Ice test devices

A technology of testing device and testing target, applied in the field of ice backflow testing device and ice adhesion testing device, which can solve the problems of mechanical damage, weight increase, and aerodynamic performance reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] [Overview]

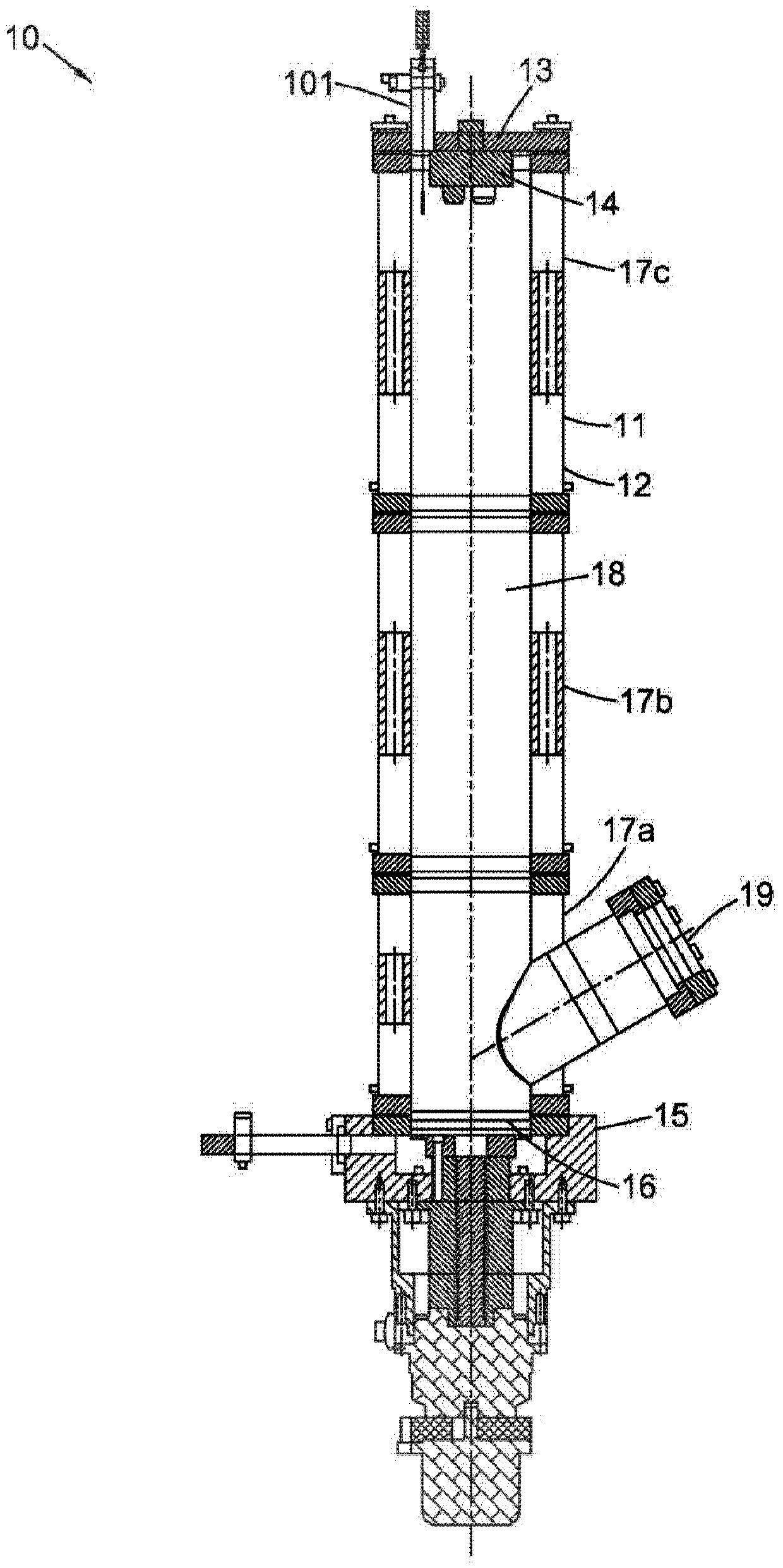

[0060] figure 1 Ice accumulation equipment in the form of a table top freezer 10 is shown. In general terms, the table-top freezing device 10 (hereinafter referred to as "freezing device") is shaped as a cylinder 11 . The cylinder 11 is delimited by a side wall 12 (hereinafter referred to as "wall"), which in this embodiment is annular in shape. The wall 12 is formed by three tubular sections in the form of wall sections: a first wall section 17a, a second wall section 17b and a third wall section 17c. The second wall portion 17b is stacked on top of the first wall portion 17a. The third wall portion 17c is stacked on top of the second wall portion 17b. In other embodiments, there may be more or fewer tubular sections. In this embodiment, each wall portion 17a, 17b, 17c is of substantially circular cross-section. Thus, the wall 12 of the cylinder 11 forms a tube of substantially circular cross-section. Wall 12 defines within it a central chamber 18 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com