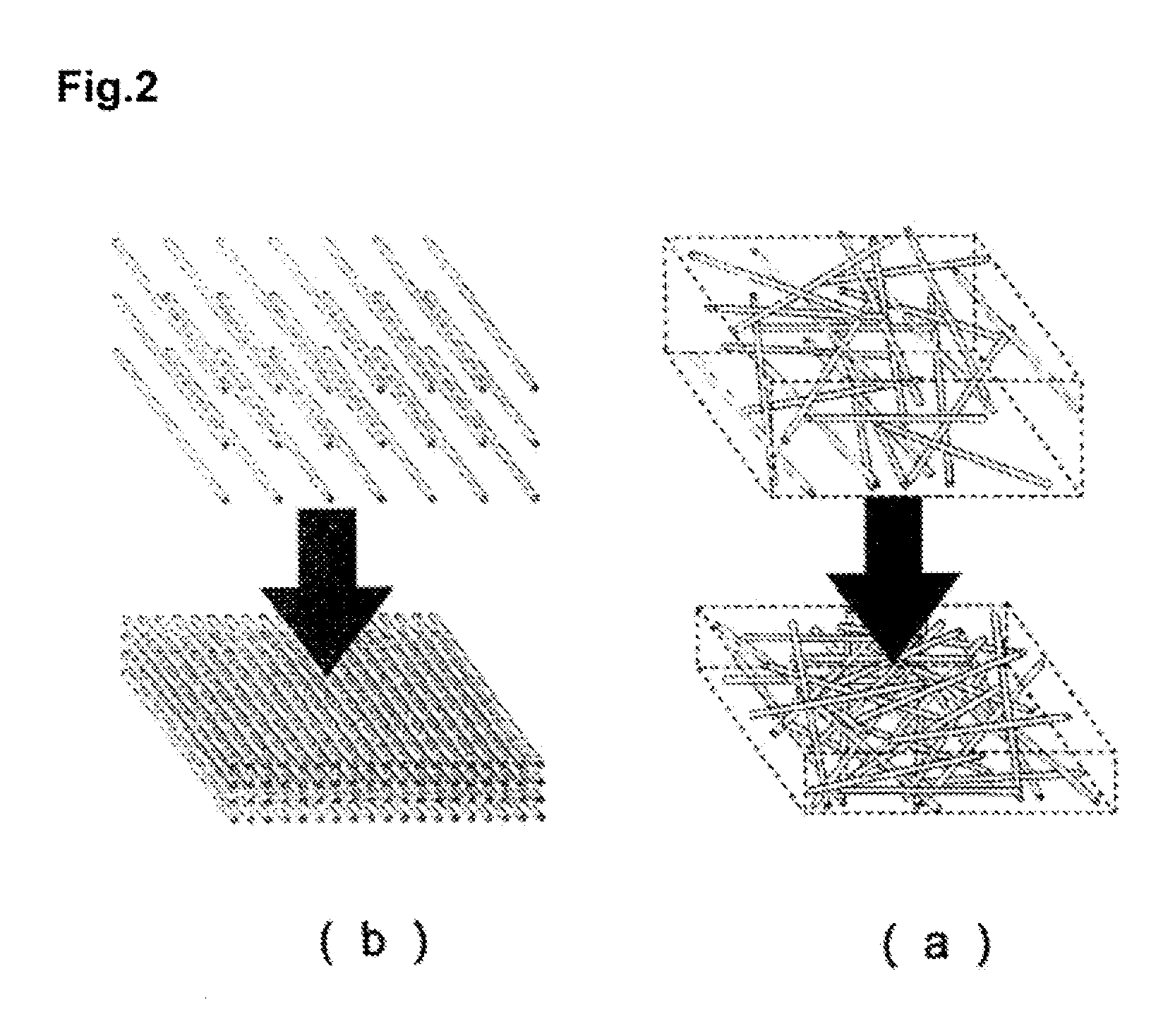

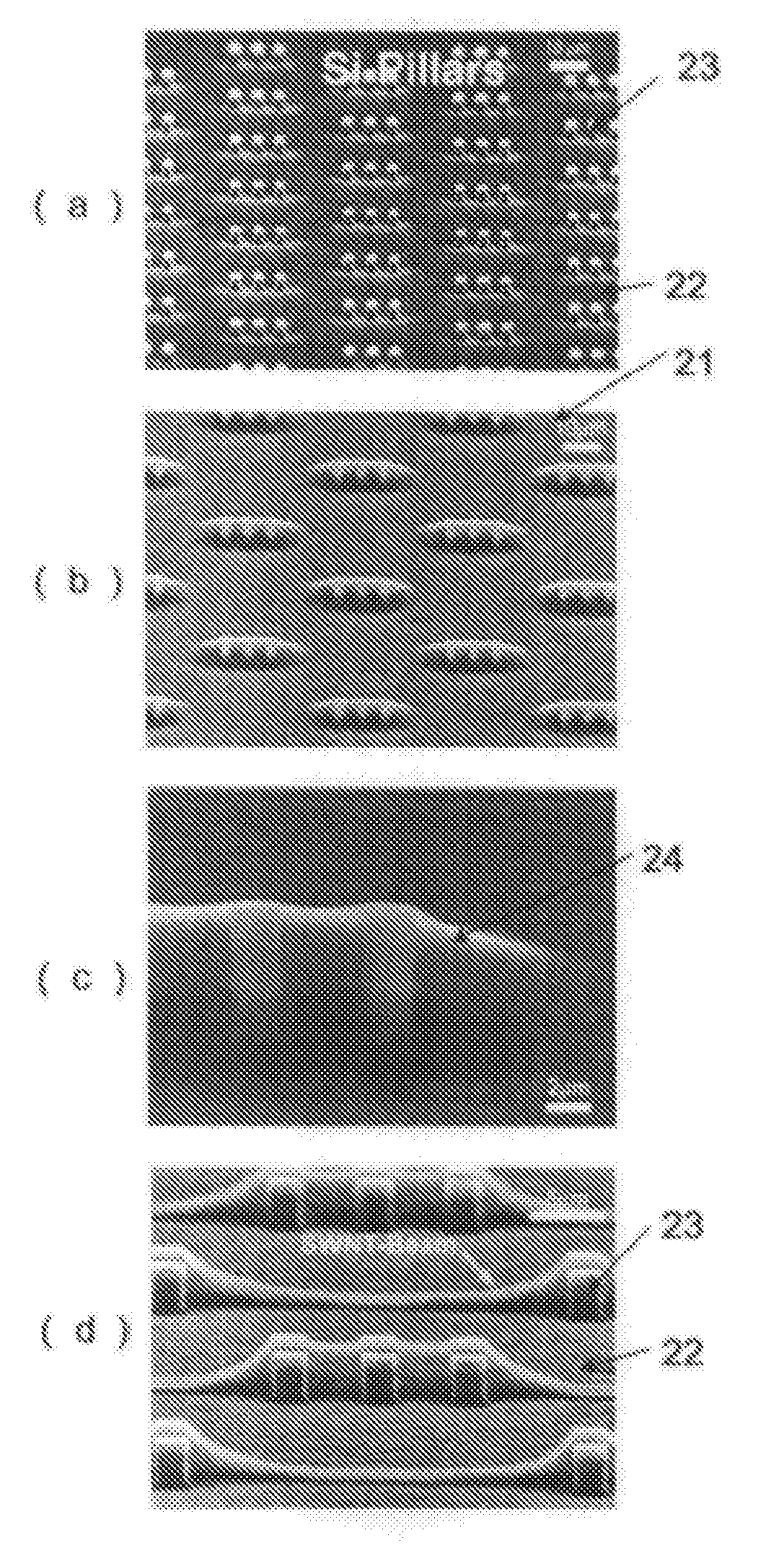

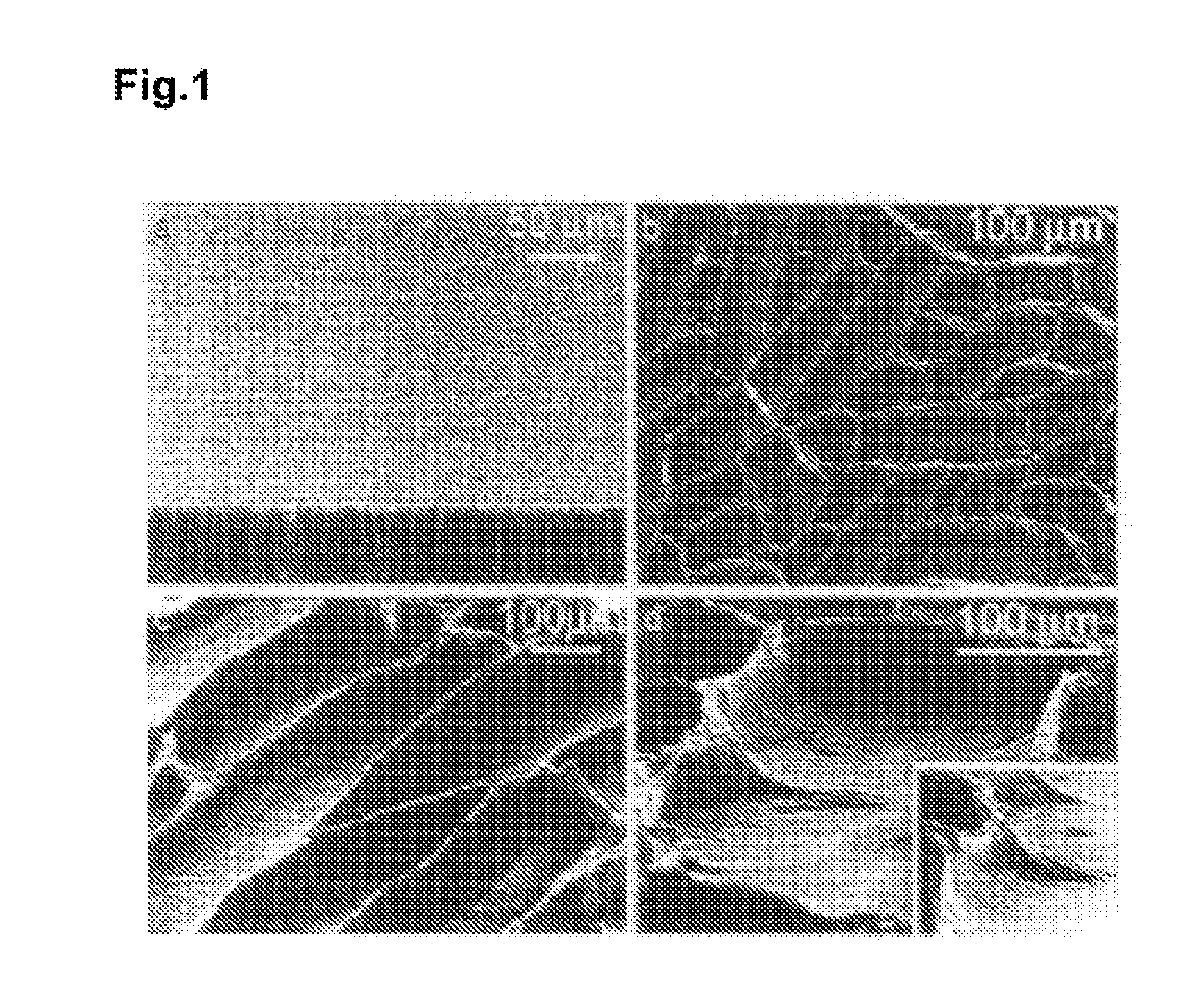

InactiveUS20110111177A1Quality improvementUniform thicknessMaterial nanotechnologyOrnamental structuresHigh densityCarbon nanotube

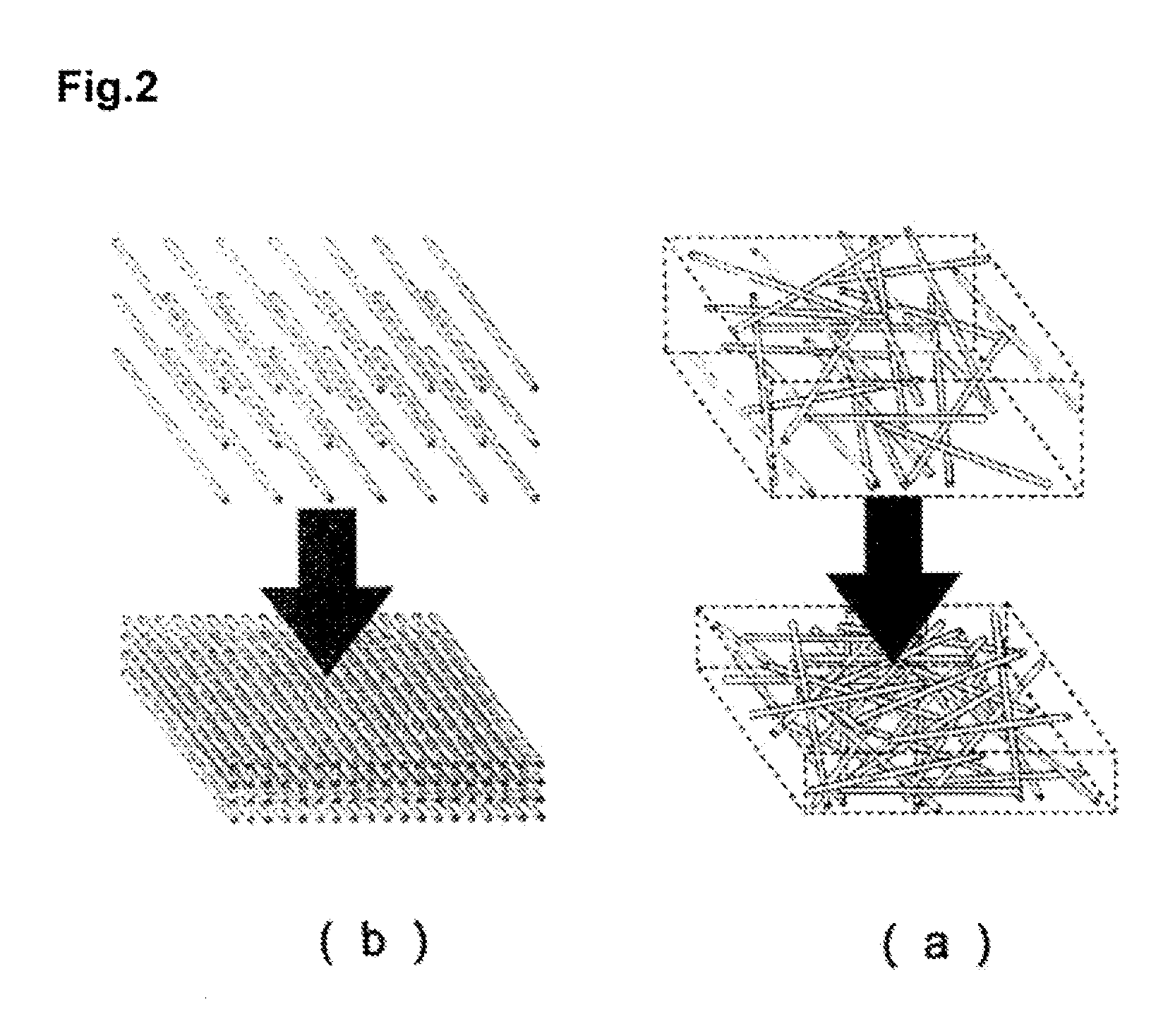

A method of producing a carbon nanotube film structure having a substrate and a carbon nanotube layer, comprises a placing step of placing a carbon nanotube film comprising a plurality of carbon nanotubes aligned in one direction within a film plane on the substrate; and a densifying step of applying a densifying treatment to the carbon nanotube film thereby forming the carbon nanotube layer having the weight density of the carbon nanotube to 0.1 g / cm3 or more. Thus, a problem of island-like shrinkage caused while a highly densified CNT layer is being manufactured is solved, and a high-quality CNT film structure wherein the aligned CNT layer having a high density and uniform thickness is deposited on the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

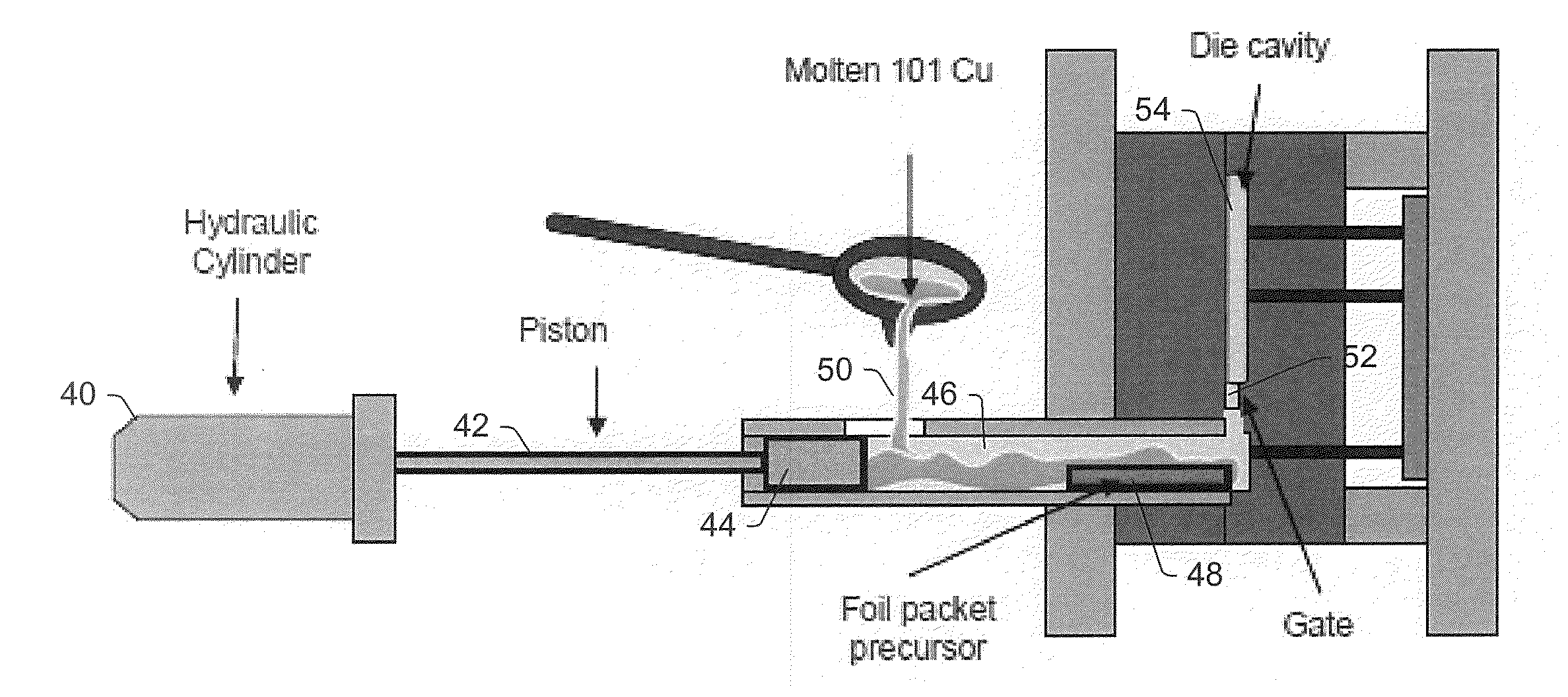

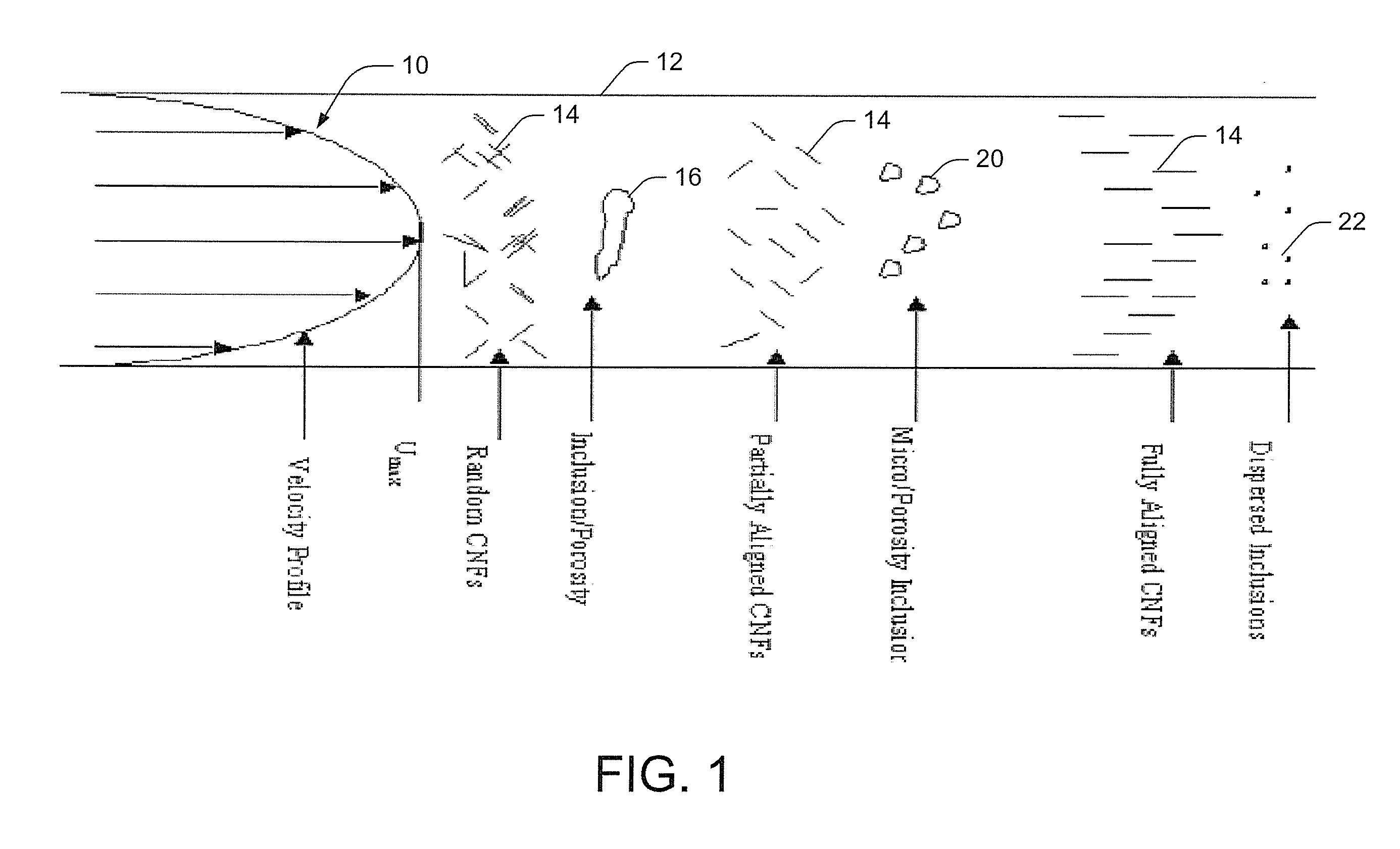

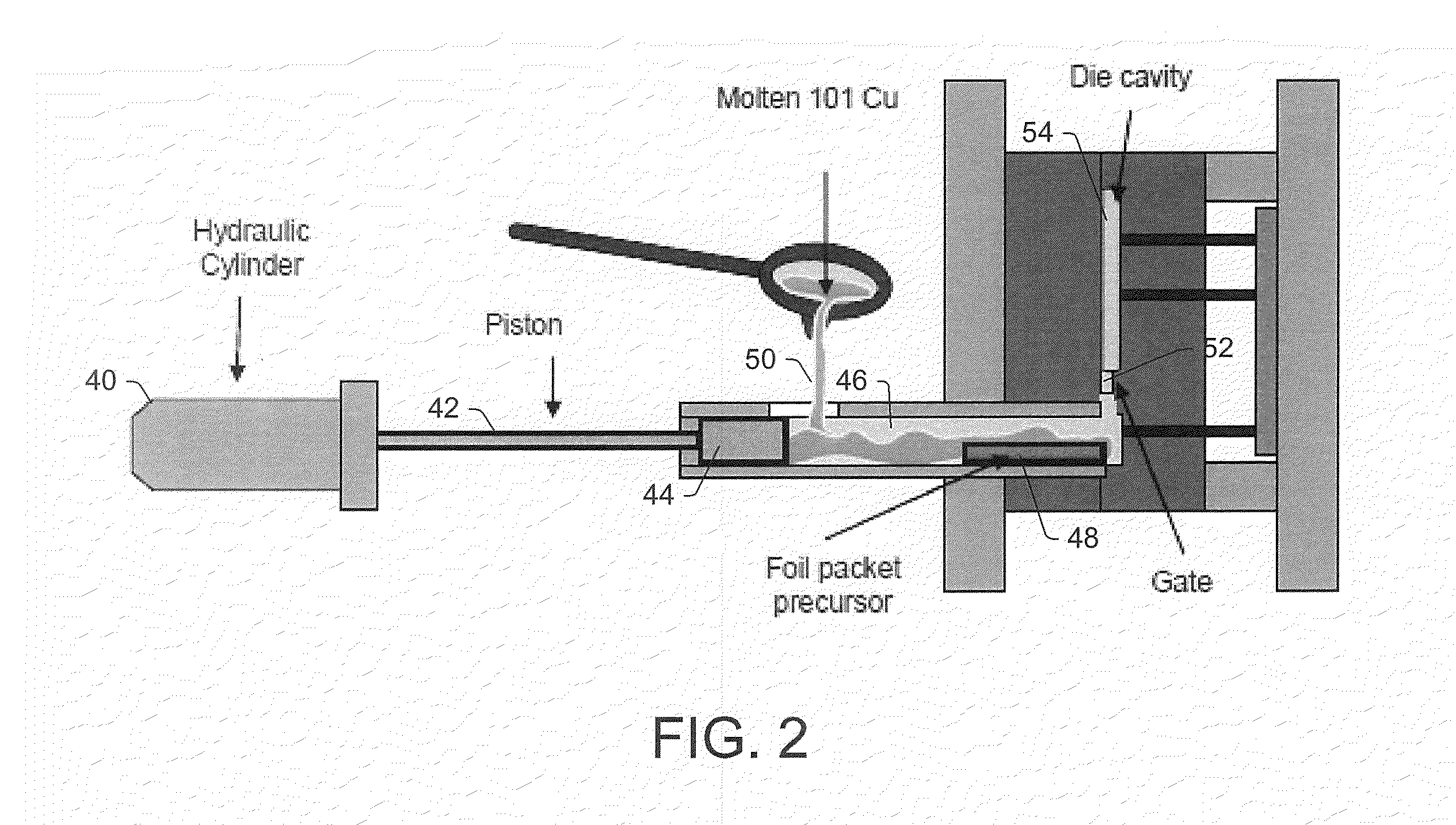

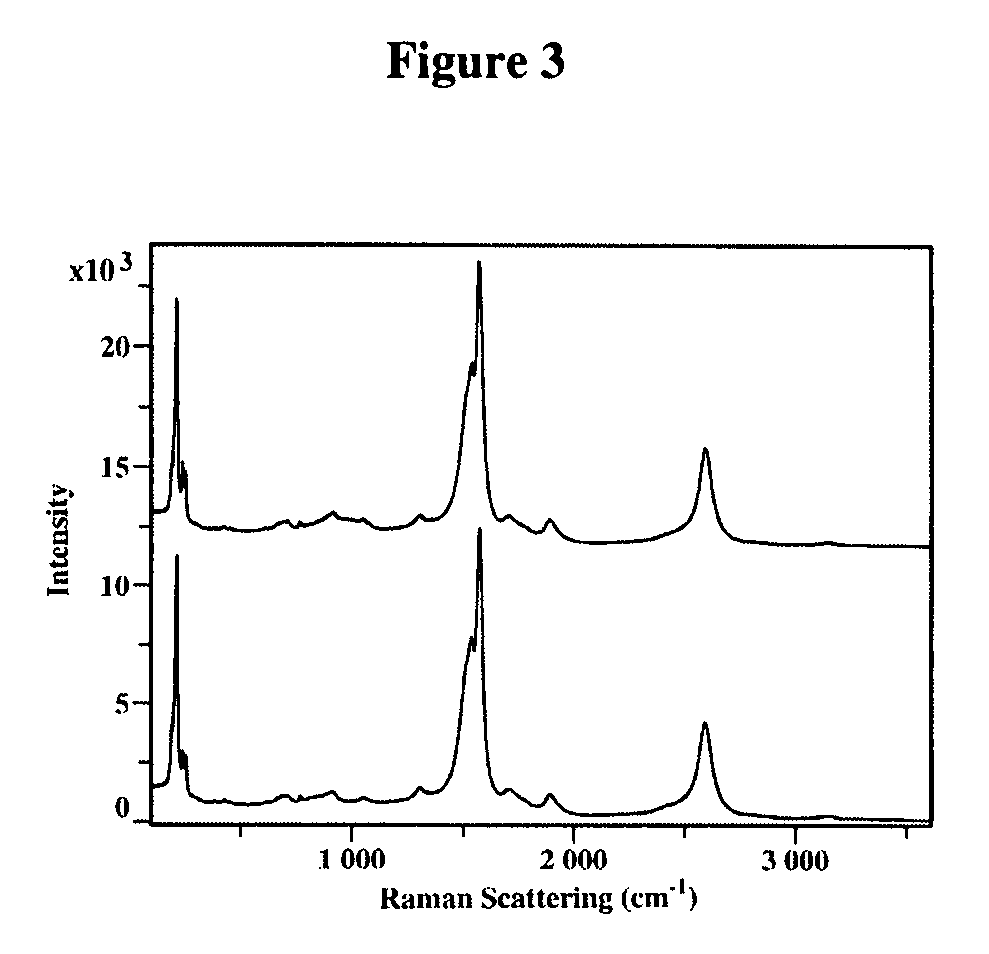

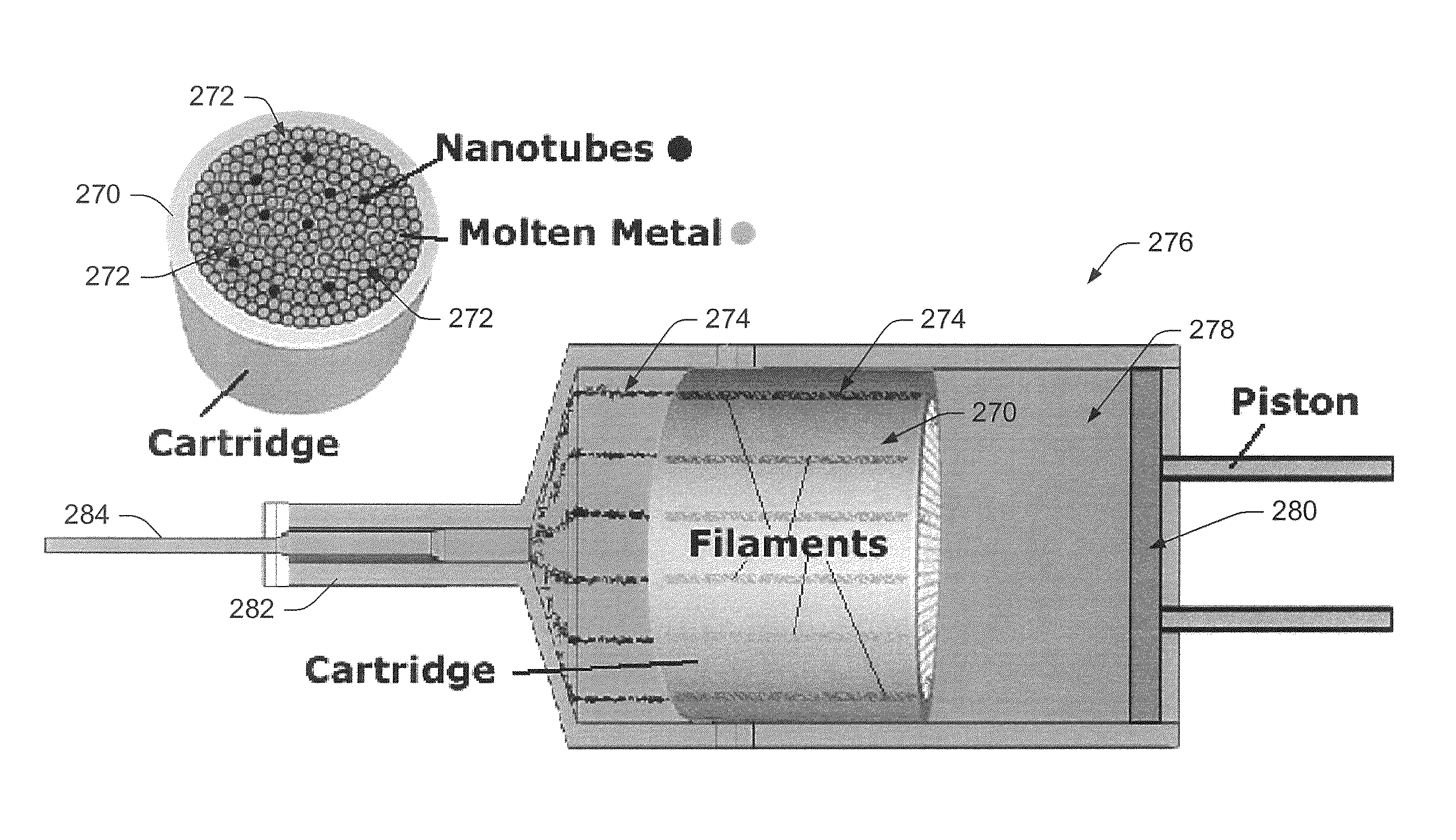

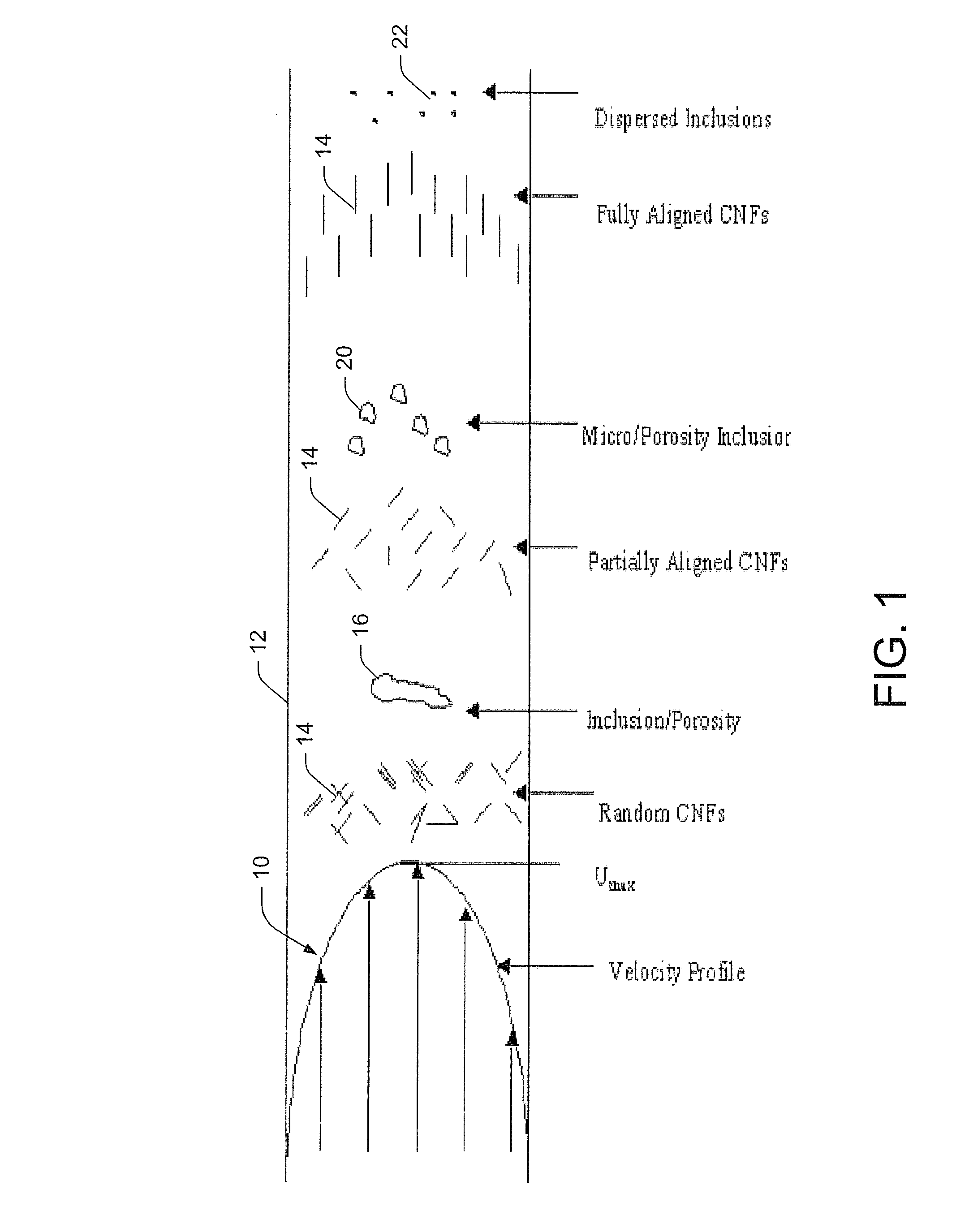

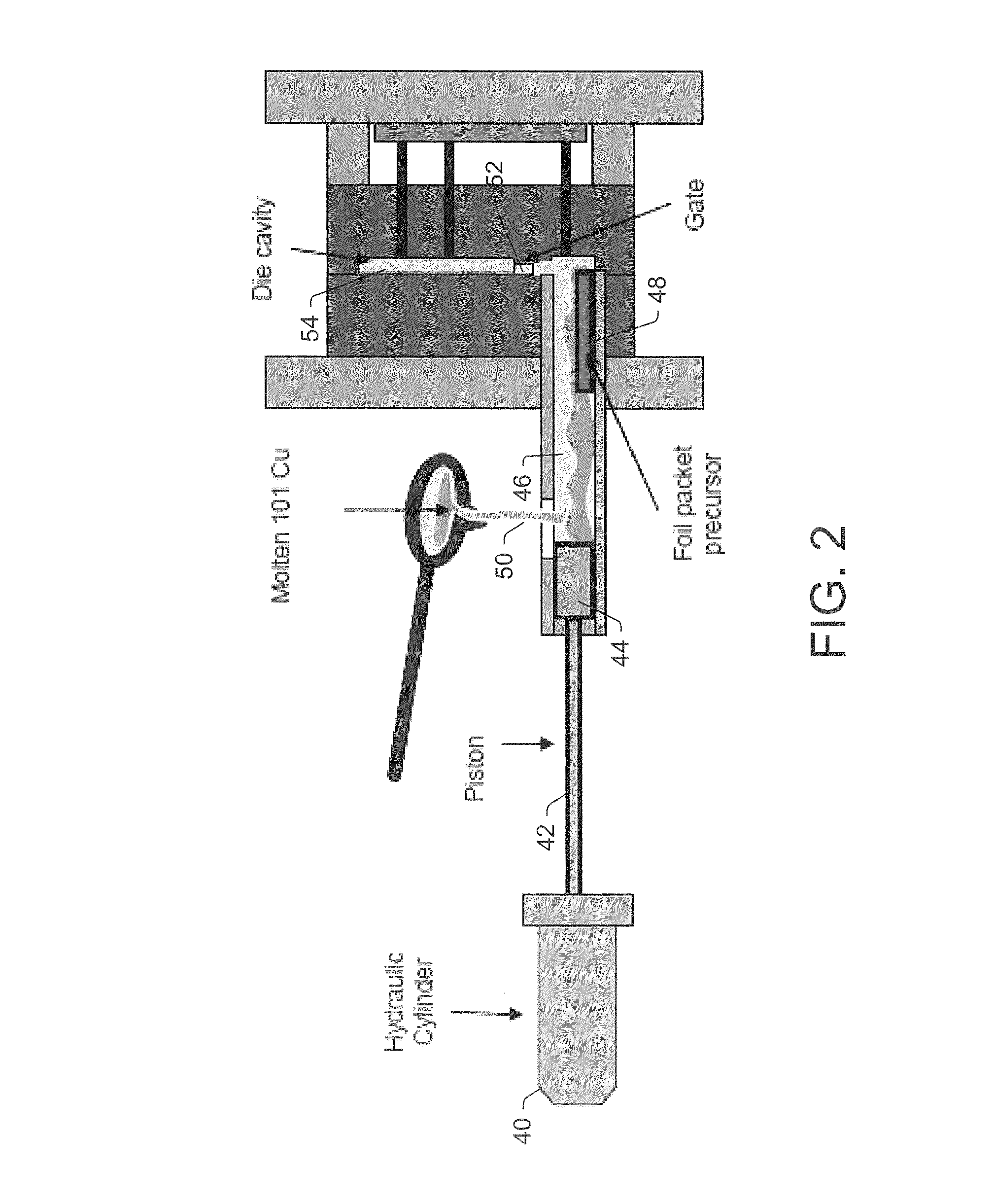

Nano-engineered ultra-conductive nanocomposite copper wire

Nano-composite structures are formed by pre-loading carbon nanotubes (CNTs) into at least one of a plurality of channels running the length of a cartridge, placing the pre-loaded cartridge in a piston chamber of a die-casting machine, creating a vacuum therein, and filing the piston chamber with molten metal to soak the pre-loaded cartridge and fill empty cartridge channels. Pressure is applied via the piston to eject the carbon nanotubes and molten metal from the cartridge channels and inject the nano-composite mixture into a rod-shaped die cavity. The internal diameter of the cavity is equal to or less than the final diameter of the nozzle. The nano-composite mixture is cooled to form a solid nano-composite rod having the first predetermined diameter, wherein the carbon nanotubes are aligned in a non-random manner. Furthermore, drawing down the nano-composite rod to smaller diameter wire further disperses the nanotubes along the length of the wire.

Owner:CLEVELAND STATE UNIVERSITY

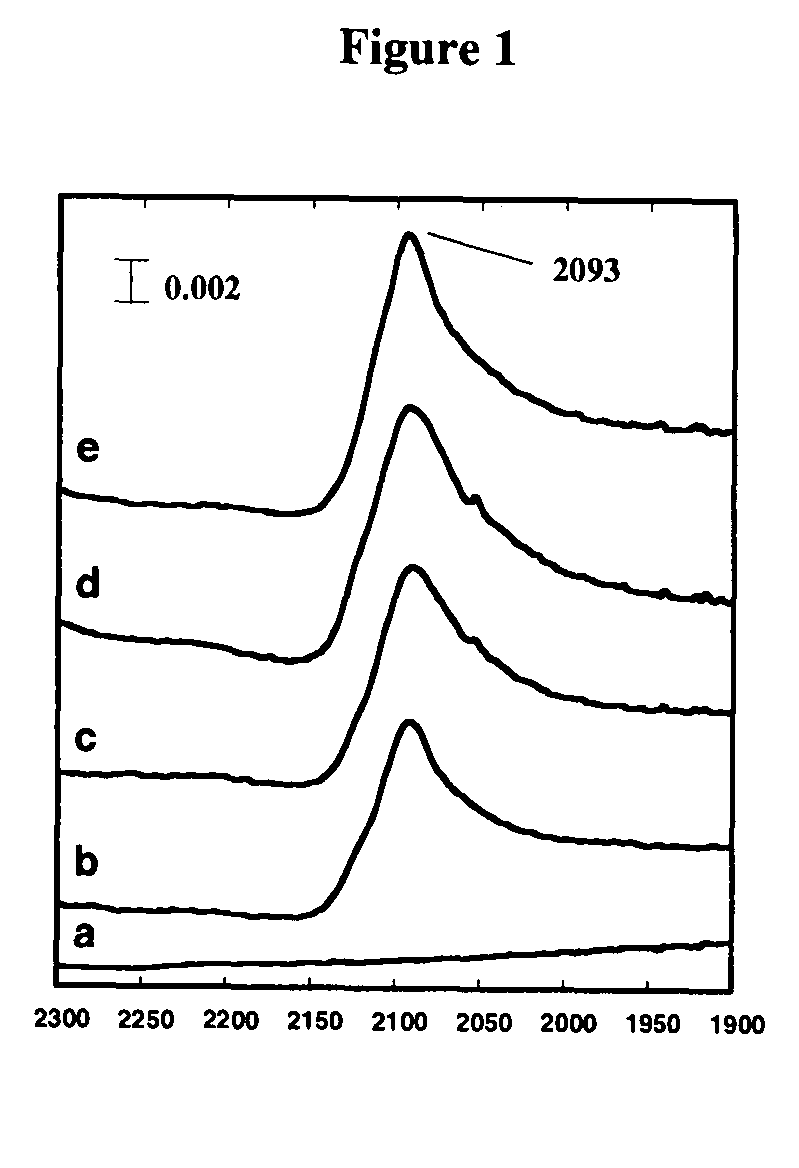

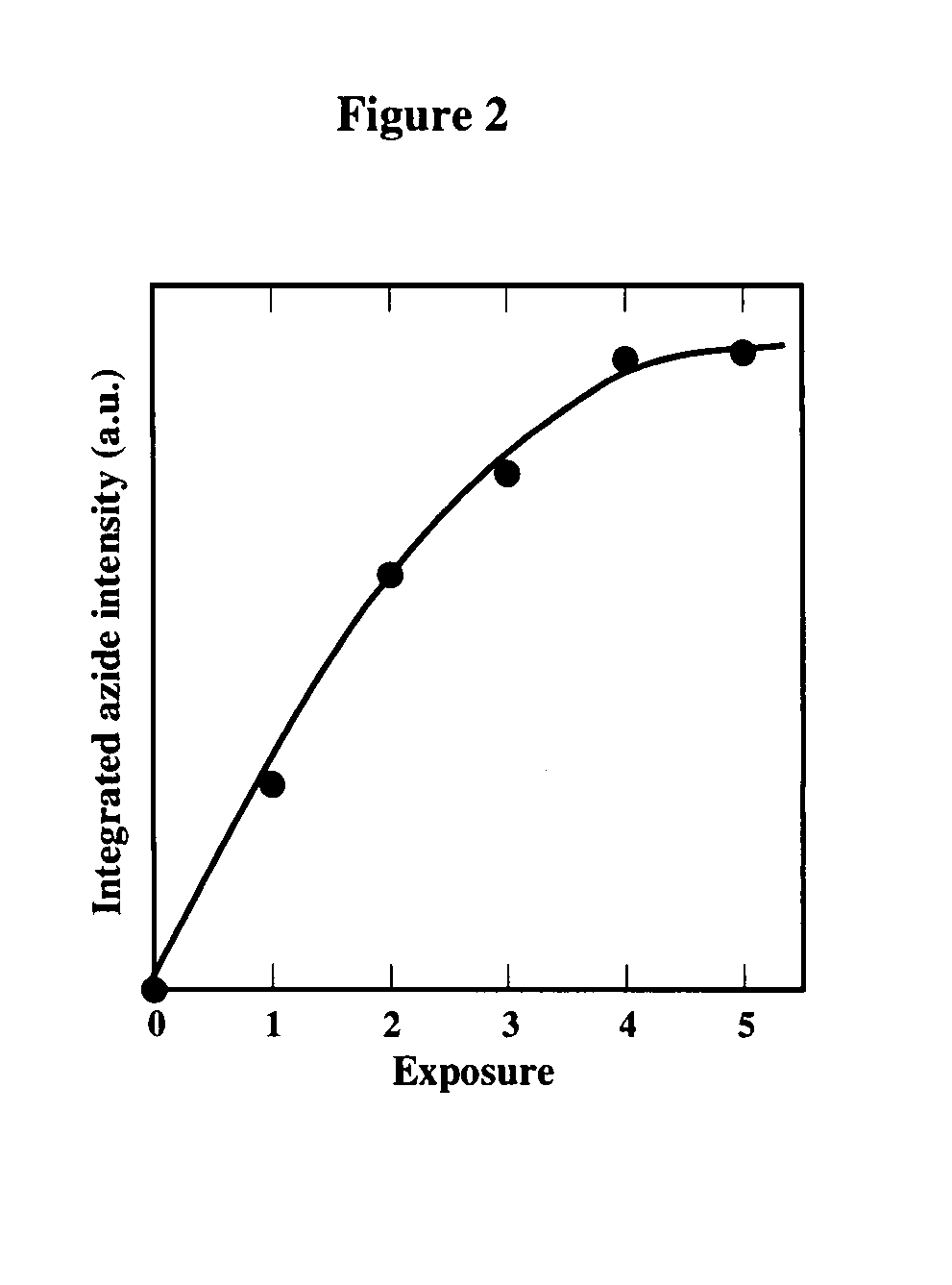

Single walled carbon nanotubes activated with hydrazoic acid

InactiveUS7879166B1Metal azide explosive compositionsMaterial nanotechnologyActivated carbonHydrazoic acid

The present invention relates generally to carbon nanotubes, and more particularly to the interaction of single wall carbon nanotubes with hydrazoic acid to introduce energetic azide groups into the nanotubes to form activated carbon nanotubes.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Nano-engineered ultra-conductive nanocomposite copper wire

Nano-composite structures are formed by pre-loading carbon nanotubes (CNTs) into at least one of a plurality of channels running the length of a cartridge, placing the pre-loaded cartridge in a piston chamber of a die-casting machine, creating a vacuum therein, and filing the piston chamber with molten metal to soak the pre-loaded cartridge and fill empty cartridge channels. Pressure is applied via the piston to eject the carbon nanotubes and molten metal from the cartridge channels and inject the nano-composite mixture into a rod-shaped die cavity. The internal diameter of the cavity is equal to or less than the final diameter of the nozzle. The nano-composite mixture is cooled to form a solid nano-composite rod having the first predetermined diameter, wherein the carbon nanotubes are aligned in a non-random manner. Furthermore, drawing down the nano-composite rod to smaller diameter wire further disperses the nanotubes along the length of the wire.

Owner:CLEVELAND STATE UNIVERSITY

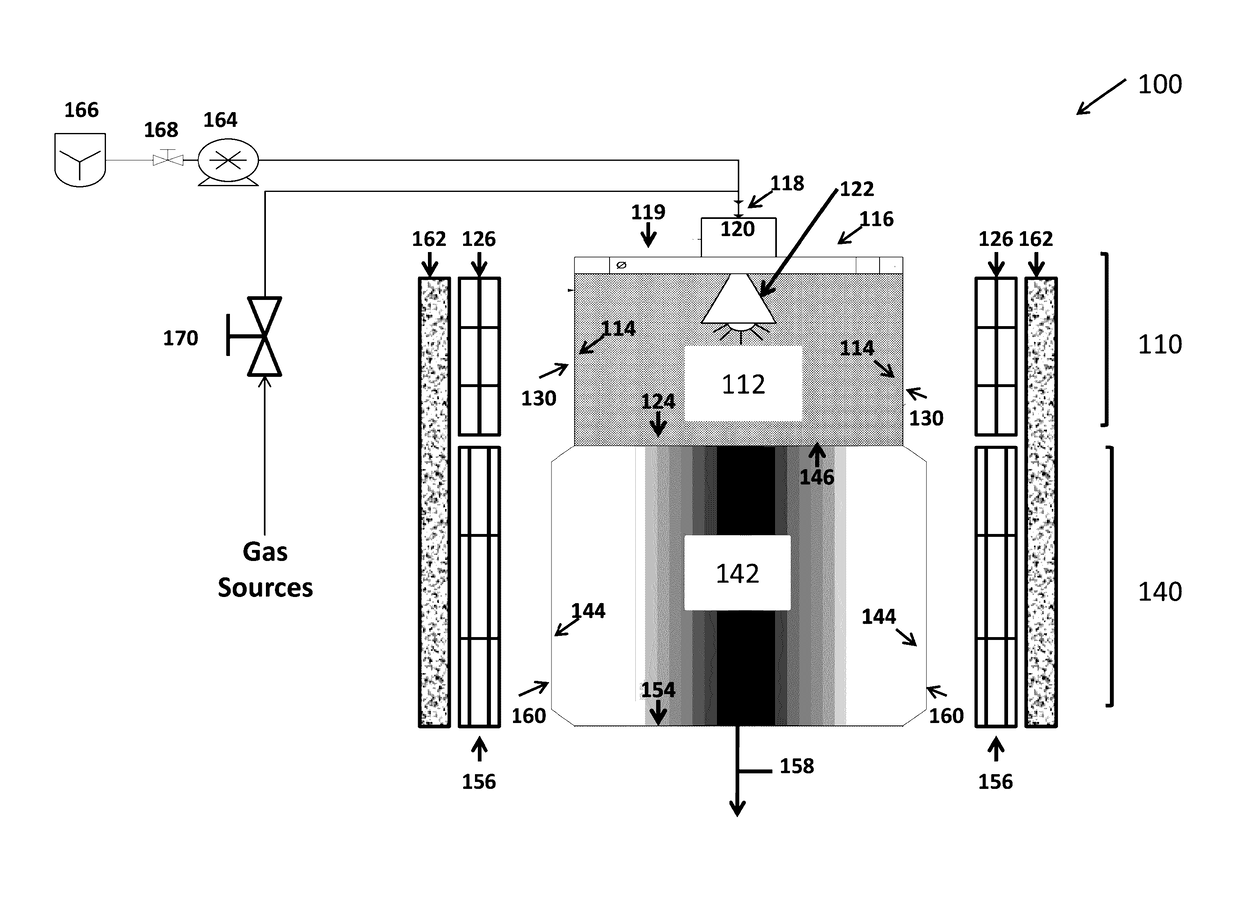

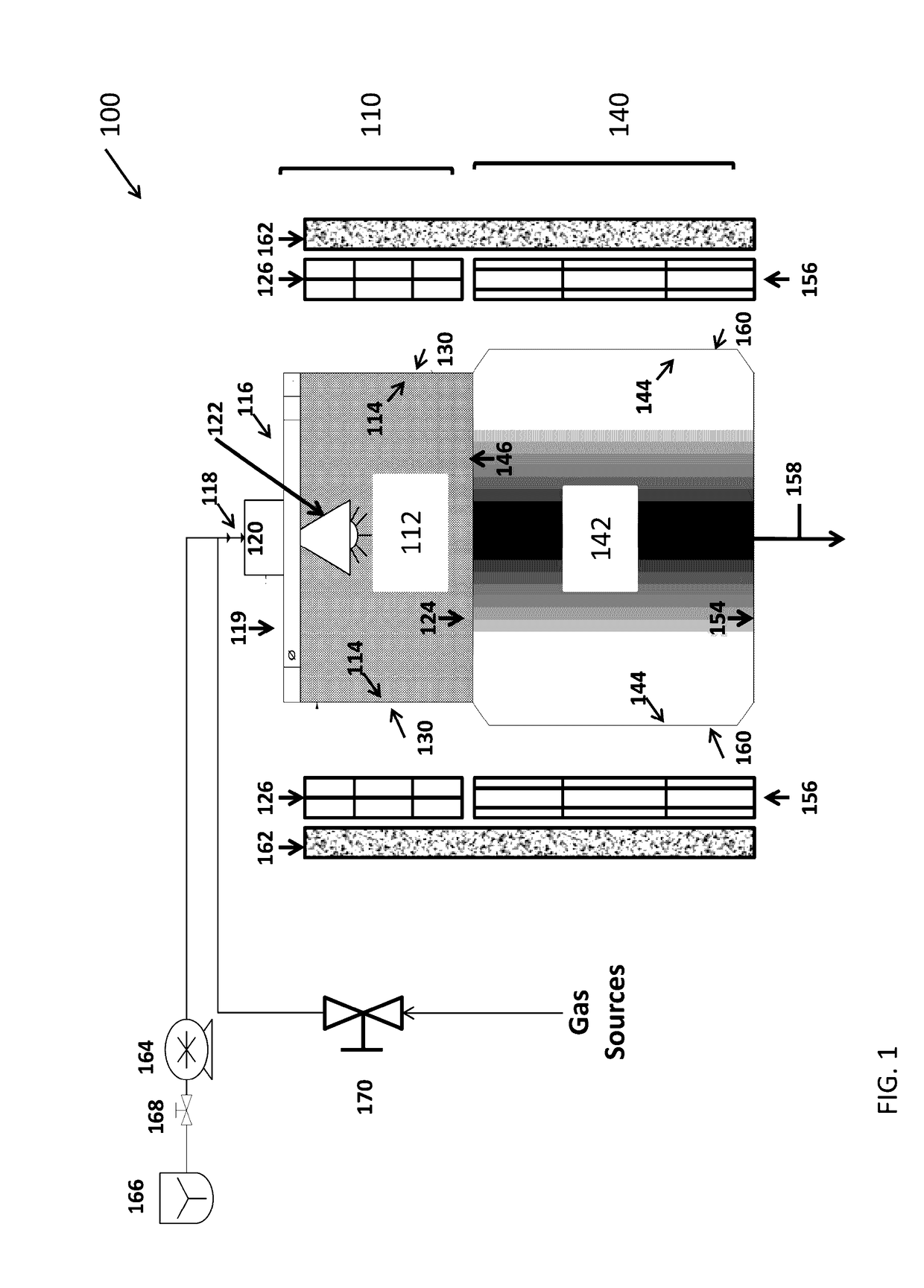

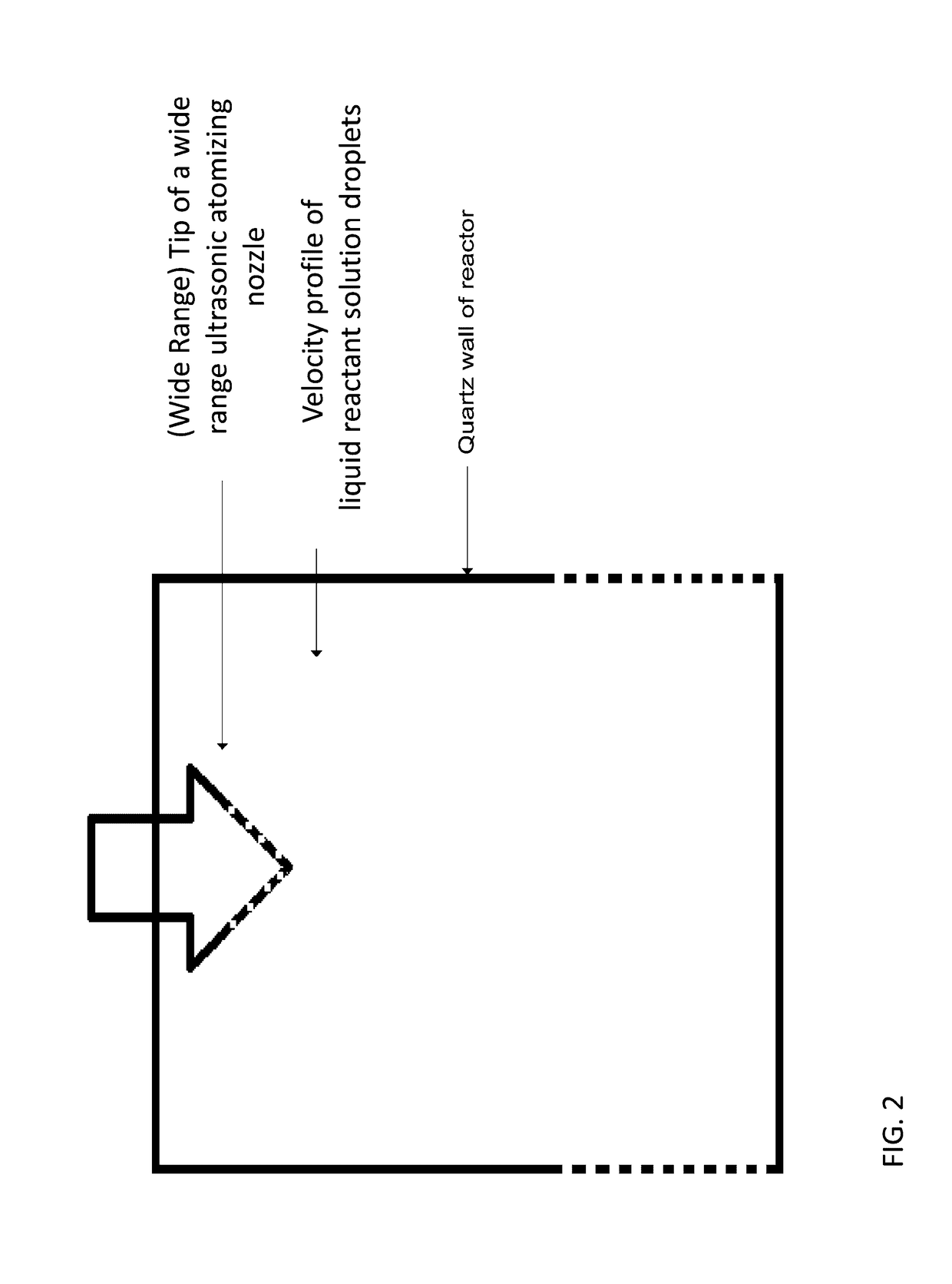

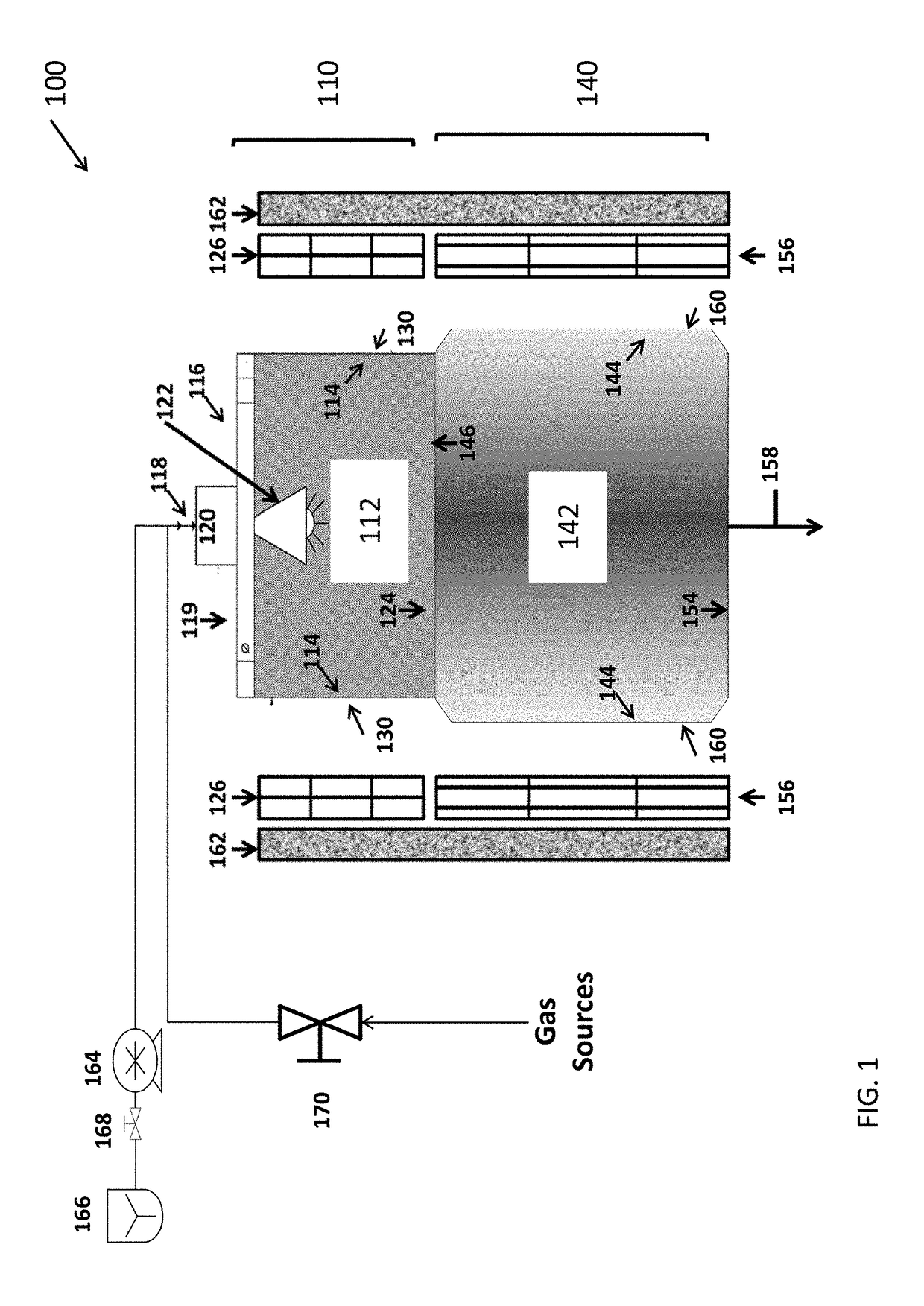

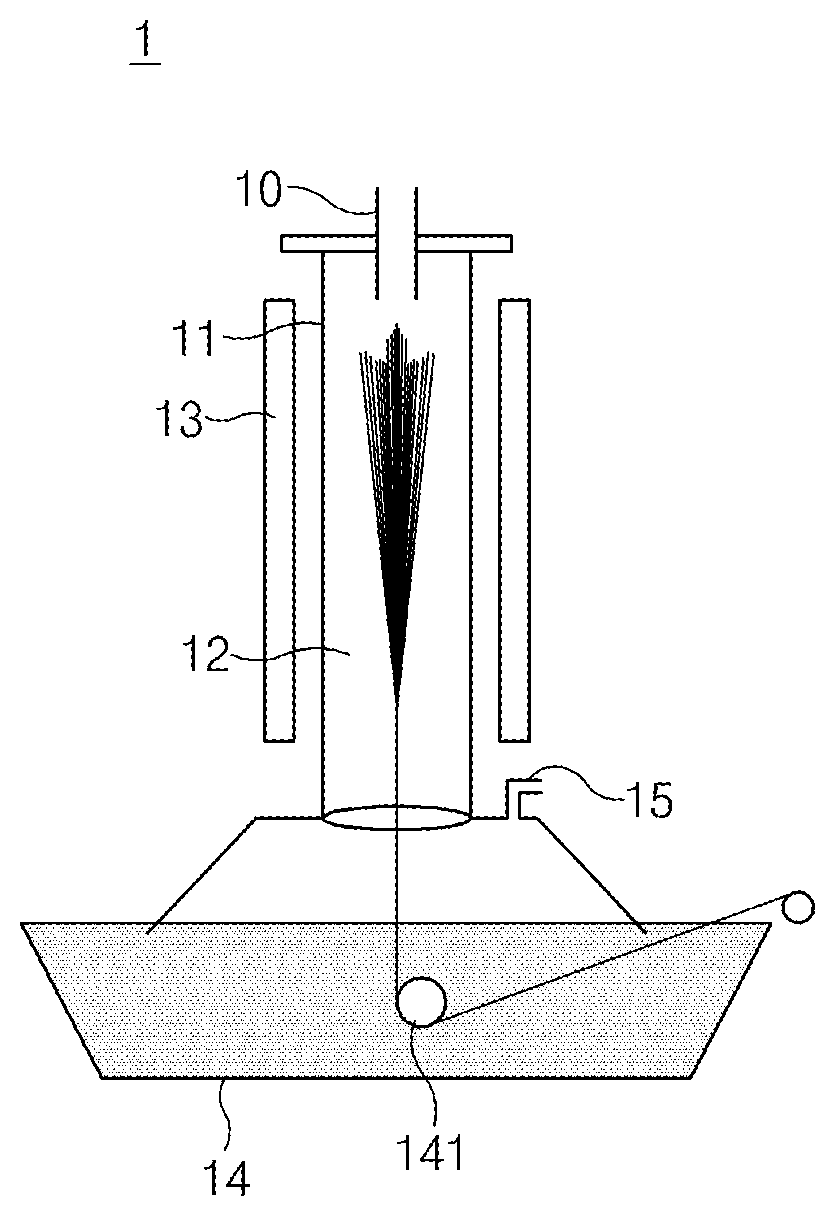

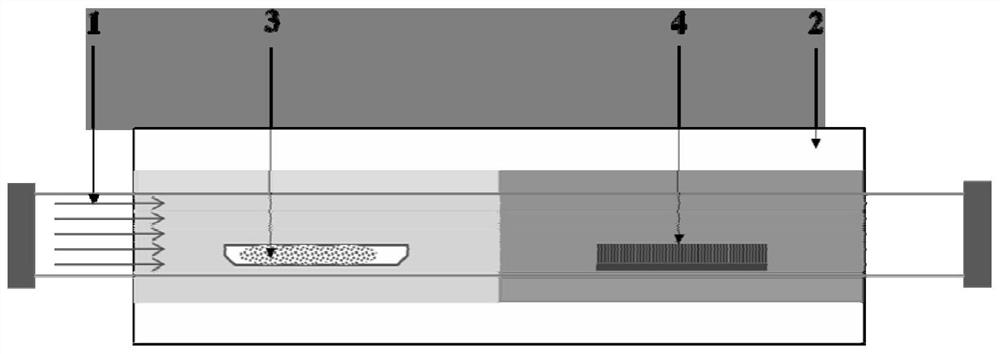

Reactor and method for synthesizing metal oxide impregnated carbon nanotubes

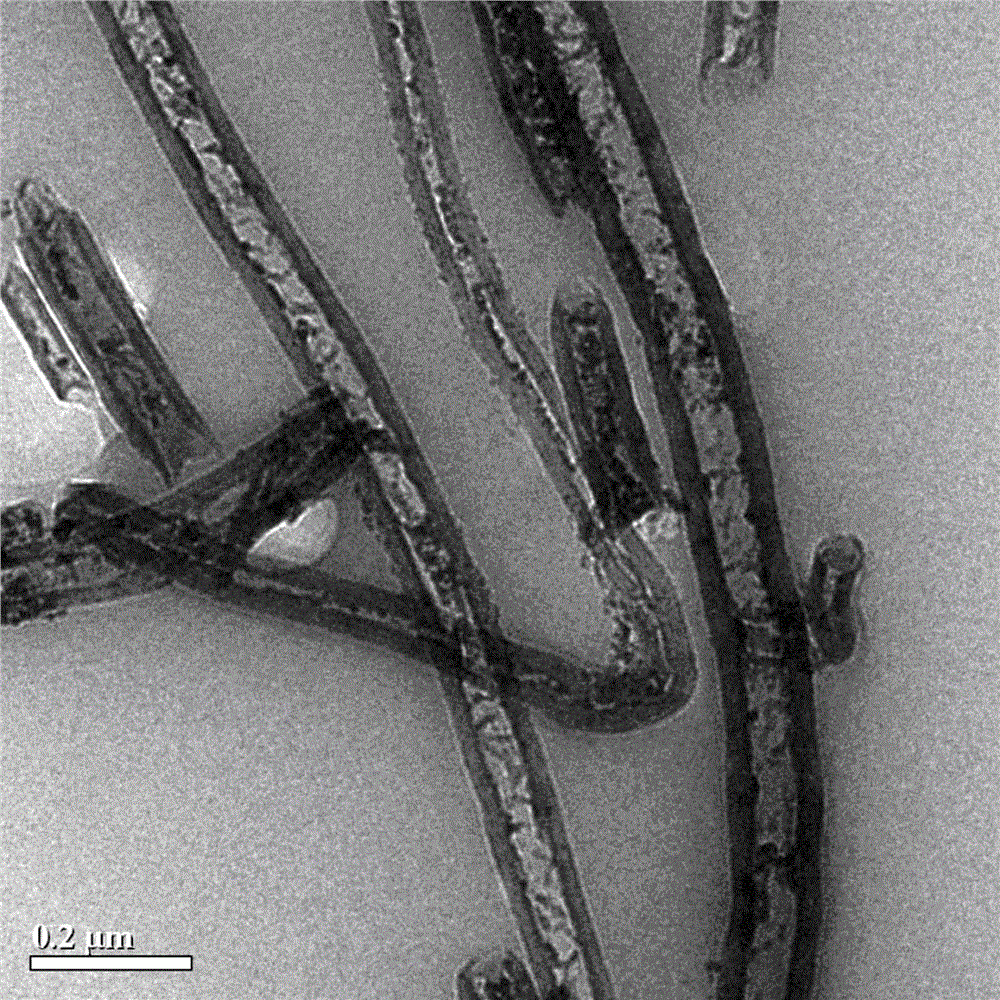

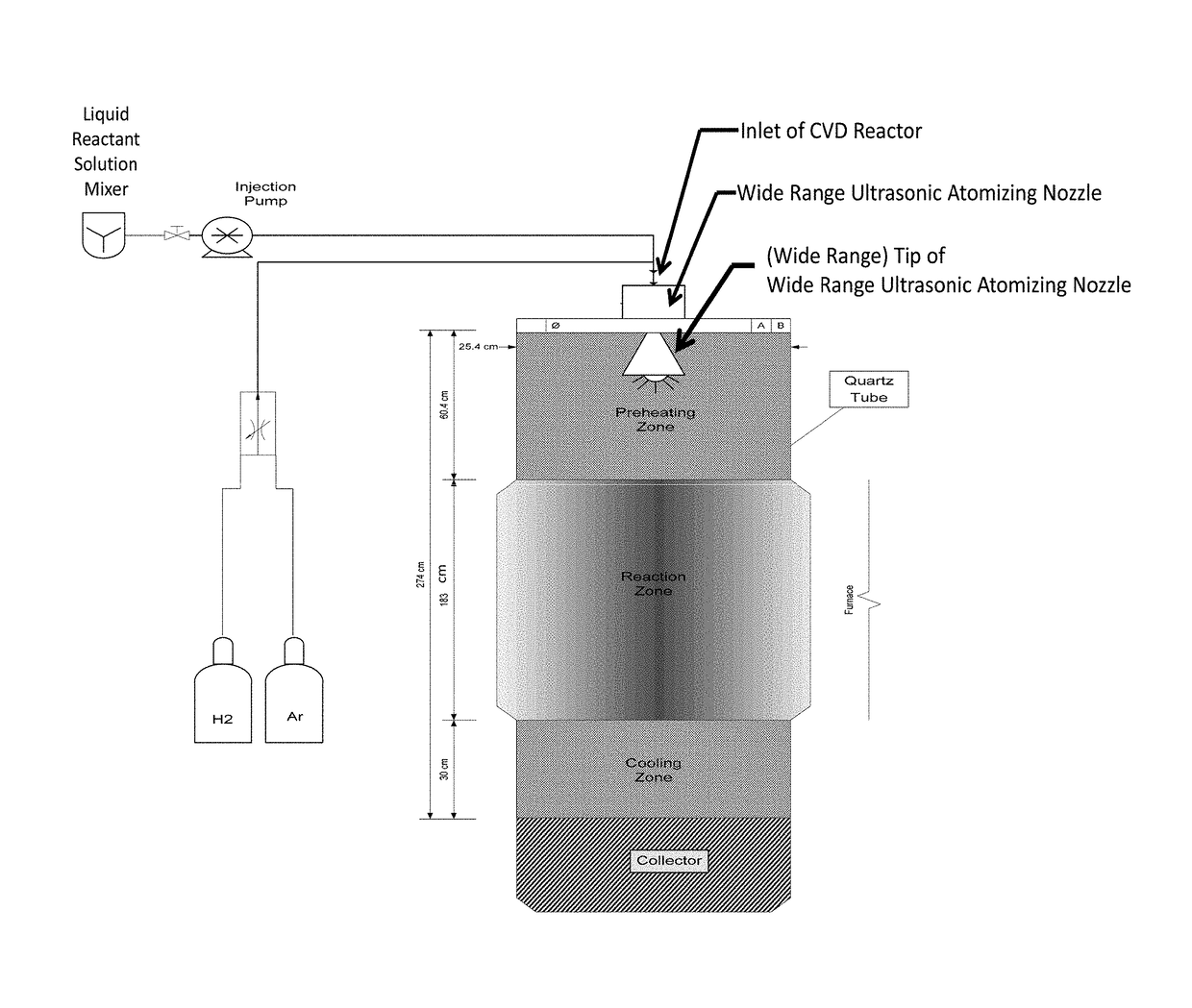

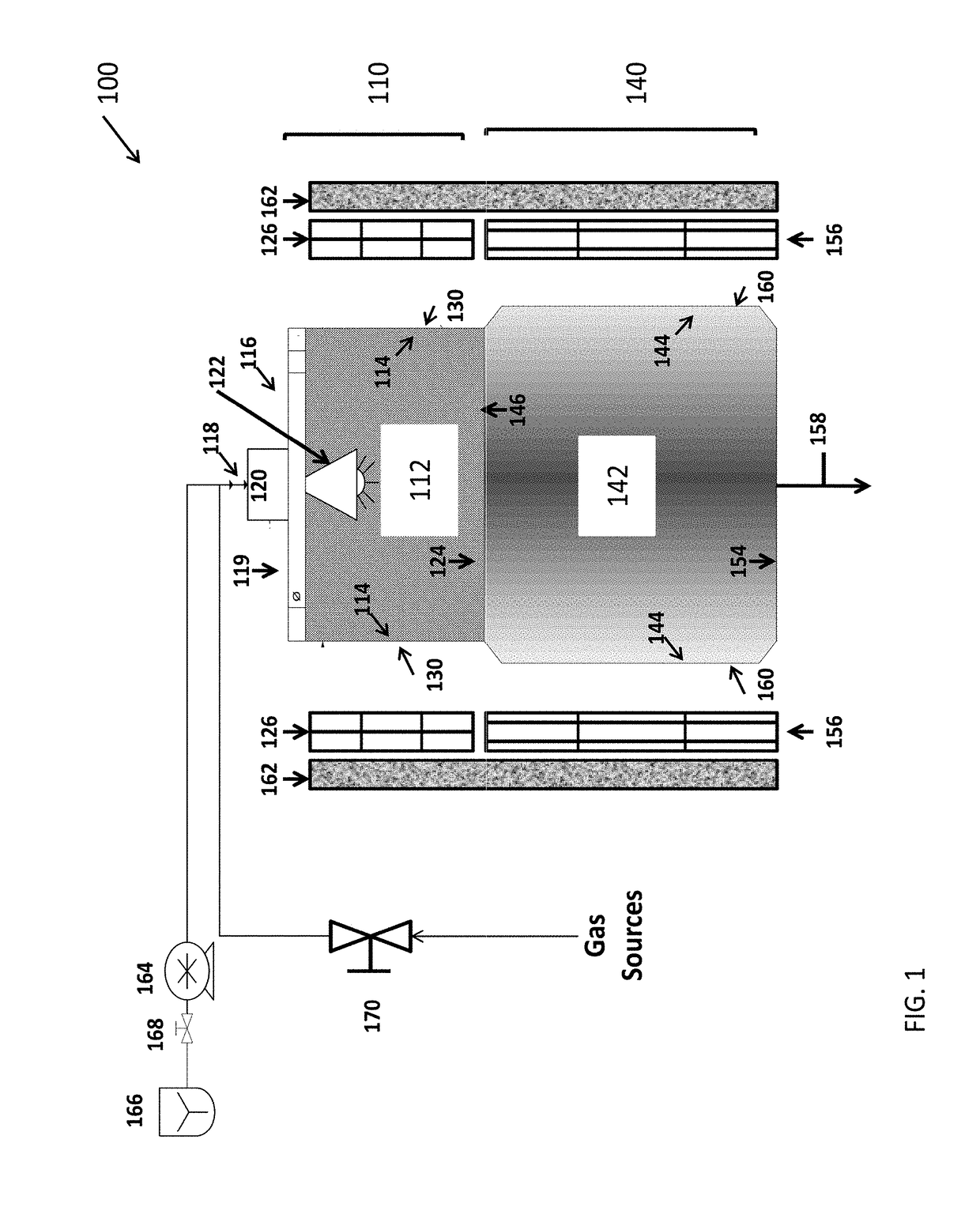

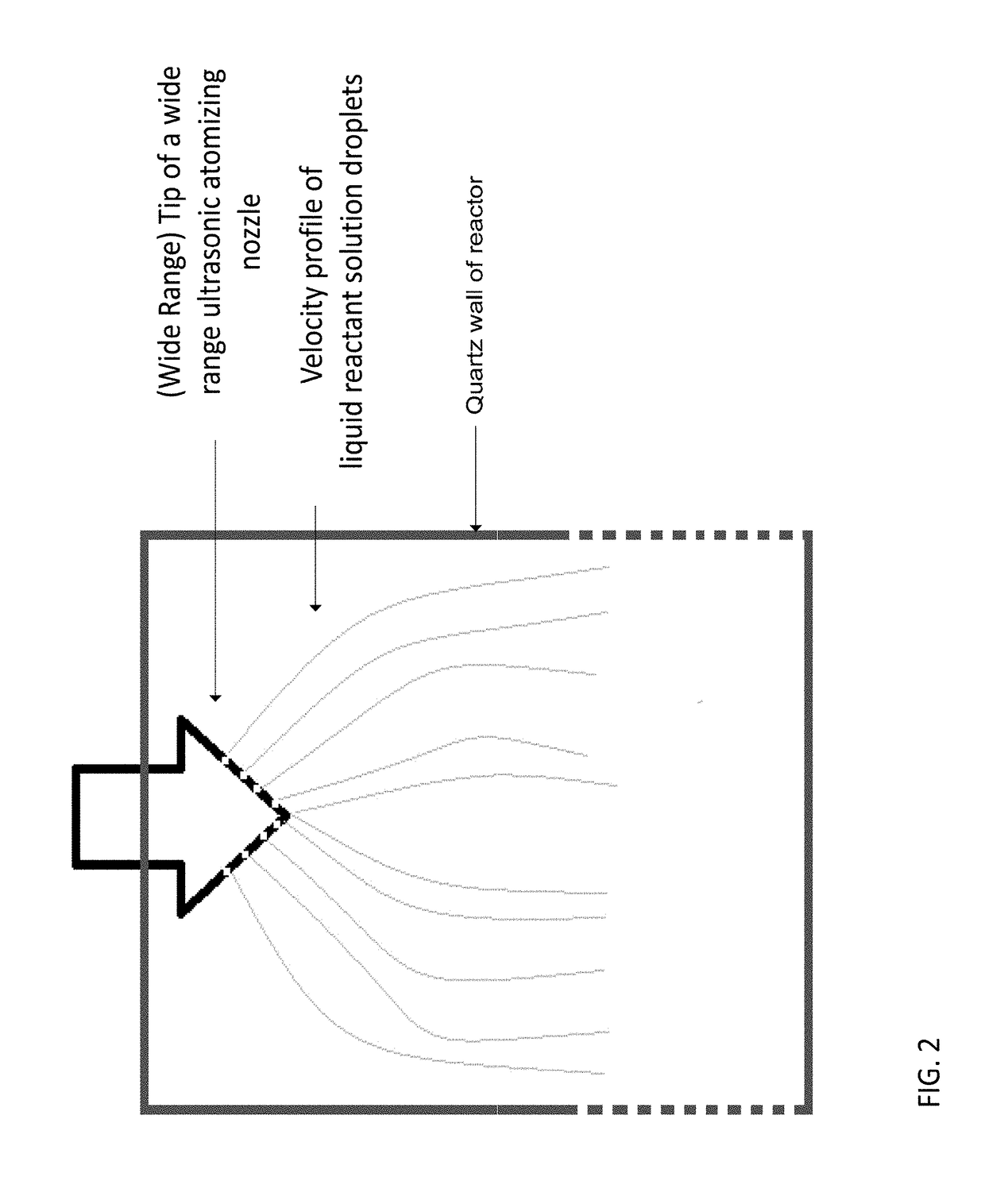

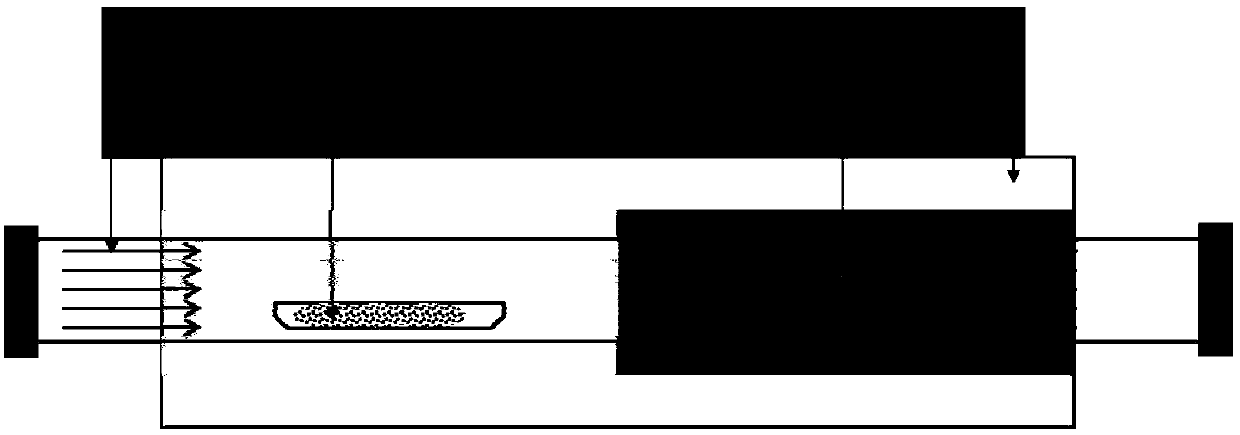

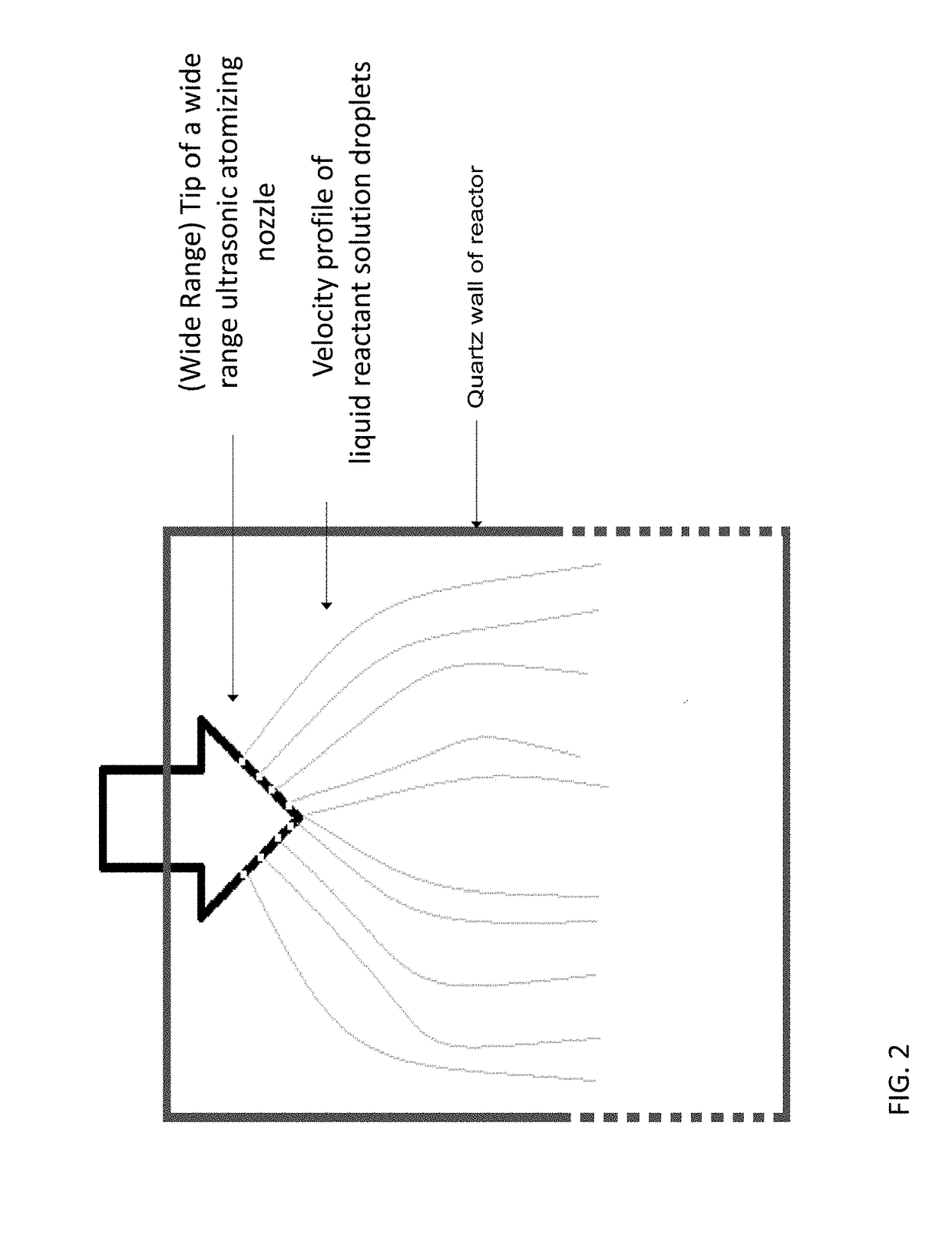

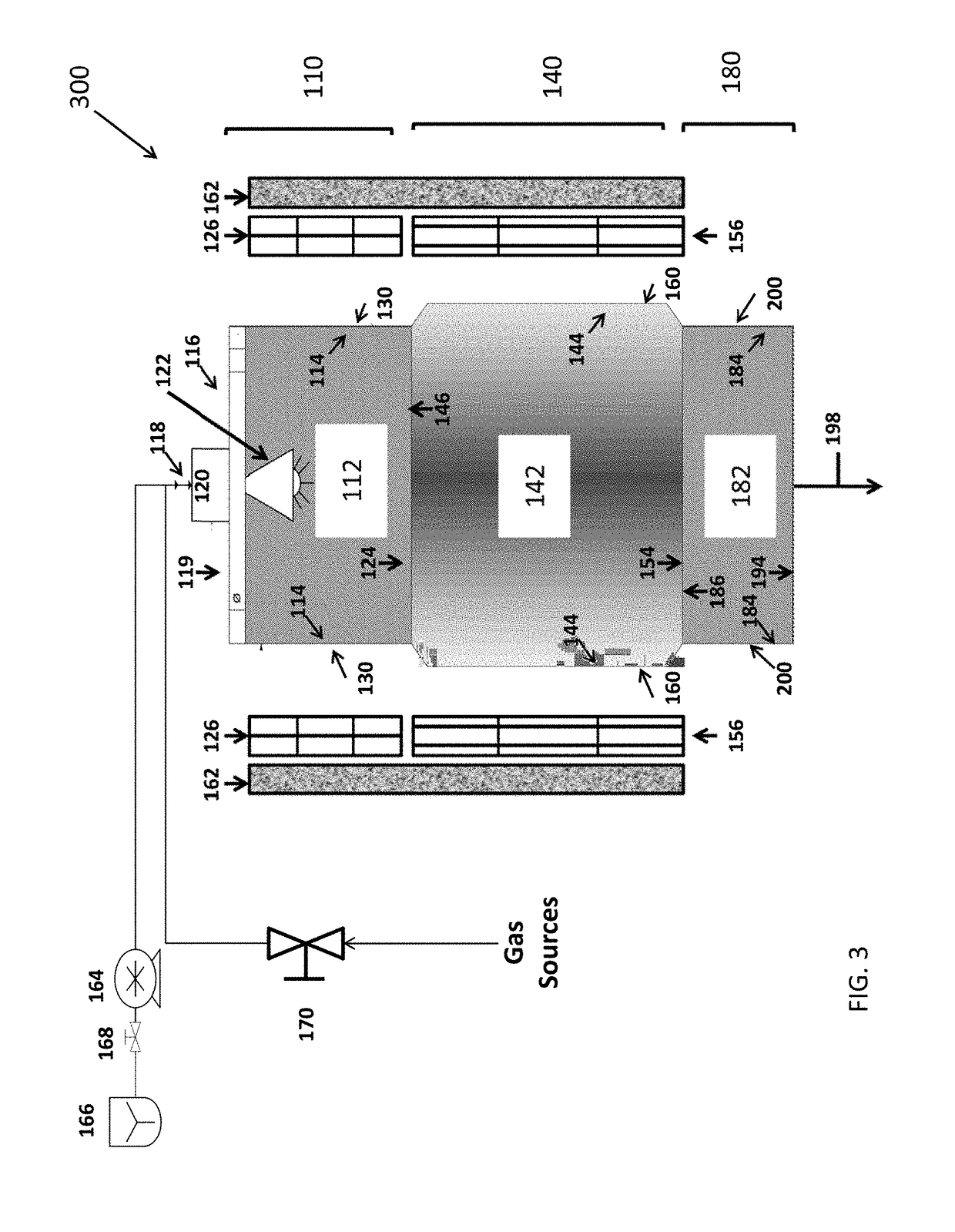

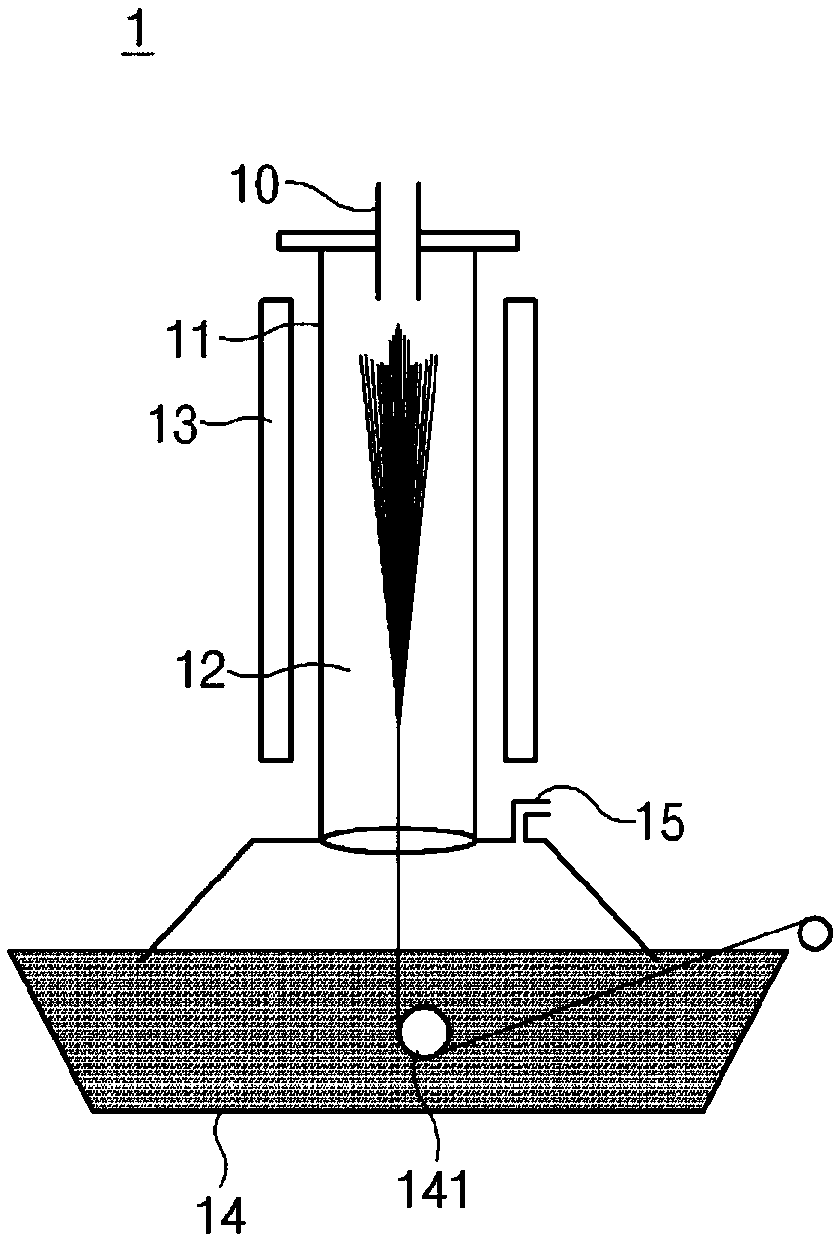

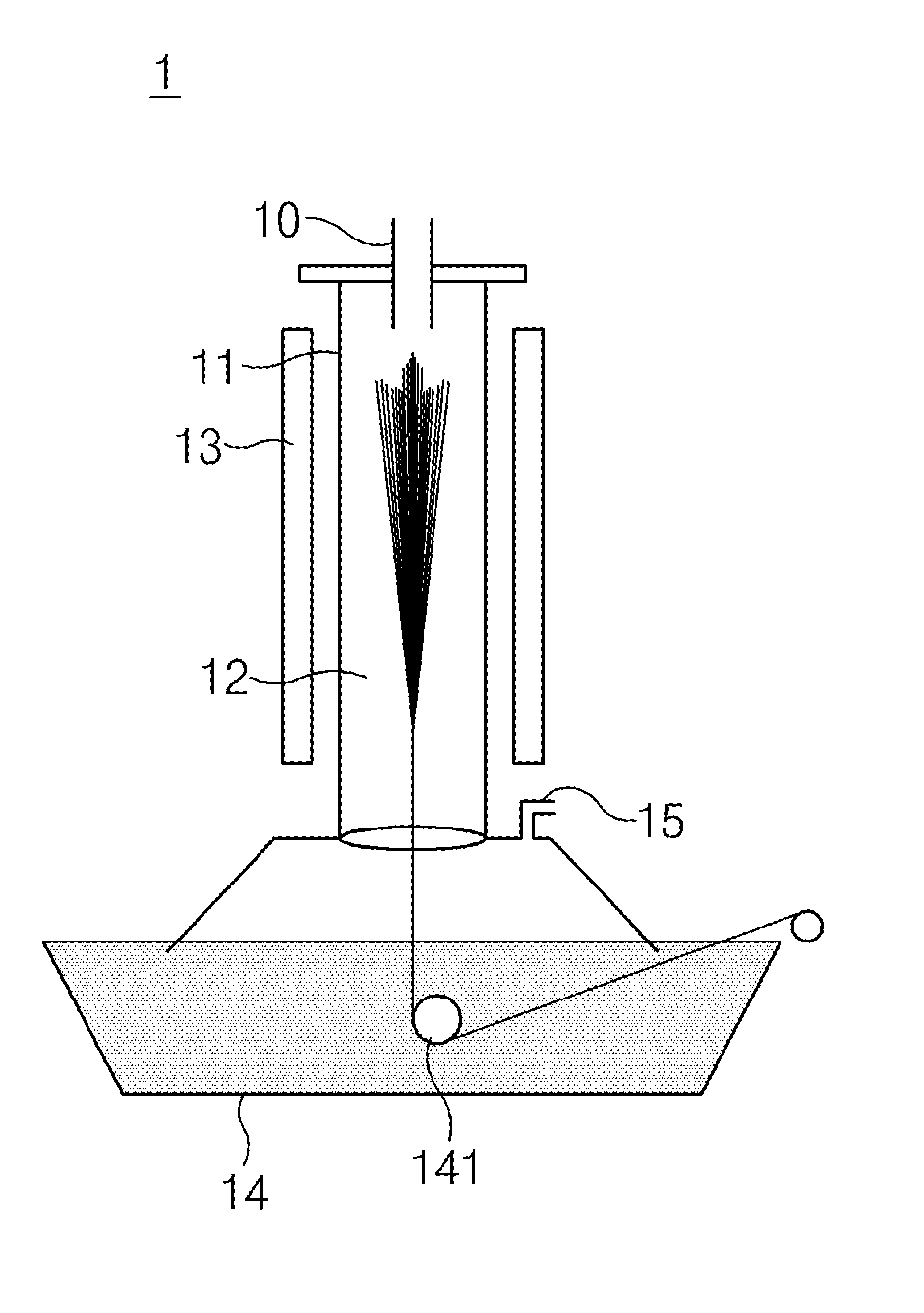

InactiveUS9670103B1Guaranteed uniform velocityMaterial nanotechnologyAluminium compoundsOrganic solventCarbon nanotube

A vertical chemical vapor deposition (CVD) reactor and a method for synthesizing metal oxide impregnated carbon nanotubes. The CVD reactor includes a preheating zone portion and a reaction zone portion, and preferably an additional cooling zone portion and a product collector. The method includes (a) subjecting a liquid reactant solution comprising an organic solvent, a metallocene, and a metal alkoxide to atomization in the presence of a gas flow comprising a carrier gas and a support gas to form an atomized mixture, and (b) heating the atomized mixture to a temperature of 200° C.-1400° C., wherein the heating forms a metal oxide and at least one carbon source compound, wherein the metallocene catalyzes the formation of carbon nanotubes from the at least one carbon source compound and the metal oxide is incorporated into or on a surface of the carbon nanotubes to form the metal oxide impregnated carbon nanotubes.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

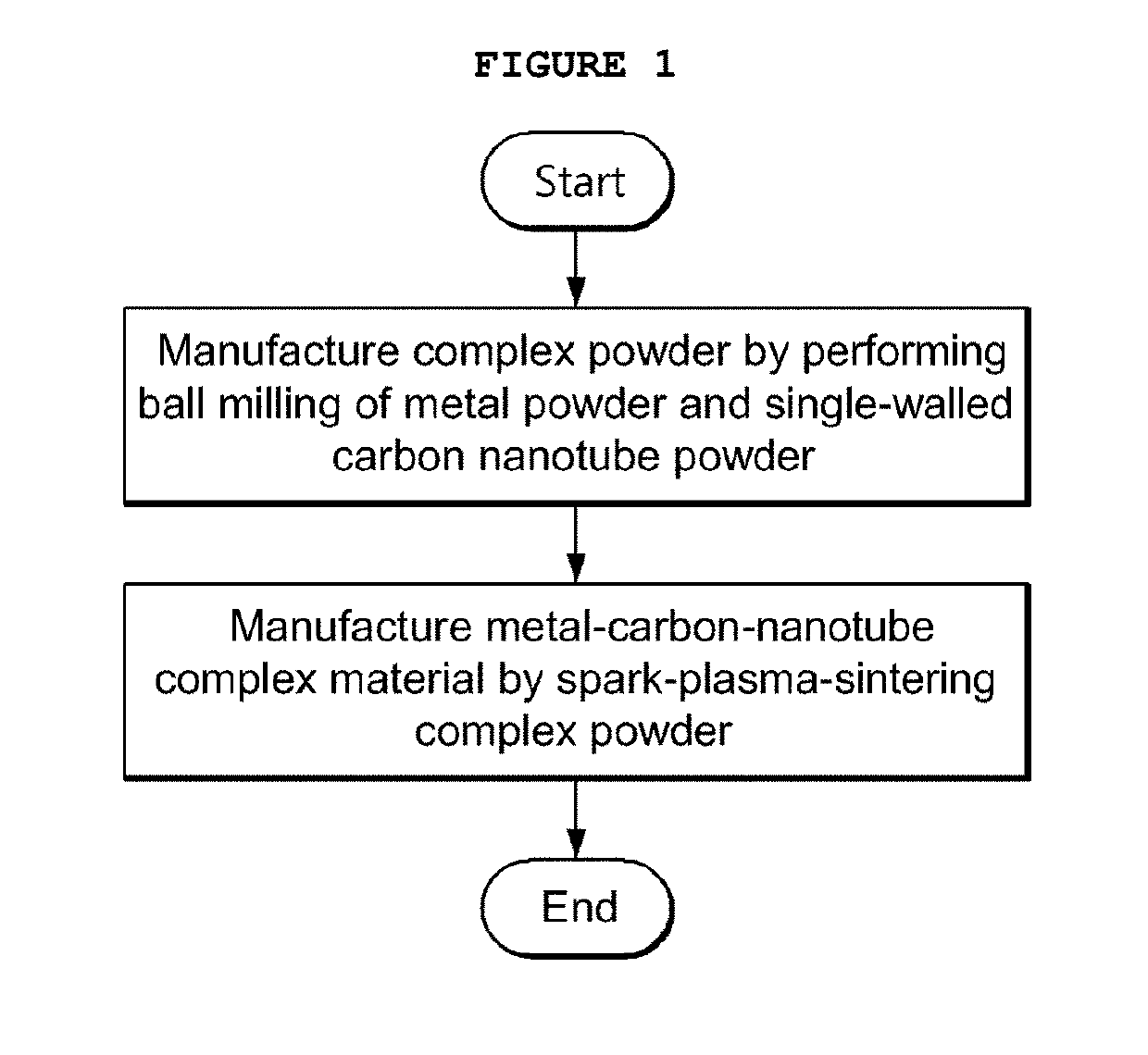

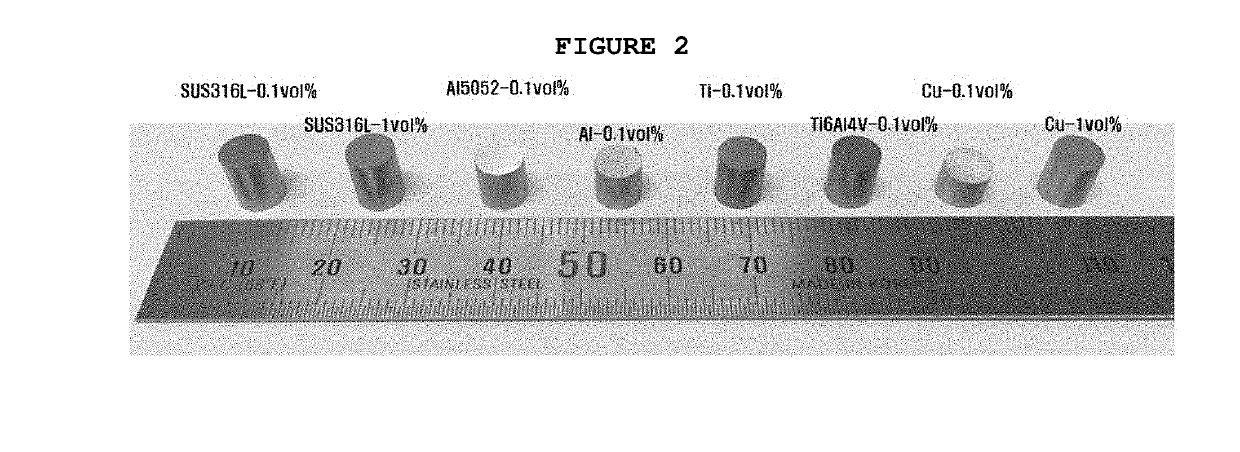

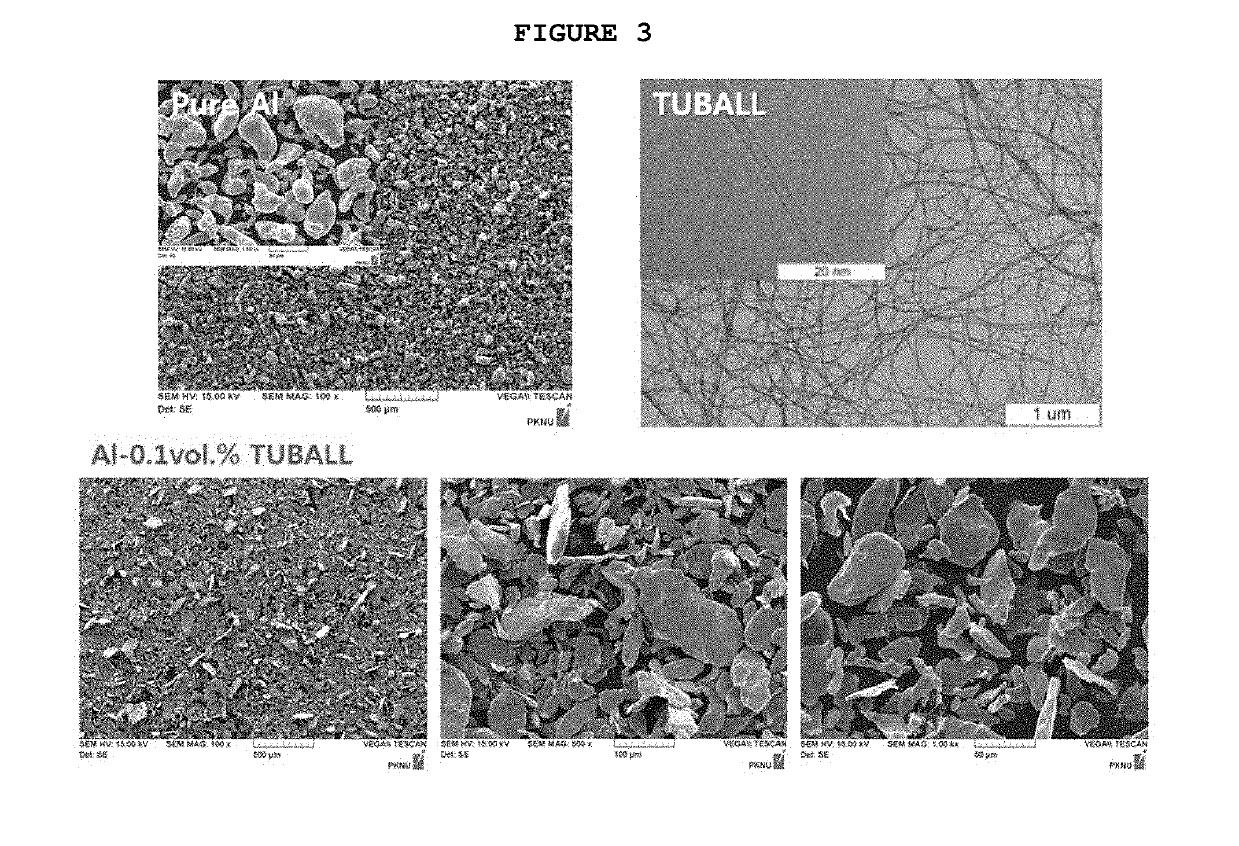

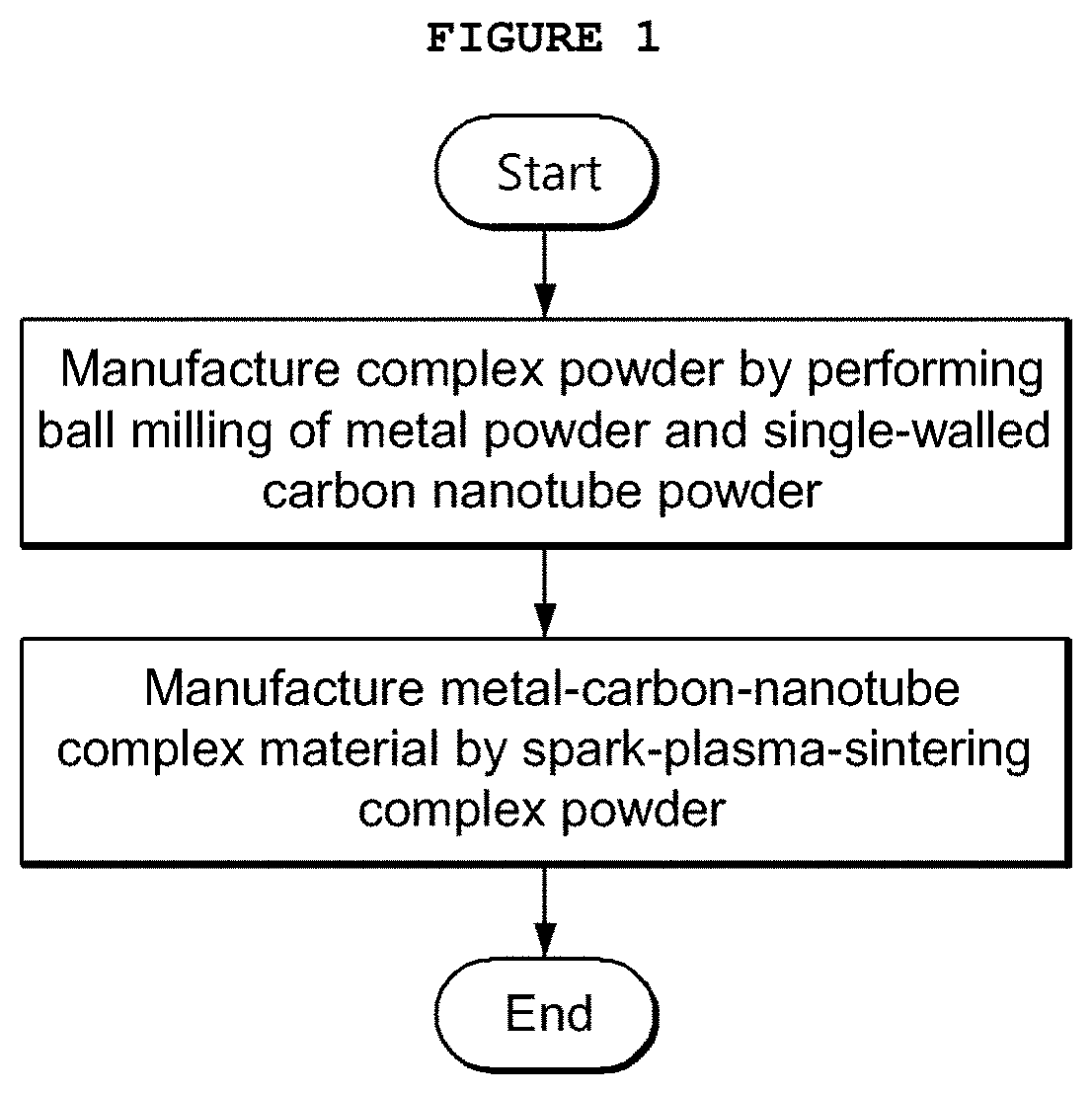

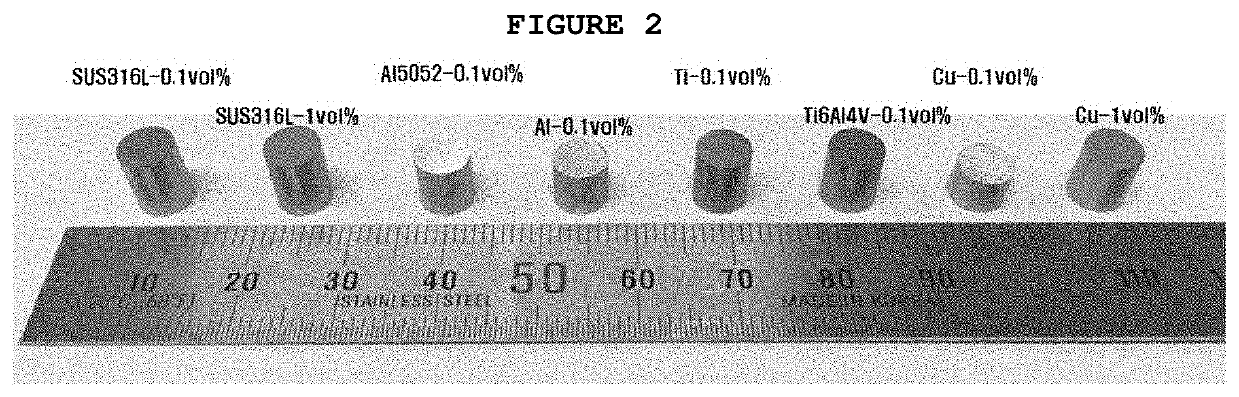

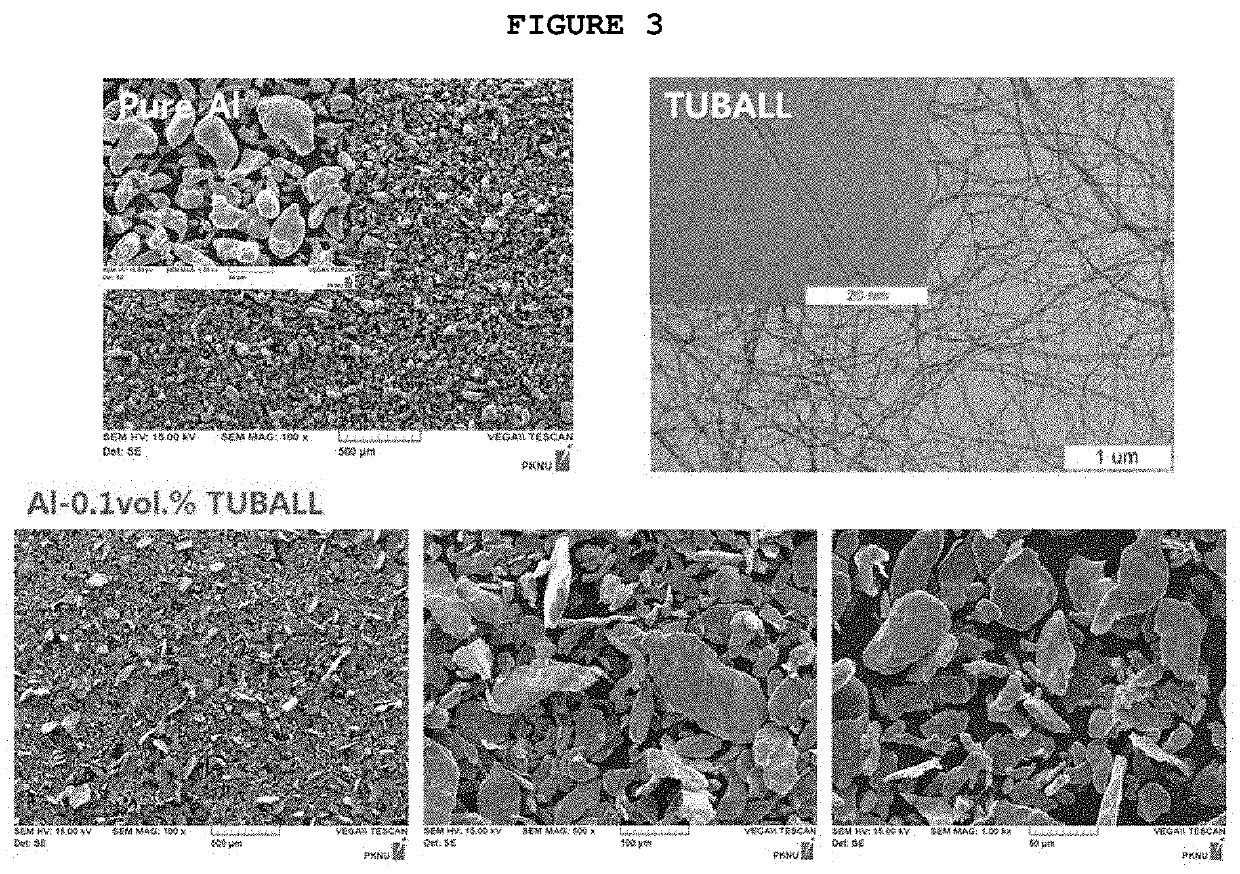

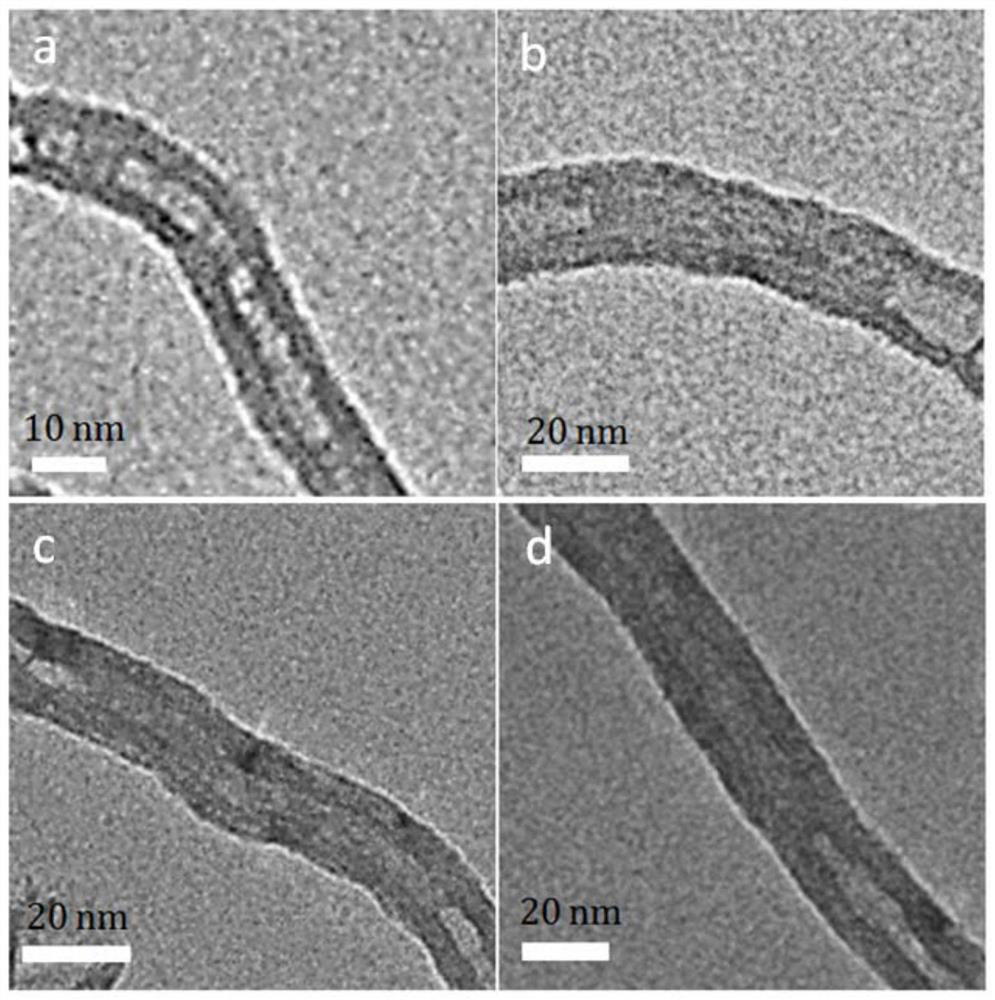

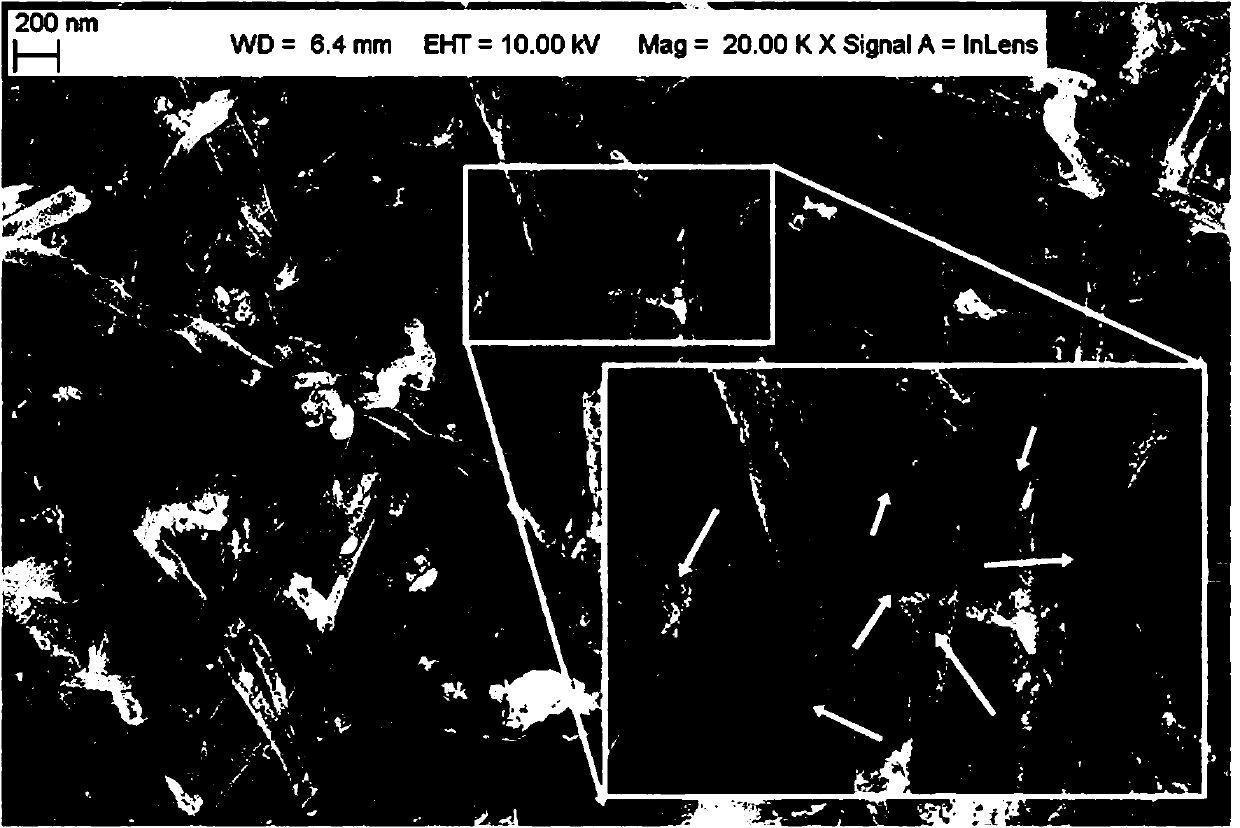

Discharge plasma sintering method for manufacturing single-walled carbon nanotube reinforced metal matrix composite and composite material produced thereby

ActiveUS20190276915A1Good physical propertiesExcellent abrasion resistanceSingle-walled nanotubesFilled nanotubesDispersityCarbon nanotube

The present invention provides a method of manufacturing a single-walled-carbon-nanotube-reinforced metal matrix complex material. The method includes (a) manufacturing a complex powder by performing ball milling of a metal powder and a single-walled carbon nanotube powder, and (b) manufacturing a metal-carbon-nanotube complex material by spark-plasma-sintering (SPS) the complex powder manufactured during step (a). According to the method of manufacturing the single-walled-carbon-nanotube-reinforced metal matrix complex material according to the present invention, in order to manufacture material parts requiring high strength and abrasion resistance, the single-walled carbon nanotube powder is added to various metal matrixes and ball milling is performed, thus manufacturing a complex powder having uniform dispersity. The manufactured complex powder is subjected to complexation in a short period of time using a spark-plasma-sintering (SPS) process, thereby easily manufacturing a bulk-type single-walled-carbon-nanotube-reinforced metal matrix complex material having excellent physical properties.

Owner:PUKYONG NAT UNIV IND ACADEMIC COOPERATION FOUND

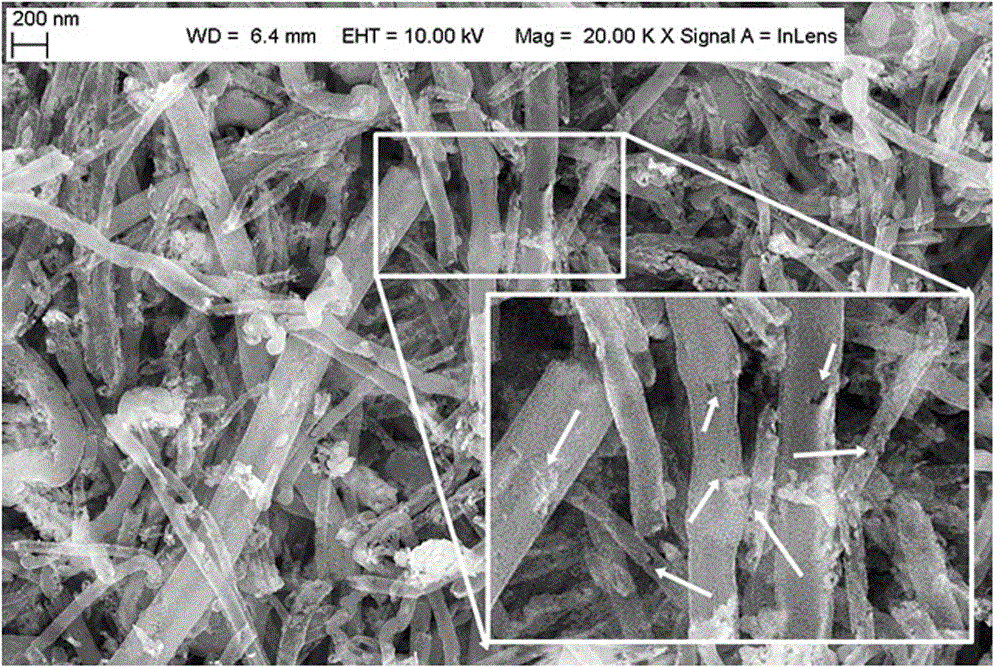

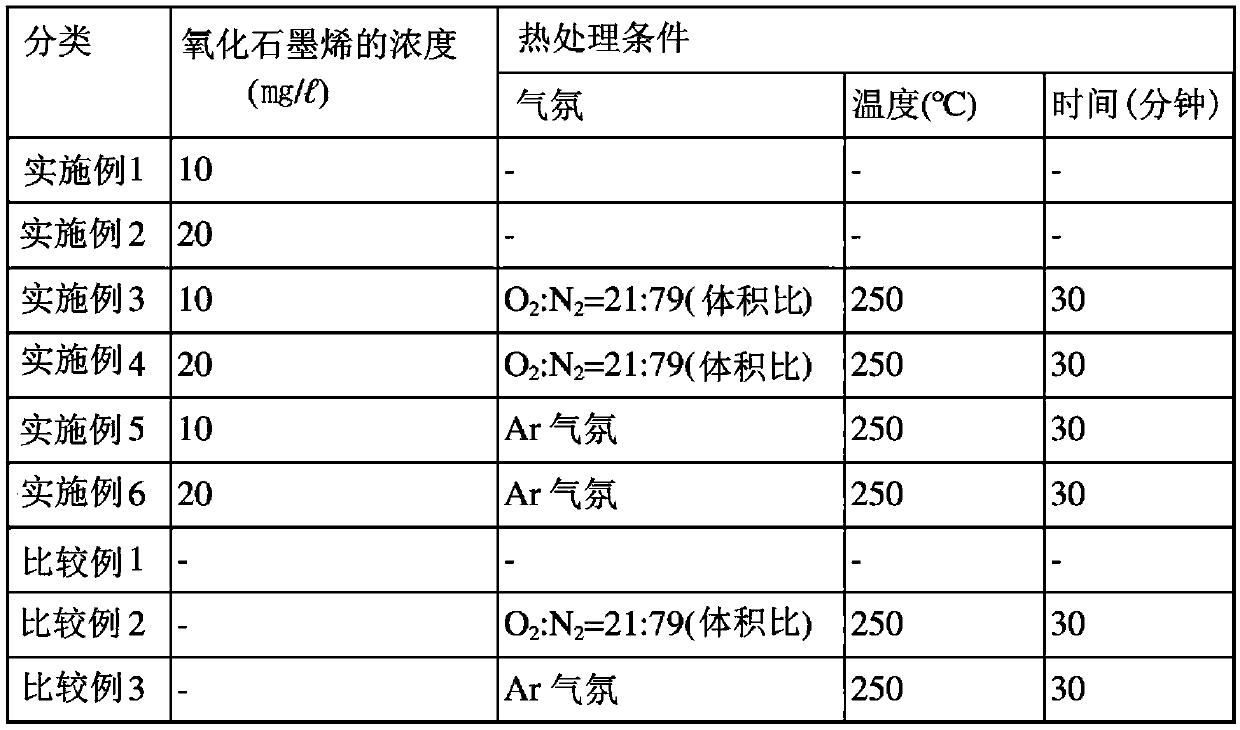

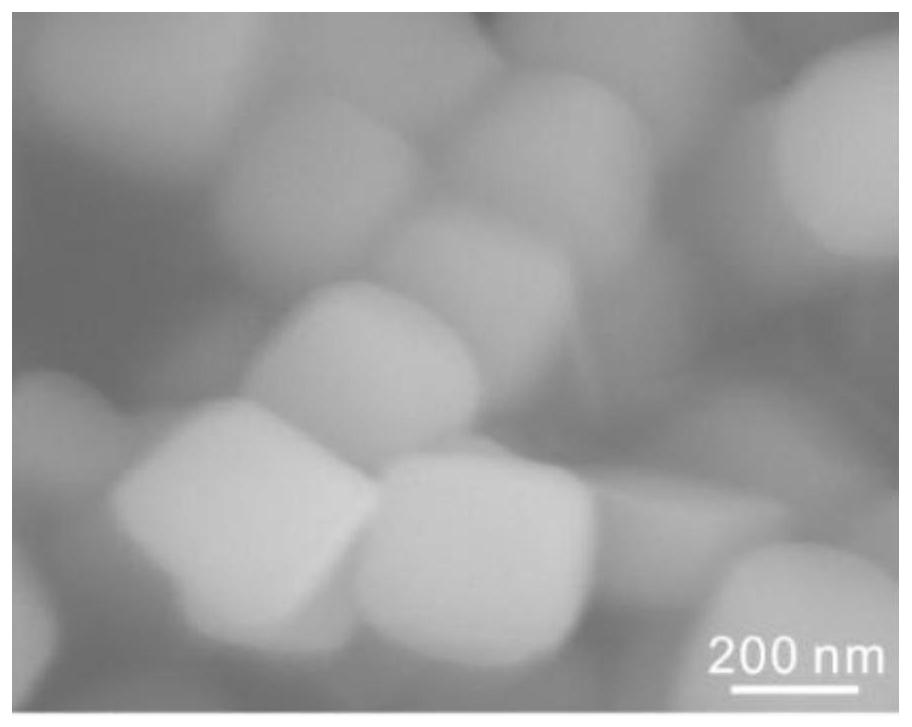

Carbon nanofiber filled with metal oxide nanoparticles and preparation method thereof

ActiveCN105948017AWeak surface structureProcess environmental protectionFilled nanotubesMetal oxide nanoparticlesNew energy

The invention relates to carbon nanofiber filled with metal oxide nanoparticles and a preparation method thereof. The carbon nanofiber filled with the metal oxide nanoparticles is prepared through the following steps: filling carbon nanofiber tubes with a metal salt solution under the action of milling, and carrying out drying and calcination, wherein the particle sizes of the metal oxide nanoparticles are in a range of 5 to 30 nm. The method provided by the invention has the characteristics of short filling time, capability of realizing high filling volume, simple process, greenness, environmental protection, low cost, easiness in industrialization, etc.; and the obtained carbon nanofiber has excellent mechanical and chemical stability, and has good application prospects in the fields of catalysis, sensors, electromagnetic shielding, new energy, biotechnology, high-performance composite materials, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for forming aluminum oxide/carbon nanotubes by ultrasonic atomization and chemical vapor deposition

InactiveUS20170275168A1Material nanotechnologyAluminium oxide/hydroxide preparationGas phaseChemistry

A vertical chemical vapor deposition (CVD) reactor and a method for synthesizing metal oxide impregnated carbon nanotubes. The CVD reactor includes a preheating zone portion and a reaction zone portion, and preferably an additional cooling zone portion and a product collector. The method includes (a) subjecting a liquid reactant solution comprising an organic solvent, a metallocene, and a metal alkoxide to atomization in the presence of a gas flow comprising a carrier gas and a support gas to form an atomized mixture, and (b) heating the atomized mixture to a temperature of 200° C.−1400° C., wherein the heating forms a metal oxide and at least one carbon source compound, wherein the metallocene catalyzes the formation of carbon nanotubes from the at least one carbon source compound and the metal oxide is incorporated into or on a surface of the carbon nanotubes to form the metal oxide impregnated carbon nanotubes.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

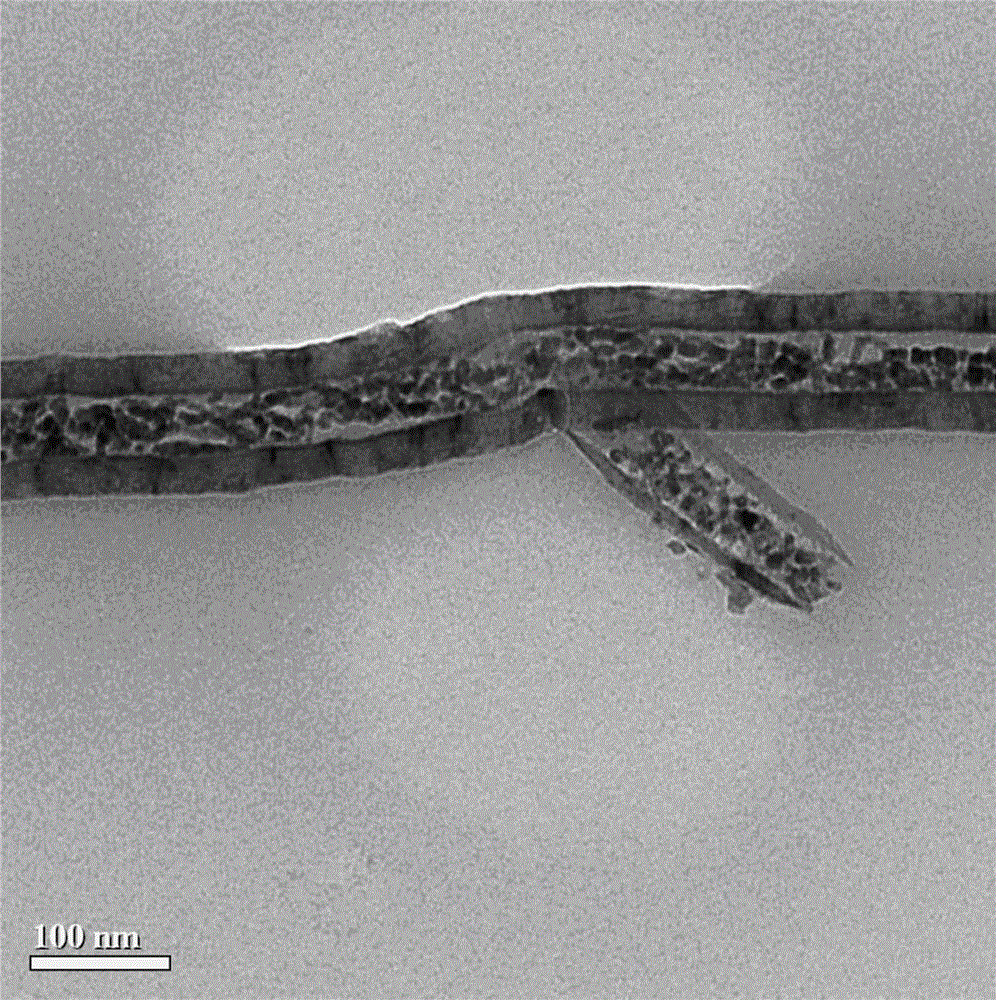

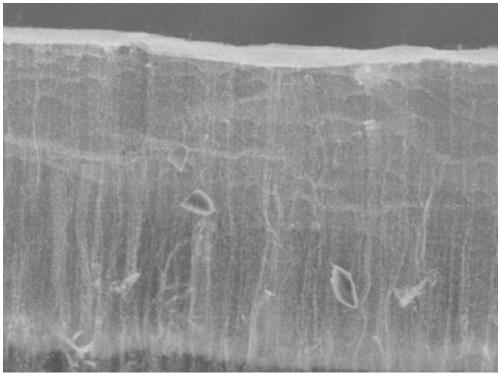

Copper-filled carbon nanotube array-based composite material and preparation method thereof

ActiveCN110143585AImprove thermal performanceFast heat conductionFilled nanotubesCarbon nanotubeCopper

The invention discloses a copper-filled carbon nanotube array-based composite material and a preparation method thereof. The preparation method comprises the following steps: a carbon nanotube array is provided; a copper-containing precursor and the carbon nanotube array are respectively placed in a first temperature zone and a second temperature zone of chemical vapor deposition equipment; the precursor is vaporized, and a reducing carrier gas carries the precursor and enters the carbon nanotube array; the reducing carrier gas and the precursor react in the carbon nanotube array to form a plurality of nano copper particles, and the plurality of nano copper particles are subjected to nucleation growth in internal pores of the carbon nanotube array to form a plurality of micron copper particles; and high-temperature annealing treatment is carried out on the carbon nanotube array filled with the micron copper particles, so that the plurality of micron copper particles are fused mutuallyto obtain the copper-filled carbon nanotube array-based composite material. The prepared copper-filled carbon nanotube array-based composite material has excellent heat conduction performance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

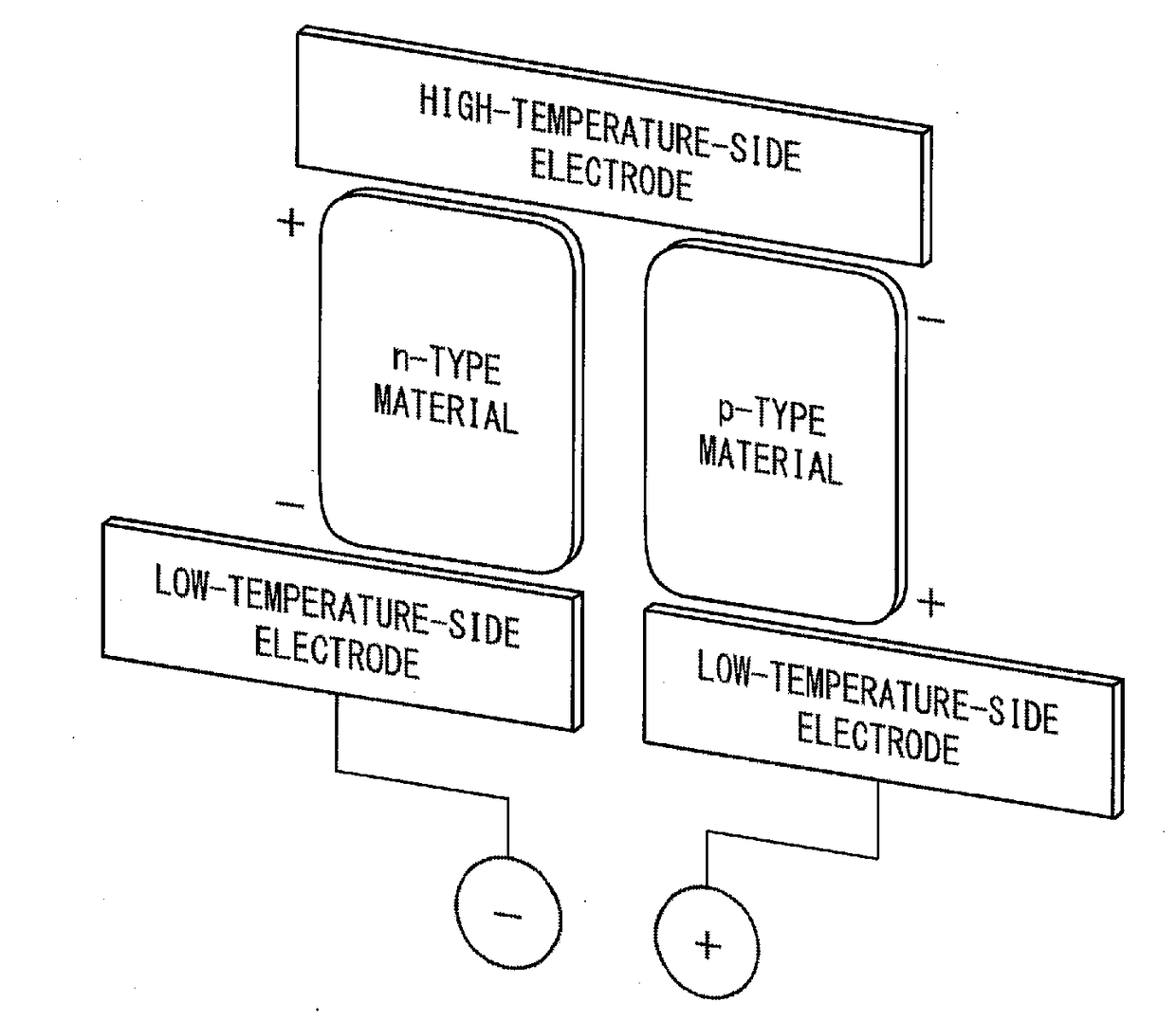

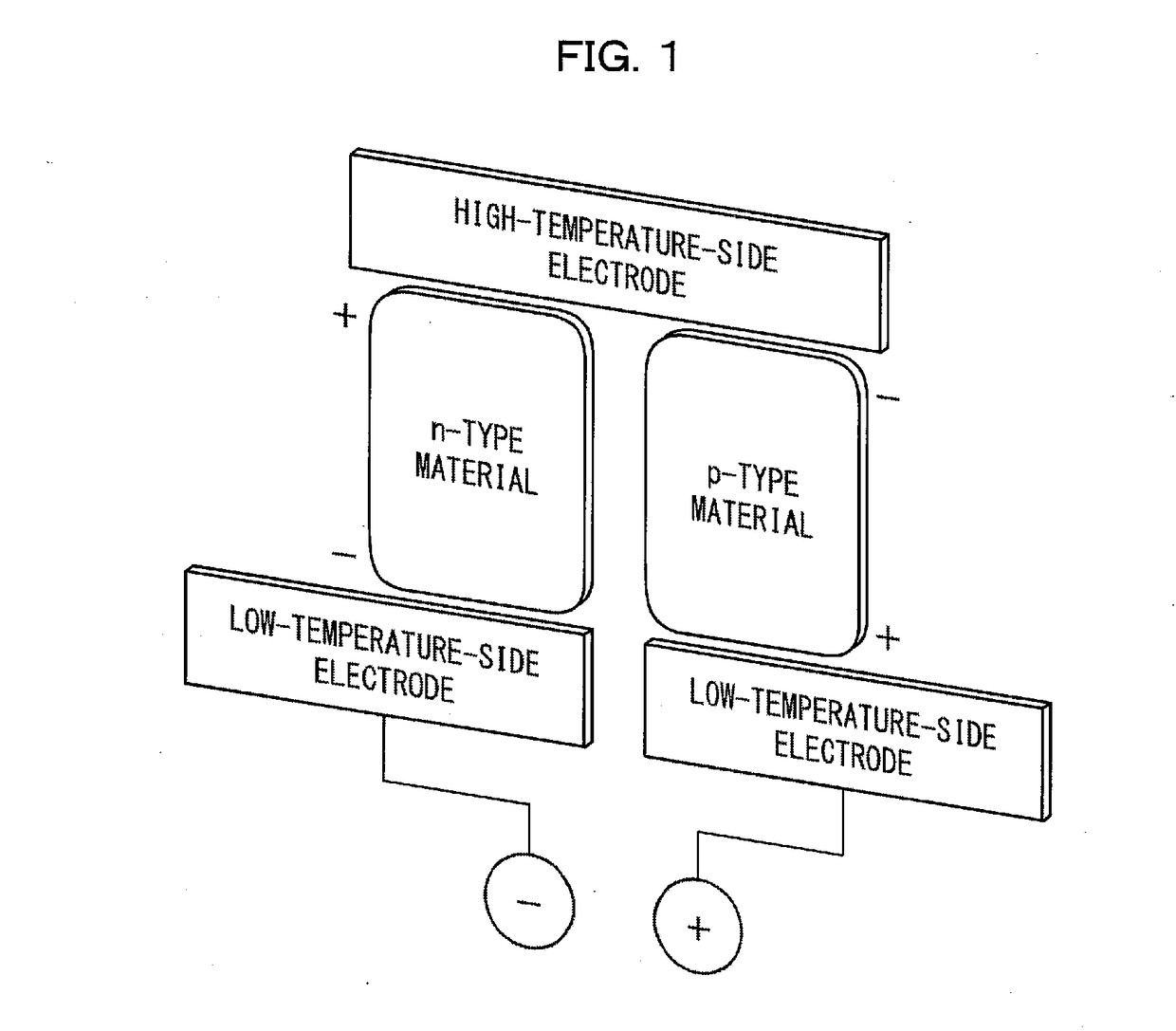

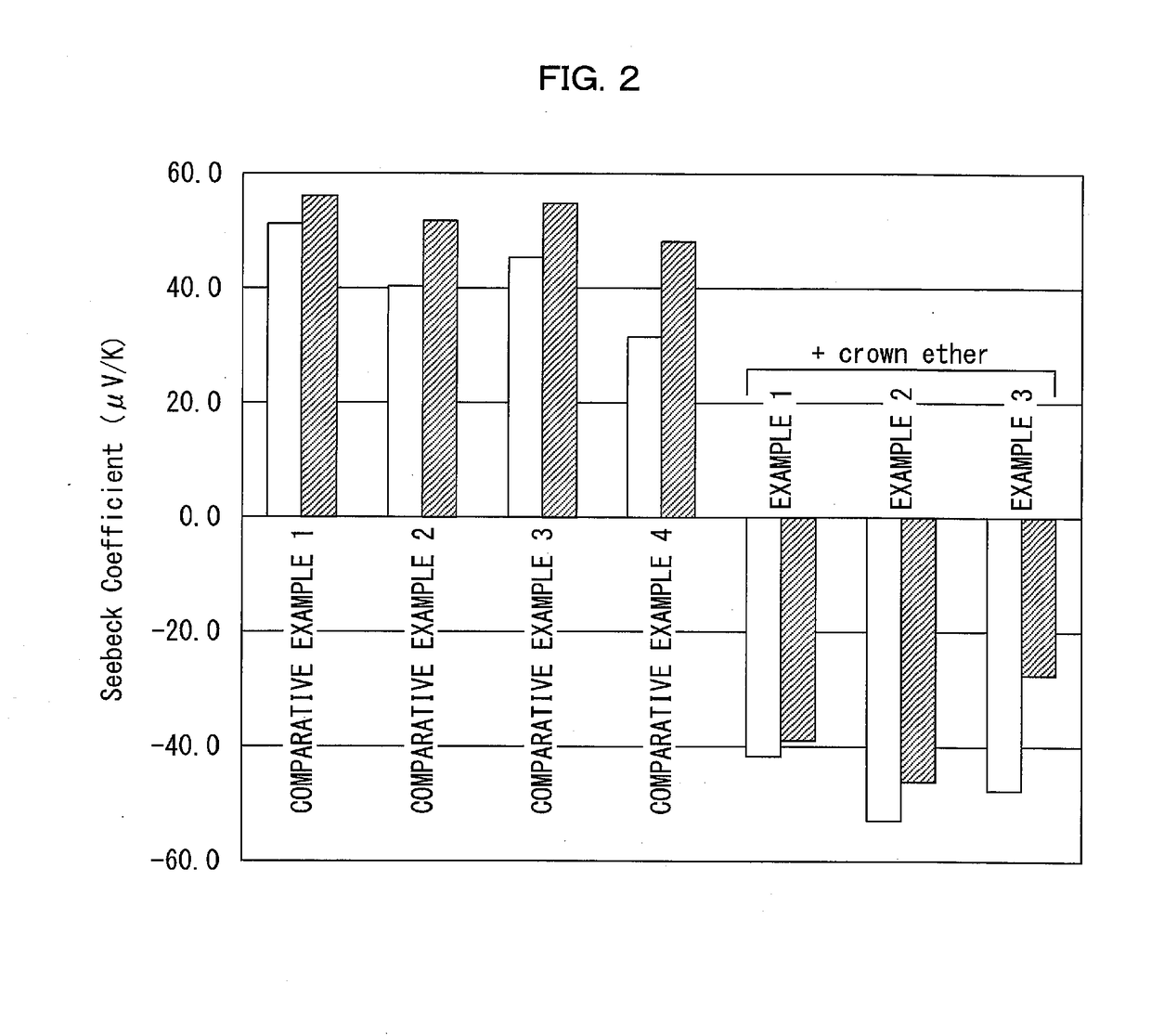

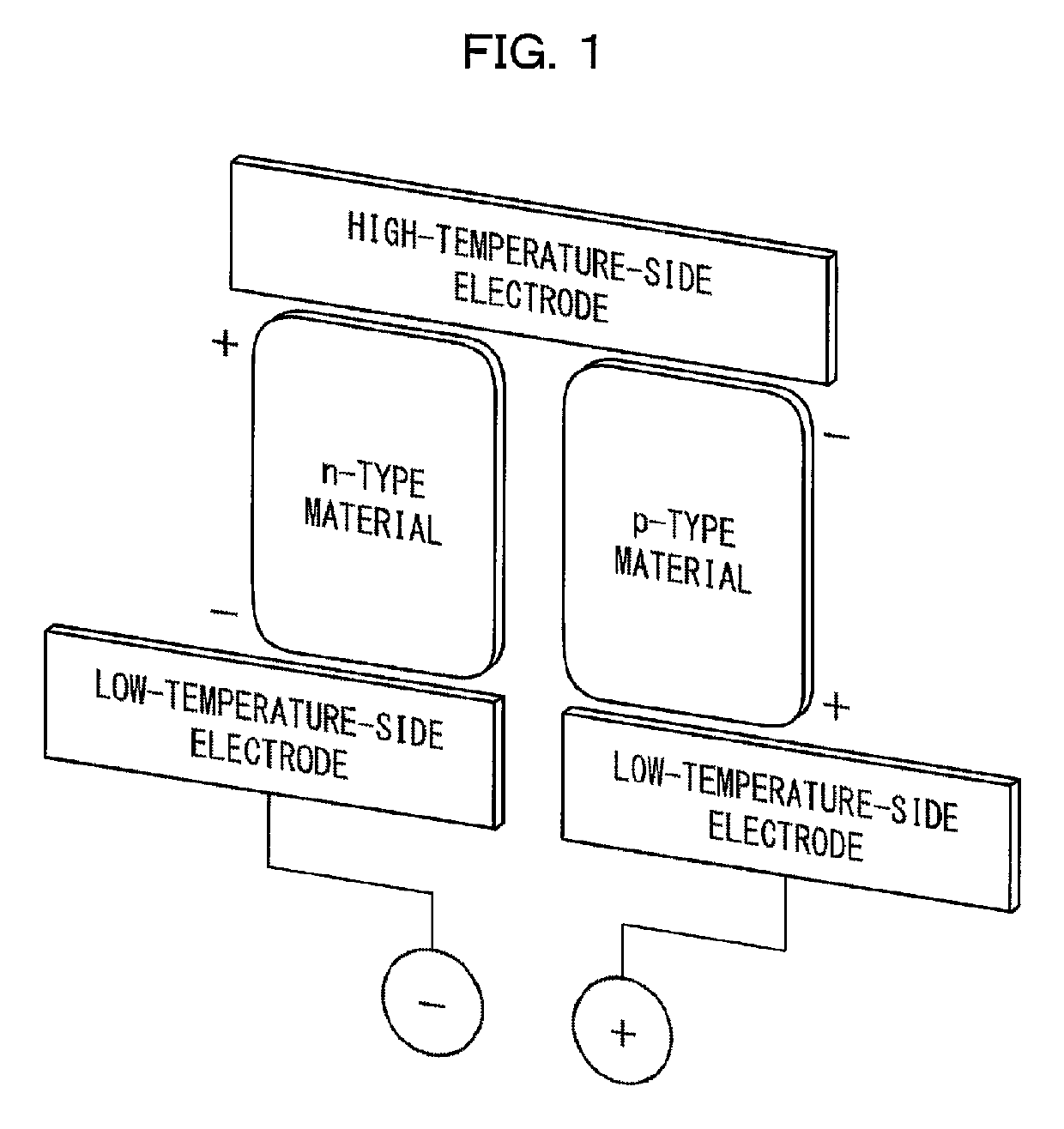

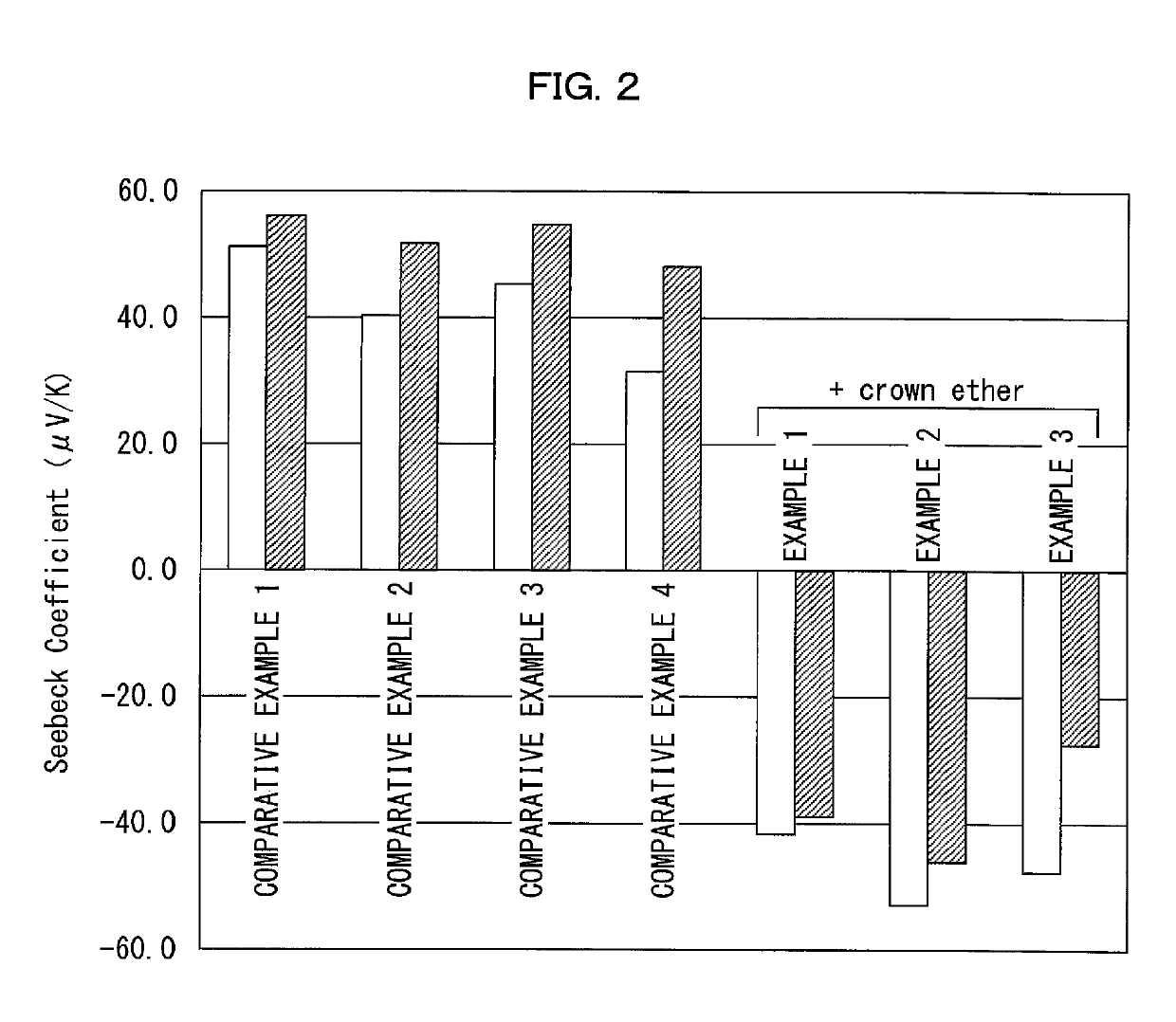

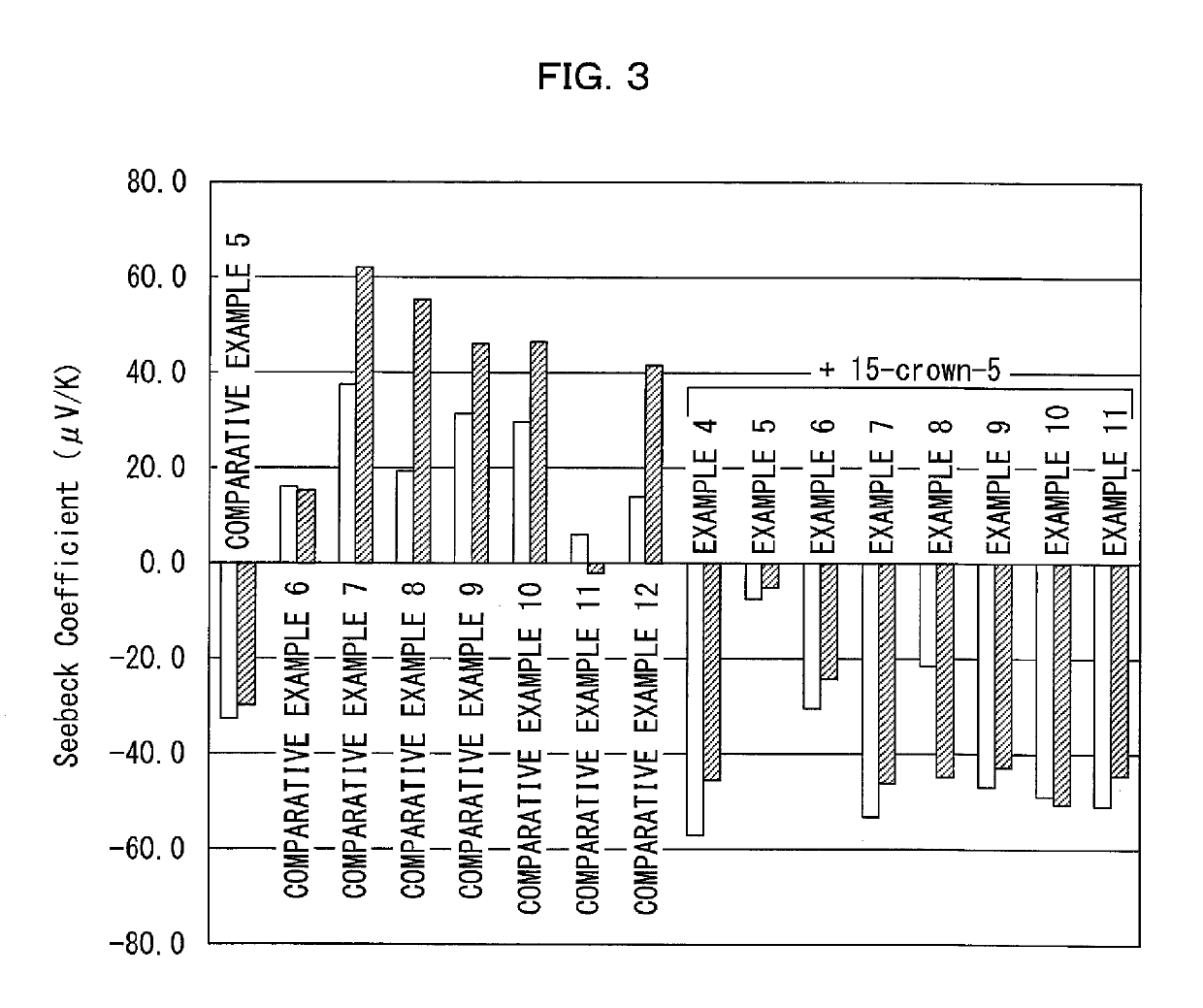

Nanomaterial dopant composition composite, dopant composition, and method for manufacturing nanomaterial dopant composition composite

InactiveUS20170197836A1Simply and changeMaterial nanotechnologyThermoelectric device with peltier/seeback effectDopantScavenger

The present invention provides a method for manufacturing a dopant composition-nanomaterial composite, which method makes it possible to simply and efficiently change a Seebeck coefficient value of a nanomaterial. This manufacture method of the present invention includes the step of putting a dopant composition in contact with a nanomaterial in a solvent, the dopant composition containing an anion, a cation, and a scavenger.

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY +1

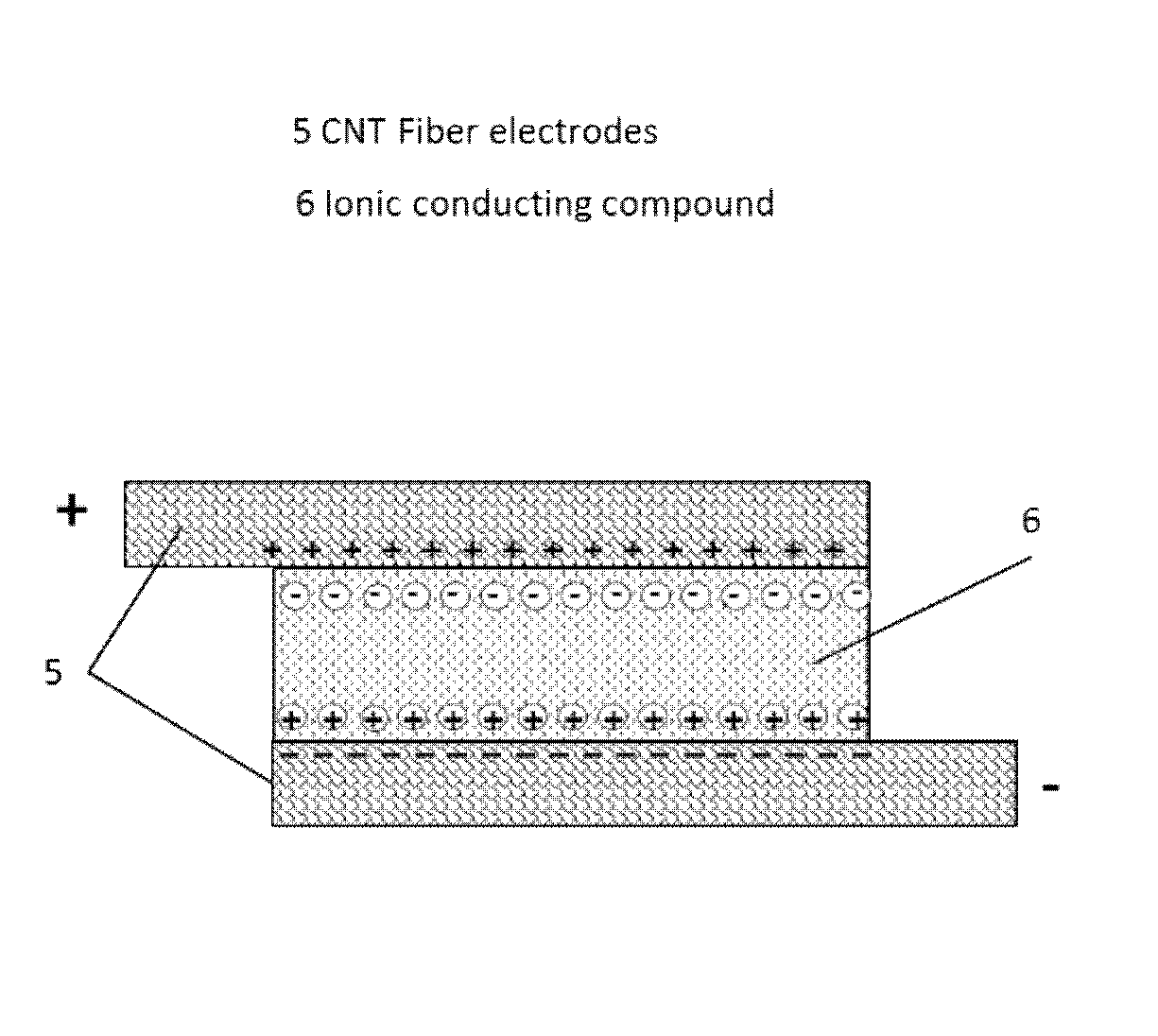

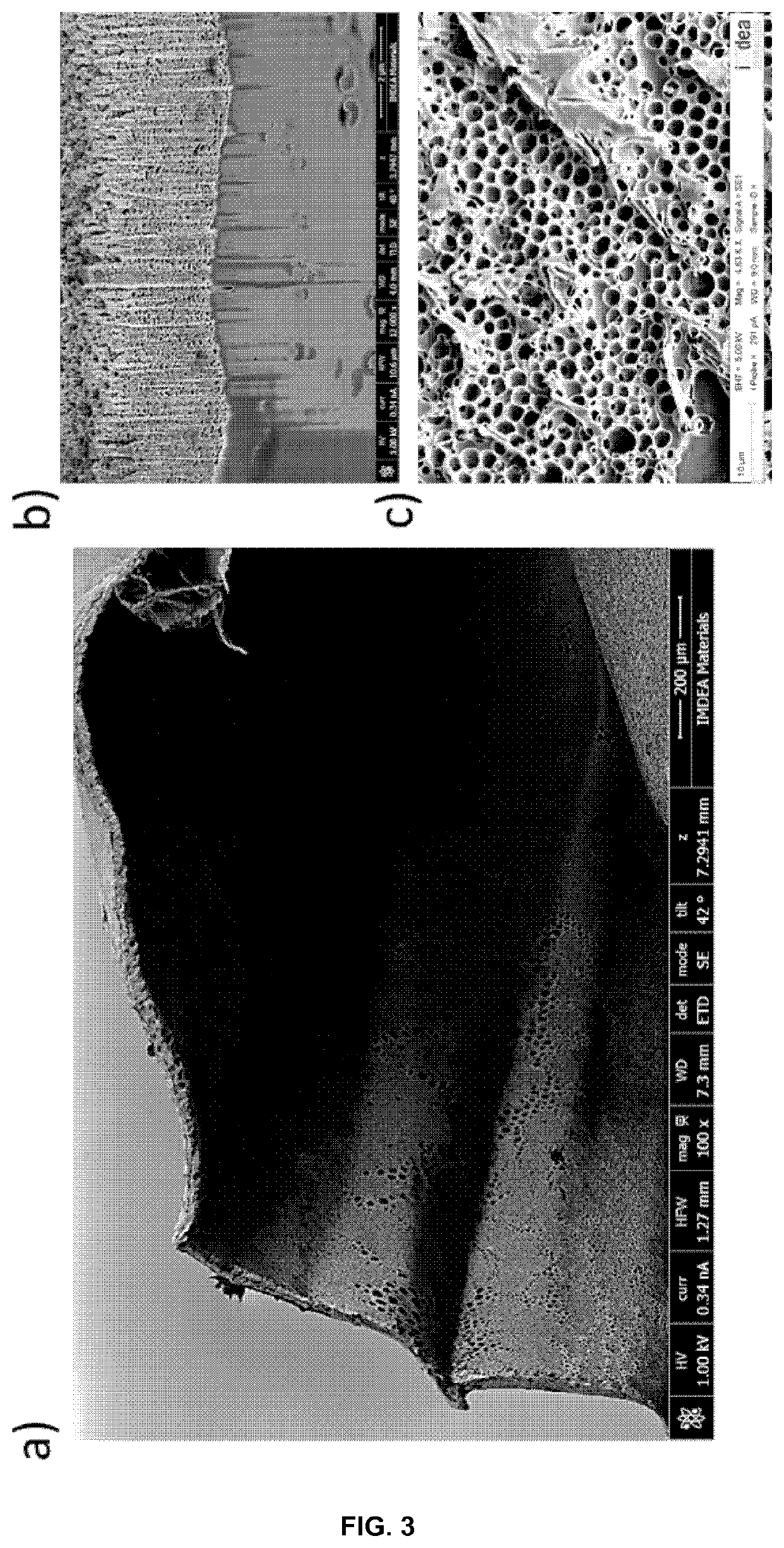

Composite comprising cnt fibres and an ionic conducting compound as part of an energy storage device

ActiveUS20180261401A1Easy to integrateAvoid the needHybrid capacitor electrolytesHybrid capacitor electrodesFiberChemical compound

The present invention relates to Composite comprising CNT fibres and an ionic conducting compound forming a homogeneous continuous phase or a two-phase bicontinuous structure and its process of obtainment by impregnation methods. Furthermore the invention relates to its use as part of an energy storage device such as an structural flexible electrochemical capacitor.

Owner:BE AEROSPACE SYST

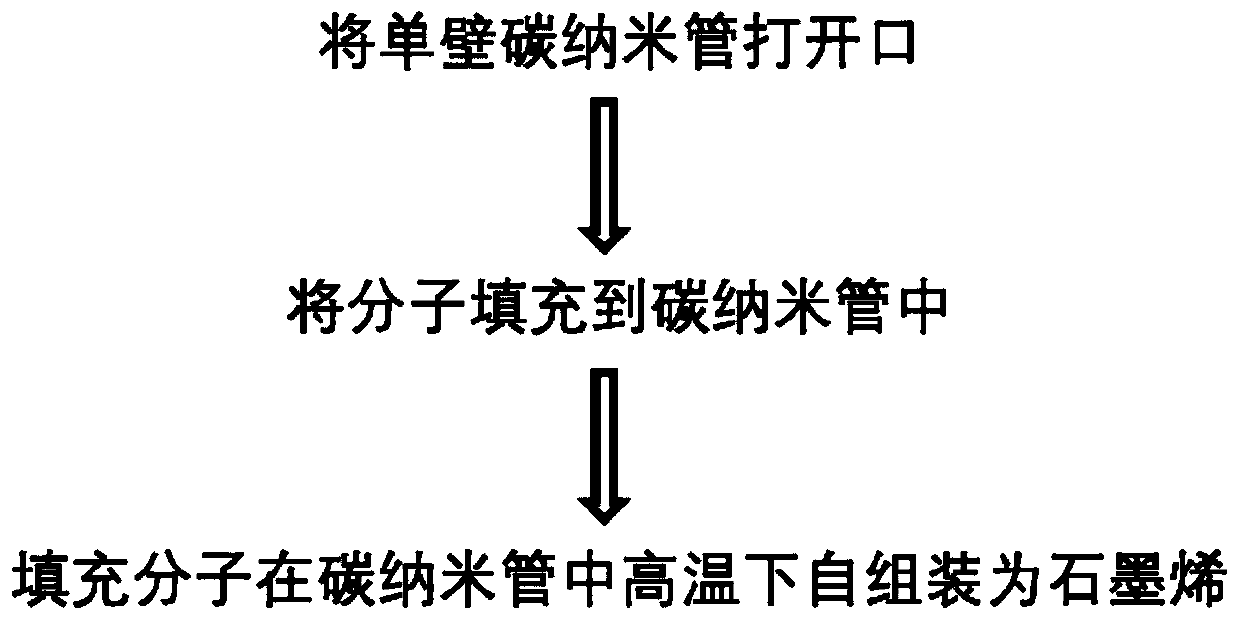

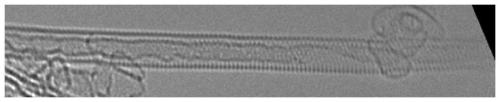

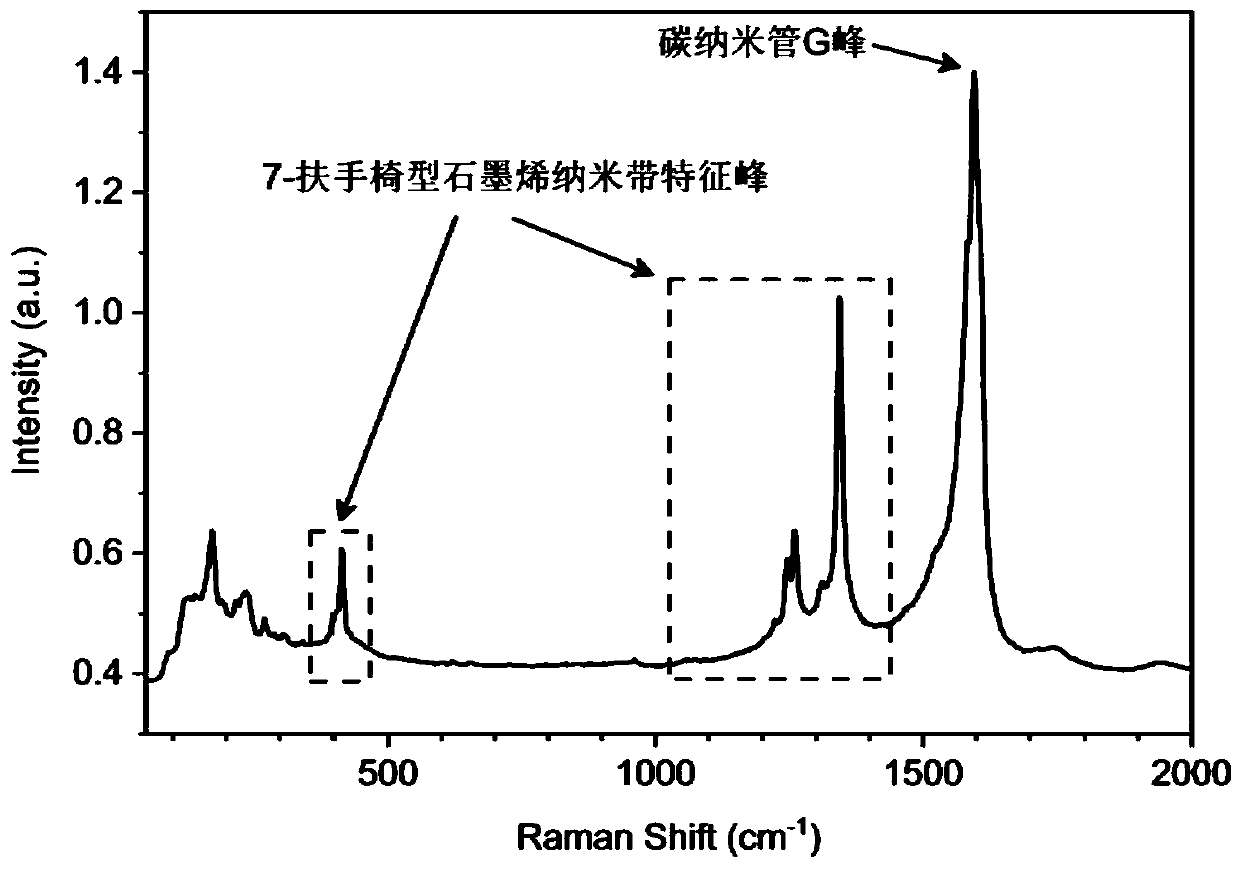

Preparation method of ultra-narrow graphene nanobelts

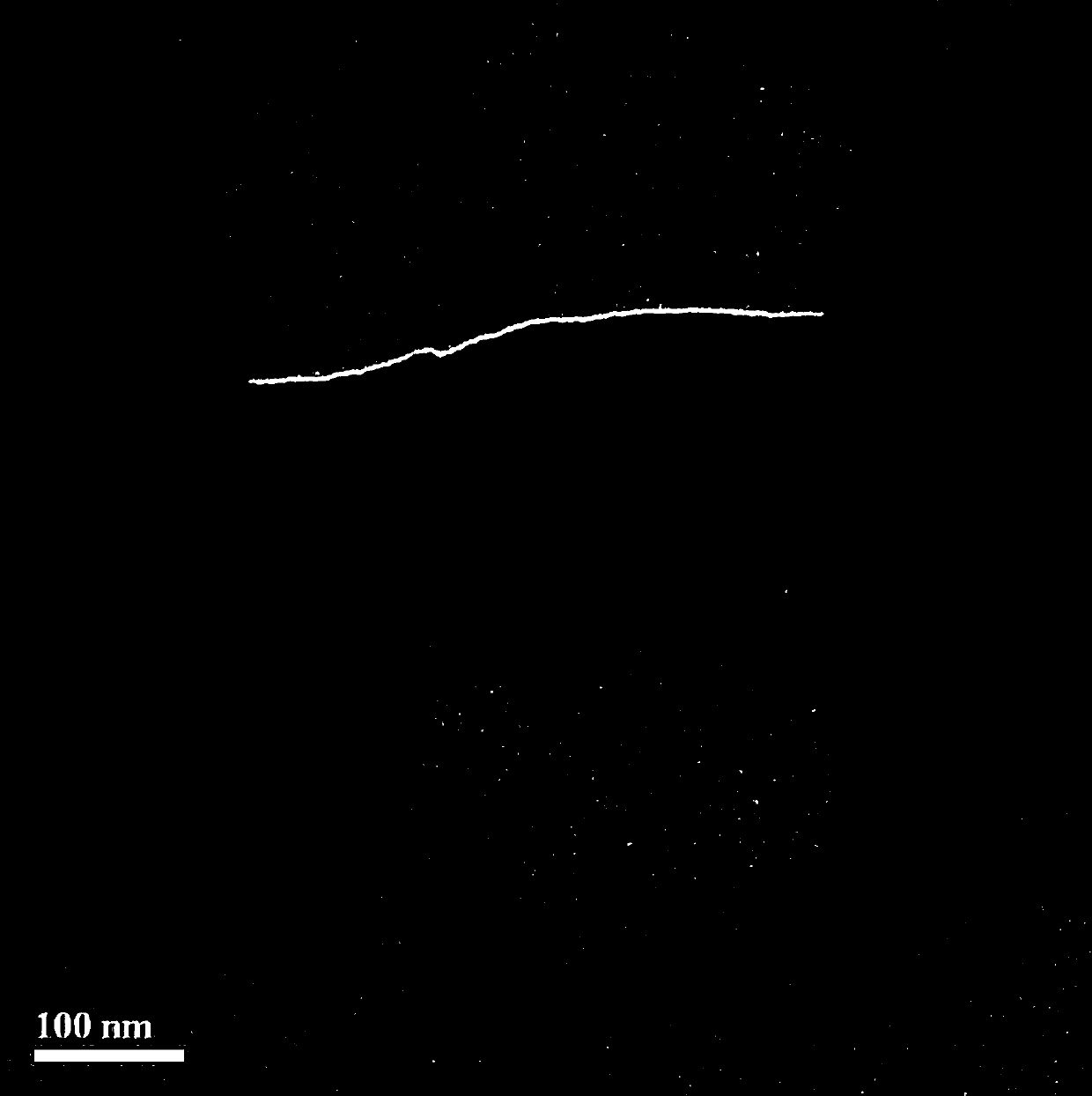

PendingCN111039284AReduce widthControl edge stateGrapheneFilled nanotubesGraphene nanoribbonsCarbon nanotube

The invention discloses a preparation method of an ultra-narrow graphene nanobelt. The preparation method comprises the following steps: S1, carrying out heat treatment on a single-walled carbon nanotube to open a port; S2, mixing the single-walled carbon nanotube treated in the step S1 and molecules for filling, and performing vacuum tube sealing; S3, carrying out molecular filling heat treatment; and S4, carrying out annealing heat treatment, so that the molecules filled in the single-walled carbon nanotube are converted into graphene nanobelt. According to the invention, by using single-walled carbon nanotubes as a template, various ultra-narrow armchair type and sawtooth type graphene nanobelts are designed and synthesized by controlling the types of precursor molecules and the diameters and the chirality of the carbon nanotubes; and the method can control the width and the edge state of graphene nanobelts, can prepare a large number of ultra-narrow graphene nanobelts, and createsnecessary conditions for the application of the ultra-narrow graphene nanobelts in the semiconductor direction.

Owner:SUN YAT SEN UNIV

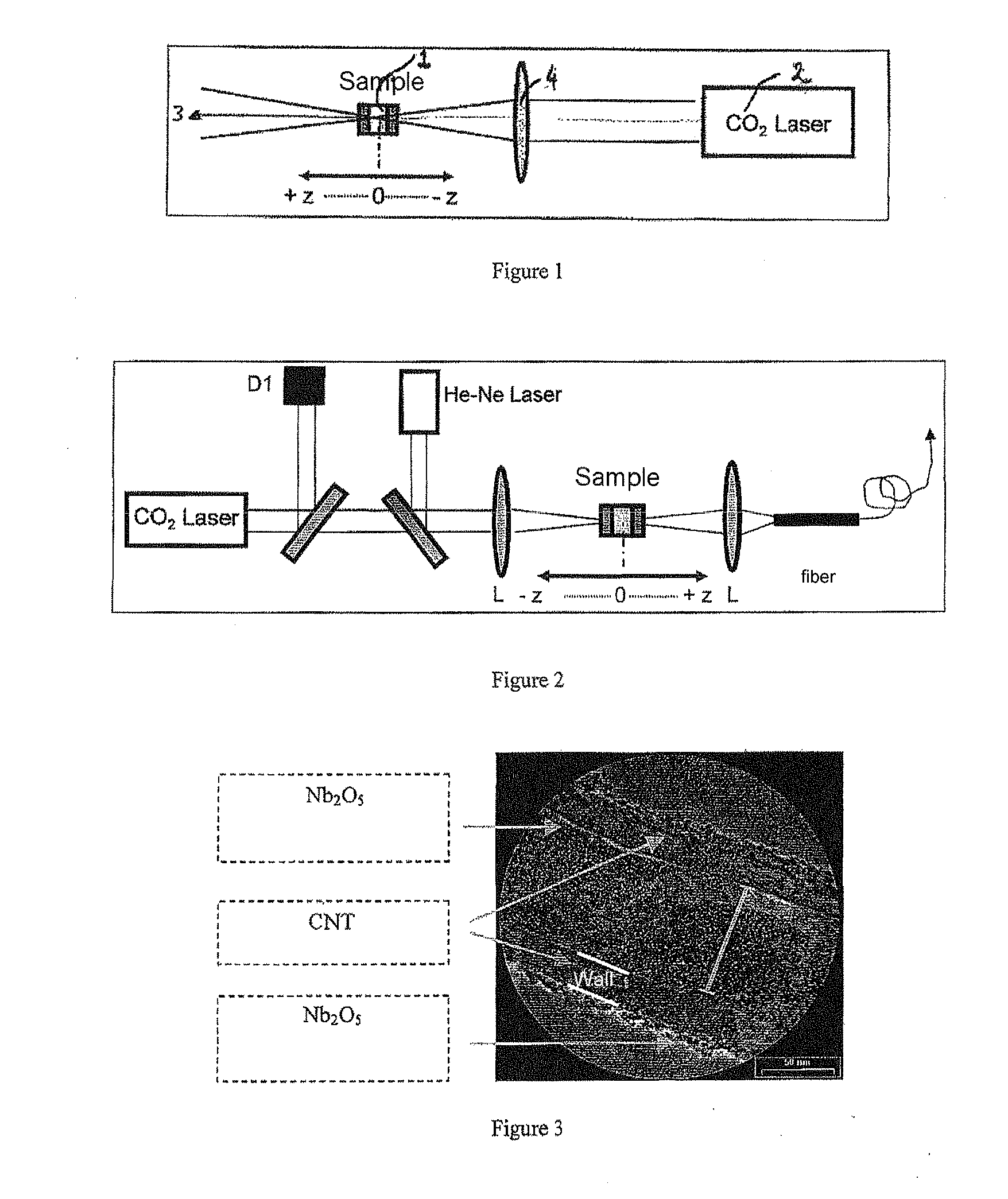

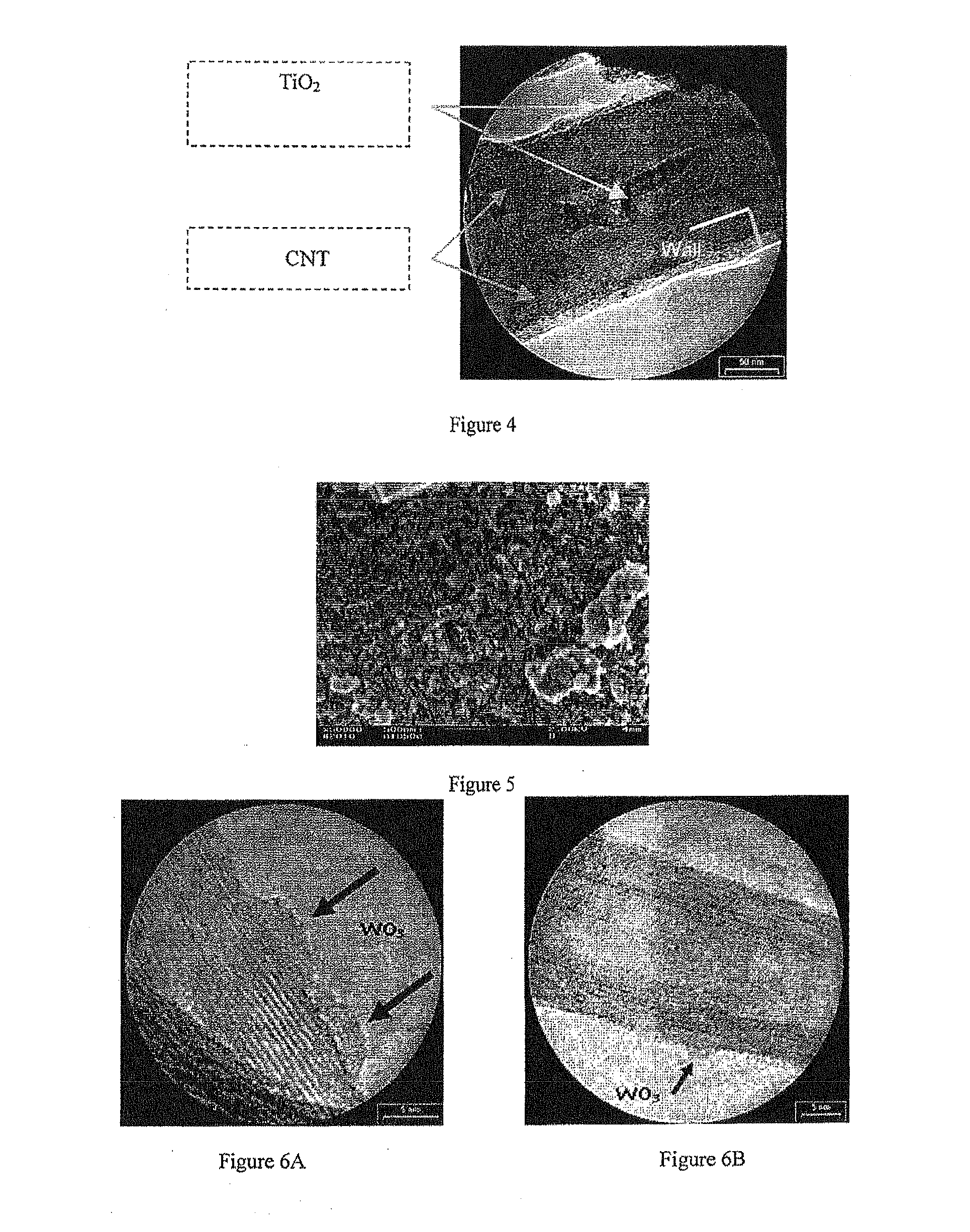

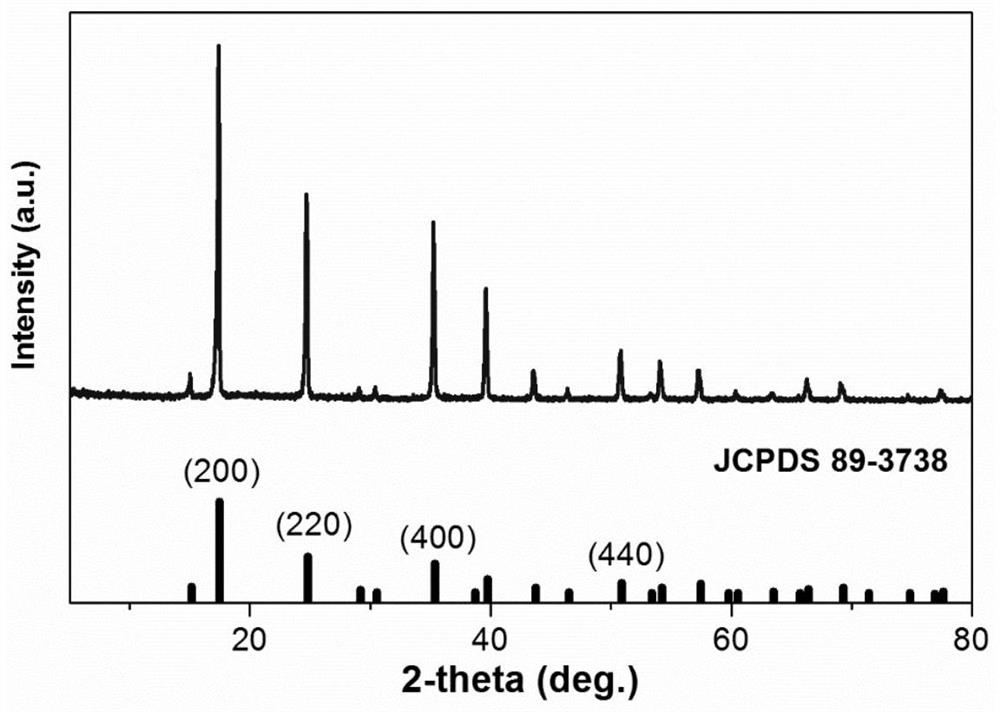

Nanocomposites, method for producing same, and use thereof in devices for protecting against electromagnetic waves

InactiveUS20120092758A1Low toxicityImprove stabilityMaterial nanotechnologyMirrorsElectromagnetic electron waveOptical limiting

A nanocomposite, comprising single-wall and / or multi-wall one-dimensional nanomaterials, and at least one nanooxide of at least one transition metal, said nanooxide filling said nanotubes and covering their walls. A process for preparing such a nanocomposite and an optical limiting device comprising such a nanocomposite in suspension in a medium that is transparent to visible and infrared radiation are disclosed.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Chemical vapor deposition reactor with preheating, reaction, and cooling zones

A vertical chemical vapor deposition (CVD) reactor and a method for synthesizing metal oxide impregnated carbon nanotubes. The CVD reactor includes a preheating zone portion and a reaction zone portion, and preferably an additional cooling zone portion and a product collector. The method includes (a) subjecting a liquid reactant solution comprising an organic solvent, a metallocene, and a metal alkoxide to atomization in the presence of a gas flow comprising a carrier gas and a support gas to form an atomized mixture, and (b) heating the atomized mixture to a temperature of 200° C.-1400° C., wherein the heating forms a metal oxide and at least one carbon source compound, wherein the metallocene catalyzes the formation of carbon nanotubes from the at least one carbon source compound and the metal oxide is incorporated into or on a surface of the carbon nanotubes to form the metal oxide impregnated carbon nanotubes.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Carbon nanotube film structure and method for manufacturing the same

InactiveUS8623495B2Quality improvementUniform thicknessMaterial nanotechnologyOrnamental structuresHigh densityCarbon nanotube

A method of producing a carbon nanotube film structure having a substrate and a carbon nanotube layer, comprises a placing step of placing a carbon nanotube film comprising a plurality of carbon nanotubes aligned in one direction within a film plane on the substrate; and a densifying step of applying a densifying treatment to the carbon nanotube film thereby forming the carbon nanotube layer having the weight density of the carbon nanotube to 0.1 g / cm3 or more. Thus, a problem of island-like shrinkage caused while a highly densified CNT layer is being manufactured is solved, and a high-quality CNT film structure wherein the aligned CNT layer having a high density and uniform thickness is deposited on the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

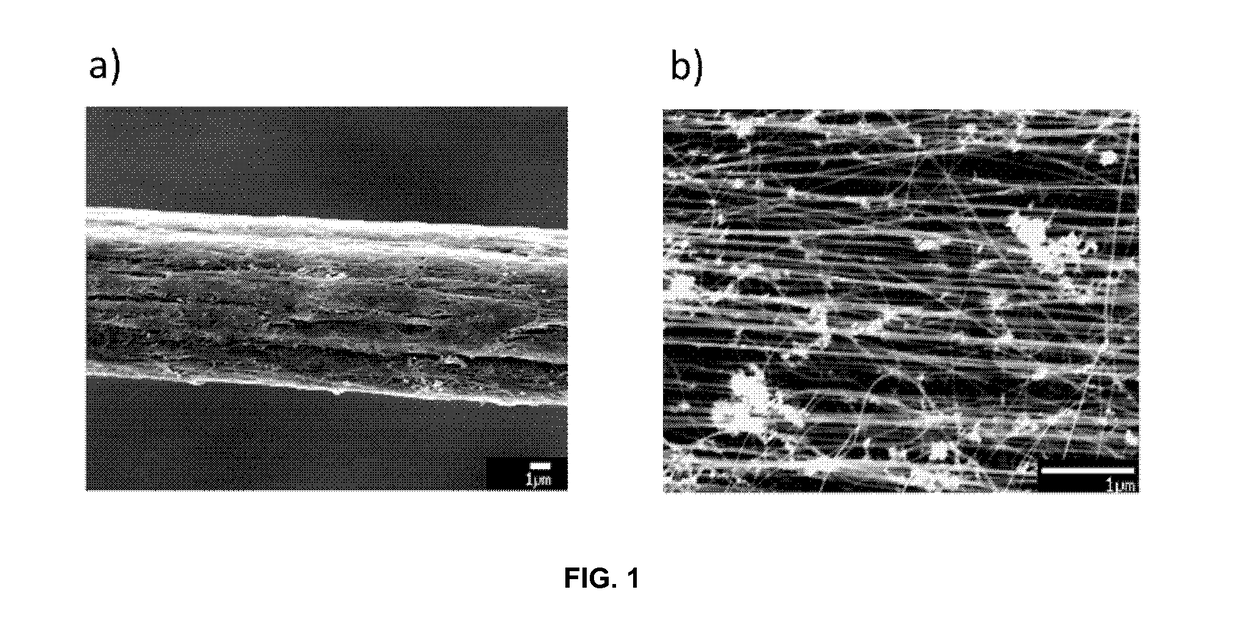

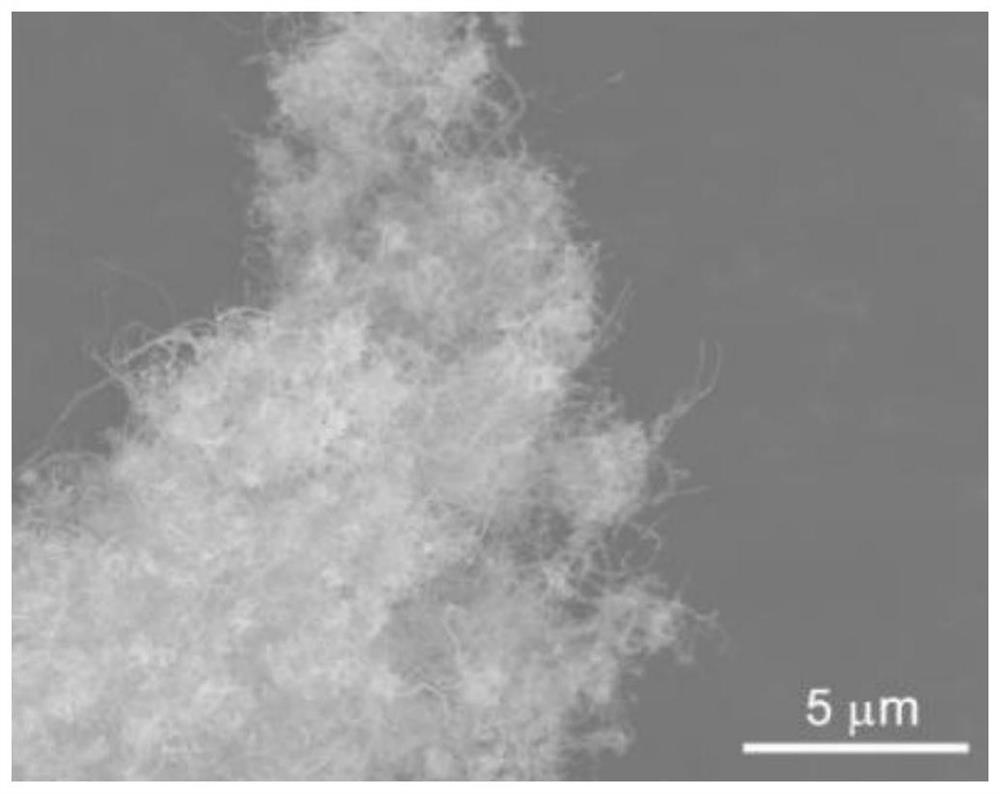

Method for producing carbon nanotube fiber and carbon nanotube fiber produced thereby

ActiveCN109563649AHigh tensile strengthImprove bindingMaterial nanotechnologyArtificial filament heat treatmentFiberCarbon nanotube

Owner:LG CHEM LTD

Method for Preparing Carbon Nanotube Fiber And Carbon Nanotube Fiber Prepared Thereby

ActiveUS20190271100A1High tensile strengthBinding forceMaterial nanotechnologyArtificial filament heat treatmentFiberCarbon nanotube

Owner:LG CHEM LTD

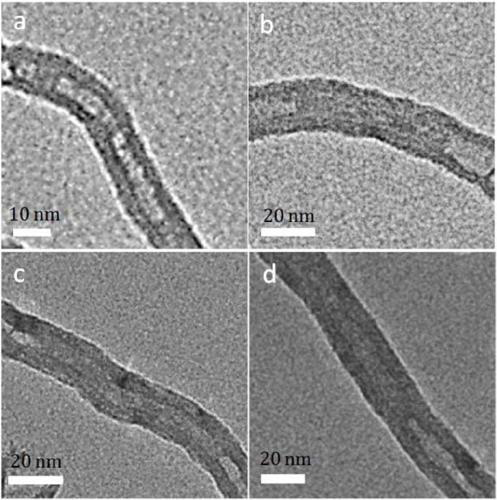

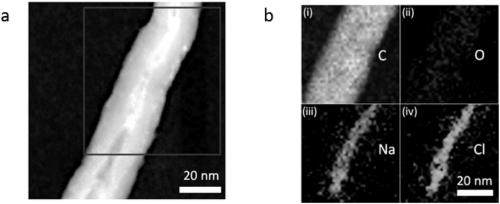

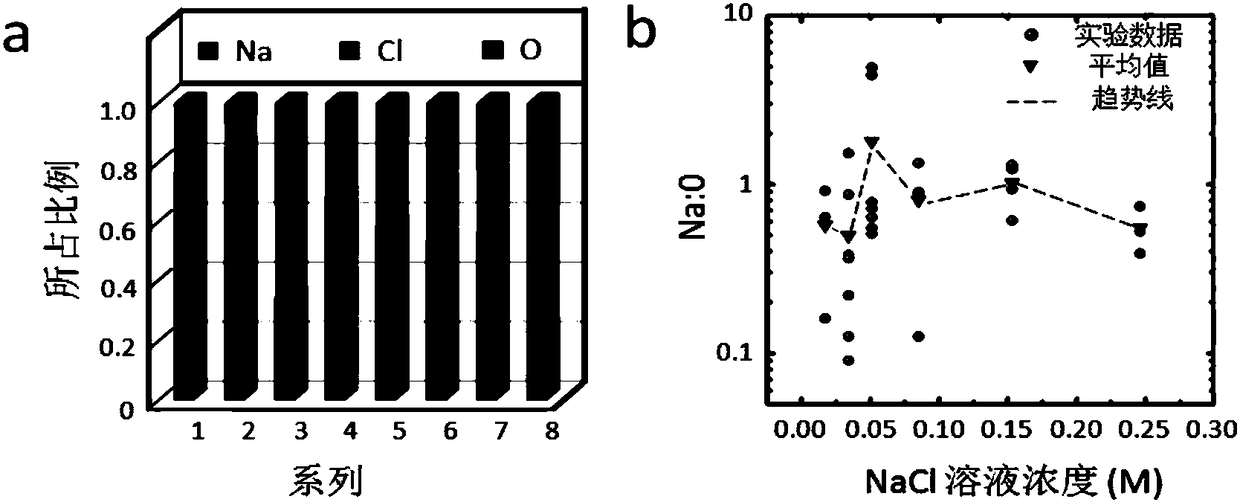

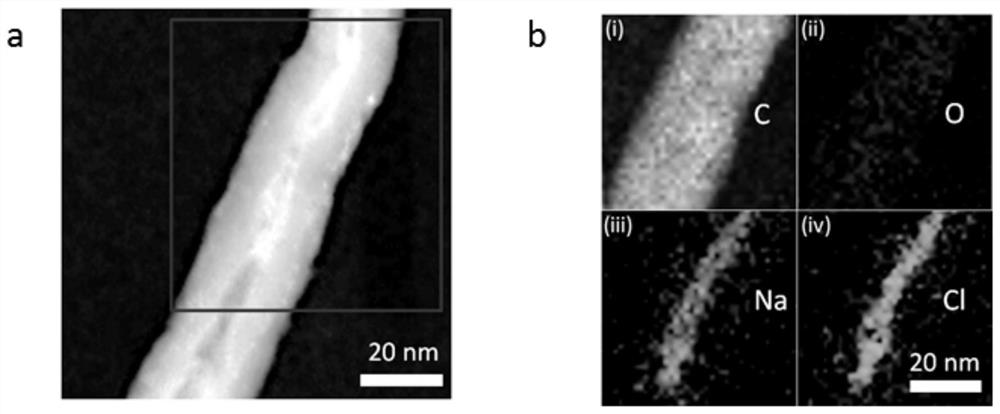

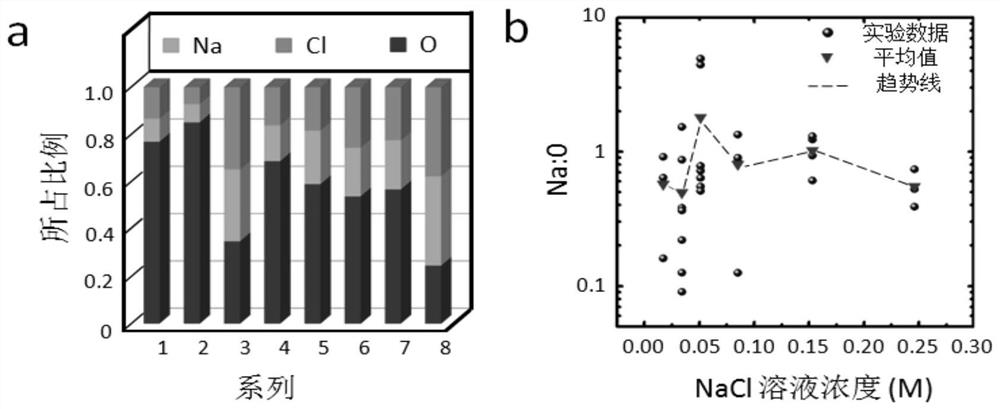

Carbon-based material based ion collection method

ActiveCN108928812AEfficient ion collection capabilityDirect observation of the effect of collected ionsWater contaminantsWater/sewage treatmentPotassiumPre treatment

The invention discloses a carbon-based material based ion collection method. The method includes the following steps: (1) performing pretreatment on a carbon-based material; and (2) soaking the pretreated carbon-based material obtained by the step (1) in a salt solution. The step (1) includes the following steps: a, performing ultrasonic processing on the carbon-based material in a solution; and b, washing the carbon-based material processed by ultrasonic with deionized water, and performing drying for later use. The method has high universality, and can be used in water solution of salt likesodium salt, potassium salt and chlorine salt or organic solutions. The method is simple in preparation process, easy in operation and low in energy consumption; the problem that salt ions are hard toremove during water purification can be solved; a new approach to enrich ions can be opened up; and the method has important meanings in the field of water treatment and good application and market promotion prospects.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Discharge plasma sintering method for manufacturing single-walled carbon nanotube reinforced metal matrix composite and composite material produced thereby

ActiveUS11053568B2Increase resistanceHigh strengthSingle-walled nanotubesFilled nanotubesManufactured materialMetal matrix composite

The present invention provides a method of manufacturing a single-walled-carbon-nanotube-reinforced metal matrix complex material. The method includes (a) manufacturing a complex powder by performing ball milling of a metal powder and a single-walled carbon nanotube powder, and (b) manufacturing a metal-carbon-nanotube complex material by spark-plasma-sintering (SPS) the complex powder manufactured during step (a). According to the method of manufacturing the single-walled-carbon-nanotube-reinforced metal matrix complex material according to the present invention, in order to manufacture material parts requiring high strength and abrasion resistance, the single-walled carbon nanotube powder is added to various metal matrixes and ball milling is performed, thus manufacturing a complex powder having uniform dispersity. The manufactured complex powder is subjected to complexation in a short period of time using a spark-plasma-sintering (SPS) process, thereby easily manufacturing a bulk-type single-walled-carbon-nanotube-reinforced metal matrix complex material having excellent physical properties.

Owner:PUKYONG NAT UNIV IND ACADEMIC COOPERATION FOUND

An ion collection method based on carbon-based materials

ActiveCN108928812BEfficient ion collection capabilityDirect observation of the effect of collected ionsWater contaminantsWater/sewage treatmentEnvironmental engineeringPre treatment

The invention discloses a carbon-based material based ion collection method. The method includes the following steps: (1) performing pretreatment on a carbon-based material; and (2) soaking the pretreated carbon-based material obtained by the step (1) in a salt solution. The step (1) includes the following steps: a, performing ultrasonic processing on the carbon-based material in a solution; and b, washing the carbon-based material processed by ultrasonic with deionized water, and performing drying for later use. The method has high universality, and can be used in water solution of salt likesodium salt, potassium salt and chlorine salt or organic solutions. The method is simple in preparation process, easy in operation and low in energy consumption; the problem that salt ions are hard toremove during water purification can be solved; a new approach to enrich ions can be opened up; and the method has important meanings in the field of water treatment and good application and market promotion prospects.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing carbon nanotube fiber and carbon nanotube fiber prepared thereby

ActiveUS11136711B2Easy to implementHigh tensile strengthMaterial nanotechnologyArtificial filament heat treatmentFiberPtru catalyst

The present invention relates to a carbon nanotube fiber and methods for preparing the same. In one embodiment, a method for preparing a carbon nanotube fiber comprises reacting a carbon source in the presence of a catalyst and a catalytic activator to form carbon nanotube aggregates, contacting the carbon nanotube aggregates with graphene oxide, and forming the carbon nanotube aggregates in contact with the graphene oxide into a carbon nanotube fiber.

Owner:LG CHEM LTD

A kind of copper-filled carbon nanotube array-based composite material and preparation method thereof

ActiveCN110143585BImprove thermal performanceFast heat conductionFilled nanotubesCarbon nanotubeNano copper

The invention discloses a copper-filled carbon nanotube array-based composite material and a preparation method thereof. The preparation method includes: providing a carbon nanotube array; placing the copper-containing precursor and the carbon nanotube array in the first temperature zone and the second temperature zone of the chemical vapor deposition equipment; vaporizing the precursor, and reducing The carrier gas carries the precursor into the carbon nanotube array; the reducing carrier gas reacts with the precursor in the carbon nanotube array to form a plurality of nano-copper particles, and the plurality Nano copper particles nucleate and grow in the internal pores of the carbon nanotube array to form a plurality of micron copper particles; high temperature annealing is performed on the carbon nanotube array filled with micron copper particles to make the plurality of micron copper particles The copper particles are fused with each other to obtain the copper-filled carbon nanotube array-based composite material. The copper-filled carbon nanotube array-based composite material prepared by the invention has excellent thermal conductivity.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

Composite comprising CNT fibres and an ionic conducting compound as part of an energy storage device

ActiveUS10692661B2Easy to integrateAvoid the needHybrid capacitor electrolytesHybrid capacitor electrodesFiberPolymer science

Owner:BE AEROSPACE SYST

Carbon nanofiber filled with metal oxide nanoparticles and preparation method thereof

ActiveCN105948017BWeak surface structureProcess environmental protectionFilled nanotubesMetal oxide nanoparticlesNew energy

Owner:GUILIN UNIV OF ELECTRONIC TECH

Nanomaterial dopant composition composite, dopant composition, and method for manufacturing nanomaterial dopant composition composite

InactiveUS10355190B2Simply and changeMaterial nanotechnologyThermoelectric device with peltier/seeback effectDopantScavenger

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY +1

Preparation method of carbon nanotube composite material

PendingCN112850689AUniform particle sizeUniform diameterHybrid capacitor electrodesFilled nanotubesCarbon layerCapacitance

The invention discloses a preparation method of a carbon nanotube composite material, and belongs to the field of electrode material preparation, and the preparation method comprises the following steps: taking a nickel-based Prussian blue substance synthesized by a normal temperature precipitation method as a precursor, and then sequentially introducing nitrogen, nitrogen and hydrogen, nitrogen, nitrogen and propylene to carry out heat treatment on the precursor. The Prussian blue analogue precursor integrates a catalyst, a nitrogen source and part of a carbon source, and compared with a traditional catalyst for a carbon nanotube, the precursor has the advantages that the particle size is uniform, and the consumption of carbon source gas can be reduced; the transition metal can improve the specific capacitance of the carbon nano tube, the nitrogen doping can improve the conductivity of the carbon nano tube, and the carbon layer can play a structural protection role on the transition metal nano particles packaged in the carbon layer, so that the cycle life of the composite material is prolonged.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com