Fast teaching method for industrial robots

An industrial robot and teaching method technology, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of inappropriate speed ratio, poor operability, and long time required to improve efficiency and reduce teaching. Error, the effect of improving teaching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments and drawings.

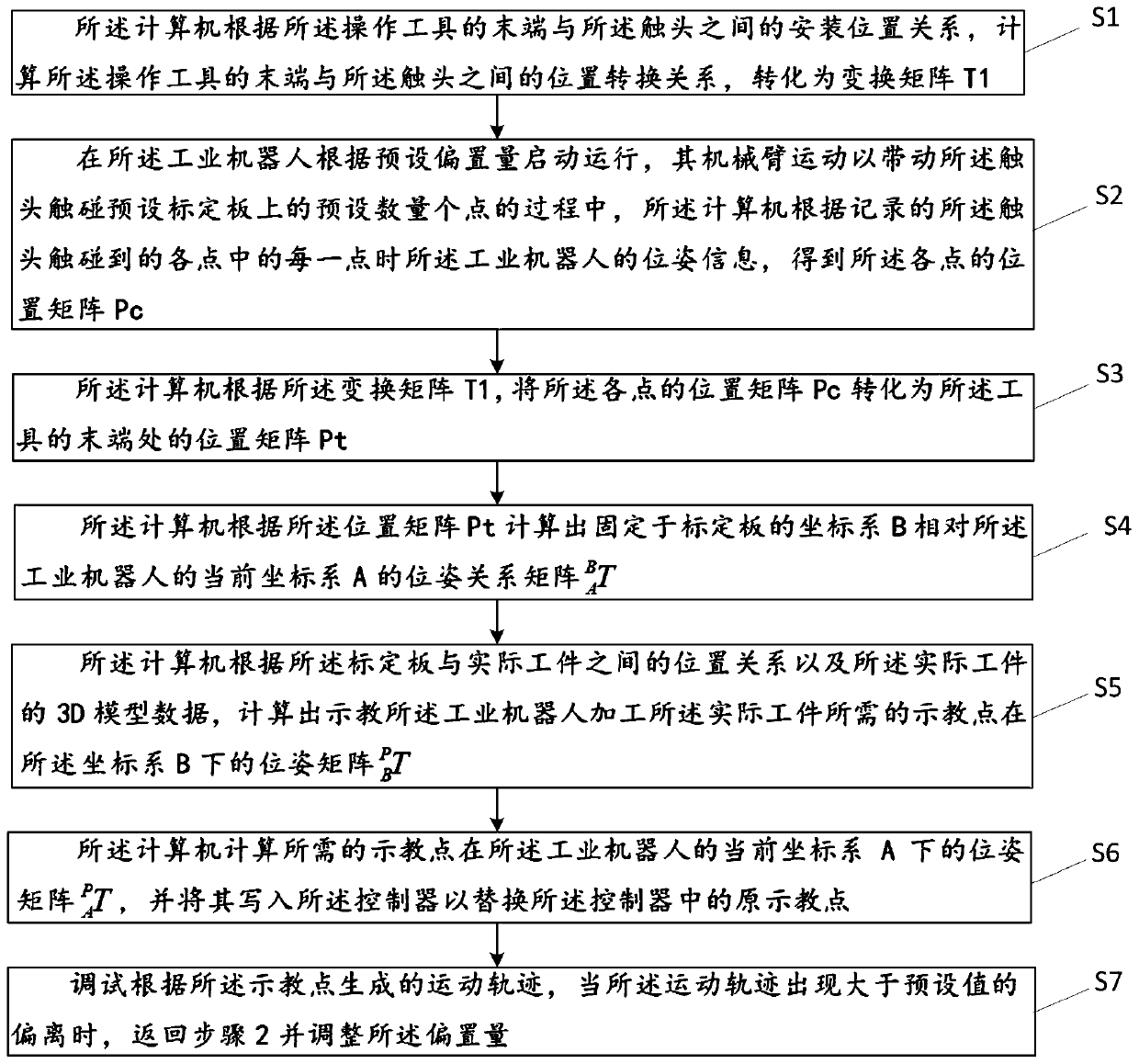

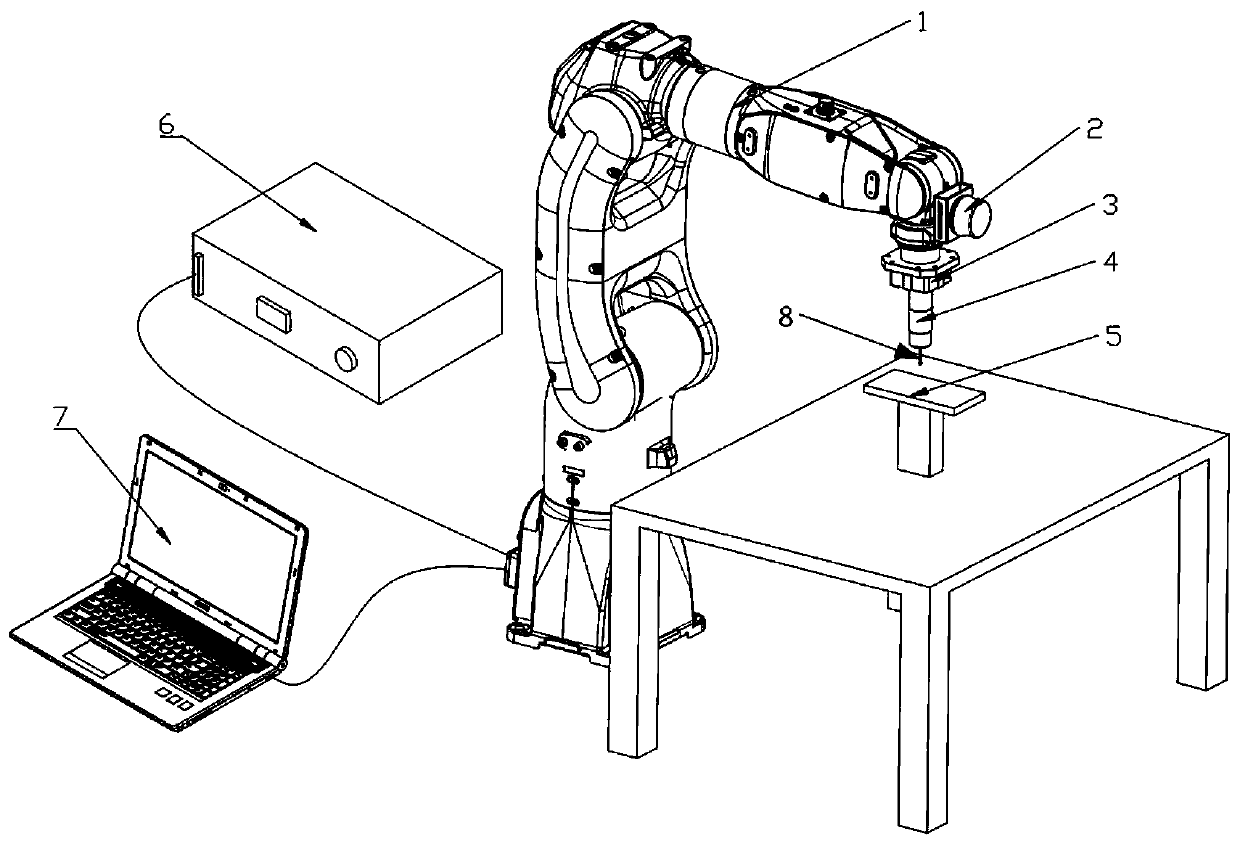

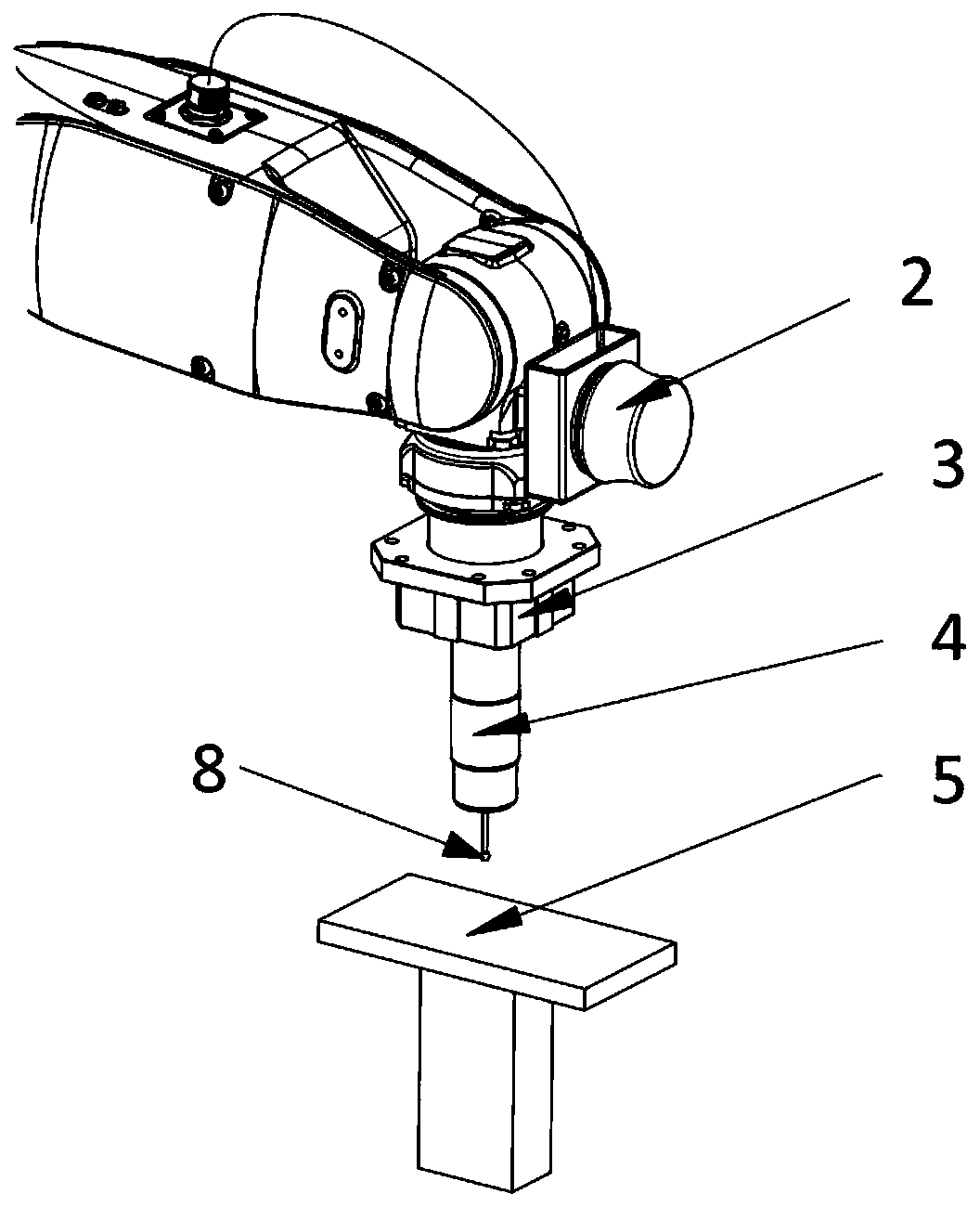

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a fast teaching method of an industrial robot, which combines figure 2 with image 3 As shown, the industrial robot has a mechanical arm 1, the end of the mechanical arm 1 is equipped with an operating tool 3, the industrial robot is connected to the controller 6, and the end of the mechanical arm 1 is equipped with a drag component 2 which is connected to the controller 6. , A sensor 4 is installed at the end of the operating tool 3, and the sensor 4 is connected to the controller 6, specifically, it can be connected to the IO port input of the controller 6. The sensor 4 is provided with a contact 8, and the robot arm 1 is driven to move by dragging the dragging component 2 to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com