Preparation method of ultra-narrow graphene nanobelts

A graphene nanoribbon and ultra-narrow technology, applied in the field of graphene, can solve the problems of large width of graphene nanoribbons, inability to synthesize graphene nanoribbons, and complicated design of precursors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

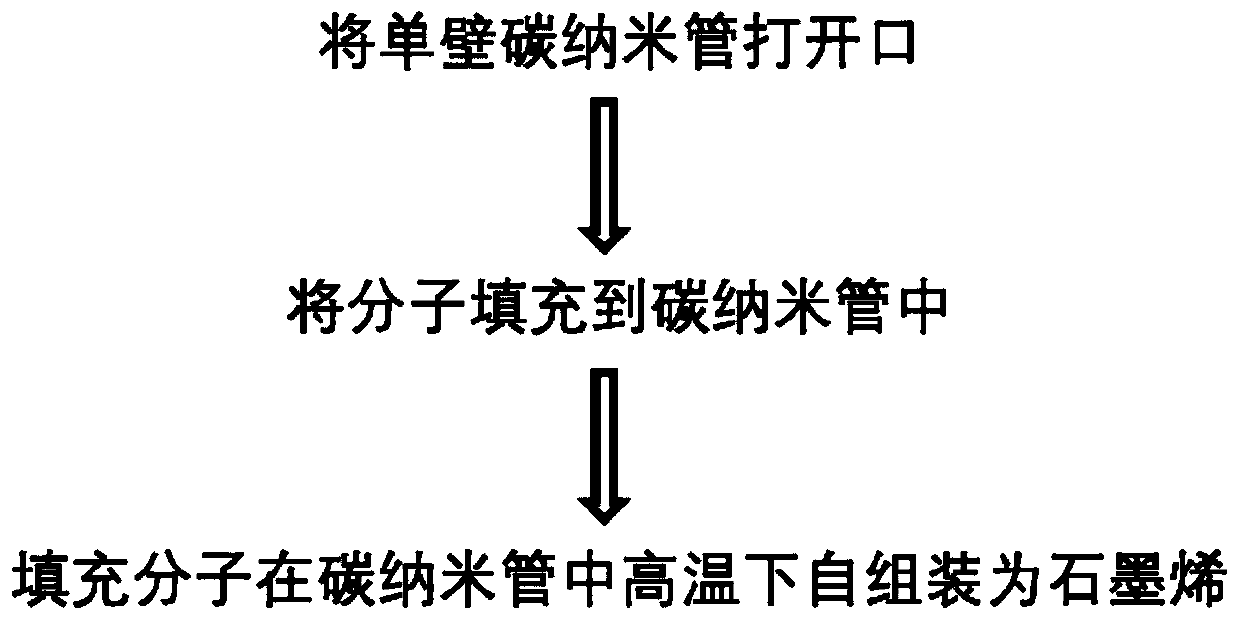

[0033] The present embodiment provides a kind of preparation method of ultra-narrow graphene nanoribbon, such as figure 1 shown, including the following steps:

[0034] S1. Perform heat treatment on the single-walled carbon nanotubes at 350-500° C., the heat treatment time is 0.5-2 hours, and the heat treatment is carried out in an atmosphere containing oxygen;

[0035] Specifically, the atmosphere containing oxygen is an air atmosphere with a humidity of less than 80% or a mixed gas atmosphere of oxygen and argon with an oxygen content of 5% to 100%.

[0036] S2. After mixing the single-walled carbon nanotubes obtained in step S1 with the molecules used for filling, vacuum seal the tubes:

[0037] Put the single-walled carbon nanotubes with open ports obtained in step S1 into a glass tube or a quartz tube together with the molecules used for filling, and use a mechanical pump or a molecular pump to pump air into the glass tube or quartz tube until the vacuum degree reaches ...

Embodiment 2

[0043] The present embodiment provides a kind of example of the preparation method of ultra-narrow graphene nanobelt as described in embodiment 1, comprises the steps:

[0044] S1. Carry out heat treatment at 450° C. for single-walled carbon nanotubes with an average diameter of 1.3 nm. The heat treatment time is 1 hour. The heat treatment is carried out in an air atmosphere with a humidity of 56%;

[0045] S2. Pack the single-walled carbon nanotubes with opened ports obtained in step S1 into a glass tube together with the ferrocene powder, and use a molecular pump to pump air into the glass tube until the vacuum degree reaches 10 -4 When it is below Pa, the glass tube is sealed and sealed by the flame of a high-temperature spray torch.

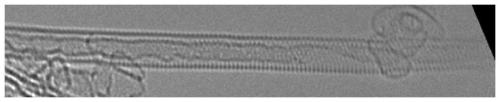

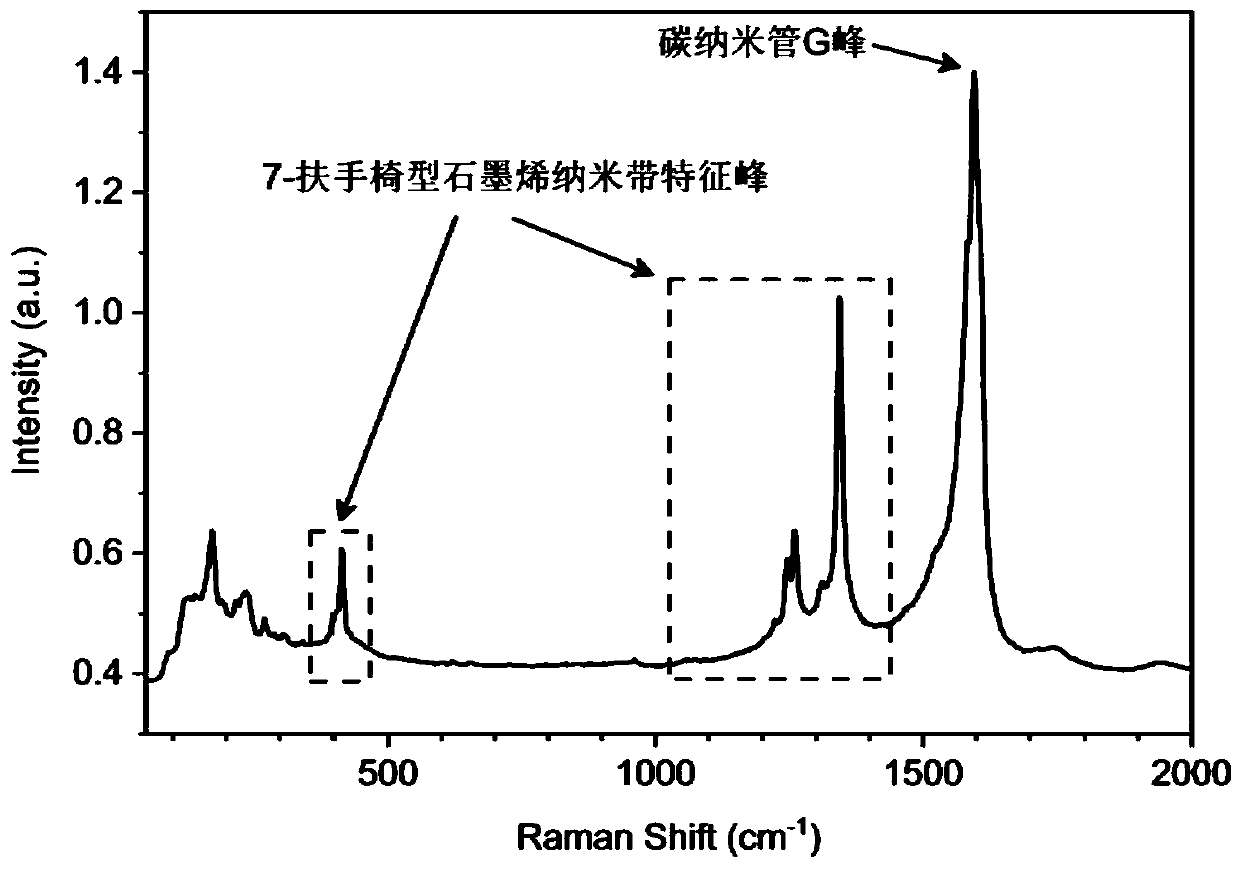

[0046] S3. Molecular filling heat treatment: The single-walled carbon nanotubes filled with ferrocene molecules obtained in step S2 are subjected to high-temperature heat treatment at 300 ° C. The heat treatment time is 36 hours. After the he...

Embodiment 3

[0050] The present embodiment provides a kind of example of the preparation method of ultra-narrow graphene nanobelt as described in embodiment 1, comprises the steps:

[0051] S1. Carry out heat treatment at 400° C. for single-walled carbon nanotubes with an average diameter of 1.4 nm. The heat treatment time is 2 hours. The heat treatment is carried out in a mixed atmosphere with a ratio of oxygen and argon of 1:4;

[0052] S2. Pack the single-walled carbon nanotubes with opened ports obtained in step S1 into a glass tube together with Terylene powder, and use a molecular pump to pump air into the glass tube until the vacuum degree reaches 10 -5 When it is below Pa, the glass tube is sealed and sealed by the flame of a high-temperature spray torch.

[0053] S3. Molecular filling heat treatment: The single-walled carbon nanotubes filled with Terylene molecules obtained in step S2 are subjected to high-temperature heat treatment at 400°C for 72 hours. After the heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com