Elastic waistline with multiple groups of elasticity, and manufacturing equipment and manufacturing method thereof

A technology for elastic waist circumference and manufacturing equipment, applied in the fields of medical science, clothing, underwear, etc., can solve the problems of large amount of glue spray, uneven surface, large wrinkles, dislocation of spandex yarn, etc., to avoid comfort, improve comfort, The effect of preventing left and right twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

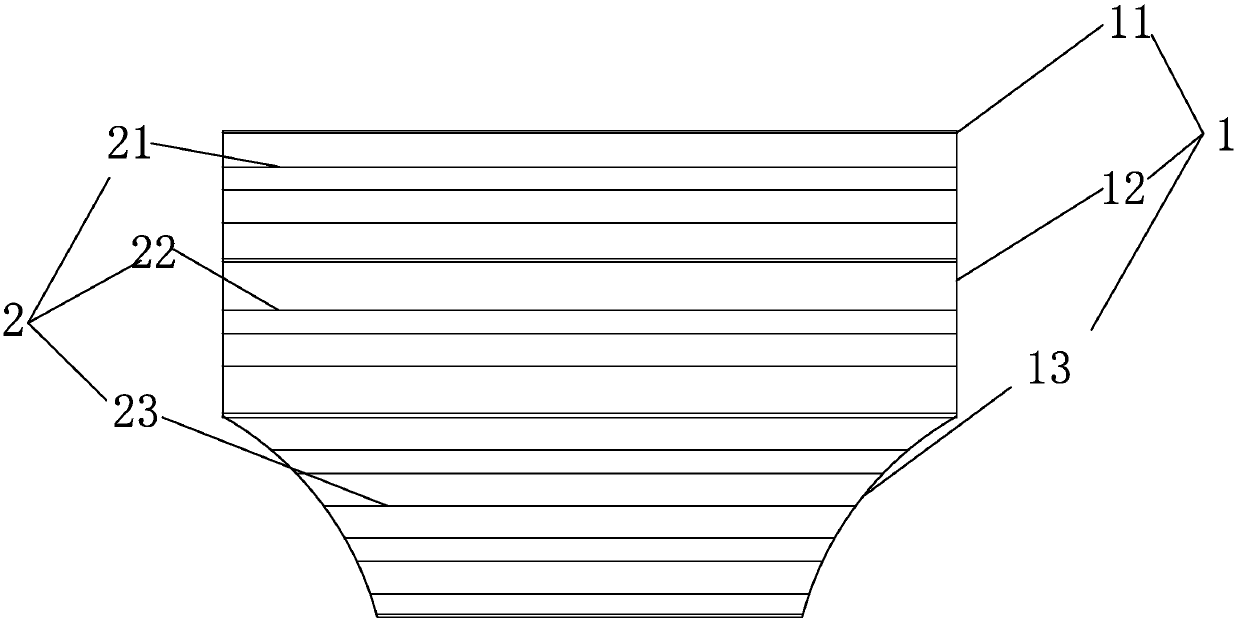

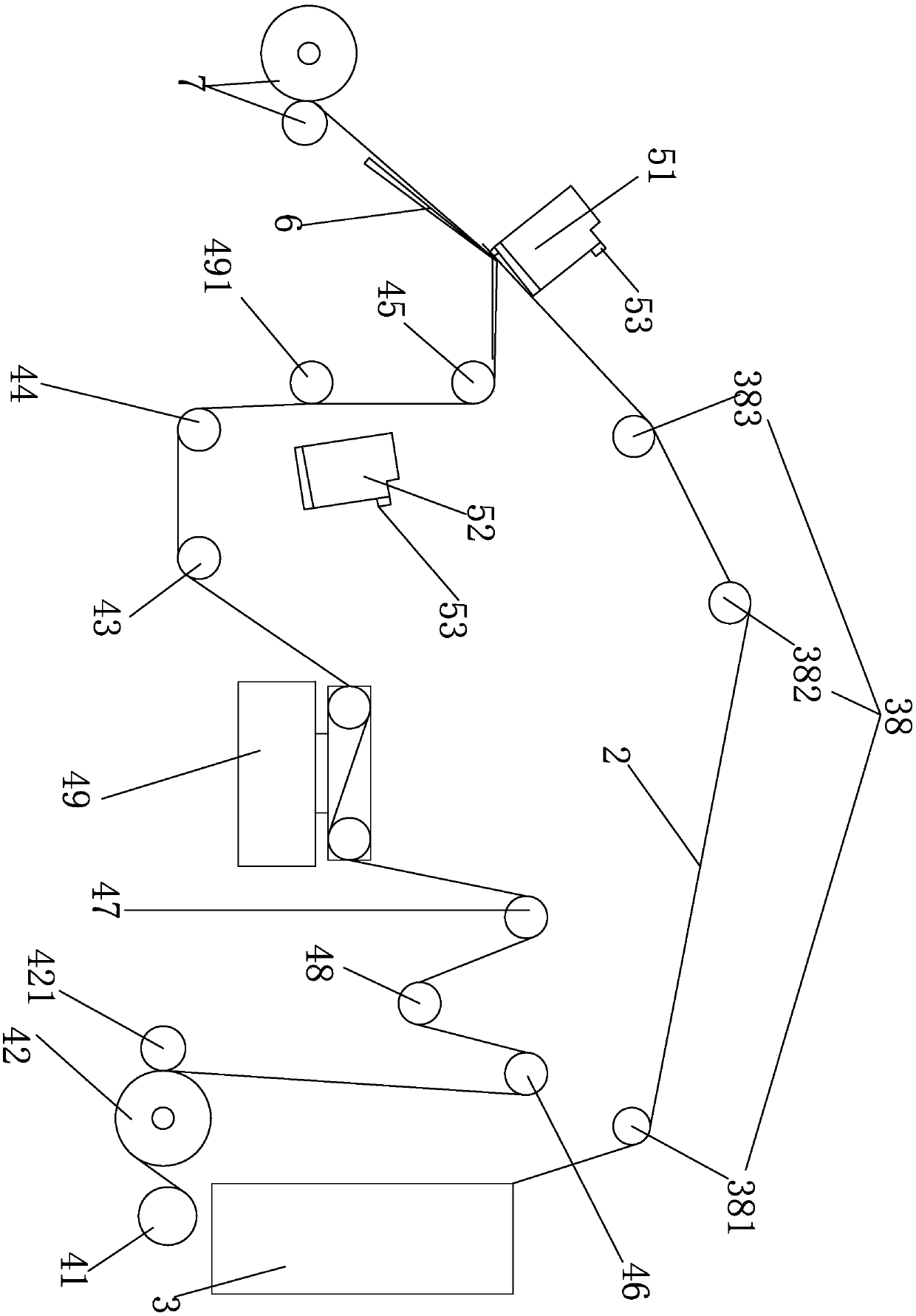

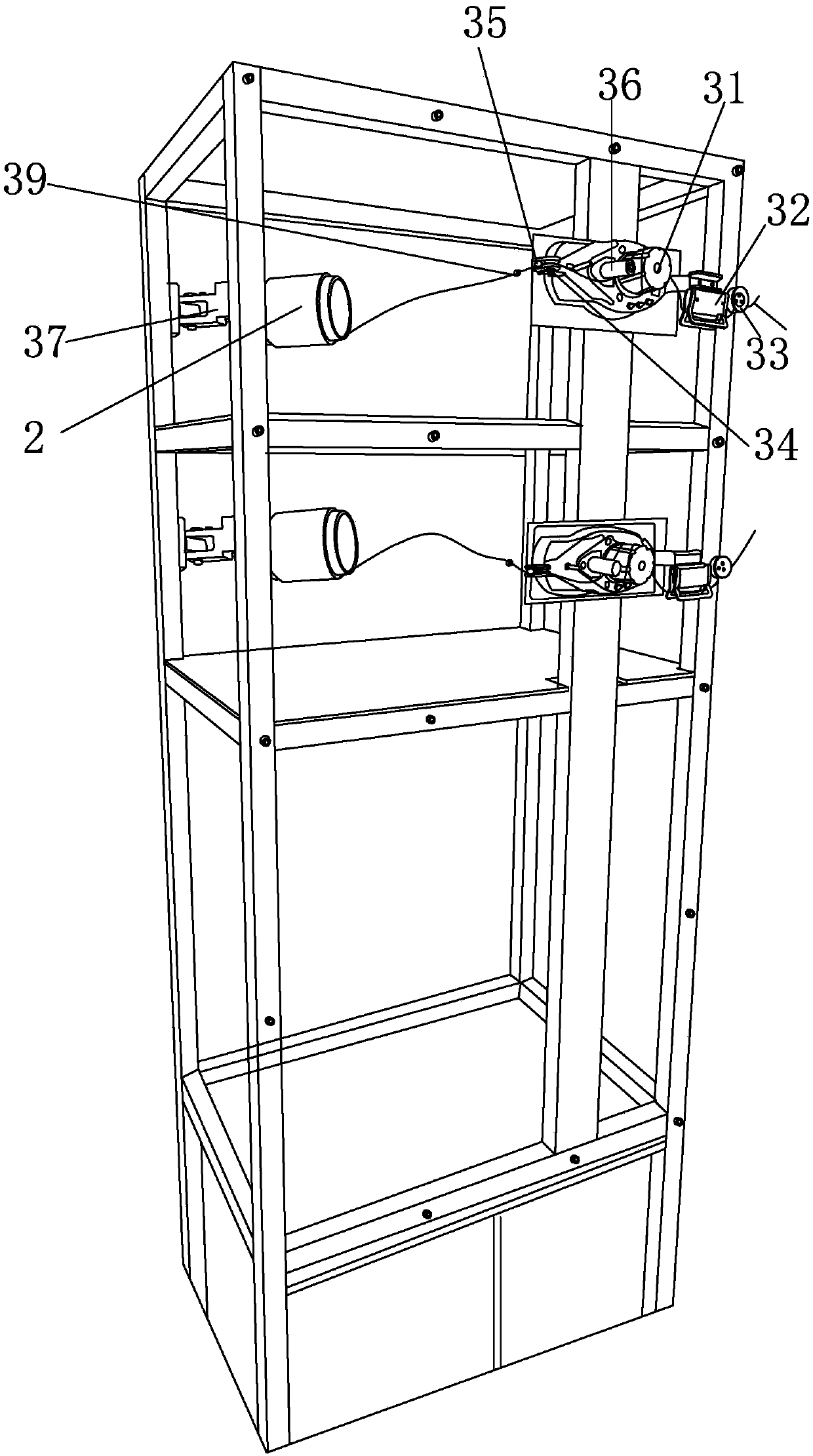

[0032] refer to Figure 1 to Figure 11 , an elastic waistline with multiple groups of elasticity, including a wrapping layer 1, spandex yarn 2 arranged in the wrapping layer 1, the wrapping layer 1 includes a first section 11, a second section 12, and a third section 13, the The spandex yarn 2 includes a first spandex yarn 21 arranged in the first section 11 , a second spandex yarn 22 arranged in the second section 12 , and a third spandex yarn 23 arranged in the third section 13 . Wherein the wrapping layer 1 is a supersoft non-woven fabric.

[0033] The distribution pitch of the first spandex filaments 21 is 2-4mm, the thickness of the first spandex filaments 21 is 400-600D, the stress in the first section 11 is 5N, and the distribution pitch of the second spandex filaments 22 is 2mm. -6mm, the thickness of the second spandex filament 22 is 150-290D, the stress of the second section 12 is 3N, the distribution pitch of the third spandex filament 23 is 2-4mm, the third spande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com