Carbon-based material based ion collection method

A carbon-based material and ion technology, applied in the field of water treatment, to achieve the effect of simple preparation process, easy operation and high universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

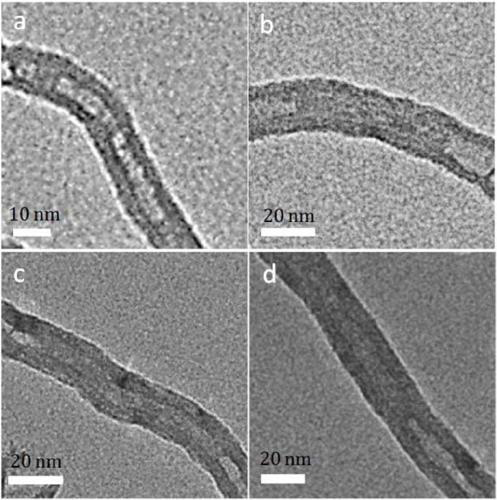

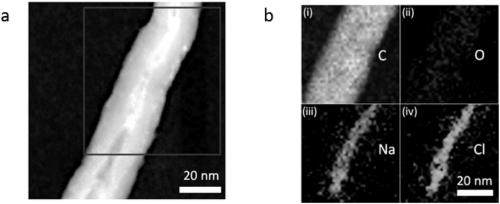

[0040] TEM testing of ion collection in carbon nanotubes

[0041]The multi-walled carbon nanotubes with an inner diameter of 5-15 nm were ultrasonically treated with analytically pure ethanol for 20 minutes, washed with deionized water, and then placed in an oven at 60° C. for 24 hours to dry. Soak the treated carbon nanotubes in 0.015M NaCl solution for 0.5 hours, then take them out, use TEM to observe the ion collection in the carbon nanotubes, and scan the obtained element distribution map to analyze the distribution of ions inside and outside the carbon nanotubes Condition. Experimental results show that the concentration of ions collected in carbon nanotubes is 2-3 orders of magnitude higher than that in the initial solution (see image 3 (a)).

Embodiment 2

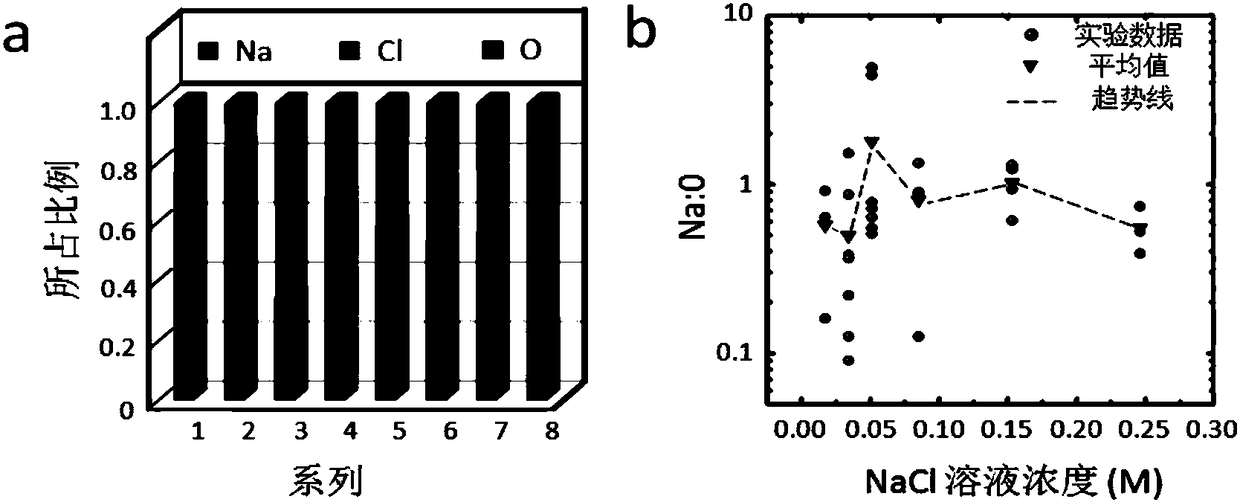

[0043] EDX tests the ratio of elements present in carbon nanotubes

[0044] The multi-walled carbon nanotubes with an inner diameter of 5-15 nm were ultrasonically treated with analytically pure ethanol for 20 minutes, washed with deionized water, and then dried in an oven at 60° C. for 24 hours. Place the treated carbon nanotubes in 0.015-0.25M NaCl solution and soak them for 0.5 hours, take them out, and conduct EDX to detect the distribution of elements inside and outside the carbon nanotubes. The experimental results show that the concentration of ions collected in the carbon tube is 2-3 orders of magnitude higher than the concentration in the initial solution (see image 3 (b)).

Embodiment 3

[0046] TEM testing of ion collection in carbon nanotubes

[0047] The multi-walled carbon nanotubes with an inner diameter of 5-15 nm were ultrasonically treated with analytically pure ethanol for 20 minutes, washed with deionized water, and then placed in an oven at 60° C. for 24 hours to dry. Place the treated carbon nanotubes in 0.034M KCl solution and soak them for 0.5 hours, then take them out, use TEM to observe the ion collection in the carbon nanotubes, and scan the element distribution to represent the distribution of ions inside and outside the carbon nanotubes. Experimental results show that the concentration of ions collected in carbon nanotubes is 2-3 orders of magnitude higher than that in the initial solution (see Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com