Glenoid fossa prosthesis and joint prosthesis with glenoid fossa prosthesis

A joint fossa and prosthesis technology, which is applied in the direction of prosthesis, hip joints, joint implants, etc., can solve the problems of fast wear of joint materials, failure of artificial joints, and lack of effective lubrication of artificial joints, so as to reduce the fixation effect, The effect of ensuring the service life and reducing the wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

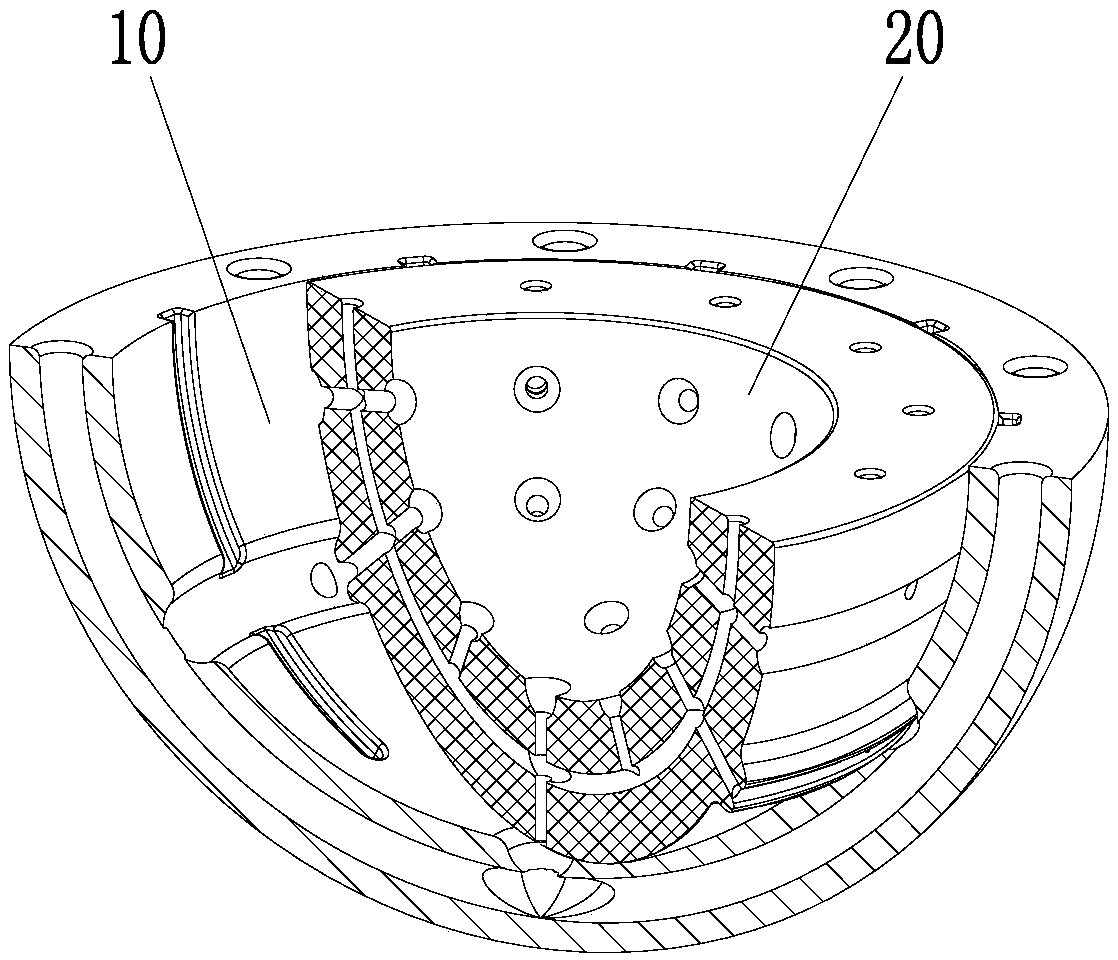

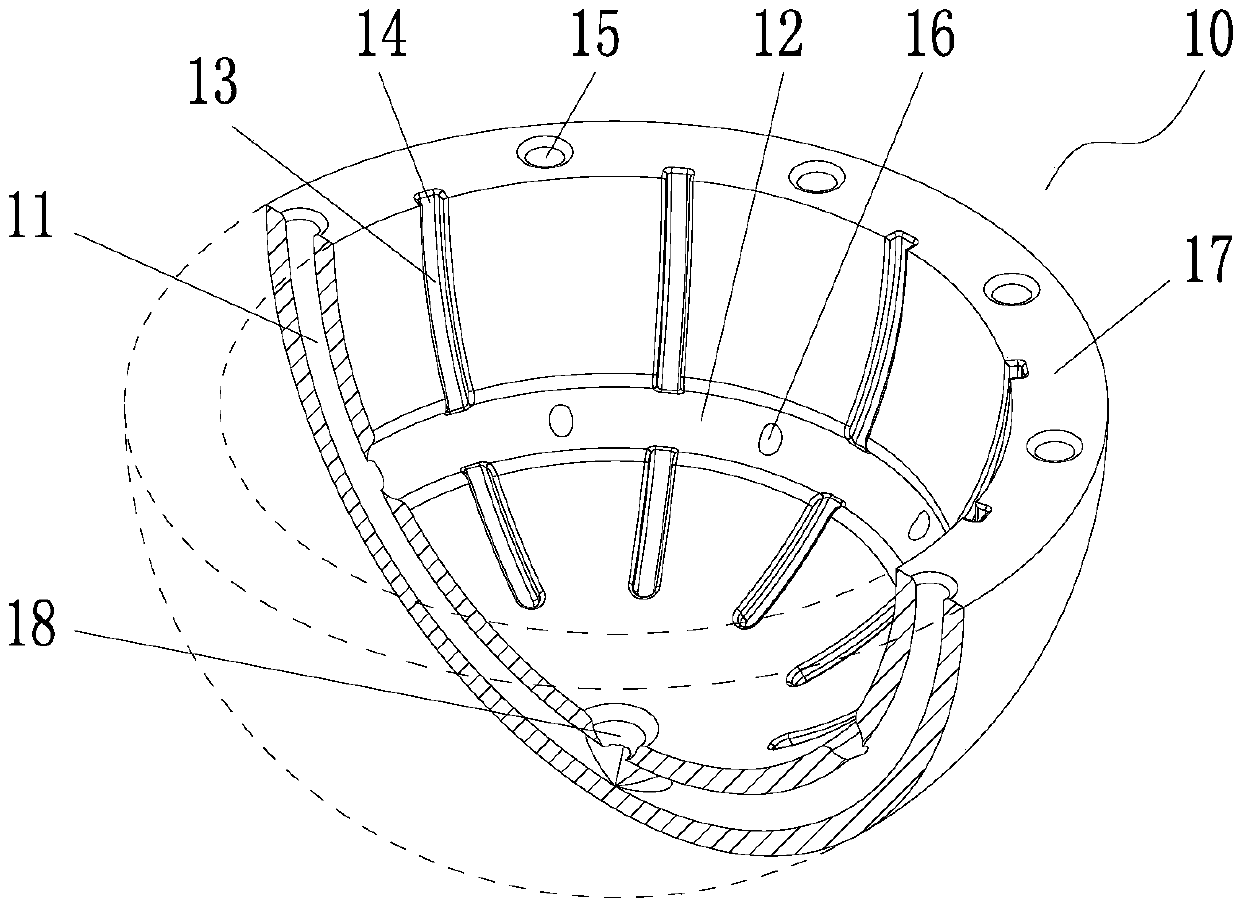

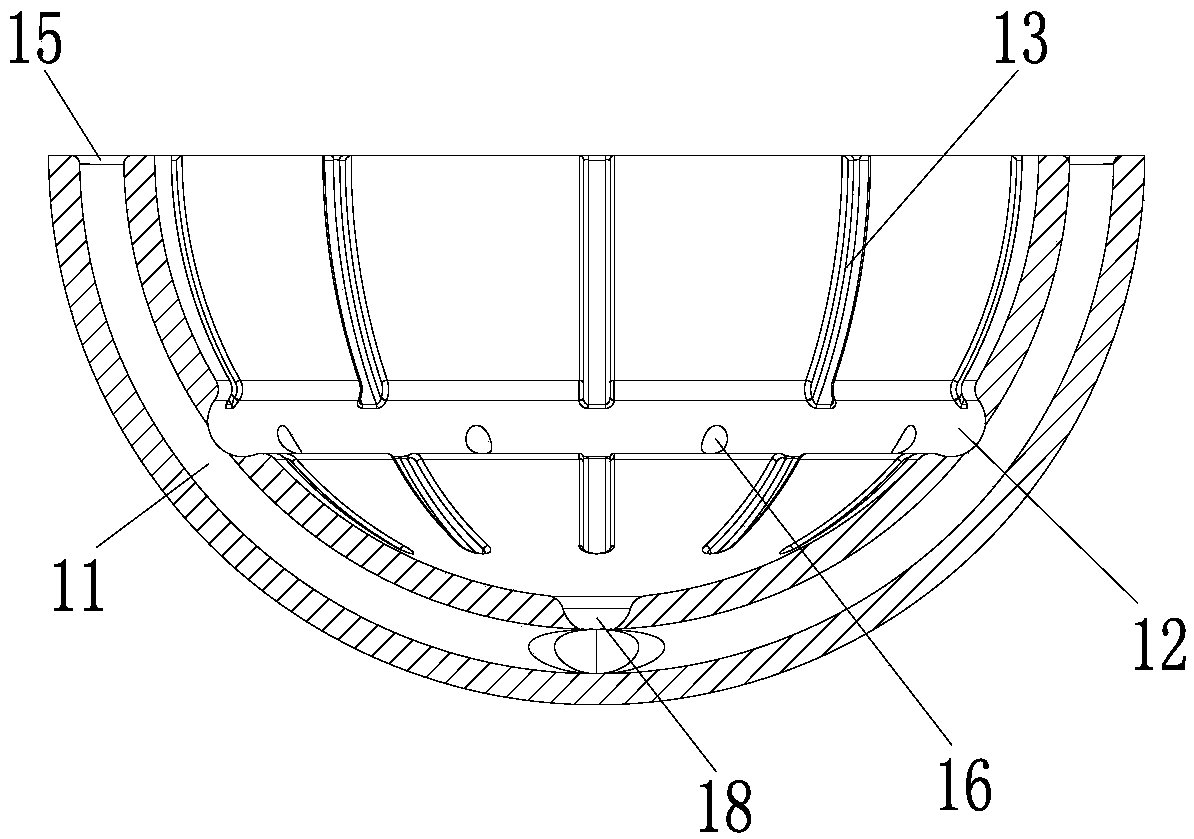

[0031] The glenoid prosthesis of the present application can be applied in joints with relative rotation and sliding, such as shoulder joints and hip joints. The glenoid prosthesis in this embodiment is an acetabular prosthesis, and can be set in the hip bone to replace the patient's native acetabulum. Specifically, such as figure 1 As shown, the glenoid prosthesis of this embodiment includes an outer cup 10 and an inner liner 20, the outer cup 10 is set in the target bone (hip bone), the inner liner 20 is set in the outer cup 10, and the joint ball head can be movably set In liner 20. The outer cup 10 is provided with a first communication channel communicating with the joint capsule, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com